Pad-Mounted Transformer Cooling & Overheating Guide | CHBEB

In-Depth Engineering: How Pad-Mounted Transformers Master the Heat Challenge

Introduction

In residential, business, and utility networks, pad-mounted transformers function quietly, but they are always combating heat. As heat builds up inside a sealed enclosure, the insulation weakens, efficiency drops, and the risk of overheating increases. This article explains how pad-mounted transformers use physics, materials, and design to manage heat, ensuring long-term reliability in real-world conditions.

Thermal Fundamentals: Heat Generation, Transfer Paths, and Cooling Mechanism

When purchasers think that small oil-immersed pad-mounted units run cool on their own, heat becomes a concern. In reality, every watt of loss turns into heat that becomes trapped inside a metal cabinet. This is one of the main challenges of pad-mounted transformer cooling. Anyone specifying, designing, or servicing these units must understand how heat forms, flows, and exits the system.

Heat Sources: Decomposing No-Load Losses, Load Losses, and Heat Generation

Transformers that are buried or have limited airflow need stricter control of temperature rise than units installed in open-air environments.

No-load losses — the heat source that never stops

The magnetic core of the transformer generates no-load losses, including:

- Hysteresis losses caused by the changing magnetic field

- Eddy current losses1 moving through the silicon steel

These losses keep pad-mounted transformers continuously warm, regardless of how much power they are delivering.

Load Losses: The Most Important Heating Factor

I²R losses occur when current flows through the windings due to the resistance of the copper.

- More load → more heat

- Overload → rapid increase in transformer temperature

- Harmonics → extra heating in both the winding and structural parts

Many field technicians search “why is my pad-mounted transformer overheating” because even small overloads can push temperatures inside a sealed enclosure far beyond the design limit.If you want a deeper understanding of how transformer insulation and oil behave under rising temperature, you may also refer to our guide “Unlocking Transformer Oil’s Superpowers: Why Is Oil Essential for Transformer Operation?” — it explains how oil aging, oxidation, and moisture all accelerate heat-related failures.

Losses from stray and harmonic waves

When stray flux interacts with structural metal parts, it produces localized hotspots that raise the temperature inside a pad-mounted transformer.

Modern loads such as EV chargers, inverters, and commercial drives introduce harmonics that significantly increase losses. If not controlled, these harmonic effects can shorten the lifespan of pad-mounted transformers.

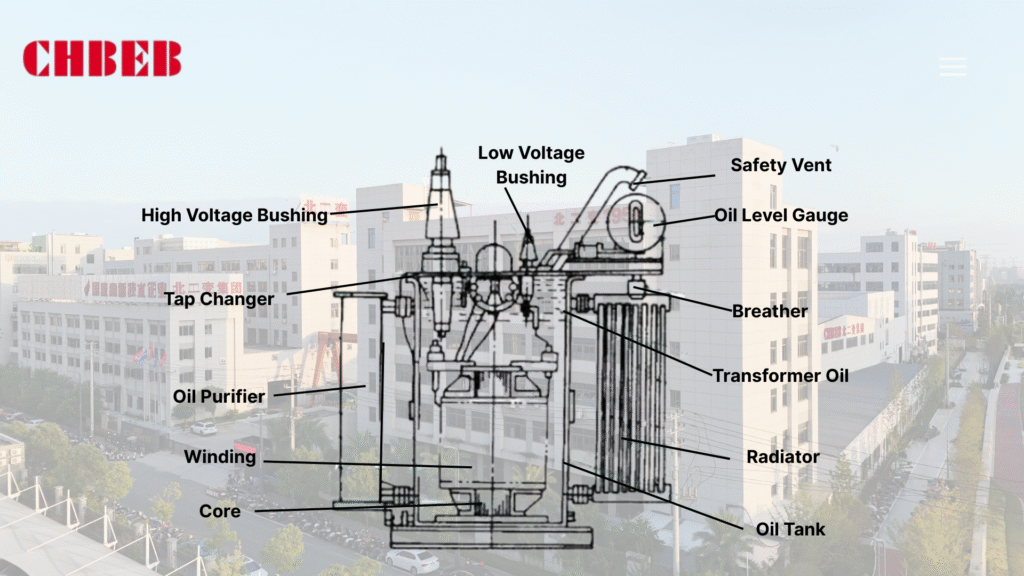

Transfer Path: The Oil-Immersed Transformer’s Three-Step Cooling (Conduction–Convection–Radiation)

The reliability of an oil-immersed pad-mount transformer depends on how well it handles three cooling stages:

1. Conduction: Heat Moves into the Oil

Windings and the core transfer heat into the transformer oil. The efficiency of this stage depends on:

- Hot oil rises

- Cool oil sinks

- Vertical ducts and proper geometry ensure smooth flow

Any blockage disrupts circulation, causing the transformer to heat up faster and age more quickly.

2. Convection: Oil Moves Around and Moves Heat Up

Natural convection circulates oil in ONAN systems:

- Hot oil rises

- Cool oil sinks

- Vertical ducts and proper geometry ensure smooth flow

Any blockage disrupts circulation, causing the transformer to heat up faster and age more quickly.

3. Radiation: Heat escapes the tank and enters the air around it.

When heat reaches the tank wall, it transfers to the surrounding air. Pad-mounted transformers rely heavily on:

- Cooling fins

- High-emissivity coatings

- Adequate airflow inside the pad enclosure

If airflow is restricted, pad-mounted transformer cooling becomes the limiting factor.

Design and Longevity: Hot Spot Control and Dynamic Load Management

Heat is most harmful when it concentrates in hot spots. If the temperature limit of a pad-mounted transformer is reached, insulation life drops very quickly.

Arrhenius Law2 and Why Hot-Spot Control Matters

Arrhenius’s thermal-aging principle states:

Every 6 °C increase in hotspot temperature cuts insulation life in half.

To manage this risk, companies use:

- IEEE/IEC thermal models

- Fiber-optic temperature sensors

- Digital twins that simulate IEEE C57.91 pad-mount temperature rise

These tools help identify worst-case hotspots before production.

Choosing the right materials and insulation

The quality of the material affects how long it can last under heat:

- AAramid paper can endure higher temperatures than cellulose paper.

- Natural and synthetic ester oils can handle more heat stress.

- Class H insulation supports higher pad-mount hot-spot temperatures.

Better insulation means the pad-mounted transformer will last longer.

Harmonics, overload, and environmental stress

Pad-mounted transformers now face higher thermal stress because of:

- EV charging loads

- Solar PV inverters

- Unbalanced three-phase demand

- High urban ambient temperatures

These factors can cause unexpected overheating, especially in sealed cabinets with limited airflow.

Practical Application: Thermal Optimization and Monitoring

Pad-mounted transformers are only reliable when the heat is always kept in check. Some of the best ways in the business are:

Fin and Radiator Optimization

Manufacturers make cooling work better by changing:

- Fin height and depth

- Space between radiators

- The shape of the air channel

- Emissivity of thermal coating

Better fins mean that the temperature of the transformer rises less.

Internal Oil Duct Engineering

Oil ducts that are made the right way:

- Increase convection circulation

- Prevent stagnant hot-oil pockets

- Reduce hotspot acceleration

Good duct design is essential for stable cooling in a pad-mounted transformer.

Active Cooling Solutions

Most pad-mounted devices use natural cooling, but when the load is high, they may require:

- Air-blowing fans

- Smart thermostats

- Ester oils that tolerate higher temperatures

These enhancements help prevent the pad-mounted transformer from overheating during peak load conditions.

Digital Monitoring and Predictive Control

Real-time monitoring is used by modern pad-mounted transformers:

- Hot-spot sensors

- SCADA-based temperature monitoring

- Predictive analytics for forecasting overloads

This turns the transformer from a passive asset into an actively monitored component, helping prevent failures before they occur.

Pad-Mounted Transformer Overheating — Common Buyer Questions Answered

“Why is a pad-mounted transformer hotter than a transformer in a substation?”

Because pad-mounted units have less room to move about. A regular substation transformer features big radiators, open air, and good airflow.

A pad-mount is inside a sealed metal cabinet that doesn’t get much airflow and is often warmer near the ground.

Higher temperature rise when there is less airflow and the same losses.

This is totally normal as long as the unit stays within its temperature range.

“What is the highest temperature that a transformer can safely reach at a hot spot?”

Most oil-immersed pad-mounted transformers follow the same rules as IEC and IEEE standards:

- 110°C hot spot for mineral oil

- Natural ester oil has a hot spot between 120 and 130°C.

If the pad-mount hot-spot stays above these limits for a long time, the insulation will age much faster.

Short peaks are fine. Long peaks are not.

“How does high temperature really shorten the life of a transformer?”

Heat is the murderer that doesn’t make noise.

Arrhenius’s laws for aging say:

Every 6–7°C rise in the temperature of a hot spot roughly cuts the life of insulation in half.

High heat dries up insulation, oxidizes oil, raises acidity, and lowers dielectric strength. This is why controlling the temperature is one of the most important factors affecting how long a pad-mounted transformer lasts.

“How do engineers figure out how hot a transformer gets?”

It usually originates from two parts:

- Load losses → find out how much the winding temperature rises

- Core losses → find out how much the oil temperature goes up

Manufacturers use both thermal models (IEEE C57.91) and practical tests:

- Indicators for winding temperature

- Measurements of top oil

- Hot-spot multipliers

The end result is a difference between the calculated and measured temperature rise at rated load. This ensures the device stays within safe limits.

“Do harmonics really make a transformer hotter?”

Of course, especially in networks today.

Harmonics from PCs, EV chargers, VFDs, and inverters increase:

- Eddy-current losses

- Stray-flux heating

- Non-sinusoidal current

This extra heat often doesn’t show up in simple load calculations. That’s why environments with high harmonics sometimes need a K-factor-rated transformer, better oil circulation, or larger cooling capacity.

“How does ONAN cooling really work in a pad-mounted transformer?”

What ONAN stands for:

Oil Natural → oil moves about on its own

Air Natural → air naturally cools the radiator

The hot oil rises to the top, cools off in the radiators, and then descends back down.

No pumps. No fans.

It’s easy to use, dependable, and quiet, but it also means the transformer depends on:

- Oil duct design

- Free passage of air

- Good arrangement of fins and radiators

If there is a blockage or limited airflow inside the pad enclosure, the temperature can go up.

“What is the normal oil temperature while the machine is running?”

Normal ranges in the field:

- Top oil temperature between 45–65°C under normal load

- 70–85°C during high load or hot weather

- 90–100°C in rare cases (acceptable only for short periods)

What matters most is not the total number, but:

- The rate of increase

- The hot-spot temperature

- Whether the temperature stays stable or keeps rising

A pad-mounted transformer that warms up and then stabilizes is good.

A unit that keeps heating up continuously needs to be checked.

⚙️ CHBEB — Real Engineering Behind Every Pad-Mounted Transformer

At CHBEB, we don’t rely on generic designs or outsourced assembly.

We engineer pad-mounted transformers with real thermal science — the kind that survives harsh climates, harmonic-heavy networks, and urban distribution loads.

What makes CHBEB different?

🔹 We understand heat.

Every design is built with IEEE C57.91 thermal modeling, optimized oil ducts, and verified hot-spot calculations.

🔹 We are more reliable than typical Chinese factories.

Our transformers go through full temperature-rise testing, not just routine tests.

🔹 We’re a practical, battle-tested manufacturer.

No exaggerated claims. Every rating, test, and drawing is backed by real factory capability.

🔹 We support your project like an engineering partner, not just a supplier.

Load analysis, harmonic assessment, cooling checks, installation environment review — we handle them with you.

🔹 We do true OEM/ODM with international standards.

IEC 60076, IEEE C57, ANSI, CE — all supported, with documented compliance.

This is why CHBEB transformers run reliably across Southeast Asia, the Middle East, Africa, Russia/CIS, and utility networks worldwide.

When heat control matters, CHBEB delivers transformers that stay cool, stable, and safe.

👉 Looking for a distribution transformer manufacturer that combines Chinese manufacturing strength with international standards?Contact CHBEB for a tailored solution or Download our full transformer catalog here.

Conclusion

Heat is the number one factor that determines whether a pad-mounted transformer operates reliably or fails early. When buyers understand how pad-mounted transformer cooling works — from oil circulation and fin design to hot-spot behavior and IEEE temperature-rise limits — they can choose equipment that stays stable even under overload, harmonics, and harsh ambient conditions.

For project owners, EPC contractors, and utility engineers, proper control of pad-mounted transformer temperature rise is more than a technical requirement — it directly affects insulation life, long-term operating cost, and grid reliability. By evaluating cooling design, hotspot limits, harmonic impact, and enclosure airflow before purchase, buyers can avoid overheating issues, extend transformer lifespan, and reduce unexpected outages in the field.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group