The Complete Pad-Mounted Transformer Buying Guide: A Strategic Selection from Needs to Installation | CHBEB

Introduction

Buying just based on price doesn’t work. Outages and penalties happen when ratings are inaccurate, the wrong sort of feed is used, or the improper materials are used. This article takes you through every step, from figuring out what you need to installing your pad-mounted transformer1, so that it is safe, reliable, and costs the least during its lifespan.

Phase 1: Strategic Planning and Needs Assessment

Planning without enough information leads to overloads, voltage drops, and noise complaints. These problems come up after the system is turned on, when repairs are costly. Set the right capacity, voltage, and design for your site by defining loads, duty, and growth immediately.

How to Figure Out Your Project’s Power and Load Needs

Don’t use a vendor template; start with the electrical reality of your site. Find out how much the transformer needs to supply now and in three to five years, and then use that information to make judgments on its nameplate and configuration.

- Demand profile: Find the peak kW/kVA, daily and seasonal diversity, and coincidence factors. Include a reasonable growth margin, which is usually between 15% and 25%.

- Load character: Keep track of motor starters, VFDs, EV charges, HVAC cycling, and non-linear loads that cause harmonic heating and voltage changes.

- Check the ratings of the secondary (e.g., 400/230 V, 415/240 V, 480/277 V, or 208/120 V) and service entry gear to be sure they can handle the voltage.

- Power quality goals: Set the facility and utility’s acceptable levels of voltage regulation, flicker, and harmonic distortion.

- Reliability goals: Make sure you know how long the system needs to be up, how long it can be down for maintenance, and if maintenance can be done without an outage.

Understanding the Two Main Types: Loop-Feed and Radial2

Picking the wrong primary configuration makes you more likely to have an outage or costs you more money. Choose a feed type that meets your needs for stability and future growth.

| Primary Configuration | How It Works | Strengths | Watch Outs | Best For |

|---|---|---|---|---|

| Radial | Single MV source feeds the transformer directly. | Lowest equipment cost; simple protection and operation. | Any upstream fault/outage drops the load; limited switching flexibility. | Small commercial sites, low criticality loads, constrained budgets. |

| Loop-Feed | Two MV cables form a loop with load-break switching in the cabinet. | Alternate source improves availability; sectionalizing enables maintenance without full outage. | Higher capex; requires trained operators and coordination with the utility. | Campuses, hospitals, retail parks, data-heavy sites, future expansions. |

For loop systems, make sure there are dead-front load-break elbows, clear labels, and interlocks so that only authorized staff can safely switch them.

Phase 2: Decoding Technical Specifications and Features

Often, copying specs from one project to another doesn’t work. Mismatch causes losses, flickering, and annoying trips. Pay attention to the few statistics and features that affect safety, compliance, and durability at your site.

Key Technical Specs: The Most Important Numbers

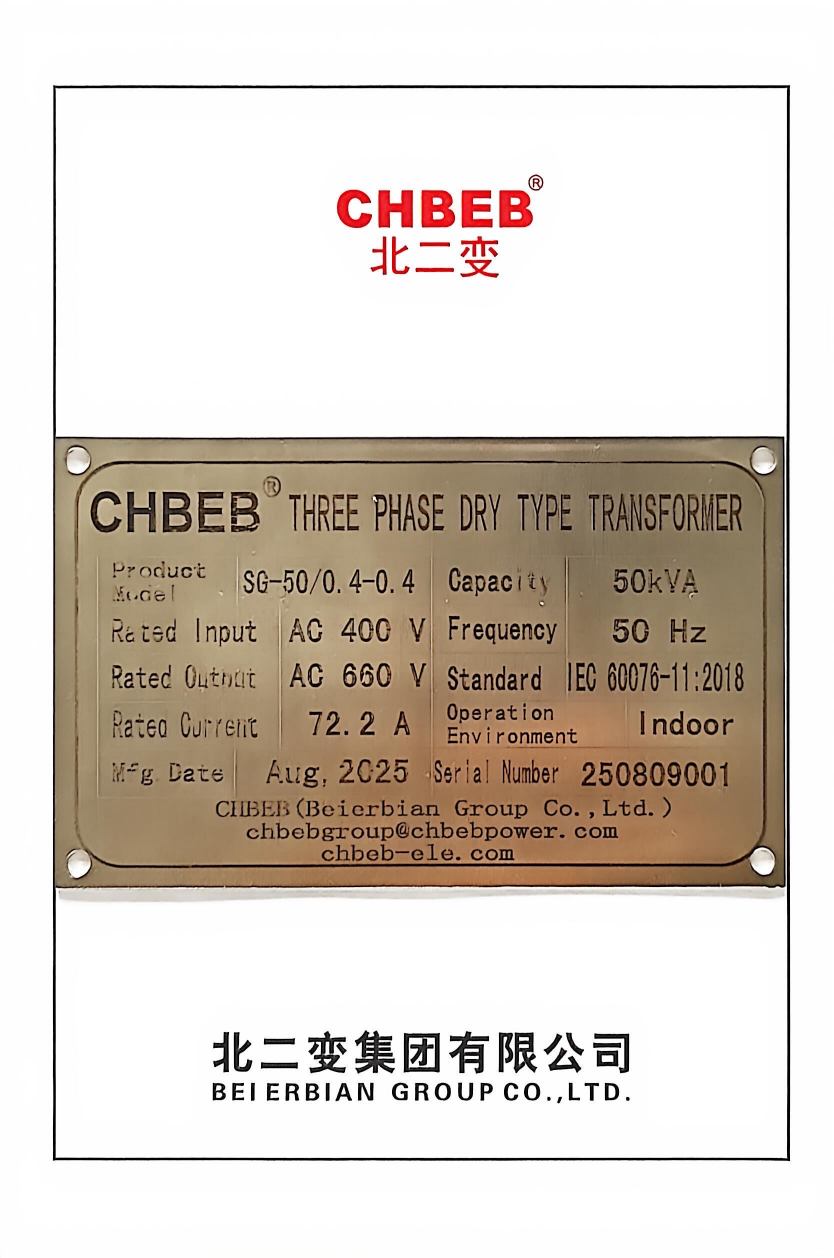

The nameplate condenses performance into a few key numbers. Learn these things so you don’t spend too much for capacity or too little for reliability.

- kVA rating: Size to meet peak demand and growth. Oversizing makes losses worse, whereas undersizing shortens life through thermal stress.

- Voltage for primary and secondary: Match the utility MV (for example, 11/22/33/35 kV) and the voltage you use (for example, 480/277 V). Check the transformer taps.

- % Impedance: Keeps the current and voltage in balance. If the fault responsibilities are too low, they will be too high; if they are too high, the voltage loss will be too high during peaks.

- Vector group3: Figure out the phase shift and the availability of the neutral (for example, Dyn for 4-wire secondaries). Changes how harmonics are handled and how grounding works.

- BIL (insulation level): Work with surge arresters and the projected switching surges on MV feeders.

- Losses (no-load/load): Guaranteed watts turn immediately into operational costs; use them to compare TCO.

- Thermal headroom and dependability are defined by the ONAN/ONAF stages and the temperature rise.

- Sound level: Very important near homes and businesses; if needed, list low-noise solutions.

- Dead-front is standard for public safety when it comes to terminations. Check the type of bushing and the elbow rating.

- Inside the cabinet, there are fault indicators, current-limiting fuses, and MV surge arresters to protect the bayonet.

| Parameter | What It Affects | Buyer Checklist |

|---|---|---|

| kVA | Thermal margin, lifespan | Peak + 15–25% growth; duty factor accounted |

| %Z | Fault level, regulation | Coordinate with breakers and flicker limits |

| Losses | Opex, heat | Price losses at your tariff for TCO |

| BIL | Surge withstand | Match arrester MCOV and feeder exposure |

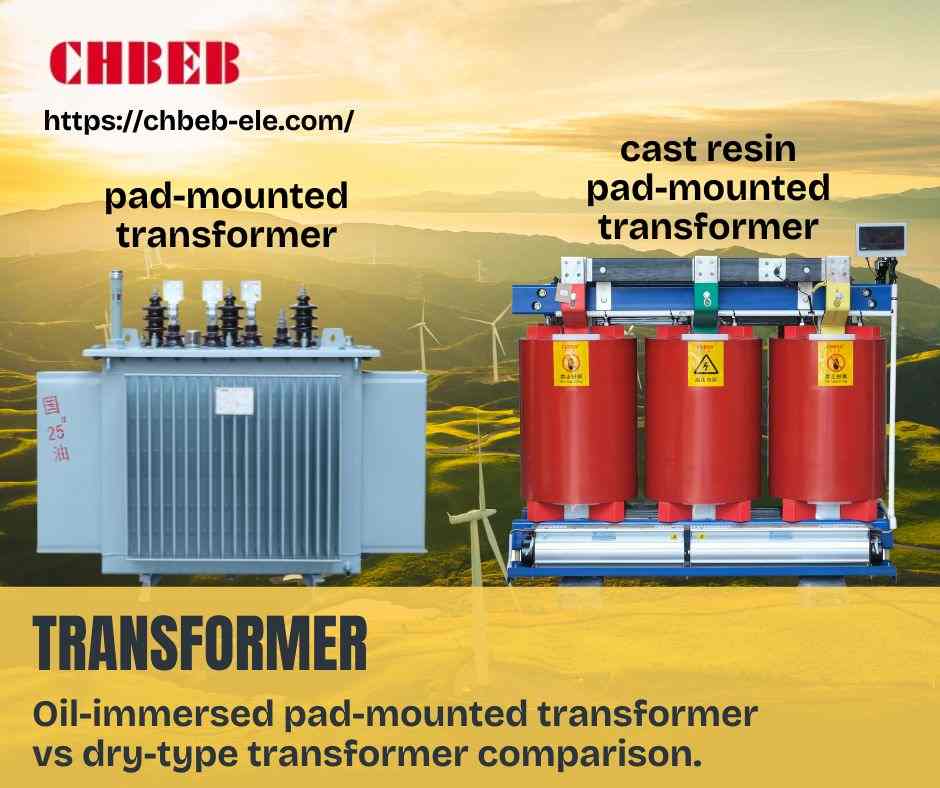

Material and Design: Transformers that are immersed in oil vs. those that are dry

Choosing the wrong construction makes things more risky and expensive. Make sure the dielectric and enclosure are right for fire safety, the environment, and maintenance.

- Oil-immersed (mineral or natural ester): This is the most frequent type of pad-mounted design. High thermal capacity, small size, and proven outdoors. Natural esters4 make the fire point and biodegradability higher, which makes it easier to get safety and environmental permits.

- Dry-type (cast resin/VPI): Good for places where liquids are not allowed or for use indoors. Bigger, usually more expensive per kVA, and more sensitive to dust and humidity. Make sure the enclosure has enough protection from the outside and enough airflow.

- For coastal and desert areas, make sure to include corrosion protection (such C4/C5-M), wildlife guards, sealed bushings, and low-noise laminations.

- Serviceability: Choose designs that have easy access to the taps, standard bushings and elbows, gaskets that can be replaced, and spare parts that are easy to find.

Phase 3: The Long-Term View: Cost, Safety, and Maintenance

The lowest bid is not always the lowest cost. If you don’t pay attention to safety and maintenance, you could have downtime and be responsible for damages. Look at lifetime losses, dependability, and serviceability now to keep availability and ROI high for decades.

Looking at Total Cost of Ownership (TCO) Beyond the Price Tag

When comparing transformers, look at more than simply capex; also look at losses and availability. Use the same formula for all bids.

TCO = Capital Expenditures + Civil/Installation + Energy Losses + Maintenance + Risk of Downtime − Residual Value

- Figure out how much the losses cost: Annual cost ≈ (No-load kW + Load-loss kW × Load2) × 8760 × tariff. Over 20 years, even modest disparities in loss add up.

- Availability value: Loop-feed, superior cooling, and strong protection cut down on downtime, which is typically worth more than little capital expenses reductions.

- Safety and compliance: Dead-front terminations, interlocks, and the right BIL/arrester coupling lower the cost of incidents and the amount of insurance coverage needed.

- Serviceability: Spare kits, standardized parts, and front access make maintenance and repairs faster and easier.

When bids are close, turn assured loss values and projected downtime into dollars. The “cheapest” unit isn’t always the least expensive to own.

Installation and upkeep: the best ways to make sure things last a long time

Even the best equipment will break down if it isn’t installed properly or checked on time. You can’t change civil works, bonding, or frequent testing.

Things You Need for Installation

- Pad and placement: A level, load-rated concrete pad with drainage away from the cabinet. Make sure there is enough space for working and ventilation.

- Grounding and bonding: Connect all metal parts; check that the ground resistance targets are fulfilled; run the earthing conductors in a short, direct path.

- Terminations: Use the right dead-front elbows, follow the bend radii, torque to spec, check the phasing and tap settings, and make sure everything is labeled clearly.

- Checks before commissioning: insulation tests, checking the ratio/phase angle, fan operation (if ONAF), alarm setpoints, and the condition of the arrester.

Maintenance Essentials

- Regular checks: seals, gaskets, paint, hinges, animal protection; clean the vents and radiators in the cabinets.

- Electrical health: Keep an eye on the trend in load and temperature, and do infrared scans every so often to find hot connections early.

- Units filled with liquid: Check the pressure relief devices and gauges; take oil samples to check for moisture and dielectric strength.

- Records and spares: Keep track of alarms and trips, and keep a spare kit (elbows, gaskets, fans, relays) on hand to speed up repairs.

Conclusion

Pad-mounted transformers are not simply oil-filled or dry-type units—they are a complete, metal-enclosed outdoor solution engineered for modern distribution networks where public safety, compact footprint, and underground cabling are essential. Installed directly on a concrete pad with a sealed, lockable cabinet, they avoid the need for separate rooms, fencing, or ad-hoc protections common with conventional units.

Why choose pad-mounted instead of “just oil or dry”

- Safety & compliance: Dead-front terminations, tamper-proof enclosure, and interlocks improve public safety and code compliance.

- Compact & aesthetic: Small footprint and clean streetscape—ideal for campuses, communities, and commercial parks.

- Underground integration: Designed for underground MV/LV cable entry, switching, and sectionalizing in one package.

- Flexible dielectric: Can be built as oil-immersed (mineral or natural ester) or dry-type—the enclosure and features remain pad-mounted.

Buyer takeaway: think beyond upfront price

- TCO control: Pad-mounted designs often reduce civil works, safety add-ons, and long-term downtime risk.

- Fit to environment: Specify coatings, cooling stages, and noise targets for desert, coastal, or community sites.

- Right spec, fewer surprises: Match kVA, %Z, vector group, and tap range to utility requirements and future growth.

In short: Choosing a pad-mounted transformer isn’t just buying a device—it’s securing safe, code-compliant, low-maintenance power distribution that fits today’s urban and industrial environments, while keeping lifetime costs under control.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group