What Is a Substation Power Transformer? Working Principle, Grid Function & OLTC Explained | CHBEB

In-Depth Understanding: The Core Function and Grid Role of Substation Power Transformers

Introduction

A substation transformer is a silent workhorse that sits at the center of every power system. It makes sure that electricity flows smoothly from generation to consumers. These huge devices, on the other hand, can take enormous voltages, manage complicated cooling, and keep stability throughout whole regional networks. To understand how modern power systems stay reliable and efficient, you need to know what their roles are.

Fundamentals: Definition, Structure, and Dual Purpose

Before we get into how substations move power across the grid, it’s important to know what makes a substation power transformer different in terms of design and function.

Definition and Positioning: What Sets Them Apart from Distribution Units

A substation power transformer is a large device that transfers electricity between voltage levels in the transmission system. It typically operates at 110–500 kV and handles over 100 MVA of power.

In contrast, distribution transformers reduce voltage for end users—usually below 35 kV—and serve localized loads such as homes or businesses.

| Type | Voltage Range | Capacity | Function |

|---|---|---|---|

| Substation Power Transformer | 110–500 kV | 60–1000 MVA | Interconnects generation and transmission systems |

| Distribution Transformer | ≤35 kV | 50–2500 kVA | Supplies local distribution networks |

The main distinction is where the grid is located. Substation transformers are the “main gatekeepers” for regional power transfer. They are located at generation, transmission, or primary substations.

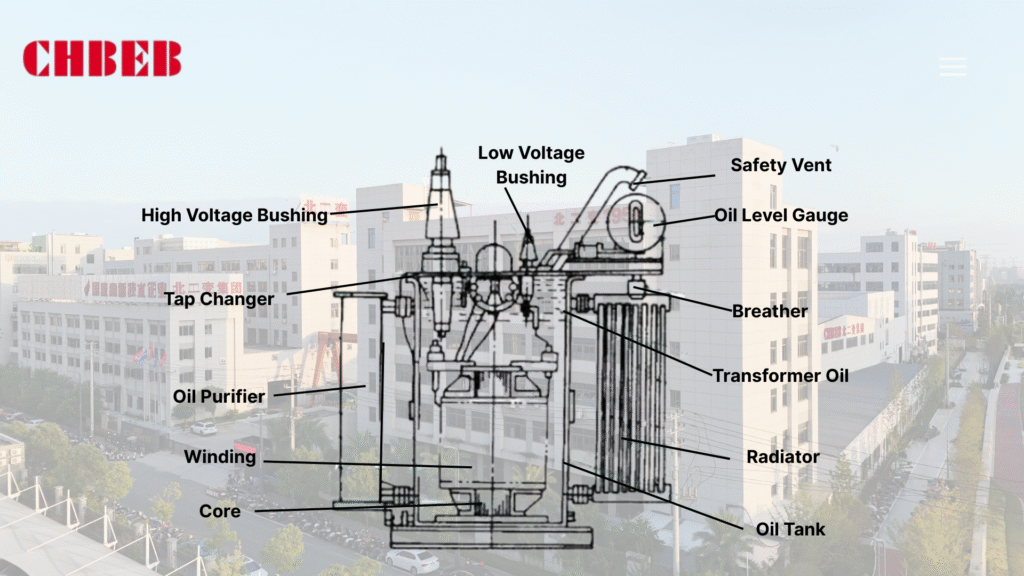

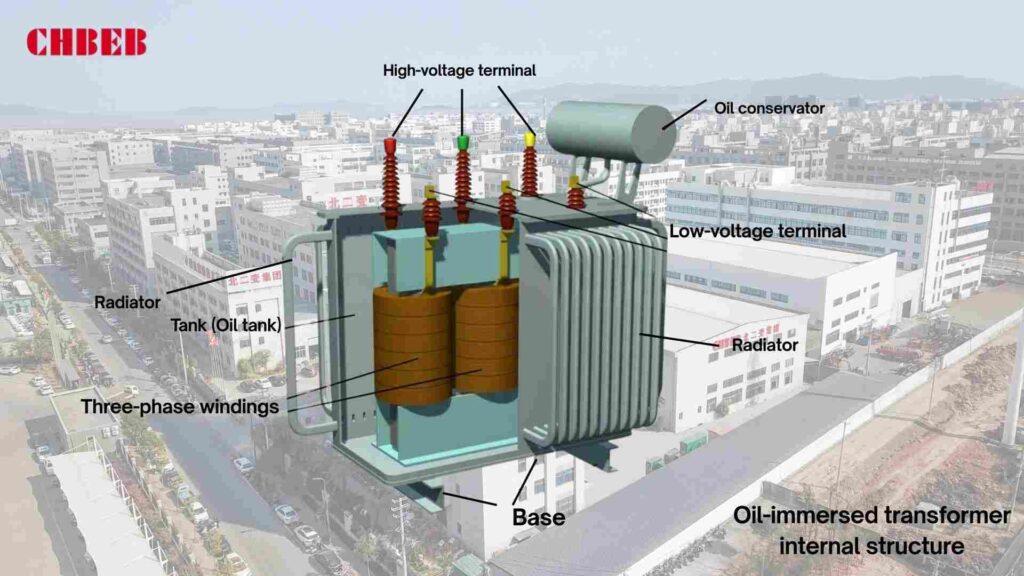

Core Structure: Key Components and Complex Cooling Systems of Large Transformers

The design of a substation transformer is far more complicated than that of smaller dry-type or pad-mounted devices. Three main engineering systems affect how well it works:

- Active Part (Core and Windings)

The laminated magnetic core efficiently guides magnetic flux, while the copper or aluminum windings handle large currents with minimal loss. - System for Cooling

Large transformers generate significant heat. They rely on oil circulation and forced-air or water cooling, as defined by IEC and IEEE cooling codes such as:- ONAN (Oil Natural Air Natural): passive circulation for mild loads.

- ONAF (Oil Natural Air Forced): adds fans to enhance cooling efficiency.

- OFWF (Oil Forced Water Forced): used in very high-power transformers, including 500 kV grid units.

- Bushings and Tanks

The primary tank, which is usually made of welded steel, holds insulating oil and keeps its shape even when it gets hot. Bushings constructed of porcelain or composite materials safely move high-voltage wires in and out of the unit.

These systems work together to create a balance of electrical efficiency, mechanical strength, and thermal regulation.

The Grid Nexus: How Substation Transformers Ensure Efficient Power Transfer

Substation transformers are the main link between the generation, transmission, and distribution layers of the electrical grid. They not only change voltage, but also maintain power flow, reduce losses, and stabilize voltage levels as loads fluctuate.

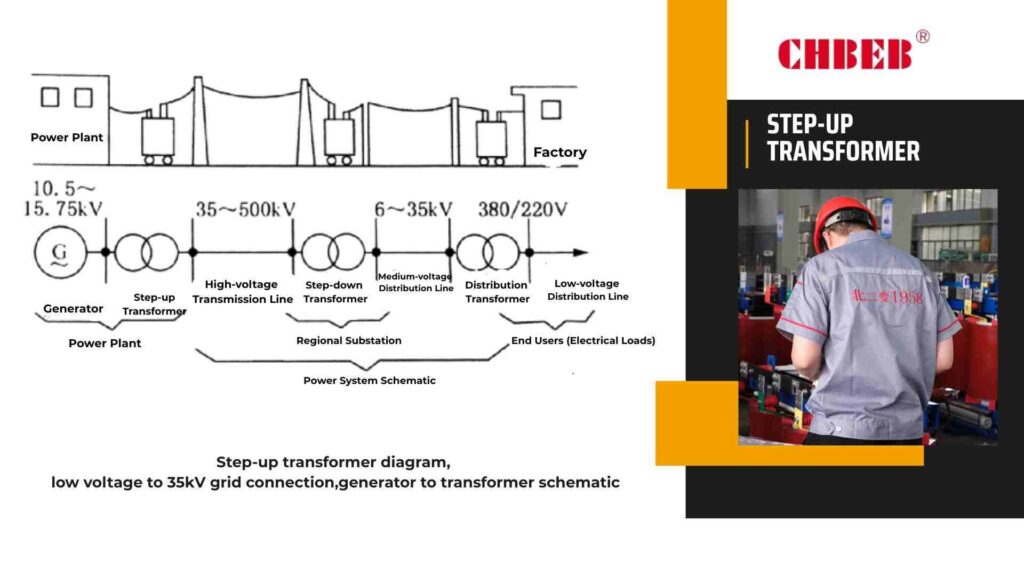

The Two Main Tasks in the Grid: Step-Up and Step-Down on the Energy Journey

Electricity is generated at medium voltages (typically 11–25 kV). Power plants use step-up transformers to increase voltage to hundreds of kilovolts, significantly reducing current and line losses, making long-distance transmission more efficient.

At the receiving end, step-down transformers in major substations lower the voltage again for safe and efficient distribution to businesses and regional networks.

This two-way procedure shows how electrical energy moves:

- Step-Up Stage: increases voltage to make transmission more efficient.

- Stage of Transmission: sends high-voltage power over great distances.

- Step-Down Stage: lowers the voltage so it can be safely distributed locally.

Power grids would lose a lot of money and voltage would drop over even short distances if there were no substation transformers.

| Function | Typical Voltage | Application |

|---|---|---|

| Step-Up Transformer | 11 → 220–500 kV | Power generation stations |

| Step-Down Transformer | 220 → 35–110 kV | Regional or primary substations |

Grid Stability: The Role and Importance of the On-Load Tap Changer (OLTC)

In real grids, voltage changes constantly due to variations in load, temperature, and distance. Substation transformers use an On-Load Tap Changer (OLTC) to maintain a stable supply by adjusting the transformer’s turns ratio without interrupting operation.

OLTCs monitor output voltage in real time and automatically switch taps to raise or lower voltage within a small range (typically ±10%). This ensures that industrial facilities and distribution networks receive a consistent power supply, even under fluctuating demand.

Modern OLTCs are equipped with motor drives, electronic controllers, and SCADA connectivity, enabling remote operation and predictive maintenance.

A well-maintained tap changer can perform over 500,000 switching operations during its service life.

Maintenance and Challenges: Ensuring Long-Term Reliability

Substation transformers are designed to endure for decades, but they need to be monitored all the time, have preventive maintenance done, and follow international standards to stay reliable.

Reliability Paramount: Maintenance Requirements and Lifespan Considerations

1. Oil Monitoring and Filtration

Transformer oil serves as both an insulator and coolant. Regular testing for moisture, acidity, and dielectric strength is vital. Dissolved gas analysis (DGA) identifies early signs of overheating or insulation breakdown.

2. Thermal Management

Infrared thermography detects hot spots caused by load imbalance or poor connections. Cooling fans and pumps require periodic cleaning and bearing inspection to ensure efficiency.

3. Electrical Testing

Routine tests include winding resistance, turns ratio, insulation resistance (IR), and power factor measurements. These ensure electrical integrity and prevent catastrophic faults.

4. Mechanical Integrity

Vibration monitoring helps detect loose core clamps or tank deformation. Foundation bolts and bushing seals are checked to prevent oil leakage and mechanical stress.

5. Digitalization and Remote Diagnostics

Smart monitoring systems equipped with IoT sensors continuously track oil temperature, load current, and tap-changer status. Cloud-based analytics can predict failures months in advance, reducing downtime and maintenance cost.

With proper operation and maintenance, substation transformers can achieve a service life of 30–40 years, though aging insulation and mechanical fatigue remain key challenges.

🔍 Frequently Asked Questions (FAQ): Substation Power Transformers

1. What’s the difference between substation transformers and distribution transformers?

Substation transformers operate at high voltages (110–500 kV) and handle regional power transfer between generation and transmission networks.

Distribution transformers, on the other hand, work below 35 kV and deliver power directly to residential, commercial, or industrial users.

In simple terms — substation transformers move electricity across regions, while distribution transformers deliver it to end consumers.

2. How does a substation transformer work?

It operates based on Faraday’s Law of Electromagnetic Induction1. Alternating current in the primary winding generates a changing magnetic field in the core, inducing voltage in the secondary winding.

Step-up transformers raise voltage for transmission efficiency, while step-down units reduce voltage for safe regional distribution.

3. Why are substation transformers so large?

Because they handle massive voltage and current levels, often reaching hundreds of megawatts.

Their size allows for stronger magnetic cores, thicker windings, and oil-based cooling systems — all necessary to manage thermal stress, magnetic flux, and insulation safely and efficiently.

4. Can a substation transformer step voltage up as well as down?

Yes. Step-up transformers at generation plants increase voltage from 11–25 kV to 220–500 kV for long-distance transmission.

Step-down transformers at primary substations then reduce it back to 35–110 kV, making power suitable for industrial or regional use.

This bidirectional capability ensures smooth voltage control across every stage of the grid.

5. How long does a substation transformer last?

With proper oil quality analysis, thermal management, and preventive maintenance, a substation transformer can operate reliably for 30–40 years.

Modern units equipped with digital monitoring and OLTC diagnostics can achieve even longer service life by predicting and preventing potential failures.

6. What is the role of transformer oil?

Transformer oil acts as both a coolant and electrical insulator.

It transfers heat from the windings to the radiators and prevents arcing or flashover between energized components.

Routine testing for moisture content, gas levels, and dielectric strength ensures stable insulation performance over decades of use.

7. What is an OLTC (On-Load Tap Changer)?

An OLTC automatically adjusts the transformer’s turns ratio while energized, maintaining constant output voltage despite load variations.

It fine-tunes voltage within a typical ±10% range, stabilizing grid performance and ensuring power reliability for industries and utilities alike.

In modern systems, OLTCs integrate motor drives, electronic control, and remote SCADA monitoring for predictive maintenance and operational accuracy.

⚙️ CHBEB — Reliable Partner for Substation and Power Transformer Solutions

For over 60 years, CHBEB has specialized in the design, manufacturing, and testing of high-voltage and distribution-grade transformers that power cities, industries, and national grids worldwide.

What We Deliver

High-Voltage Expertise

From 35 kV to 500 kV substation power transformers engineered to IEC 600762 and GB standards, ensuring precision, durability, and efficiency.

Proven Reliability

A certified supplier to the State Grid Corporation of China, CHBEB maintains a spotless record of safety and long-term operational stability across thousands of projects.

Engineering Integration

Advanced oil-immersed and dry-type designs featuring smart OLTC control, digital monitoring, and low-loss core technology for optimal grid performance.

Global Presence

Serving Russia, Southeast Asia, Africa, and Belt and Road countries, CHBEB adapts every transformer to meet regional grid conditions, climates, and standards.

Fast Delivery & Full Certification

With factories in Wenzhou and Nanjing and a logistics hub in Beijing, CHBEB ensures rapid fulfillment and provides IEC/CE documentation for seamless international approval.

At CHBEB, we don’t just build transformers — we build confidence into every grid we serve.

Our mission is simple: to deliver high-efficiency, low-loss, and globally compliant power solutions that keep the world’s substations running safely, reliably, and for decades to come.

👉 Looking for a distribution transformer manufacturer that combines Chinese manufacturing strength with international standards?Contact CHBEB for a tailored solution or Download our full transformer catalog here.

Conclusion

Substation power transformers are more than heavy electrical machines — they are the guardians of grid stability and efficiency. Through decades of engineering evolution, they’ve learned to balance extreme voltage, heat, and demand while silently securing energy for entire regions.

From the precise operation of an On-Load Tap Changer (OLTC) to the chemistry of transformer oil, every detail defines reliability. That’s why proper design, material control, and predictive maintenance matter more than ever as grids evolve toward renewable and smart automation.

For engineers and utilities, the takeaway is clear: investing in a well-engineered, certified power transformer is not just buying equipment — it’s securing decades of safety and performance for your network and your customers.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group