Which Chinese Transformer Manufacturer Is Best in 2025? Buyer’s Guide & Checklist | CHBEB

Introduction

In 2025, many global buyers will search for the best Chinese transformer manufacturer 2025, hoping to find one perfect choice. The reality? There is no universal best. Every project has unique technical, financial, and operational requirements. The smart approach is to evaluate transformer suppliers against your project’s specific needs—capacity, voltage, efficiency, certification, and budget.

Debunking the Myth: No Single “Best” Transformer Manufacturer

Believing one brand is always “best” often results in mismatched purchases and increased risks. Instead, clarify what “best” means for your situation. A supplier that excels in utility grid projects may not be the right choice for a data center or an industrial facility.

Defining “Best”: Start with Your Project Needs

Before you compare Chinese transformer manufacturers, define your own requirements:

- Voltage & Capacity: Distribution transformers and high-voltage power transformers follow very different design standards.

- Application: Utility grids, renewable energy plants, factories, mining, or data centers.

- Priorities: Is your focus on lowest upfront cost, maximum long-term efficiency, or fastest delivery?

Key Insight: The “best” Chinese transformer supplier is the one that meets your business and technical needs—not a one-size-fits-all solution.

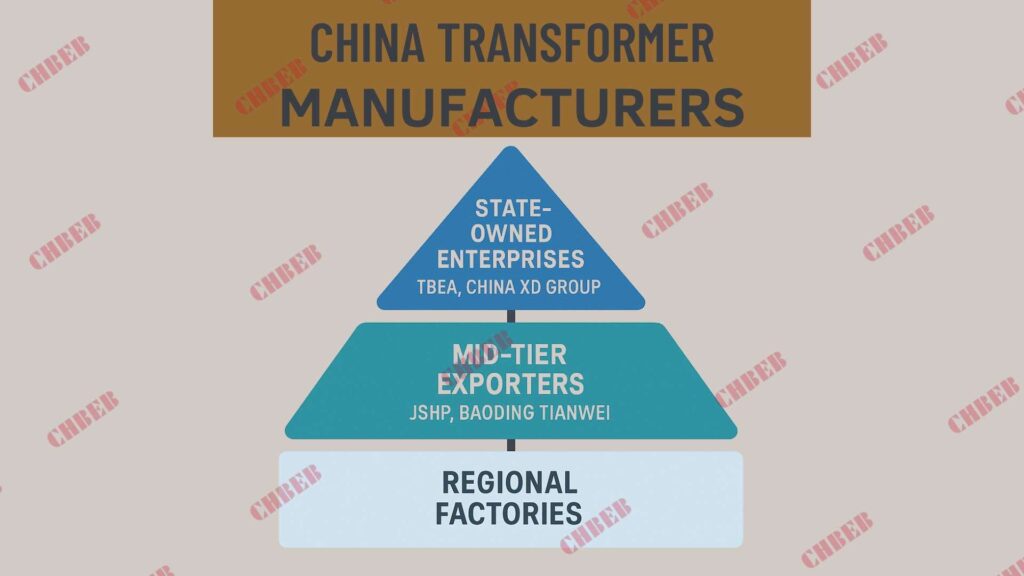

Market Overview: Types of Chinese Transformer Manufacturers

China’s transformer industry is broad, and understanding the positioning of suppliers helps buyers avoid missteps:

- State-Owned Enterprises (e.g., TBEA1, China XD Group2): Experts in ultra-high-voltage (UHV) and mega EPC projects.

- Mid-Tier Exporters (e.g., JSHP, Baoding Tianwei): Balance global certifications, reliability, and competitive pricing.

- Regional Factories: Offer low prices but often limited in advanced testing and after-sales service.

Result: Choose a supplier whose scale, quality systems, and experience match your project’s size and risk tolerance.

Evaluation and Vetting: Finding the Right Supplier

Hard Criteria: Technical Skills, Certifications & Track Record

- Capabilities: Can they deliver on kVA, voltage, loss levels, and cooling method (oil-immersed or dry-type)?

- Certifications: ISO9001, ISO14001, IEC, CE, or KEMA for international acceptance.

- References: Evidence of success in grid tenders, EPC contracts, or export projects to your region.

Soft Criteria: Service, Communication & Transparency

- After-Sales Support: Warranty terms, spare parts availability, and response times.

- Communication: Professional English support, clear documentation, fast feedback.

- Pricing Transparency: Itemized quotations, clear delivery terms, and guaranteed loss values.

Supplier Evaluation Checklist

| Category | Key Questions | Red Flags |

|---|---|---|

| Technical | Do specs match kVA, voltage, and losses? | Vague or generic answers |

| Certifications | Are IEC/ISO documents valid and verifiable? | Fake or expired certificates |

| Experience | Do they have relevant project references? | No case studies or hidden clients |

| Service | Is warranty and spare parts included? | Avoids after-sales discussions |

| Pricing | Is the quote itemized and transparent? | Hidden costs or unclear scope |

International Procurement & Risk Mitigation

Without a clear roadmap, international sourcing can lead to hidden costs and delays. A structured process reduces these risks:

- Inquiry: Send an RFQ with detailed specifications (kVA, voltage, cooling, loss values, and standards).

- Evaluation: Compare technical offers, certifications, and pricing.

- Audit: Arrange third-party inspections or video audits before signing.

- Contract: Define delivery schedule, penalties, guaranteed losses, and payment terms.

- Production: Approve drawings and witness factory acceptance tests.

- Logistics: Confirm insurance, packaging, and customs documents.

- After-Sales: Secure warranty contacts and spare parts agreements.

Common Risks and Solutions

- Fake Certifications → Verify directly with issuing authorities.

- Hidden Costs → Request full, itemized quotes including logistics and accessories.

- Late Delivery → Add penalty clauses in the contract.

- Quality Problems → Hire SGS, TÜV, or trusted local inspectors before shipment.

Conclusion

Choosing a reliable Chinese transformer supplier is not about chasing one “best” brand. It is about finding the supplier that aligns with your project’s budget, technical requirements, compliance standards, and risk profile.

By applying a structured procurement process—defining specifications, verifying certifications, auditing production, and securing clear contracts—buyers can confidently source oil-immersed, dry-type, or low-loss transformers from China in 2025.

✅ Final takeaway: Stop searching for “the best” in general. Define what “best” means for your project, and select the supplier that matches those needs for long-term reliability and value.

Learn More

Looking for the right dry-type or oil-immersed transformer for your project? Download our latest product catalog or explore product categories to discover reliable, low-loss transformer solutions tailored to your requirements.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group