Global Dry-Type Transformer Manufacturers: An In-Depth Analysis & Buyer’s Guide | CHBEB

Introduction

It can be hard to choose the correct dry-type transformer1 maker. Safety, technical gaps, and cost trade-offs are things that buyers often have trouble understanding. This book looks at industry trends, the best worldwide suppliers, and the most important factors to consider when choosing a partner for your project.

Part 1: An Overview of the Market and Its Main Technologies

When you don’t have any context, you have to guess when you make a purchase. A lot of people don’t know why dry-type transformers are becoming more popular. By looking at the factors that drive the market and the differences in technology, you can be sure that your selections are in line with the needs of your project and that your investment will last.

Why Dry-Type Transformers Are Becoming More Popular: Safety, the Environment, and Key Drivers

People are choosing dry-type transformers more and more because they are naturally safe from fire, good for the environment, and work well indoors. Key factors are:

- Safety: No flammable liquid, lower fire danger, great for places with a lot of people.

- No oil leaks, less maintenance, and recyclable materials are good for the environment.

- Urbanization: More and more hospitals, schools, malls, data centers, and underground substations are using them.

- Regulation: Stricter fire and environmental rules make it more likely that dry-type will be used.

Cast Resin vs. Vacuum Pressure Impregnated (VPI)2: A Technology Showdown

There are two main technologies that rule the dry-type market:

- Cast Resin: Windings are wrapped in epoxy resin, which makes them very strong and resistant to moisture. This type of resin is good for humid or coastal areas.

- VPI (Vacuum Pressure Impregnated): Windings that have been soaked in varnish under vacuum and pressure. They are flexible, cost-effective, and can handle more thermal cycling.

It depends on the environment, the load profile, and the project’s priorities which one to use.

Part 2: Profiles of the World’s Best Manufacturers

Buyers risk making bad partnerships if they don’t know what each provider is good at. By looking at the best players, you’ll have a better idea of who is best at digitalization, heavy industry, or infrastructure. This will make sure that your project gets the proper competence.

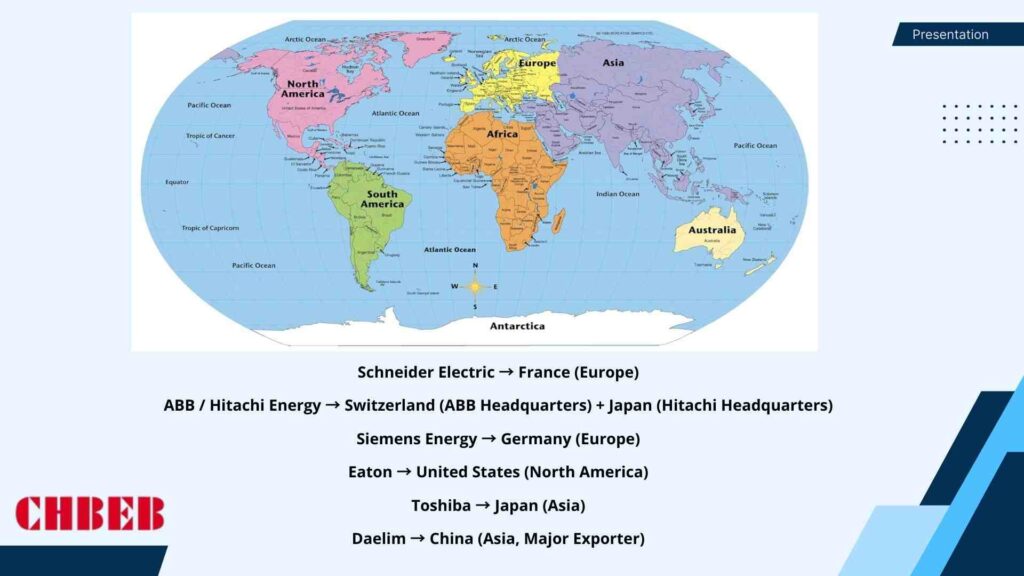

Schneider Electric: The First Company to Use Digital Technology and Smart Grids

Schneider Electric is the best at putting dry-type transformers into digital systems. Their EcoStruxure™ technology lets you keep an eye on things in real time, plan maintenance ahead of time, and save energy. They are a great alternative for digital-ready projects because they are well-known in data centers, commercial buildings, and smart buildings.

ABB (Hitachi Energy): The World’s Biggest Utility and Heavy Industry Company

ABB, which is now part of Hitachi Energy, is the best at doing large industry and utility-scale work. Their cast-resin and VPI designs are very sturdy and work well in difficult industrial environments, high power settings, and situations where renewable energy is used. Global service networks make sure that help is available in practically every corner of the world.

Siemens Energy: The Industry & Infrastructure Expert

Siemens Energy works on infrastructure, industrial automation, and making sure that energy is always available. Their dry-type transformers have superior insulation, minimal losses, and small footprints. They are good for infrastructure and transportation projects since they can be customized and have engineering support.

Other Important Global Suppliers

- Eaton: Makes adaptable VPI designs for businesses and factories.

- Toshiba: Known for being reliable throughout Asia-Pacific and in projects with a lot of infrastructure.

- Daelim is a developing player that focuses on exports and offers reasonable prices.

- Local champions: Suppliers in the area often offer affordable solutions that meet local codes.

Part 3: Comparative Analysis & Purchasing Strategy

Just looking at the price doesn’t tell you how much anything is worth. A lot of purchasers don’t think about service, lifecycle expenses, or vendor stability. A organized comparison makes sure you get not just the equipment you need, but also dependable help and savings over time.

Multi-Dimensional Comparison: Product, Service, and Market Position

| Manufacturer | Technology Focus | Market Strength | Best Fit |

|---|---|---|---|

| Schneider Electric | Cast Resin, Digital Integration | Strong in smart buildings & data centers | Digital-ready, efficiency-focused projects |

| ABB / Hitachi Energy | Cast Resin & VPI | Utility & heavy industry | Large-scale renewables, utility grids |

| Siemens Energy | Cast Resin | Infrastructure & transport | Industrial, transport, infrastructure |

| Others (Eaton, Toshiba, Daelim) | VPI & Cast Resin | Regional strength, competitive pricing | Cost-sensitive or localized projects |

How to Choose the Best Option for Your Project

- Set the kVA, voltage, environment, and fire/safety codes as required.

- Check out the technology: Cast Resin vs. VPI for load and climate.

- Look at the costs over the life of the product, including losses, maintenance, and downtime concerns.

- Check the vendor’s support: is it available globally or only in certain areas?

- Make sure that the certifications IEC, IEEE/ANSI, CE, and UL are all up to date.

- Think about customization: special enclosures, noise, and monitoring.

To get the most out of your dry-type transformer investment, you need to be sure that it fits technically, is compliant, and is from a reliable source.

Conclusion

Safety, sustainability, and digital integration are shaping the global market for dry-type transformers. Well-known manufacturers like Schneider Electric, ABB/Hitachi Energy, and Siemens Energy set high benchmarks in technology, certification, and worldwide service networks, making them the preferred choice for utility-scale, industrial, and infrastructure projects.

At the same time, regional and local manufacturers also play a vital role. They often provide faster delivery, competitive pricing, and flexible customization that global giants may not always offer. For projects in emerging markets or with unique requirements, these manufacturers can deliver reliable, efficient, and standards-compliant solutions tailored to local conditions.

As Nikola Tesla once said, The spread of electricity will do more to improve life on earth than any other single advance.

In the same spirit, whether from a global leader or a trusted regional supplier, dry-type transformers remain essential to powering communities safely, sustainably, and reliably for decades.

Learn More

Looking for the right dry-type transformer for your project? Download our latest product catalog or browse our product categories to find reliable solutions tailored to your needs.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group