Safety and Regulations for Step Up and Step Down Transformers: Are You Compliant?

Are you worried about the safety of your transformer installations? You’re not alone. Many engineers and facility managers struggle with the complex world of transformer regulations.

Safety and regulations for step up and step down transformers are crucial for protecting people, equipment, and the environment. They cover international standards, safe operating procedures, and environmental compliance. Understanding these regulations is essential for anyone working with transformers.

In my 20 years as an electrical engineer, I’ve seen the consequences of neglecting transformer safety and regulations. This guide will walk you through the key aspects of transformer safety, from international standards to environmental compliance. Whether you’re a seasoned professional or new to the field, you’ll gain valuable insights to ensure your transformer installations are safe, efficient, and compliant.

International Standards: Understanding Key IEC and IEEE Regulations?

Have you ever felt overwhelmed by the sheer number of transformer standards? You’re not alone. Navigating the maze of IEC and IEEE regulations can be daunting.

International standards for transformers, set by IEC and IEEE, ensure global consistency in safety, performance, and testing. These standards cover design requirements, testing procedures, and performance criteria for both step up and step down transformers.

Let me share a story from my early career. I once worked on a project where we overlooked a crucial IEC standard. The result? A costly redesign and project delays. Since then, I’ve made it my mission to stay on top of these regulations.

Key IEC Standards

IEC (International Electrotechnical Commission) standards are widely adopted globally. Here are some crucial ones for transformers:

-

IEC 60076: Power Transformers

- Covers general requirements, temperature rise limits, and insulation levels.

- Specific parts address different aspects like gas-filled transformers and reactors.

-

IEC 61558: Safety of Transformers, Reactors, Power Supply Units

- Focuses on safety requirements for various types of transformers.

- Includes specific standards for isolating transformers and control transformers.

-

IEC 60085: Electrical Insulation – Thermal Evaluation and Designation

- Defines thermal classes for insulating materials used in transformers.

Important IEEE Standards

IEEE (Institute of Electrical and Electronics Engineers) standards are particularly influential in North America:

-

IEEE C57.12.00: General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers

- Establishes basic requirements for ratings, construction, and testing.

-

IEEE C57.12.90: Test Code for Liquid-Immersed Distribution, Power, and Regulating Transformers

- Outlines test methods to ensure compliance with performance requirements.

-

IEEE C57.154: Standard for Liquid-Immersed Transformers Designed to Operate at Temperatures Above Conventional Limits

- Addresses high-temperature insulation systems for improved efficiency.

Comparison Table: IEC vs IEEE Standards

| Aspect | IEC Standards | IEEE Standards |

|---|---|---|

| Global Adoption | Widely used internationally | Primarily used in North America |

| Focus | Comprehensive coverage of all transformer types | Detailed specifications for specific transformer types |

| Testing Methods | Emphasizes routine and type tests | Provides detailed test codes |

| Efficiency Standards | Covered in IEC 60076-20 | Addressed in IEEE C57.12.00 |

| Environmental Considerations | Included in various parts of IEC 60076 | Specific standards like IEEE C57.154 for high-temperature operation |

Understanding these standards is crucial for ensuring your transformers meet global safety and performance requirements. In my experience, familiarizing yourself with both IEC and IEEE standards gives you a comprehensive view of best practices in transformer design and operation.

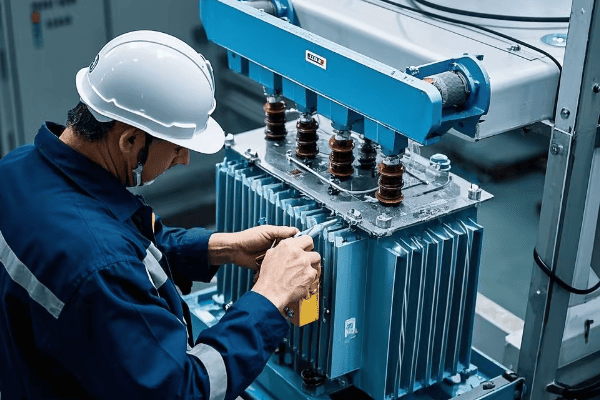

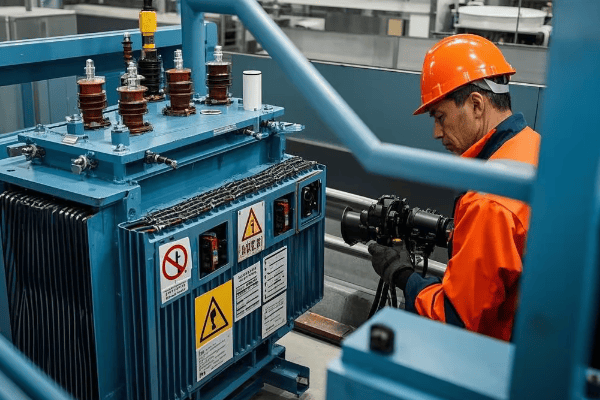

Safe Operating Procedures: Best Practices for Personnel and Equipment Safety?

Have you ever wondered if your transformer operating procedures are truly safe? It’s a question that keeps many engineers and facility managers up at night.

Safe operating procedures for step up and step down transformers involve proper handling, regular maintenance, and emergency protocols. These practices protect both personnel and equipment from potential hazards like electrical shocks, fires, and explosions.

I’ll never forget the day I witnessed a near-miss incident at a substation. A technician narrowly avoided severe injury due to inadequate safety procedures. That experience reinforced my commitment to promoting and following strict safety protocols.

Personal Protective Equipment (PPE)

Safety starts with proper PPE. Here’s what I always ensure my team wears:

- Insulated Gloves: Rated for the appropriate voltage level.

- Safety Goggles: To protect against arc flashes and oil splashes.

- Fire-Resistant Clothing: Essential when working with oil-filled transformers.

- Safety Shoes: With electrical hazard protection.

Lockout/Tagout (LOTO) Procedures

LOTO is crucial for preventing accidental energization during maintenance:

- Identify all energy sources.

- Notify affected personnel.

- Shut down the equipment.

- Isolate energy sources.

- Apply lockout devices and tags.

- Verify zero energy state.

I always double-check these steps, even if I’m working alone. It’s a habit that has kept me safe throughout my career.

Regular Maintenance Checks

Preventive maintenance is key to safe operation. Here’s my checklist:

-

Visual Inspections:

- Check for oil leaks.

- Inspect bushings for cracks or contamination.

- Look for signs of overheating or damage.

-

Electrical Tests:

- Measure insulation resistance.

- Perform turns ratio tests.

- Check for partial discharge.

-

Oil Analysis:

- Test for moisture content.

- Check for dissolved gases.

- Analyze acidity levels.

I recommend performing these checks at least annually, or more frequently for critical installations.

Safety Procedure Checklist

| Procedure | Frequency | Responsible Personnel |

|---|---|---|

| PPE Inspection | Before each use | All personnel |

| LOTO Implementation | Before any maintenance | Authorized technicians |

| Visual Inspection | Monthly | Maintenance team |

| Electrical Tests | Annually | Qualified electricians |

| Oil Analysis | Semi-annually | Specialized technicians |

| Emergency Drills | Bi-annually | All personnel |

By following these procedures, you can significantly reduce the risk of accidents and ensure the longevity of your transformer equipment. Remember, safety is not just about following rules—it’s about creating a culture of awareness and responsibility.

Environmental Compliance: Regulations for Handling Transformer Oil and Other Potential Pollutants?

Are you concerned about the environmental impact of your transformer operations? You should be. Environmental regulations are becoming increasingly stringent, and non-compliance can lead to hefty fines and reputational damage.

Environmental compliance for transformers focuses on proper handling and disposal of transformer oil and other potential pollutants. Regulations cover oil spill prevention, PCB management, and noise control. Adhering to these rules is crucial for protecting the environment and maintaining legal compliance.

I once consulted for a company that faced severe penalties due to improper transformer oil disposal. It was a wake-up call for them, and for me, it reinforced the importance of staying up-to-date with environmental regulations.

Transformer Oil Management

Transformer oil is a potential environmental hazard. Here’s how to manage it properly:

-

Spill Prevention:

- Install containment barriers around transformers.

- Regularly inspect for leaks.

- Maintain detailed oil level records.

-

Oil Disposal:

- Use licensed disposal facilities.

- Keep disposal records for at least three years.

- Consider oil recycling options where possible.

-

Oil Testing:

- Regularly test for contaminants, especially PCBs.

- Maintain a testing schedule and record results.

PCB Management

Polychlorinated Biphenyls (PCBs) are highly regulated due to their environmental persistence:

-

Identification:

- Test all transformers manufactured before 1979 for PCBs.

- Label PCB-containing equipment clearly.

-

Handling:

- Use specialized equipment for PCB-contaminated transformers.

- Train personnel in proper PCB handling procedures.

-

Disposal:

- Use EPA-approved disposal methods for PCB-contaminated oil and equipment.

- Maintain detailed records of PCB disposal.

Environmental Compliance Checklist

| Aspect | Regulation | Compliance Action |

|---|---|---|

| Oil Spills | Clean Water Act | Install containment systems |

| PCBs | Toxic Substances Control Act | Test and label equipment |

| Noise | Local Ordinances | Measure and mitigate noise levels |

| SF6 Gas | EPA Regulations | Monitor and report SF6 levels |

| VOCs | Clean Air Act | Control and report emissions |

Staying compliant with environmental regulations requires constant vigilance. I recommend assigning a dedicated environmental compliance officer for large transformer installations. For smaller operations, ensure that at least one team member is well-versed in current environmental regulations.

Conclusion

Safety and environmental compliance in transformer operations are crucial. Follow international standards, implement robust safety procedures, and adhere to environmental regulations. Regular training, vigilant monitoring, and proactive maintenance are key to ensuring safe, efficient, and environmentally responsible transformer operations.

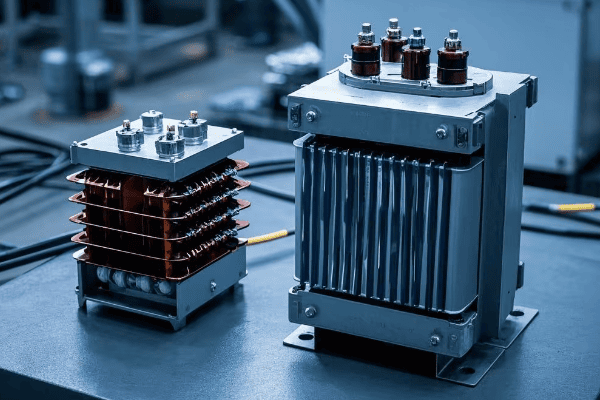

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group