Unveiling the “Green Box”: How Transformer Substations Power and Protect Your Neighborhood

Introduction

The transformer substation1, a modest, silent green box that most people walk by every day, is important to every community. It could look normal, but within is the system that keeps your devices charged and your lights on. Let’s open this “green box” and find out how it safely and quietly fuels your town.

Core Function: The Working Principle and Integrated Structure

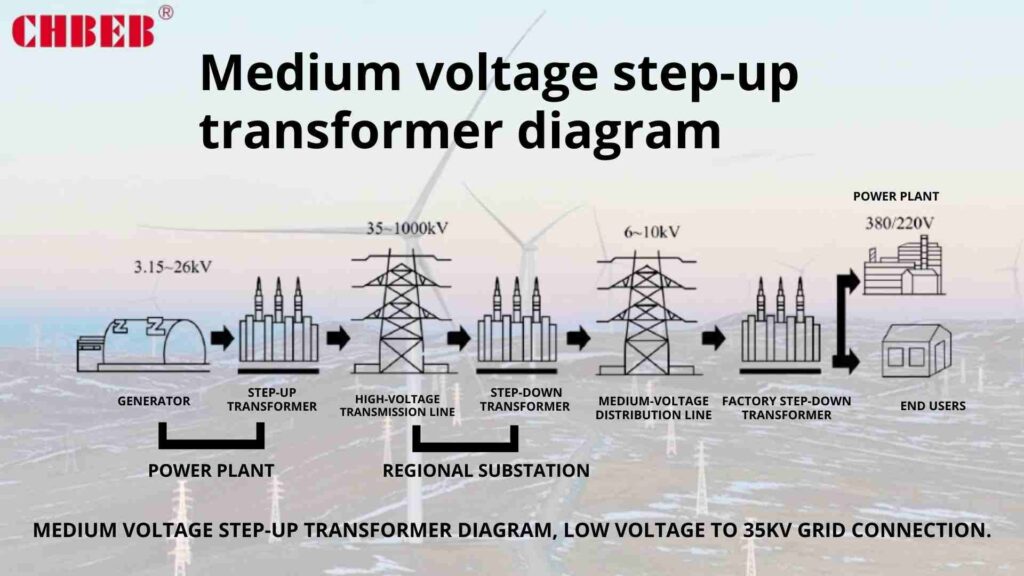

Transformer substations connect the high-voltage grid to local customers in modern distribution networks. These units are small, smart, and made to change, protect, and control power all in one box.

Role and Definition: The “Voltage Faucet” of the Distribution Grid

Think of electricity as water that is under pressure. It travels well over great distances on high-voltage lines, but before it gets to homes and businesses, the pressure must to drop to a level that is safe to use.

The transformer substation does this task. It lowers the voltage from 10 to 35 kV to 0.4 kV, making it safe to use every day.

Usually, each box-type substation has:

- Power transformer (to change the voltage)

- High-voltage switchgear (for safety and control)

- Low-voltage distribution cabinet (for lines that go out)

- Auxiliary circuits for lighting, measuring, and watching

This combination turns it into a small power distribution center that can automatically find and fix problems and keep the power supply stable in real time.

Anatomy Inside: The Integrated Design of the Transformer and Switchgear

The inside of the green shell is meticulously designed for both safety and performance.

- There is an oil-immersed or dry-type transformer in the transformer compartment that lowers the voltage.

- The HV and LV switchgear sections have breakers, fuses, and protection relays that govern the circuits that come in and go out.

- The busbars and wires connect each system through channels that are insulated and fireproof.

Most modern box-type substations are put together in a factory, tested, and sealed against dust and rain (IP54 or higher). This design ensures quick installation, minimal maintenance, and a long service life, especially in tough places like deserts or coastal areas.

Community Safety: Addressing Concerns About Noise, EMF, and Physical Risk

People often worry about transformer substations that are close to homes. Will they be loud, give off radiation, or be dangerous if you touch them? In fact, these boxes have a number of safety features that make them as safe as any other piece of public utility equipment.

“Three Lines of Defense” Against Electric Shock and Fire

- Separation of electricity

Metal barriers and grounding systems completely surround each chamber. Even maintenance staff can’t touch live parts without following the right steps. - Protection Against Overcurrent and Fault

When there is too much electricity, a short circuit, or a problem with the insulation, circuit breakers and relays immediately turn off the power. The time it takes to respond is measured in milliseconds. - Preventing fires and keeping structures safe

Self-extinguishing insulation is used in dry-type transformers. Fire-resistant fluids fill oil-type systems, and pressure-relief valves keep them safe.The enclosure is built of galvanized steel or aluminum alloy and is painted with paint that doesn’t rust. It also has ventilation grilles to keep heat from building up.

These layers work together to make a “three-line defense system” that protects both the equipment and the people who live nearby.

Scientific Facts: Understanding Electromagnetic Fields (EMF) and Safe Distance

All electrical devices, from hair dryers to phone chargers, give off electromagnetic fields (EMF) as a natural consequence. Transformers make EMFs, but only in extremely small amounts.

International standards like WHO, IEEE, and ICNIRP2, along with scientific studies, show that EMF exposure near distribution transformers is well below acceptable levels.

The international exposure limit for the public is 100 µT, however typical EMF values measured 1 meter from a box substation range from 0.2 to 3 µT (microteslas).

Most countries say that substations should be a few meters away from buildings, not because of the risk of radiation, but for maintenance access and ventilation. To sum up, you can walk, live, or park next to one without worrying.

Practical Know-How: Types, Maintenance, and Common Issues

Knowing a few basic things about how substations are built and kept up helps people in the area appreciate how quiet and reliable they are.

Design Types: American vs. European Box Style and the Humming Sound Explained

There are two main design philosophies that box-type substations usually follow:

- American Style (Transformer on a Pad)

- An oil-filled tank holds both a transformer and switchgear.

- Small size and easy-to-understand design.

- Used a lot in North America and places with strict safety rules.

- European Style (Small, Prebuilt Substation)

- Separate areas for high voltage (HV), transformer, and low voltage (LV) systems.

- Stresses the importance of modularity and ease of maintenance.

- Common in cities in China, the Middle East, and Europe.

People sometimes hear a “humming sound,” but it’s not an electrical risk. It’s just the iron core of the transformer vibrating naturally under changing magnetic flux. Engineers use step-lap silicon-steel core cutting, vacuum varnishing, and elastic mounts to reduce the noise.

It’s about as loud as a quiet conversation (50–55 dB), and you can’t hear it more than a few meters away.

Common Problems and How to Fix Them

Box substations are made to work without anyone being there, but they nevertheless are checked on a regular basis:

- Check for rust or loose connectors by looking at them.

- Cleaning the filters in the ventilation system and checking the grounding continuity.

- Using remote SCADA systems to keep an eye on load balance and temperature sensors.

Scheduled maintenance can help you avoid common problems like worn-out insulation or cables that have been used too often. Many new units also have IoT sensors that transmit alarms before problems happen. This keeps the power in your community consistent all day and night.

⚙️ CHBEB — Reliable Partner for Box-Type and Distribution Transformers

Behind every “green box” that powers homes and communities, there are engineers, factories, and suppliers who make reliability possible. CHBEB is one of China’s trusted manufacturers of distribution and box-type substations, combining over 60 years of transformer expertise with modern production and testing technology.

From Wenzhou to Nanjing, CHBEB operates three manufacturing bases and a logistics office in Beijing, ensuring both strong production capacity and rapid nationwide delivery. Every transformer and substation is tested under IEC 60076 and IEC 62271-202 standards, guaranteeing low loss, safety, and long-term performance even in coastal or high-humidity regions.

What Makes CHBEB Stand Out

- Complete Range: From 50 kVA to 3150 kVA dry-type and oil-immersed distribution transformers, as well as integrated box-type substations.

- Quality Without Compromise: 100 % new copper, high-grade silicon steel, and epoxy insulation tested to Class F/H fire ratings.

- Proven Reliability: Certified supplier for the State Grid Corporation of China, maintaining a flawless record of safety and stability.

- Fast Delivery: Standard units ready for dispatch within 24 hours; customized solutions within 2–3 weeks.

- Global Reach: Exported to Russia, Southeast Asia, Africa, and Belt and Road countries, supporting EPC contractors and utilities worldwide.

Whether it’s a neighborhood upgrade or an industrial substation project, CHBEB delivers tested quality, certified performance, and long-term engineering reliability — ensuring every green box operates safely and efficiently.

👉 Looking for a distribution transformer manufacturer that combines Chinese manufacturing strength with international standards?Contact CHBEB for a tailored solution or Download our full transformer catalog here.

🔍 Frequently Asked Questions (FAQ)

1. What’s the purpose of those green boxes on the street?

They’re compact transformer substations that step high-voltage electricity (10–35 kV) down to 0.4 kV for local use. Inside, they contain transformers, switchgear, and control panels — essentially a full mini power center hidden in plain sight.

2. Do these boxes give off radiation?

No. The electromagnetic fields (EMF) around a box-type substation are extremely low — far below international safety limits set by WHO and ICNIRP. Standing near one is as safe as using household electronics.

3. How far should I stay from a transformer box?

There’s no danger zone. The few meters of distance often seen around these boxes are for maintenance access and ventilation, not for radiation safety.

4. Why does it make a humming sound?

That gentle hum is simply the vibration of the magnetic core when alternating current passes through. It’s normal, harmless, and usually kept below 55 dB — similar to a quiet conversation.

5. Is it oil-immersed or dry-type inside?

Both types exist. Urban and residential areas mostly use dry-type transformers for fire safety, while oil-immersed units are common in outdoor or large-capacity applications.

6. Can I get an electric shock if I touch the green box?

No — all external parts are grounded and sealed. Live conductors are completely enclosed in metal compartments. Even maintenance crews follow strict lockout procedures before opening.

7. Can these boxes catch fire?

Extremely rare. Dry-type units use self-extinguishing insulation, while oil-immersed designs use fire-resistant fluids. Each enclosure is made from galvanized or aluminum alloy with pressure-relief and ventilation systems to prevent ignition.

Conclusion

The green transformer substation you pass every day is more than a simple utility box—it’s a compact, intelligent power system that quietly supports modern life. Inside, layers of engineering precision ensure electricity is delivered safely, efficiently, and sustainably to every home and business.

Whether built as a dry-type or oil-immersed system, each box-type substation reflects decades of progress in insulation, protection, and smart monitoring—turning complex power conversion into everyday convenience.

So next time you see that silent green box on your street, remember: it’s not just equipment. It’s the unseen bridge between high-voltage grids and the comfort of your daily life—a quiet symbol of how engineering keeps communities connected and safe.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group