What Is a Dry Type Transformer? Beginner’s Guide to Definition, Types & Benefits | CHBEB

What Is a Dry Type Transformer? A Quick-Start Guide for Beginners

Introduction

A lot of buyers mix up dry and oil-immersed transformers. This can lead to wrong choices, safety hazards, and higher expenditures. This quick-start guide tells you what a dry type transformer is, how it works, and when it’s the best option.

Fundamentals: Definition, Structure, and the Core Safety Principle

PAS lead: Oil systems make people worry about fires, leaks, and frequent checks. These worries make projects take longer and make it harder to find a good place to put them. Dry type transformers get rid of all the oil, giving modern buildings safe, clean, low-maintenance power.

Concept Overview: The Main Difference Between Oil-Based Units and Other Units

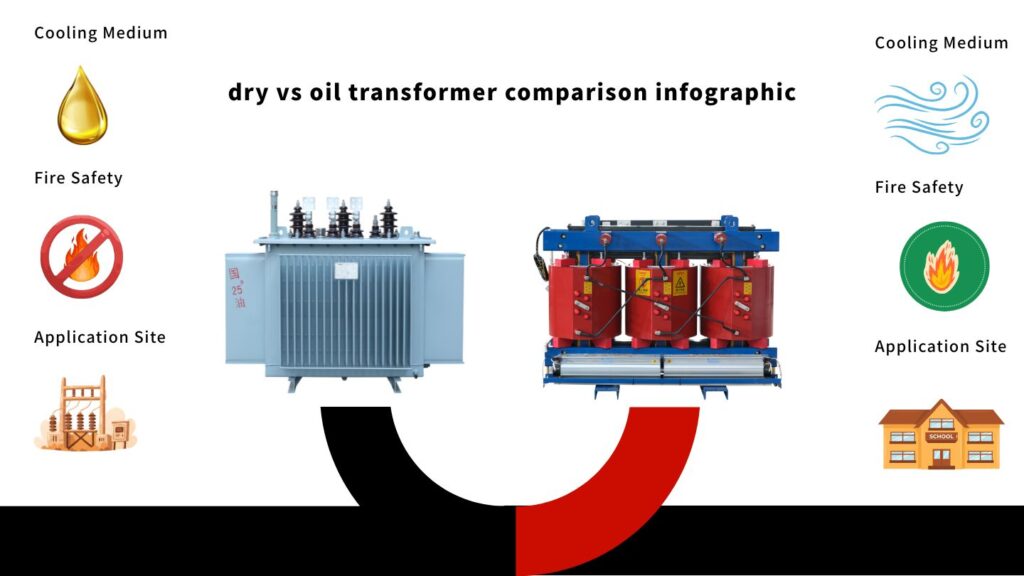

Mineral or ester oil is used to insulate and cool oil-immersed transformers. Air and solid insulation (such varnish or epoxy glue) are used in dry type transformers. Getting rid of liquid lowers the chance of leaks, makes it easier to get building permits, and lowers the amount of fire load in buildings.

| Comparison | Oil-Immersed Transformer | Dry Type Transformer |

|---|---|---|

| Cooling & Insulation | Oil bath; liquid dielectric | Air cooling; solid dielectric |

| Fire Load | Higher (combustible oil) | Very low (no oil) |

| Maintenance | Oil testing, sealing, filtration | Minimal; visual checks, cleaning |

| Typical Placement | Outdoor yards, substations | Indoor rooms, public buildings |

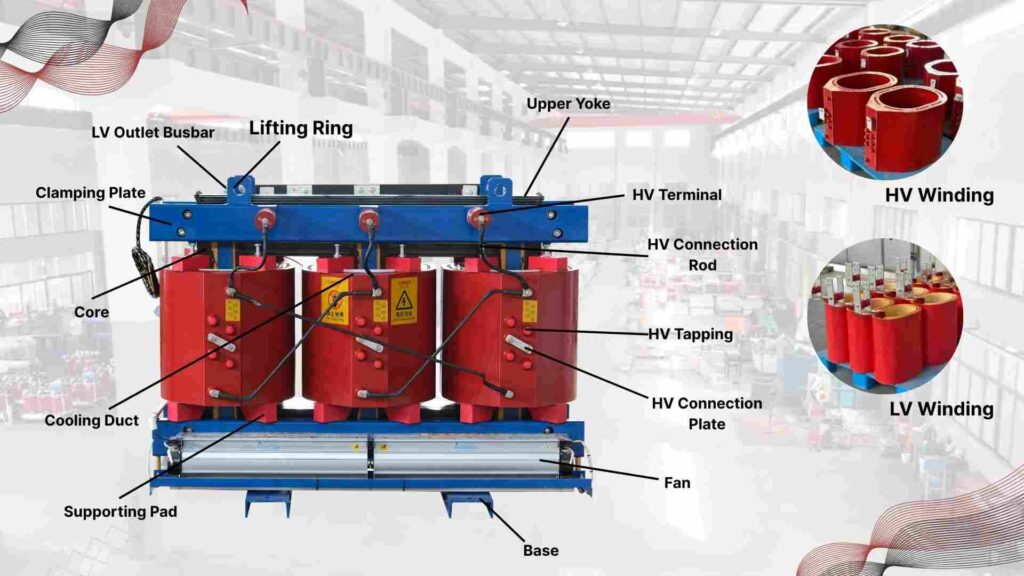

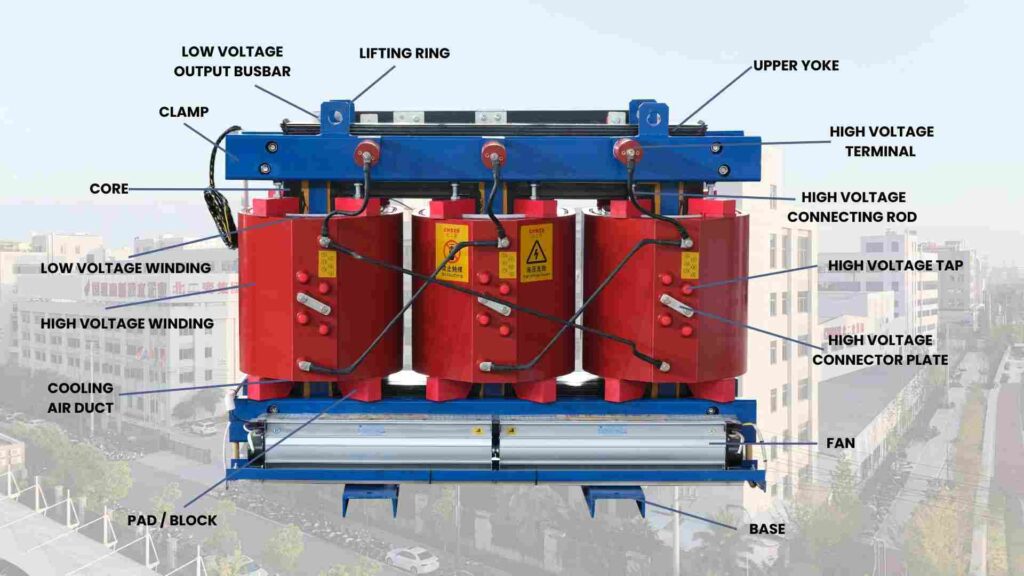

A Look Inside: The Three Main Parts of a Dry Transformer

- Core: Stacks of grain-oriented silicon steel1 make a magnetic channel with minimal loss and stable induction.

- Windings: Copper or aluminum wires that are insulated with varnish or epoxy give the wires dielectric strength and heat resistance.

- Cooling Path: Natural air (AN) or forced air (AF) carries heat away from coils to keep the temperature from going too high.

Result: It runs quietly, regulates itself consistently, and lasts a long time, all without having to deal with oil or spills.

The Value Proposition: Core Benefits and Internal Types

PAS lead: A lot of people are afraid that not using oil will make them less productive. That doubt can stop safer updates. Modern dry kinds fulfill the same performance standards, but they are safer, more sustainable, and easier to use every day.

Three Big Benefits: Safety from Fire, Eco-Friendliness, and the Fact That It Doesn’t Need Any Maintenance

- No combustible oil means a lot less fire load and easier indoor fire safety architecture.

- Eco-Friendliness: No oil leaks or trash; green buildings are easier to follow environmental rules.

- Low Maintenance: No sampling or filtration; regular checks focus on cleanliness, ventilation, and terminations.

| Benefit | What It Means | Impact |

|---|---|---|

| Safety | Minimal fire and spill risk | Better fit for hospitals, schools, transit, data centers |

| Environment | No oil handling or contamination | Smoother approvals; fewer mitigation systems |

| Operations | Simpler inspections and cleaning | Lower OPEX and downtime over service life |

A Simple Explanation of the Key Selection Difference Between VPI and Cast Resin

It depends on the environment, the job, and the budget whether to use VPI or cast resin. This short guide will help you match type to risk and performance.

| Feature | VPI (Vacuum Pressure Impregnated) | Cast Resin (Epoxy Encapsulated) |

|---|---|---|

| Insulation System | Varnish impregnated windings | Solid epoxy cast coils |

| Moisture Resistance | Good | Excellent (suited to humid/coastal) |

| Mechanical Strength | Good | Very high; robust under short-circuit stress |

| Typical Use | Commercial/light industrial indoors | Heavy-duty, harsh, or corrosive sites |

| Budget Sensitivity | Generally lower CAPEX | Higher CAPEX; lower risk in tough sites |

Quick tip: If you’re on a tight budget, go with VPI for interior projects. If you’re worried about humidity, pollution, or mechanical stress, go with cast resin.

Decision Making: Dry vs. Oil—When and Why to Choose Dry?

PAS lead: The price up front typically makes people buy oil. That choice can incorporate fire systems, spill controls, and service that happens on a regular basis. Dry type units take away those problems, which helps keep budgets in check for the life of the asset.

The Ultimate Trade-Off: Weighing Cost, Capacity, and Maintenance

| Parameter | Dry Type Transformer | Oil-Immersed Transformer |

|---|---|---|

| Initial Cost | Often higher | Often lower |

| Maintenance | Minimal; no oil handling | Oil testing, sealing, filtration |

| Cooling Efficiency | Moderate (AN/AF) | High (oil convection) |

| Fire/Spill Risk | Very low | Present; requires mitigation |

| Best Fit | Indoor, public, renewables, metro | Outdoor yards, high-capacity substations |

Use dry type when you want to keep fire load to a minimum, installations are indoors or in public places, and you want low lifetime maintenance.

When outside nameplate capacity and cooling performance are more important than extra safety measures and service routines, use oil-immersed

.

Frequently Asked Questions (FAQ)

1. What is a dry type transformer?

A dry type transformer transfers electrical energy using air or resin insulation instead of oil. It’s clean, safe, and ideal for indoor or fire-sensitive environments such as hospitals, offices, and renewable projects.

2. What’s the difference between dry type and oil-immersed transformers?

Oil-immersed transformers use insulating oil for cooling and insulation, while dry type units rely on air or solid resin. Dry transformers are safer, require less maintenance, and can be installed indoors.

3. Can a dry type transformer catch fire?

It’s extremely unlikely. Dry type transformers use non-flammable materials such as epoxy resin or air insulation, eliminating the fire and explosion risks linked to oil-immersed designs.

4. Do dry type transformers need maintenance?

They require minimal maintenance. Routine inspections focus on ventilation, dust removal, and terminal tightening—no oil testing or replacement is needed throughout their service life.

5. Which is better: Cast Resin or VPI dry type transformer?

Both are reliable. VPI is cost-effective for clean indoor environments, while Cast Resin provides superior moisture and mechanical protection in humid or heavy-duty sites.

6. Can dry type transformers be used outdoors?

Yes. When housed in a sealed IP45 or higher-rated enclosure, dry transformers operate safely outdoors, even in humid, coastal, or dusty environments.

7. Why are dry type transformers usually more expensive than oil types?

Their solid insulation and fireproof design raise initial cost, but they save money over time through reduced maintenance, no oil handling, and enhanced safety compliance.

⚙️ CHBEB — Reliable Partner for Dry Type Distribution Transformers

When it comes to dry type transformer manufacturing, CHBEB stands among China’s most experienced and trusted suppliers. With over 60 years of transformer production expertise, the company has mastered both technical precision and global reliability — serving utilities, EPC contractors, and industrial buyers worldwide.

Our Manufacturing Network

CHBEB operates two factories in Wenzhou, one in Nanjing, and a Beijing office, ensuring large-scale production capacity and fast global delivery. Each factory is equipped with advanced VPI and Cast Resin production lines that comply with IEC 600762, ISO9001, and CE standards.

Why CHBEB for Dry Type Transformers:

- High-End Materials: Every unit uses 100% new copper, Class F/H insulation, and premium silicon steel for maximum efficiency.

- Full Testing Assurance: All dry type transformers undergo strict routine and type tests — including insulation resistance, partial discharge, and temperature rise.

- Proven Reliability: CHBEB is a qualified supplier for the State Grid Corporation of China, maintaining a zero-accident record in global projects.

- Fast OEM/ODM Service: From prototype to batch delivery, customized orders can be completed in as little as one week for urgent projects.

- Global Focus: With exports to Russia, Southeast Asia, Africa, and Belt & Road countries, CHBEB supports local distributors and contractors with on-site service and certification assistance.

- Green Manufacturing: Our dry type transformers are designed for fire safety, low noise, and eco-compliance, ideal for hospitals, schools, and renewable energy systems.

💡 Looking for a reliable dry type transformer manufacturer that combines Chinese manufacturing strength with international quality?

👉 Contact CHBEB today at [email protected] or visit www.chbeb-ele.com to get your customized solution or download our full dry type transformer catalog.

Conclusion

Dry type transformers represent the new standard for safe, efficient, and environmentally responsible power distribution.

By eliminating oil, they reduce fire and spill risks while simplifying installation and maintenance — a clear advantage for modern commercial and industrial projects.

When properly designed and certified, VPI and Cast Resin types deliver decades of stable performance with minimal lifetime cost.

For project engineers and procurement managers, the key is to look beyond price tags — true value lies in tested quality, transparent materials, and proven reliability from a trusted manufacturer.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group