What Is an Oil-Immersed Transformer?

Are you struggling with power distribution challenges in your industrial setup? The solution might be simpler than you think.

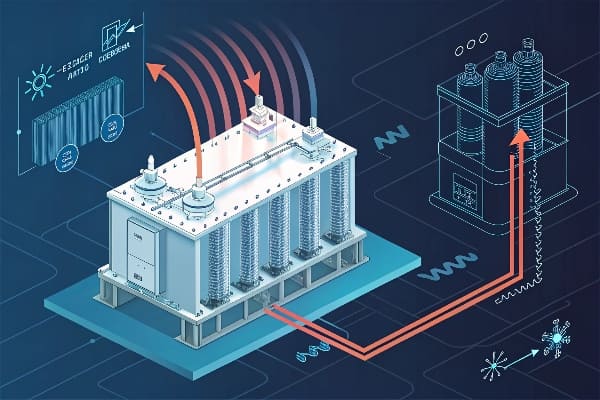

An oil-immersed transformer is a type of electrical transformer that uses oil as a coolant and insulator. It’s designed for high-voltage applications and is known for its efficiency in heat dissipation and electrical insulation.

I’ve seen many industries benefit from oil-immersed transformers. Let’s dive deeper into how these transformers work and why they might be the right choice for your power distribution needs.

Oil-immersed Transformer: Working Principle

Have you ever wondered how these massive transformers manage to handle such high voltages without breaking a sweat? The secret lies in their unique working principle.

Oil-immersed transformers work on the principle of electromagnetic induction, using oil as both a coolant and insulator. The oil surrounds the core and windings, efficiently dissipating heat and providing excellent electrical insulation.

In my years of experience with power systems, I’ve come to appreciate the elegance of oil-immersed transformers. Here’s a deeper look at how they function:

Core Components

The main parts of an oil-immersed transformer include:

- Core: Usually made of laminated silicon steel sheets

- Windings: Primary and secondary coils, typically made of copper

- Insulating Oil: Mineral oil or synthetic alternatives

- Tank: Houses all components and the insulating oil

- Bushings: For connecting external circuits

- Cooling System: Radiators or fans for larger units

Electromagnetic Induction

The basic principle is simple:

- When AC voltage is applied to the primary winding, it creates a changing magnetic field in the core.

- This changing magnetic field induces a voltage in the secondary winding.

- The ratio of primary to secondary turns determines the voltage transformation.

Role of Oil

The oil in these transformers serves multiple crucial functions:

| Function | Description |

|---|---|

| Cooling | Absorbs and dissipates heat from the core and windings |

| Insulation | Provides electrical insulation between components |

| Arc Suppression | Helps quench arcs that may form during operation |

| Moisture Protection | Prevents moisture from degrading the insulation |

Heat Dissipation

One of the most impressive aspects of oil-immersed transformers is their cooling efficiency:

- As the transformer operates, heat is generated in the core and windings.

- The oil absorbs this heat through direct contact.

- Natural convection circulates the oil, carrying heat to the tank walls.

- For larger transformers, external radiators or forced-air cooling may be used.

In my experience, this cooling system is what allows oil-immersed transformers to handle such high power ratings efficiently.

Types of Oil-Filled Transformers

Are you wondering which type of oil-filled transformer might be best for your specific needs? You’re not alone in this quest.

Oil-filled transformers come in various types, including distribution transformers, power transformers, and specialty transformers. Each type is designed for specific voltage levels, power ratings, and applications, ranging from residential power distribution to large industrial use.

Throughout my career, I’ve worked with various types of oil-filled transformers. Let me break down the main categories for you:

Distribution Transformers

These are the workhorses of the power grid:

- Voltage Range: Typically 34.5 kV and below

- Power Rating: Usually up to 2500 kVA

- Applications: Residential areas, small commercial buildings

- Features: Often pole-mounted or pad-mounted

Power Transformers

These handle the heavy lifting in power transmission:

- Voltage Range: Can go up to 765 kV or higher

- Power Rating: From a few MVA to hundreds of MVA

- Applications: Power plants, large industrial facilities, substations

- Features: Usually very large, with advanced cooling systems

Specialty Transformers

These are designed for specific applications:

| Type | Application | Special Features |

|---|---|---|

| Furnace Transformers | Electric arc furnaces | High current output, robust design |

| Rectifier Transformers | DC power supply | Special winding configurations |

| Traction Transformers | Electric railways | Compact design, vibration resistant |

Cooling Methods

The cooling method used can also categorize oil-filled transformers:

- ONAN (Oil Natural Air Natural): Relies on natural oil circulation and air cooling

- ONAF (Oil Natural Air Forced): Uses fans to enhance air cooling

- OFAF (Oil Forced Air Forced): Uses pumps for oil circulation and fans for air cooling

- ODAF (Oil Directed Air Forced): Directs oil flow through windings for more efficient cooling

In my experience, choosing the right type of transformer and cooling method is crucial for optimal performance and longevity.

Maintenance and Safety Considerations for Oil-Immersed Transformers

Are you concerned about keeping your oil-immersed transformer in top shape? You should be – proper maintenance is key to longevity and safety.

Maintaining oil-immersed transformers involves regular oil testing, monitoring for leaks, and periodic inspections. Safety considerations include fire prevention, environmental protection, and proper handling of transformer oil.

Over the years, I’ve learned that a well-maintained transformer is a reliable transformer. Here’s what you need to know about maintenance and safety:

Regular Maintenance Tasks

- Oil Testing: Check oil quality at least annually

- Visual Inspections: Look for leaks, rust, or damage monthly

- Thermal Imaging: Conduct annually to detect hot spots

- Bushing Maintenance: Clean and inspect bushings yearly

- DGA (Dissolved Gas Analysis): Perform annually or as needed

Oil Quality Management

The health of the transformer oil is crucial:

| Test | Frequency | Purpose |

|---|---|---|

| Dielectric Strength | Annually | Ensures insulating properties |

| Acidity | Annually | Checks for oil degradation |

| Moisture Content | Bi-annually | Prevents insulation breakdown |

| Interfacial Tension | Annually | Indicates oil contamination |

Safety Considerations

Safety should always be your top priority:

- Fire Prevention: Install fire suppression systems

- Spill Containment: Use proper oil containment methods

- Grounding: Ensure proper grounding of the transformer

- Personal Protective Equipment: Use when handling oil or working near transformers

- Emergency Procedures: Have clear protocols for oil leaks or electrical faults

Environmental Concerns

In today’s world, environmental responsibility is crucial:

- Use biodegradable transformer oils when possible

- Have a proper disposal plan for old transformer oil

- Implement spill prevention and response plans

- Consider retrofilling with more environmentally friendly oils

Predictive Maintenance

I’ve found that predictive maintenance can save a lot of trouble:

- Online Monitoring: Use sensors for real-time data on key parameters

- Trend Analysis: Track oil quality and electrical parameters over time

- Acoustic Monitoring: Detect partial discharges early

- Load Analysis: Ensure the transformer isn’t consistently overloaded

In my experience, a comprehensive maintenance and safety program not only extends the life of your transformer but also prevents costly downtime and potential environmental incidents.

Conclusion

Oil-immersed transformers are vital for efficient power distribution. With proper maintenance and safety measures, they offer reliable performance and longevity. Understanding their types and care needs is key to maximizing their benefits in various applications.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group