Dry-Type Transformer Price Table: 100 kVA, 500 kVA, 2000 kVA Examples | CHBEB

Introduction

You shouldn’t have to guess how much a transformer will cost. Prices are hard to pin down because materials, requirements, and lead times change. This guide makes the prices of 2025 dry-type transformers obvious by turning them into tables and steps. This will help you plan correctly and buy with confidence.

2025 Dry-Type Transformer Price Guide: Cost by kVA Ratings

When you skip capacity, voltage, or safety adders, you get sticker shock. To avoid underbids and change orders, you should know the price ranges and what is included.

What is the price of a dry-type transformer per kVA?

Assumptions: three-phase, 50/60 Hz, standard indoor installation, normal impedance, IEC/IEEE compliance, ex-works (no freight, tax, or extras). VPI is about the same as the baseline, but cast resin costs more.

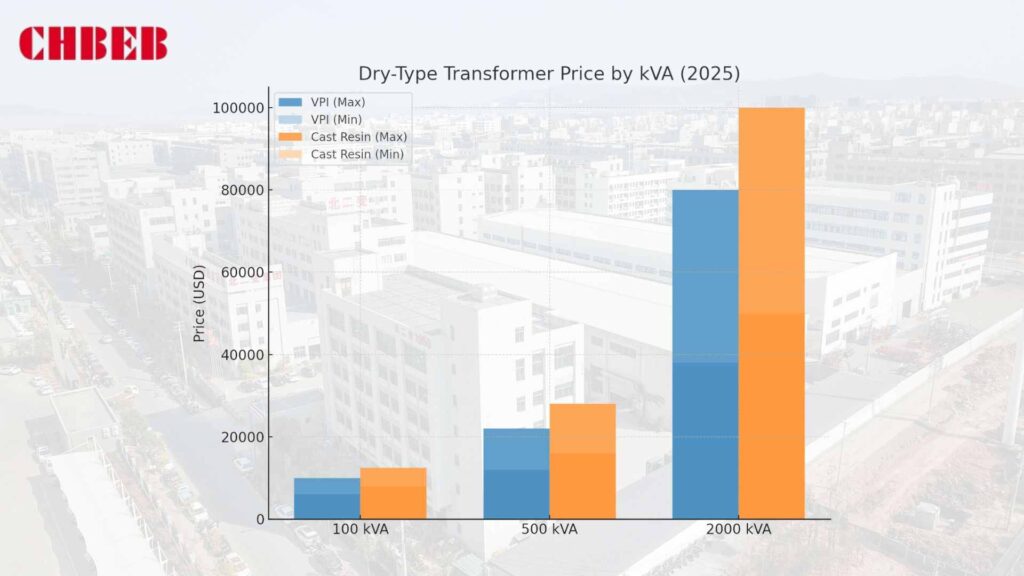

| Rating | Typical HV/LV (kV) | VPI Price Range (USD) | Cast-Resin1 Price Range (USD) | Approx. $/kVA (VPI) | Typical Use Cases |

|---|---|---|---|---|---|

| 100 kVA | 6–11 / 0.4 | $6,000–$10,000 | $8,000–$12,500 | $60–$100 | Shops, small offices, light commercial |

| 500 kVA | 6–15 / 0.4–0.69 | $12,000–$22,000 | $16,000–$28,000 | $24–$44 | Campuses, retail hubs, small factories |

| 2000 kVA | 11–24 / 0.4–0.69 | $38,000–$80,000 | $50,000–$100,000 | $19–$40 | Hospitals, metro stations, larger plants |

- Cast-resin premium: usually 15–30% more than VPI at the same rating.

- For a higher voltage class (22–35 kV), add 8–20% for BIL, insulation, and clearances.

- Low-loss cores (amorphous/Hi-B): add 10–15% up front and cut no-load losses.

The VPI standard spec says that for every kVA: 100 kVA: $60–$100/kVA; 500 kVA: $24–$44/kVA; 2000 kVA: $19–$40/kVA. Higher ratings lower the price per kVA.

What Will Cause the Prices of Dry-Type Transformers to Change in 2025?

Small design choices add up rapidly. Add prices early to stop the budget from going up.

- Copper is more expensive and has fewer losses, while aluminum is less expensive and has a bigger cross-section.

- Core steel: High-grade grain-oriented or amorphous cores cut down on losses when there is no load, but they also raise the cost per unit.

- Class F/H, low-smoke/halogen-free resins, and humidity protection add to the cost of the insulation system.

- Fans (AF), RTDs, relays, thermal scanners, and Modbus/IEC 61850 gateways add 3 to 15% for cooling and monitoring.

- Acoustics and enclosure: Filters and coatings that make designs quieter and raise IP/NEMA ratings by 5–20%.

- Compliance and testing: IEC/IEEE routine and type tests, UL/CE markings, witness FAT, and paperwork all take time and money.

- Freight, customs, and foreign exchange rates can change the price of goods by 5% to 25%.

- Lead time: Quotes can go up a lot because to rush premiums and backlog cycles.

Total Cost of Ownership (TCO)2: More than the Price Tag

It can cost more later to buy an inexpensive unit. Energy losses and downtime are sometimes much bigger than tiny capex reductions. Don’t simply look at the quote; look at the lifetime cost.

Why efficiency is important for the long-term costs of transformers

Every hour, there are losses. No-load runs all the time, and load losses go up with current and harmonics. Saving a few kilowatts can save you a lot of money over your lifetime.

A simplistic example:

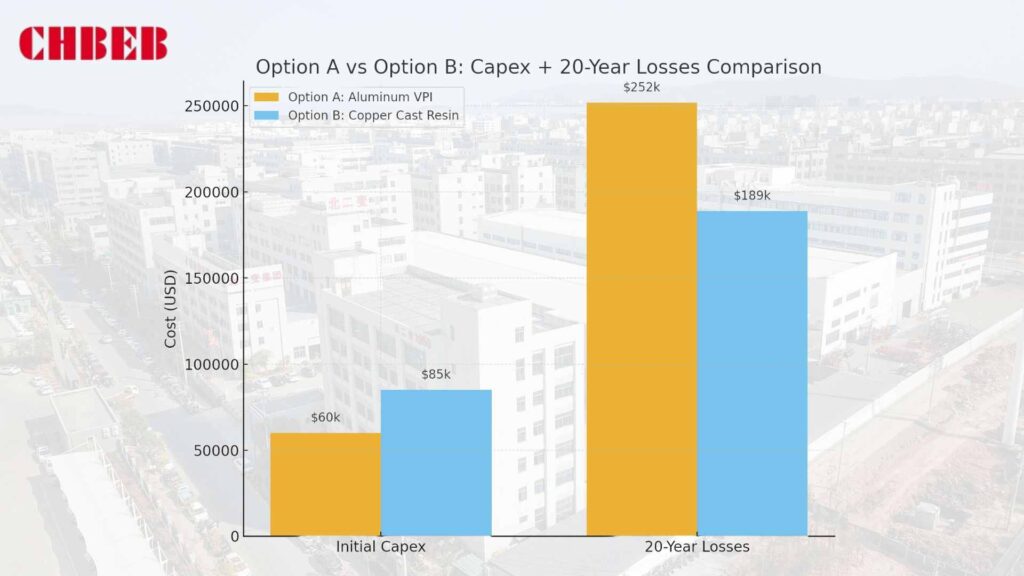

- Option A: 2000 kVA, Aluminum VPI: Buy for $60,000; lose about 12 kW.

- Option B: 2000 kVA, Copper Cast-Resin: Buy for $85,000; losses are about 9 kW.

Let’s say $0.12 per kilowatt-hour, 8,760 hours per year, and 20 years.

A: 12 × 8,760 × $0.12 = $12,614 every year, which is $252,000 over 20 years.

B: 9 × 8,760 × $0.12 = around $9,460 a year, or $189,000 over 20 years.

Energy delta: B saved almost $63,000, which helped make up for the increased capital expenditures, not including the thermal margin, uptime, and resale value.

- Make loss assurances in the PO stricter (with penalties for going over).

- Think about harmonics (drives/EV). It may be necessary to use a K-factor or derating.

- Check the ambient temperature, altitude, and duty cycle; these all affect the rise in temperature and the life of the device.

How to Get a Formal Quote for a Transformer in 2025

When specifications are unclear, quotes change. Give a clear brief to generate numbers that are similar and can be defended.

- kVA and duty: continuous rating, overloads, and temperature/altitude.

- Voltage and taps: LV/HV, vector group, tap range/steps (off-load/OLTC).

- Technology: VPI or cast resin; conductor made of copper or aluminum.

- Loss targets: no-load/load losses are assured, and there is a punishment schedule.

- Class (e.g., 80K/100K), natural/forced air, and fan phases for temperature rising and cooling.

- Enclosure and IP/NEMA: for indoor and outdoor use, with filters and coatings for coastal and corrosive environments.

- Sound: maximum dB(A) at a certain distance; site limitations.

- Compliance: IEC/IEEE editions, UL/CE, routine/type tests, and witness FAT.

- Monitoring: RTDs, relays, and communications (Modbus, IEC 61850, and BACnet).

- Logistics: making crates, finding lifting points, setting footprint limitations, and delivery windows.

- Commercials: warranty, service SLAs, spare parts, training, and references.

Tip: Ask vendors to provide you a price for a baseline and a low-loss option next to each other. Then compare the cost of capital plus 10/20 years of energy.

Conclusion

The cost of a dry-type transformer in 2025 depends mainly on its kVA rating, voltage level, and design choices (e.g., insulation system, core materials, technology). Using benchmarks such as 100 / 500 / 2000 kVA helps set realistic budgets, while accounting for adders like higher voltage class, low-loss cores, and enclosure/IP requirements prevents surprises later.

Looking beyond the sticker price is essential. By evaluating the Total Cost of Ownership (TCO)—including energy losses, maintenance, and downtime—buyers can identify options that save more over the service life of the unit.

A clear and accurate RFQ, backed by firm loss guarantees and compliance checks (IEC/IEEE, UL/CE where applicable), remains the best way to secure a transformer that is reliable, efficient, and cost-effective for decades of operation.

Learn More

Want to explore more transformer solutions? Download our latest product catalog or browse our product categories to find the right transformer for your project.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group