Have you ever experienced a sudden blackout in your neighborhood? The culprit might be a blown transformer. But what exactly happens when a transformer fails, and why should you care?

When a transformer blows, it can cause widespread power outages, potential safety hazards, and significant disruption to daily life. Common causes include lightning strikes, overloading, or equipment failure. The immediate impact is a loss of electricity to homes and businesses in the affected area. Utility companies respond by isolating the damaged transformer, assessing the cause, and either repairing or replacing the unit. Understanding these events is crucial for public safety and helps in developing better prevention strategies.

In this comprehensive guide, I’ll walk you through the causes, impacts, and solutions when a transformer blows. Whether you’re a homeowner concerned about power reliability or a professional in the energy sector, this article will provide valuable insights into these critical events and how to handle them.

Understanding Transformer Failures: Common Causes and Warning Signs?

Have you ever wondered why transformers sometimes fail unexpectedly? These crucial components of our power grid can sometimes break down, leading to widespread outages. But what are the main reasons for these failures, and how can we spot them before they happen?

Transformer failures are often caused by factors like overloading, insulation breakdown, lightning strikes, or poor maintenance. Common warning signs include unusual noises (buzzing or humming), oil leaks, overheating, or frequent circuit breaker trips. Regular inspections and monitoring of key parameters like oil temperature, gas accumulation, and electrical readings can help identify potential issues before they lead to catastrophic failure. Understanding these causes and signs is crucial for preventing unexpected outages and ensuring the longevity of transformer equipment.

Key Aspects of Transformer Failures

Let’s dive deeper into the main factors:

- Overloading and Capacity Issues

- Environmental and External Factors

- Internal Component Failures

- Maintenance-Related Problems

- Warning Signs and Early Detection

Overloading and Capacity Issues

Pushing transformers beyond their limits:

- Excessive current flow leading to overheating

- Insulation degradation due to prolonged overloading

- Mismatch between transformer capacity and actual load demands

I recently investigated a transformer failure in an industrial park. The root cause was a significant increase in power demand from new facilities, pushing the existing transformer beyond its rated capacity. This overloading led to accelerated aging of the insulation and eventual failure.

Environmental and External Factors

Nature’s impact on transformer health:

- Lightning strikes causing voltage surges

- Extreme temperatures affecting cooling efficiency

- Moisture ingress leading to insulation breakdown

- Physical damage from accidents or vandalism

During a severe thunderstorm last year, I witnessed firsthand how a direct lightning strike to a pole-mounted transformer resulted in immediate failure. The surge protection devices were overwhelmed, leading to internal arcing and explosion.

Internal Component Failures

The weak links within:

- Winding insulation breakdown

- Core steel degradation

- Bushing failures

- Tap changer malfunctions

Here’s a quick overview of common internal failures:

| Component | Failure Mode | Potential Impact |

|---|---|---|

| Windings | Insulation breakdown | Short circuit, overheating |

| Core | Lamination degradation | Increased losses, overheating |

| Bushings | Cracking, contamination | Flashover, oil leaks |

| Tap Changers | Contact wear, mechanism failure | Voltage regulation issues |

Maintenance-Related Problems

The importance of proper care:

- Inadequate oil maintenance leading to contamination

- Loose connections causing hotspots

- Neglected cooling systems reducing efficiency

- Delayed repairs of minor issues escalating to major failures

Warning Signs and Early Detection

Spotting trouble before it’s too late:

- Unusual noises (buzzing, humming, or crackling)

- Oil leaks or low oil levels

- Discoloration or bulging of the transformer tank

- Frequent circuit breaker trips

- Abnormal temperature readings

Key points about transformer failures:

- Overloading is a common cause of premature failure

- Environmental factors can significantly impact transformer lifespan

- Internal component failures often result from cumulative stress

- Proper maintenance is crucial for preventing unexpected breakdowns

- Early detection of warning signs can prevent catastrophic failures

In my experience, understanding these failure modes is crucial for effective transformer management. I recall a case where regular oil analysis revealed increasing levels of dissolved gases, indicating internal arcing. By addressing this issue promptly, we prevented a potential explosion and extended the transformer’s service life.

For example, in a recent project upgrading an old substation, we implemented advanced monitoring systems on all transformers. These systems continuously track key parameters like oil temperature, dissolved gas levels, and partial discharge activity. This proactive approach has significantly reduced unexpected failures and improved overall grid reliability.

As we move on to discuss the immediate impacts of transformer failures, keep these causes and warning signs in mind. Understanding the root causes of failures is the first step in developing effective prevention and response strategies.

Immediate Impacts: What Happens When a Transformer Blows Out?

Have you ever experienced a sudden blackout and wondered about the chain of events that follows? When a transformer blows out, it sets off a series of immediate consequences that can affect entire communities. But what exactly happens in those crucial moments, and how does it impact our daily lives?

When a transformer blows out, it typically results in an immediate power outage for the area it serves. This can range from a few houses to entire neighborhoods or industrial complexes. The failure often involves a loud bang or explosion, sometimes accompanied by smoke or fire. Electrically, it causes a sudden interruption in power flow, potentially damaging sensitive equipment. Safety systems activate to isolate the damaged transformer, preventing further damage to the grid. The impact extends beyond just loss of power, affecting traffic lights, communication systems, and critical infrastructure, potentially disrupting daily life and business operations.

Key Immediate Effects of a Blown Transformer

Let’s examine the main consequences:

- Power Outage and Its Scope

- Physical and Electrical Hazards

- Impact on Infrastructure and Daily Life

- Emergency Response Activation

- Grid Stability and Cascading Effects

Power Outage and Its Scope

The immediate loss of electricity:

- Sudden blackout in the affected area

- Scope depends on transformer size and location in the grid

- Duration can range from hours to days, depending on the severity

I once responded to a transformer failure that affected a small town. The immediate blackout caught everyone off guard, from residential areas to the local hospital. The scope of the outage highlighted the critical role of individual transformers in our power distribution system.

Physical and Electrical Hazards

Dangers at the failure site:

- Risk of fire or explosion from oil-filled transformers

- Electrical arcing and potential for electrocution

- Release of toxic gases or materials

During a recent incident, I witnessed the aftermath of a transformer explosion. The scattered debris and lingering smoke underscored the importance of maintaining a safe perimeter around damaged equipment.

Impact on Infrastructure and Daily Life

Ripple effects across the community:

- Traffic disruptions due to non-functioning signals

- Communication breakdowns (cell towers, internet)

- Business interruptions and economic losses

- Potential health risks (food spoilage, medical equipment failure)

Here’s a quick overview of potential impacts:

| Sector | Immediate Impact | Potential Long-term Consequences |

|---|---|---|

| Residential | Loss of lighting, heating/cooling | Food spoilage, discomfort |

| Commercial | Business interruption | Revenue loss, data loss |

| Industrial | Production halt | Equipment damage, missed deadlines |

| Public Services | Traffic chaos, emergency service disruption | Safety risks, public dissatisfaction |

Emergency Response Activation

Mobilizing to address the crisis:

- Utility company emergency protocols initiated

- Coordination with local emergency services

- Public safety announcements and community updates

Grid Stability and Cascading Effects

Preventing wider system failure:

- Automatic isolation of the failed transformer

- Load redistribution to prevent overloading of other transformers

- Risk of cascading failures in weakened grid sections

Key points about immediate impacts of transformer failures:

- Power outages can vary greatly in scope and duration

- Physical and electrical hazards pose immediate safety risks

- The impact extends far beyond just loss of electricity

- Emergency response systems are crucial for managing the situation

- Grid stability can be compromised, risking wider system failures

In my experience, the immediate aftermath of a transformer failure is often chaotic and requires swift, coordinated action. I recall a case where a main substation transformer failed during a heatwave. The sudden loss of power to air conditioning systems in a densely populated urban area quickly escalated into a public health concern. This incident highlighted the critical need for robust emergency response plans and public communication strategies.

For example, in a recent industrial park outage caused by a transformer failure, we saw how the lack of power cascaded into production losses, spoiled materials, and missed shipments. This event emphasized the importance of backup systems and contingency planning for businesses in critical sectors.

As we move on to discuss safety risks and emergency responses to transformer explosions, keep these immediate impacts in mind. Understanding the full scope of consequences helps in developing more effective response strategies and emphasizes the importance of prevention and maintenance in our power distribution systems.

Safety First: Risks and Emergency Responses to Transformer Explosions?

Have you ever wondered what happens in the crucial moments after a transformer explodes? The scene can be chaotic and dangerous, but knowing the risks and proper responses can make a significant difference. What are the key safety concerns, and how should emergency teams and the public react?

Transformer explosions pose significant safety risks, including fire hazards, electrical dangers, and potential release of toxic materials. Immediate emergency responses include evacuating the area, contacting utility companies, and deploying firefighting teams with specialized equipment for electrical fires. Public safety measures involve establishing a safe perimeter, managing traffic, and issuing safety advisories. Utility crews focus on de-energizing the area, assessing damage, and initiating repairs. Key risks include electrocution, burns from hot oil or fire, and exposure to PCBs in older transformers. Proper training and equipment for first responders are crucial for safe and effective management of these incidents.

Key Aspects of Safety and Emergency Response

Let’s break down the main elements:

- Immediate Safety Risks

- Emergency Response Protocols

- Public Safety Measures

- Utility Company Actions

- Long-term Safety Considerations

Immediate Safety Risks

Dangers in the aftermath:

- Fire and explosion risks from burning oil

- Electrical hazards from live wires and equipment

- Toxic fume inhalation from burning materials

- Physical dangers from debris and unstable structures

I once arrived at the scene of a transformer explosion shortly after it occurred. The intense heat, acrid smoke, and scattered debris created a hazardous environment that required extreme caution and specialized equipment to navigate safely.

Emergency Response Protocols

Coordinated action to manage the crisis:

- Fire department deployment with specialized electrical fire equipment

- Utility company emergency crews for power management

- Medical teams on standby for potential injuries

- Hazmat teams for managing oil spills and toxic materials

During a recent transformer failure incident, I observed the seamless coordination between different emergency response teams. Their well-rehearsed protocols ensured a swift and effective response, minimizing risks to both responders and the public.

Public Safety Measures

Protecting the community:

- Evacuation of the immediate area

- Traffic control to prevent access to danger zones

- Public announcements and safety advisories

- Coordination with local authorities for broader impact management

Here’s a quick guide to public safety actions:

| Distance from Incident | Public Action | Authority Response |

|---|---|---|

| Within 100 meters | Immediate evacuation | Establish safety perimeter |

| 100-500 meters | Stay indoors, close windows | Issue safety advisories |

| Beyond 500 meters | Be alert, follow instructions | Monitor situation, prepare for wider evacuation if needed |

Utility Company Actions

Managing the power crisis:

- De-energizing the affected area to prevent further damage

- Damage assessment and repair planning

- Rerouting power to minimize outage impact where possible

- Communication with customers about outage duration and safety

Long-term Safety Considerations

Addressing ongoing concerns:

- Environmental cleanup of oil spills or contamination

- Structural integrity assessments of affected infrastructure

- Review and update of safety protocols and equipment

- Public education on transformer safety and reporting issues

Key points about safety and emergency response:

- Immediate risks include fire, electrical hazards, and toxic exposure

- Coordinated emergency response is crucial for effective management

- Public safety measures focus on evacuation and information dissemination

- Utility companies play a vital role in managing the electrical aspects

- Long-term safety involves cleanup, assessment, and protocol improvements

In my experience, the effectiveness of the emergency response often depends on pre-planning and regular drills. I recall a case where a transformer explosion occurred near a school. The well-practiced evacuation plans and clear communication channels between the school, emergency services, and utility company ensured a swift and safe response, preventing any injuries.

For example, in a recent incident involving an older transformer containing PCBs, the emergency response included specialized hazmat teams. Their expertise in handling these toxic materials was crucial in preventing environmental contamination and ensuring the safety of both responders and the public.

As we move on to discuss the restoration process after a transformer failure, remember that safety remains the top priority throughout the entire incident management and recovery phase. Understanding these safety protocols and emergency responses is crucial for anyone involved in power distribution systems or community emergency planning.

Restoration Process: How Utility Companies Handle Blown Transformers?

Have you ever wondered about the behind-the-scenes work that goes into restoring power after a transformer blows? The process is often more complex and time-consuming than many people realize. But what exactly do utility companies do to get the lights back on, and why can it sometimes take longer than expected?

When a transformer blows, utility companies follow a systematic restoration process. It begins with safety assessments and isolation of the damaged equipment. Crews then conduct a detailed damage evaluation to determine if repair or replacement is necessary. For minor issues, repairs might be possible on-site. Major failures often require complete transformer replacement, which can involve heavy machinery and specialized equipment. The process includes removing the damaged unit, installing a new one, testing connections, and gradually restoring power. Timeframes can vary from a few hours for simple repairs to several days for complete replacements, depending on the severity of the damage and availability of replacement parts.

Key Steps in the Transformer Restoration Process

Let’s examine the main stages:

- Initial Assessment and Safety Measures

- Damage Evaluation and Decision Making

- Repair or Replacement Procedures

- Testing and Power Restoration

- Post-Incident Analysis and Reporting

Initial Assessment and Safety Measures

Securing the site and gathering information:

- Dispatching crews to the location

- Establishing a safe work perimeter

- Assessing immediate risks and hazards

- Coordinating with emergency services if necessary

I once led an emergency response team to a blown transformer in a residential area. Our first priority was to secure the area and ensure no live wires posed a threat to the public or our crew. This initial phase is crucial for safe and effective restoration.

Damage Evaluation and Decision Making

Determining the extent of the problem:

- Inspecting external and internal transformer components

- Analyzing fault indicators and sensor data

- Deciding between repair and replacement options

- Estimating restoration time and resource needs

During a recent incident, we used advanced diagnostic tools to quickly assess the internal damage to a failed transformer. This rapid evaluation allowed us to make an informed decision between on-site repair and full replacement, minimizing downtime.

Repair or Replacement Procedures

Taking action based on the assessment:

- For repairs: Addressing specific damaged components

- For replacements: Removing old unit and installing new one

- Managing oil handling and environmental considerations

- Coordinating logistics for equipment and personnel

Here’s a comparison of repair vs. replacement scenarios:

| Aspect | Repair Scenario | Replacement Scenario |

|---|---|---|

| Typical Duration | 4-12 hours | 1-3 days |

| Equipment Needed | Specialized tools | Heavy machinery, new transformer |

| Cost Implication | Lower, if feasible | Higher, but often necessary |

| Long-term Reliability | Depends on damage extent | Generally more reliable |

Testing and Power Restoration

Ensuring safe and reliable operation:

- Conducting thorough testing of repaired or new equipment

- Gradual re-energizing of the transformer

- Monitoring for any abnormalities during power-up

- Restoring power to affected areas in phases

Post-Incident Analysis and Reporting

Learning from the event:

- Detailed analysis of the failure cause

- Reviewing the effectiveness of the response

- Updating procedures based on lessons learned

- Reporting to regulatory bodies and internal stakeholders

Key points about the transformer restoration process:

- Safety is the top priority in the initial assessment phase

- Detailed damage evaluation guides the decision between repair and replacement

- The restoration process can vary significantly in complexity and duration

- Thorough testing is crucial before restoring power

- Post-incident analysis helps improve future responses and prevent recurrences

In my experience, the efficiency of the restoration process often depends on preparedness and resource availability. I recall a case where we had pre-positioned spare transformers in strategic locations. When a failure occurred in a remote area, we were able to replace the damaged unit much faster than usual, significantly reducing downtime for the affected community.

For example, during a recent restoration project following a severe storm, we utilized mobile substations to temporarily restore power while working on permanent repairs. This innovative approach allowed us to minimize the impact on critical infrastructure like hospitals and emergency services, showcasing the importance of flexible and creative solutions in power restoration.

As we move on to discuss prevention and maintenance strategies, it’s important to remember that while efficient restoration is crucial, preventing transformer failures in the first place is always the best approach. Understanding the restoration process helps appreciate the complexity of power distribution systems and the importance of proactive maintenance.

Prevention and Maintenance: Strategies to Avoid Future Transformer Failures?

Have you ever wondered how we can prevent the chaos and disruption caused by transformer failures? While responding to emergencies is crucial, avoiding them altogether is even better. But what strategies can utility companies and facility managers employ to keep transformers running smoothly and prevent unexpected breakdowns?

Preventing transformer failures involves a combination of regular maintenance, proactive monitoring, and strategic upgrades. Key strategies include routine oil testing and filtration, regular thermal imaging to detect hotspots, continuous monitoring of key parameters like temperature and gas levels, and scheduled load testing. Implementing modern diagnostic tools such as dissolved gas analysis (DGA) and partial discharge monitoring can help detect issues before they escalate. Additionally, proper load management, upgrading aging infrastructure, and implementing robust surge protection are crucial for long-term reliability. Regular training for maintenance staff and adhering to manufacturer guidelines also play vital roles in prevention.

Essential Prevention and Maintenance Strategies

Let’s explore the main approaches:

- Regular Inspection and Testing

- Proactive Monitoring and Diagnostics

- Oil Maintenance and Management

- Load Management and Capacity Planning

- Upgrading and Modernization Efforts

Regular Inspection and Testing

Keeping a close eye on transformer health:

- Visual inspections for signs of wear, leaks, or damage

- Electrical testing to check insulation integrity

- Thermal imaging to identify hotspots

- Acoustic testing for internal fault detection

I recently implemented a comprehensive inspection program for a large industrial client. By conducting monthly visual checks and quarterly thermal scans, we were able to identify and address several potential issues before they led to failures, significantly improving system reliability.

Proactive Monitoring and Diagnostics

Staying ahead of potential problems:

- Continuous monitoring of key parameters (temperature, pressure, etc.)

- Dissolved Gas Analysis (DGA) for early fault detection

- Partial Discharge (PD) monitoring for insulation assessment

- Online monitoring systems for real-time data analysis

During a recent upgrade project, we installed advanced online monitoring systems on critical transformers. The real-time data provided by these systems allowed us to detect a developing fault in its early stages, enabling a planned intervention that prevented an unexpected outage.

Oil Maintenance and Management

Ensuring the lifeblood of transformers remains healthy:

- Regular oil sampling and analysis

- Oil filtration and regeneration

- Moisture removal to maintain insulation properties

- Timely oil replacement when necessary

Here’s a quick guide to oil maintenance activities:

| Activity | Frequency | Purpose |

|---|---|---|

| Oil Sampling | Quarterly | Check for contaminants and degradation |

| Filtration | Annually or as needed | Remove particles and moisture |

| DGA | Semi-annually | Detect internal faults |

| Oil Replacement | Every 7-10 years or as indicated | Maintain insulation properties |

Load Management and Capacity Planning

Balancing efficiency and longevity:

- Regular load studies to ensure transformers operate within rated capacity

- Implementing load-tap changers for voltage regulation

- Strategic placement of power factor correction equipment

- Planning for future load growth and system upgrades

Upgrading and Modernization Efforts

Keeping up with technological advancements:

- Replacing aging transformers with more efficient models

- Upgrading monitoring and protection systems

- Implementing smart grid technologies for better system management

- Enhancing surge protection and grounding systems

Key points about prevention and maintenance strategies:

- Regular inspections and testing are fundamental to preventing failures

- Proactive monitoring allows for early detection of developing issues

- Proper oil maintenance is crucial for transformer longevity

- Effective load management helps prevent overloading and premature aging

- Upgrading and modernization efforts can significantly improve reliability

In my experience, a comprehensive prevention and maintenance strategy can dramatically reduce the incidence of transformer failures. I recall a case where we implemented a rigorous maintenance program for a utility company. Over three years, we saw a 70% reduction in unexpected transformer failures, resulting in improved reliability and significant cost savings.

For example, in a recent project for a data center, we implemented a state-of-the-art monitoring system that included online DGA and PD monitoring. This investment paid off when the system detected a rapidly developing fault, allowing for an emergency shutdown and repair that prevented a catastrophic failure and potential data loss.

As we conclude our discussion on transformer failures and their management, it’s clear that while responding effectively to failures is important, preventing them through diligent maintenance and proactive strategies is the key to ensuring a reliable and efficient power distribution system. By understanding and implementing these preventive measures, we can significantly reduce the occurrence of transformer failures and their impact on our communities and businesses.

Conclusion

Transformer failures, while disruptive, can be managed effectively through understanding their causes, implementing proper safety measures, and following efficient restoration processes. Prevention remains the best strategy, involving regular maintenance, proactive monitoring, and timely upgrades. By adopting these approaches, we can significantly reduce the frequency and impact of transformer failures, ensuring more reliable power distribution for all.

Have you ever wondered how large buildings or industrial complexes receive their power? The answer lies in a crucial device that often goes unnoticed. But what exactly is this unsung hero of our power distribution system?

A three phase distribution transformer is an electrical device that steps down medium-voltage three-phase power (typically 6kV to 33kV) to lower voltages (400V or 415V) for industrial, commercial, and large residential use. It consists of a three-legged core with primary and secondary windings on each leg, allowing for efficient power transfer. These transformers are crucial in the power distribution chain, offering improved efficiency, lower transmission losses, and more balanced load handling compared to single-phase systems.

In this comprehensive guide, I’ll take you through the structure, operation, and voltage regulation mechanisms of three phase distribution transformers. Whether you’re an engineer, project manager, or simply curious about power systems, this article will provide valuable insights into these essential components of our electrical infrastructure.

What Is a Three Phase Distribution Transformer?

Have you ever seen those large, cylindrical devices in industrial areas or near commercial complexes and wondered about their purpose? These are often three phase distribution transformers, but what exactly are they, and why are they so important for our power distribution system?

A three phase distribution transformer is a specialized electrical device designed to convert medium-voltage three-phase power (typically 6kV to 33kV) into lower voltage levels (usually 400V or 415V) suitable for industrial, commercial, and large residential applications. It uses electromagnetic induction to step down voltage while maintaining the three-phase nature of the power supply. These transformers are crucial for efficient power distribution in high-load scenarios, offering better voltage stability, higher power capacity, and improved energy efficiency compared to single-phase systems.

Key Aspects of Three Phase Distribution Transformers

Let’s break down the main features:

- Purpose and Function

- Three-Phase vs. Single-Phase Comparison

- Voltage and Capacity Ranges

- Applications

- Advantages and Considerations

Purpose and Function

The primary role in power distribution:

- Step down medium voltage to low voltage for end-user consumption

- Maintain three-phase power characteristics throughout transformation

- Provide efficient power distribution for high-load applications

I recently visited a new industrial park where three phase distribution transformers were being installed. It was fascinating to see how these devices could handle the massive power requirements of multiple factories while maintaining stable voltage levels.

Three-Phase vs. Single-Phase Comparison

Understanding the key differences:

- Three-phase systems offer higher power capacity

- More efficient for large loads and motor-driven equipment

- Better voltage stability and load balancing

During a recent project, we had to decide between multiple single-phase transformers and a three-phase unit for a commercial complex. The three-phase option ultimately provided better efficiency and simplified installation.

Voltage and Capacity Ranges

Meeting diverse power needs:

- Primary voltages: Typically 6kV, 11kV, 22kV, or 33kV

- Secondary voltages: Usually 400V or 415V (line-to-line)

- Capacity ranges from 100 kVA to 2500 kVA for most distribution applications

Here’s a quick overview of common ratings:

| Primary Voltage | Secondary Voltage | Typical Capacities |

|---|---|---|

| 11kV | 400V | 250, 500, 1000 kVA |

| 22kV | 400V | 500, 1000, 1500 kVA |

| 33kV | 415V | 1000, 1500, 2000 kVA |

Applications

Versatile use in various settings:

- Industrial facilities and factories

- Commercial complexes and shopping centers

- Large residential developments and high-rise buildings

- Hospitals and data centers

- Renewable energy integration (wind farms, solar plants)

Advantages and Considerations

Understanding the pros and potential challenges:

- Advantages: Higher efficiency, better load balancing, suitable for motor loads

- Considerations: Higher initial cost, more complex installation, requires balanced loads

Key points about three phase distribution transformers:

- They are crucial for stepping down voltage in three-phase power systems

- Offer higher efficiency and capacity compared to single-phase systems

- Commonly used in industrial and large commercial applications

- Come in various voltage and capacity ratings to suit different needs

- Provide better performance for motor loads and balanced power distribution

In my experience, understanding these basic aspects of three phase transformers is crucial for effective power system planning. I recall a project where we initially underestimated the growth potential of an industrial area. By choosing a three phase transformer with slightly higher capacity, we were able to accommodate the rapid expansion of several factories without major infrastructure changes.

For example, in a recent data center project, we used a large three phase transformer to power the entire facility. Its ability to handle the massive, constant load while maintaining voltage stability was crucial for the center’s 24/7 operation.

As we move on to discuss the internal structure of these transformers, keep these basic characteristics in mind. Understanding how the external design relates to the internal components will give you a more comprehensive view of how these essential devices function in our power distribution systems.

Internal Structure: Core Types, Windings, and Cooling?

Have you ever wondered what’s inside those large three phase transformers? The internal structure of these devices is a marvel of electrical engineering. But what are the key components that make up this structure, and how do different designs affect performance?

The internal structure of a three phase distribution transformer consists of three main components: the core, windings, and cooling system. The core, typically made of laminated silicon steel, can be either shell-type or core-type. Windings are arranged in primary and secondary coils, usually in Delta or Wye configurations. Cooling systems can be oil-based (ONAN/ONAF) or dry-type (AN/AF). The choice of core type, winding configuration, and cooling method significantly impacts the transformer’s efficiency, size, and suitability for different applications.

Key Internal Components of Three Phase Transformers

Let’s examine the main internal elements:

- Core Types and Structures

- Winding Configurations

- Cooling Systems

- Insulation Materials

- Structural Components and Tank

Core Types and Structures

The magnetic heart of the transformer:

- Shell-type core: Windings surrounded by core material

- Core-type: Core legs pass through the center of windings

- Three-legged or five-legged designs for different applications

I recently had the opportunity to compare shell-type and core-type transformers during a factory tour. The difference in magnetic flux paths and their impact on efficiency was fascinating to observe in real-world applications.

Winding Configurations

Arranging the electrical coils:

- Delta (Δ) configuration: Better for handling unbalanced loads

- Wye (Y) configuration: Provides a neutral point, useful for grounding

- Various combinations (e.g., Delta-Wye, Wye-Wye) for different needs

During a recent project, we had to carefully consider the winding configuration to match the specific needs of an industrial client with a mix of three-phase and single-phase loads.

Cooling Systems

Managing heat for optimal performance:

- Oil-immersed: ONAN (Oil Natural Air Natural) or ONAF (Oil Natural Air Forced)

- Dry-type: AN (Air Natural) or AF (Air Forced)

- Hybrid systems for special applications

Here’s a quick comparison of cooling methods:

| Cooling Method | Advantages | Typical Applications |

|---|---|---|

| ONAN | Simple, reliable | Outdoor installations |

| ONAF | Higher capacity in compact size | Industrial settings |

| Dry-type AN | Environmentally friendly, fire-resistant | Indoor, commercial buildings |

| Dry-type AF | High capacity in non-oil design | Data centers, hospitals |

Insulation Materials

Ensuring electrical isolation and safety:

- Oil-paper insulation for oil-immersed transformers

- Epoxy resin or similar materials for dry-type units

- Special materials for high-temperature applications

Structural Components and Tank

Housing and supporting the internal elements:

- Tank design for oil containment and heat dissipation

- Core clamping structures to minimize vibration

- Bushings for external connections

- Tap changer mechanisms for voltage adjustment

Key points about the internal structure:

- Core type affects the transformer’s size, efficiency, and magnetic characteristics

- Winding configurations determine voltage relationships and load handling capabilities

- Cooling systems are crucial for maintaining optimal operating temperatures

- Insulation materials play a vital role in safety and long-term reliability

- Structural components must withstand electrical and mechanical stresses

In my experience, understanding the internal structure is crucial for selecting the right transformer for specific applications. I recall a case where a client initially wanted a standard oil-filled transformer for a new shopping mall. After considering the fire safety requirements and maintenance concerns, we opted for a dry-type unit with forced air cooling. This choice not only met the technical requirements but also simplified the installation process and reduced long-term maintenance needs.

For example, in a recent project for a large manufacturing plant, we specified a transformer with a five-legged core design. This choice provided better handling of unbalanced loads and harmonic currents, which were common in the facility’s power system due to various motor drives and welding equipment.

As we move on to discuss how three phase transformers work, keep these internal components in mind. Understanding their interactions is key to grasping the overall function and efficiency of these essential devices in our power distribution systems.

How a Three Phase Transformer Works: Electromagnetic Induction in Three Legs?

Have you ever wondered how a three phase transformer manages to handle three separate phases of electricity simultaneously? The process might seem complex, but it’s based on fundamental principles of electromagnetism. But how exactly does this principle apply to the three-legged structure of these transformers?

A three phase transformer works on the principle of electromagnetic induction, with each leg of the core handling one phase of the three-phase power. When alternating current flows through the primary windings, it creates a changing magnetic field in each leg of the transformer’s core. This changing magnetic field induces a voltage in the secondary windings of each leg. The 120-degree phase difference between the three phases is maintained throughout the transformation process. The three-legged core structure provides a closed magnetic circuit, allowing efficient energy transfer from the primary to the secondary side while maintaining the phase relationships.

Key Aspects of Three Phase Transformer Operation

Let’s break down how these transformers function:

- Electromagnetic Induction in Three Phases

- Core and Magnetic Flux Paths

- Phase Relationships and Balanced Operation

- Load Handling and Efficiency

- Harmonics and Special Considerations

Electromagnetic Induction in Three Phases

The fundamental principle at work:

- Each leg of the core handles one phase of the three-phase power

- Changing current in primary windings creates a changing magnetic field

- Magnetic field induces voltage in secondary windings

- Process occurs simultaneously in all three legs

I recently used a small-scale model to demonstrate this principle during a training session. Seeing the synchronized operation of all three phases really helped clarify the concept for the participants.

Core and Magnetic Flux Paths

Understanding the magnetic circuit:

- Three-legged core provides a closed path for magnetic flux

- Flux in each leg is 120 degrees out of phase with the others

- Core design minimizes magnetic losses and improves efficiency

During a recent project, we used advanced simulation software to visualize the magnetic flux paths in different core designs. This analysis was crucial in selecting the most efficient transformer for a critical industrial application.

Phase Relationships and Balanced Operation

Maintaining three-phase characteristics:

- 120-degree phase difference maintained between phases

- Balanced operation crucial for optimal performance

- Winding configurations (Delta or Wye) affect phase relationships

Here’s a simplified view of phase relationships:

| Phase | Angle | Typical Color Code |

|---|---|---|

| A | 0° | Red |

| B | 120° | Yellow |

| C | 240° | Blue |

Load Handling and Efficiency

Adapting to varying power demands:

- Ability to handle balanced and slightly unbalanced loads

- Higher efficiency compared to three single-phase transformers

- Load sharing between phases for optimal performance

Harmonics and Special Considerations

Dealing with power quality issues:

- Impact of harmonic currents on transformer operation

- Special designs for handling non-linear loads

- Importance of proper sizing and selection for harmonic-rich environments

Key points about three phase transformer operation:

- Electromagnetic induction occurs simultaneously in all three legs

- Core design is crucial for efficient magnetic flux paths

- Phase relationships are maintained throughout the transformation

- Balanced operation is key to optimal efficiency

- Special considerations are needed for harmonic-rich environments

In my experience, understanding these operational principles is crucial for effective transformer management and troubleshooting. I recall a case where a transformer was experiencing excessive heating in one leg. By analyzing the phase currents and harmonic content, we discovered that a large number of single-phase, non-linear loads were connected to one phase, causing unbalance and harmonic distortion. This insight led to a redistribution of loads and the installation of harmonic filters, resolving the issue.

For example, in a recent project involving a large data center, we implemented three phase transformers specifically designed to handle the high harmonic content typical in such environments. These units featured oversized neutrals and special core designs to manage the harmonic currents effectively, ensuring reliable operation in this critical facility.

As we move on to discuss voltage regulation in distribution transformers, keep these operational principles in mind. Understanding how three phase transformers handle power flow and maintain phase relationships is key to appreciating the complexities of voltage regulation in these essential devices.

Voltage Regulation in Distribution Transformers: Tap Changers and Load Response?

Have you ever wondered how distribution transformers maintain stable output voltage despite fluctuations in input voltage or load? This crucial aspect of transformer operation ensures reliable power delivery to end-users. But how exactly do transformers achieve this voltage regulation, and what mechanisms are involved?

Voltage regulation in distribution transformers is primarily achieved through tap changers and the transformer’s inherent response to load changes. Tap changers adjust the turns ratio of the transformer by changing the number of active turns in the winding, allowing for voltage adjustment. There are two main types: No-Load Tap Changers (NLTC) for offline adjustments and On-Load Tap Changers (OLTC) for real-time voltage control. Additionally, transformers have a natural voltage drop under load, which is considered in their design. The combination of tap changing and load response characteristics allows transformers to maintain output voltage within acceptable limits despite input voltage fluctuations and varying load conditions.

Key Aspects of Voltage Regulation in Distribution Transformers

Let’s examine the main elements of voltage regulation:

- Tap Changers: Types and Operation

- Load Response and Voltage Drop

- Automatic Voltage Regulation Systems

- Factors Affecting Voltage Regulation

- Importance in Power Quality Management

Tap Changers: Types and Operation

Adjusting transformer turns ratio:

- No-Load Tap Changers (NLTC): Manual adjustment when de-energized

- On-Load Tap Changers (OLTC): Automatic adjustment while energized

- Typical range of ±5% in 2.5% steps

I recently oversaw the installation of a transformer with an OLTC in a critical industrial facility. The ability to make real-time voltage adjustments proved invaluable in maintaining stable power supply during significant load variations.

Load Response and Voltage Drop

Natural transformer behavior under load:

- Voltage drop occurs as load increases

- Impedance voltage: measure of transformer’s internal voltage drop

- Careful design to balance efficiency and voltage regulation

During a recent project, we had to carefully consider the expected load profile to select a transformer with appropriate impedance characteristics, ensuring good voltage regulation across various operating conditions.

Automatic Voltage Regulation Systems

Enhancing regulation capabilities:

- Voltage sensors and control circuits

- Automatic tap changing based on output voltage

- Integration with smart grid systems for optimized operation

Here’s a simplified view of automatic voltage regulation:

| Input Voltage Change | Load Change | Tap Changer Response |

|---|---|---|

| Increase | – | Decrease turns ratio |

| Decrease | – | Increase turns ratio |

| – | Increase | Increase turns ratio |

| – | Decrease | Decrease turns ratio |

Factors Affecting Voltage Regulation

Understanding influences on regulation performance:

- Power factor of the load

- Transformer impedance

- Line voltage drop

- Harmonic content in the load current

Importance in Power Quality Management

Ensuring reliable and stable power supply:

- Maintaining voltage within acceptable limits for end-user equipment

- Reducing stress on electrical systems

- Supporting power factor correction and harmonic mitigation efforts

Key points about voltage regulation in distribution transformers:

- Tap changers are primary mechanisms for voltage adjustment

- Load response characteristics influence natural voltage regulation

- Automatic systems enhance regulation capabilities

- Multiple factors affect regulation performance

- Proper regulation is crucial for overall power quality

In my experience, effective voltage regulation is critical for maintaining power quality and equipment longevity. I recall a project where a manufacturing plant was experiencing frequent equipment malfunctions. Upon investigation, we discovered that the existing transformer’s voltage regulation was inadequate for the highly variable load profile. By upgrading to a transformer with an OLTC and implementing an automatic voltage regulation system, we significantly improved power quality and reduced equipment failures.

For example, in a recent smart grid project, we integrated advanced voltage regulation systems into distribution transformers. These systems not only maintained stable voltage but also communicated with other grid components to optimize overall power flow and efficiency. This approach demonstrated how modern voltage regulation techniques can contribute to broader power system optimization.

As we conclude our discussion on voltage regulation, it’s clear that this aspect of transformer operation is crucial for reliable power distribution. Whether you’re designing a new power system or troubleshooting existing issues, understanding these voltage regulation mechanisms is key to ensuring stable and efficient electrical supply.

Applications of Three Phase Distribution Transformers in Power Systems?

Have you ever wondered where three phase distribution transformers are typically used and why they’re chosen over single-phase alternatives? These versatile devices play a crucial role in various power distribution scenarios, but their applications might be more diverse than you think. So, in what situations are three phase distribution transformers most commonly deployed, and what benefits do they offer?

Three phase distribution transformers are widely used in industrial facilities, commercial complexes, large residential developments, and renewable energy installations. They’re essential for powering heavy machinery in factories, supplying consistent power to office buildings and shopping centers, and distributing electricity in high-rise apartments. In renewable energy, they help integrate wind farms and solar plants into the grid. Three phase transformers are chosen for their higher efficiency, better load balancing, and ability to handle large power capacities. They’re particularly beneficial for motor loads and in applications requiring stable, three-phase power supply.

Key Application Areas for Three Phase Distribution Transformers

Let’s explore the main uses:

- Industrial Power Distribution

- Commercial and Institutional Buildings

- Large Residential Complexes

- Renewable Energy Integration

- Specialized Applications

Industrial Power Distribution

Powering manufacturing and processing facilities:

- Factories and production lines

- Chemical plants and refineries

- Mining operations and heavy industry

I recently worked on a project to upgrade the power distribution system in a large automotive manufacturing plant. The use of high-capacity three phase transformers was crucial in handling the diverse and heavy loads of welding equipment, robotic assembly lines, and HVAC systems.

Commercial and Institutional Buildings

Supplying reliable power to large structures:

- Office buildings and corporate campuses

- Shopping malls and retail centers

- Hospitals and healthcare facilities

- Educational institutions

During a recent renovation of a major shopping center, we installed multiple three phase transformers to handle the complex power needs of hundreds of stores, food courts, and climate control systems. The ability to balance loads across phases was key to efficient power distribution.

Large Residential Complexes

Meeting the power needs of high-density housing:

- High-rise apartment buildings

- Gated communities and large housing developments

- Mixed-use residential and commercial complexes

Here’s a quick overview of typical transformer sizes for different residential applications:

| Application | Typical Transformer Size | Key Considerations |

|---|---|---|

| Small Apartment Building | 100-250 kVA | Balanced load distribution |

| High-Rise Residential | 500-1000 kVA | Vertical power distribution |

| Large Housing Complex | 1000-2500 kVA | Multiple distribution points |

Renewable Energy Integration

Supporting green energy initiatives:

- Wind farms: Stepping up voltage from turbine generators

- Solar power plants: Integrating large-scale photovoltaic systems

- Hydroelectric installations: Connecting to the grid

Specialized Applications

Addressing unique power distribution challenges:

- Data centers and server farms

- Transportation hubs (airports, train stations)

- Water treatment and pumping stations

- Temporary power for large events or construction sites

Key points about three phase transformer applications:

- They are crucial in industrial settings for powering heavy machinery

- Commercial and institutional buildings rely on them for stable power supply

- Large residential complexes benefit from their efficient power distribution

- Renewable energy projects often require them for grid integration

- Specialized applications showcase their versatility in various sectors

In my experience, the choice of three phase transformers in these applications often leads to significant improvements in power quality and efficiency. I recall a project for a new data center where the decision to use high-efficiency three phase transformers not only met the immediate power needs but also provided the flexibility to accommodate future expansion. The balanced power distribution was crucial for the sensitive server equipment.

For example, in a recent wind farm project, we used a series of three phase transformers to step up the voltage from individual turbines and then again at the substation level for grid connection. This multi-stage approach using three phase units allowed for efficient power collection and transmission, maximizing the farm’s output to the grid.

As we conclude our exploration of three phase distribution transformer applications, it’s clear that these devices play a vital role in our modern power infrastructure. Whether powering industrial processes, ensuring comfort in commercial spaces, or enabling the integration of renewable energy, three phase transformers are essential components in efficient and reliable power distribution systems.

Top 10 Chinese Manufacturers of Three Phase Distribution Transformers?

Are you looking for reliable suppliers of three phase distribution transformers for your international projects? With China being a major player in the global electrical equipment market, it’s worth exploring the top manufacturers from this region. But which Chinese companies stand out in producing high-quality, export-ready three phase transformers?

Leading Chinese manufacturers of three phase distribution transformers include CHBEB, CHINT, TBEA, XD Group, and Sieyuan Electric. These companies offer transformers with voltage ratings from 6kV to 66kV and capacities from 100kVA to 5000kVA. They are known for their adherence to international standards like IEC and ANSI, competitive pricing, and strong export capabilities. Many of these manufacturers provide customization options, comprehensive documentation, and after-sales support, making them popular choices for international projects in regions like Africa, Southeast Asia, and along the Belt and Road initiative countries.

Overview of Top Chinese Three Phase Transformer Manufacturers

Let’s examine the key players and their offerings:

- CHBEB (China Bei Er Bian)

- CHINT

- TBEA

- XD Group

- Sieyuan Electric

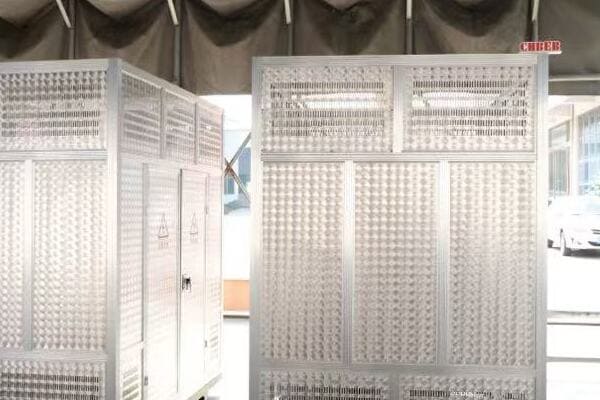

CHBEB (China Bei Er Bian)

Specializing in customized solutions:

- kVA Range: 100-2500 kVA

- Voltage Range: 6-33kV

- Key Features: Supports copper/aluminum windings, with/without tap changers, strong OEM capabilities

- Export Markets: Middle East, Africa

I recently visited CHBEB’s manufacturing facility and was impressed by their rigorous testing procedures for export-grade transformers. Their ability to customize units for specific environmental conditions, like high-temperature or high-humidity areas, sets them apart in the international market.

CHINT

Known for cost-effective solutions:

- kVA Range: 100-2000 kVA

- Voltage Range: 10-22kV

- Key Features: Comprehensive product line, fast delivery, competitive pricing

- Export Markets: Asia, Africa

During a recent project in Southeast Asia, we sourced transformers from CHINT. Their ability to deliver a large quantity of standardized units quickly was crucial for meeting our tight project timeline.

TBEA

High-end transformer solutions:

- kVA Range: 250-3150 kVA

- Voltage Range: 6-66kV

- Key Features: Experience in national grid projects, support for ultra-high voltage products

- Export Markets: Central Asia, Belt & Road countries

Here’s a comparison of these top manufacturers:

| Manufacturer | kVA Range | Voltage Range | Key Strength | Main Export Regions |

|---|---|---|---|---|

| CHBEB | 100-2500 kVA | 6-33kV | Customization | Middle East, Africa |

| CHINT | 100-2000 kVA | 10-22kV | Cost-effective | Asia, Africa |

| TBEA | 250-3150 kVA | 6-66kV | High-end solutions | Central Asia, Belt & Road |

| XD Group | 400-5000 kVA | 20-110kV | EPC projects | Latin America, Africa |

| Sieyuan | 250-2500 kVA | 10-33kV | GIS integration | Southeast Asia, LATAM |

XD Group

Comprehensive power equipment manufacturer:

- kVA Range: 400-5000 kVA

- Voltage Range: 20-110kV

- Key Features: Complete system for substation and distribution transformers, suitable for rail transit and power plant projects

- Export Markets: Latin America, Africa

Sieyuan Electric

Integrated power solutions provider:

- kVA Range: 250-2500 kVA

- Voltage Range: 10-33kV

- Key Features: Strong GIS system integration capabilities, compatible with remote monitoring systems

- Export Markets: Southeast Asia, Latin America

Key points about Chinese three phase transformer manufacturers:

- They offer a wide range of voltage and capacity options

- Many provide customization capabilities for specific project needs

- Strong focus on international standards compliance for export markets

- Competitive pricing combined with reliable quality

- Extensive experience in various global markets

In my experience, these Chinese manufacturers have consistently demonstrated their ability to meet diverse project requirements. I recall a large-scale industrial park development where we sourced transformers from multiple Chinese manufacturers on this list. By leveraging the specific strengths of each company – such as CHBEB’s customization capabilities for harsh environments and CHINT’s cost-effective standard units for widespread deployment – we were able to optimize the overall power distribution system while managing costs effectively.

For example, in a recent project in a remote area with unstable grid voltage, we utilized TBEA’s transformers known for their robust design and voltage regulation capabilities. This choice significantly improved power quality and reliability in the challenging operating environment.

When considering Chinese manufacturers for your three phase transformer needs, it’s crucial to evaluate not just the technical specifications and pricing, but also factors like after-sales support, documentation quality, and the manufacturer’s experience in your specific application area. This comprehensive approach will help ensure you select the right partner for your power distribution projects.

FAQs: Common Questions About Three Phase Transformers?

Are you still puzzled by some aspects of three phase transformers? You’re not alone. Many professionals and curious individuals have questions about these essential components of our power distribution system. Let’s address some of the most frequently asked questions to deepen your understanding.

FAQs about three phase transformers often cover their function, differences from single-phase units, common configurations, and installation considerations. Three phase transformers primarily function to step voltage up or down while maintaining three-phase power characteristics. They differ from single-phase transformers in their ability to handle higher loads more efficiently. Common configurations include Delta-Wye and Wye-Wye connections. Installation typically requires consideration of factors like load balancing, cooling requirements, and proper grounding. Understanding these aspects is crucial for proper selection, installation, and maintenance of three phase transformers.

Frequently Asked Questions About Three Phase Transformers

Let’s address some common queries:

- Function and Purpose

- Three-Phase vs. Single-Phase Differences

- Common Configurations and Connections

- Installation and Maintenance Considerations

- Efficiency and Load Handling

Function and Purpose

Q: What is the main function of a three phase transformer?

A: The primary function of a three phase transformer is to step voltage up or down in a three-phase power system while maintaining the phase relationships. It allows for efficient power transmission and distribution in industrial, commercial, and large-scale residential applications.

I often use an analogy to explain this: think of a three phase transformer as a traffic interchange that not only changes the "speed" (voltage) of the electricity but also manages three "lanes" (phases) of power flow simultaneously, ensuring smooth and efficient "traffic" (power) movement.

Three-Phase vs. Single-Phase Differences

Q: How does a three phase transformer differ from a single-phase transformer?

A: The main differences include:

- Power Capacity: Three phase units can handle higher loads more efficiently

- Core Structure: Typically uses a three-legged core design

- Winding Arrangement: Has three sets of primary and secondary windings

- Load Balancing: Better suited for balanced three-phase loads

- Efficiency: Generally more efficient for large power applications

During a recent educational workshop, we compared small single-phase and three phase transformers side by side. The structural differences, especially in the core and winding arrangements, were striking and helped participants understand the distinct capabilities of each type.

Common Configurations and Connections

Q: What are the typical configurations for three phase transformers?

A: Common configurations include:

- Delta-Wye (Δ-Y): Most common for step-down distribution

- Wye-Wye (Y-Y): Used when a neutral is required on both sides

- Delta-Delta (Δ-Δ): Less common, used in some industrial applications

Here’s a quick overview of these configurations:

| Configuration | Primary | Secondary | Common Use |

|---|---|---|---|

| Delta-Wye | Delta | Wye | General distribution |

| Wye-Wye | Wye | Wye | When neutral is needed on both sides |

| Delta-Delta | Delta | Delta | Some industrial applications |

Installation and Maintenance Considerations

Q: What are key factors in installing and maintaining three phase transformers?

A: Important considerations include:

- Proper foundation and clearances

- Cooling system requirements (oil or air)

- Load balancing across all three phases

- Regular oil testing and insulation checks

- Monitoring of temperature and load conditions

I recently oversaw the installation of several three phase transformers in a new industrial complex. The precision required in positioning, connecting, and balancing loads across all three phases was crucial for optimal performance.

Efficiency and Load Handling

Q: How efficient are three phase transformers and how do they handle varying loads?

A: Three phase transformers are generally very efficient, often exceeding 98% efficiency at full load. They handle varying loads well, especially when the load is balanced across all three phases. Key points include:

- Better efficiency compared to equivalent single-phase units

- Ability to handle large motor loads effectively

- Importance of load balancing for optimal performance

Key points from these FAQs:

- Three phase transformers maintain phase relationships while changing voltage levels

- They offer significant advantages over single-phase units for large power applications

- Various configurations are used to suit different system requirements

- Proper installation and maintenance are crucial for long-term performance

- They provide high efficiency, especially with balanced loads

In my experience, understanding these fundamental aspects is crucial for anyone involved in power distribution projects. I recall a situation where a maintenance team’s thorough understanding of three phase transformer characteristics helped them quickly diagnose and resolve a phase imbalance issue, minimizing downtime for an entire manufacturing facility.

For example, during a recent upgrade of a commercial building’s power system, we used these FAQs as a basis for educating the facility management team. This knowledge empowered them to better monitor and maintain their new three phase transformer, ensuring optimal performance and longevity.

Remember, while these FAQs provide a good overview, always consult manufacturer specifications and local regulations for detailed information specific to your situation. Continuous learning and staying updated on the latest developments in transformer technology are key to effectively managing and maintaining these crucial components of our power infrastructure.

Conclusion

Three phase distribution transformers are vital components in modern power systems, efficiently stepping down medium voltage to usable levels for industrial, commercial, and large-scale residential applications. Understanding their structure, operation, and voltage regulation mechanisms is crucial for effective power system design and management. From their internal core and winding configurations to their applications in various sectors, these transformers play a key role in delivering reliable, balanced three-phase power. As technology advances, three phase transformers continue to evolve, adapting to new challenges in our ever-growing and changing power needs.

Have you ever wondered how the high-voltage electricity from power plants safely reaches your home? The answer lies in a crucial device that often goes unnoticed. But what exactly is this unsung hero of our power grid?

A distribution transformer is an electrical device that converts medium-voltage electricity (typically 6kV to 33kV) into lower voltages (230V or 400V) for end-user applications. It serves as the final link between the utility grid and consumers, stepping down voltage levels to make them safe and usable for homes, businesses, and industries. Distribution transformers are essential components in power networks, enabling efficient and safe electricity delivery to millions of users.

In this comprehensive guide, I’ll take you through the structure, function, and operation of distribution transformers in the power grid. Whether you’re an engineer, project manager, or simply curious about how electricity reaches your doorstep, this article will provide valuable insights into these critical components of our electrical infrastructure.

What Is a Distribution Transformer?

Have you ever noticed those barrel-shaped devices mounted on poles or in green boxes near your neighborhood? These are likely distribution transformers, but what exactly do they do, and why are they so important for our daily power needs?

A distribution transformer is a type of electrical transformer designed to convert medium-voltage electricity from the power grid (typically 6kV to 33kV) into lower voltages (usually 230V or 400V) suitable for end-user consumption. It acts as the final step in the electrical distribution system, providing the crucial link between the utility’s distribution network and the consumer’s service entrance. Distribution transformers come in various forms, including oil-filled, dry-type, pole-mounted, and pad-mounted configurations, each suited for specific installation environments and load requirements.

Key Aspects of Distribution Transformers

Let’s break down the main features:

- Purpose and Function

- Types of Distribution Transformers

- Position in the Power Grid

- Voltage and Capacity Ranges

- Key Design Considerations

Purpose and Function

The primary role in power distribution:

- Step down medium voltage to low voltage for end-user consumption

- Provide electrical isolation between primary and secondary circuits

- Enable efficient power distribution over wide areas

I recently visited a new residential development where distribution transformers were being installed. It was fascinating to see how these devices, no larger than a small car, could power entire blocks of homes.

Types of Distribution Transformers

Adapting to various installation environments:

- Oil-filled transformers: Common for outdoor installations

- Dry-type transformers: Preferred for indoor or environmentally sensitive areas

- Pole-mounted transformers: Used in overhead distribution systems

- Pad-mounted transformers: Installed at ground level, often in urban areas

During a recent project, we had to choose between oil-filled and dry-type transformers for a new commercial complex. The decision process highlighted the importance of understanding each type’s strengths and limitations.

Position in the Power Grid

Bridging the gap between utility and consumer:

- Located at the end of the distribution network

- Typically the last transformer before consumer connection

- Often found in residential areas, commercial zones, and industrial parks

Here’s a simplified view of a distribution transformer’s position:

| Grid Component | Voltage Level | Next Step |

|---|---|---|

| Transmission Lines | 69kV – 765kV | Substation Transformer |

| Distribution Lines | 4kV – 34.5kV | Distribution Transformer |

| Consumer Supply | 120V – 480V | End-User Equipment |

Voltage and Capacity Ranges

Meeting diverse power needs:

- Primary voltages: Typically 6kV, 11kV, 22kV, or 33kV

- Secondary voltages: Usually 230V (single-phase) or 400V (three-phase)

- Capacity ranges from 5 kVA to 2500 kVA for most distribution applications

Key Design Considerations

Ensuring reliability and efficiency:

- Cooling methods (oil or air)

- Insulation systems

- Efficiency and losses

- Environmental factors (temperature, humidity, pollution)

Key points about distribution transformers:

- They are crucial for stepping down voltage to usable levels

- Come in various types to suit different installation environments

- Serve as the final link between the power grid and consumers

- Handle a wide range of voltages and capacities

- Design must balance efficiency, reliability, and environmental factors

In my experience, understanding these basic aspects of distribution transformers is crucial for effective power system planning. I recall a project where we underestimated the growth potential of a new commercial area. By choosing transformers with slightly higher capacity and the ability to add forced cooling later, we were able to accommodate the area’s rapid expansion without major infrastructure changes.

For example, in a recent rural electrification project, we used a combination of pole-mounted and pad-mounted distribution transformers. This approach allowed us to efficiently cover a wide area with varying population densities, showcasing the versatility of different transformer types in real-world applications.

As we move on to discuss the internal structure of distribution transformers, keep these basic characteristics in mind. Understanding how the external design relates to the internal components will give you a more comprehensive view of how these essential devices function in our power distribution systems.

Internal Structure of a Distribution Transformer: Core, Windings, Insulation?

Have you ever wondered what’s inside those mysterious boxes or cylinders that bring electricity to your neighborhood? The internal structure of a distribution transformer is a marvel of electrical engineering. But what are the key components that make up this structure, and how do they work together to transform voltage?

The internal structure of a distribution transformer consists of three main components: the core, windings, and insulation system. The core, typically made of laminated silicon steel, provides a path for magnetic flux. The windings, usually copper or aluminum, consist of primary (high-voltage) and secondary (low-voltage) coils wrapped around the core. The insulation system, which may be oil or solid materials like epoxy resin, provides electrical isolation and cooling. This arrangement allows for efficient voltage transformation while maintaining electrical isolation between primary and secondary circuits.

Key Internal Components of Distribution Transformers

Let’s examine the main internal elements:

- Core Structure and Materials

- Primary and Secondary Windings

- Insulation Systems

- Tap Changers

- Structural Components and Tank

Core Structure and Materials

The magnetic heart of the transformer:

- Typically made of grain-oriented silicon steel laminations

- Designed to provide a low-reluctance path for magnetic flux

- Common shapes include shell-type or core-type configurations

I recently had the opportunity to inspect a disassembled distribution transformer. The precision in the core’s lamination assembly was impressive, showcasing how crucial this component is for efficient operation.

Primary and Secondary Windings

Conducting the electrical magic:

- Primary (high-voltage) winding connected to the distribution line

- Secondary (low-voltage) winding delivers power to consumers

- Usually made of copper for better conductivity, though aluminum is sometimes used

During a factory tour, I observed the winding process for distribution transformers. The skill required to achieve the precise number of turns and maintain proper insulation between layers was remarkable.

Insulation Systems

Protecting and cooling the vital components:

- Oil-filled transformers: Mineral oil surrounds core and windings

- Dry-type transformers: Solid insulation materials like epoxy resin

- Hybrid systems combining solid and liquid insulation

Here’s a quick comparison of insulation types:

| Insulation Type | Advantages | Typical Applications |

|---|---|---|

| Oil | Excellent cooling, self-healing | Outdoor, high capacity |

| Epoxy Resin | Fire resistant, environmentally friendly | Indoor, urban areas |

| Hybrid | Combines benefits of both | Special applications |

Tap Changers

Adjusting voltage ratios:

- Allow for minor voltage adjustments to compensate for line voltage variations

- Can be on-load or off-load type

- Critical for maintaining stable output voltage

Structural Components and Tank

Housing and supporting the internal elements:

- Tank or enclosure protects internal components

- Cooling fins or radiators for heat dissipation

- Bushings for external connections

- Monitoring and protection devices

Key points about the internal structure:

- The core provides a path for magnetic flux, crucial for voltage transformation

- Windings transform voltage through electromagnetic induction

- Insulation systems provide both electrical isolation and cooling

- Tap changers allow for voltage adjustment to maintain output stability

- Structural components protect and support the internal elements

In my experience, understanding the internal structure is crucial for troubleshooting and maintenance. I recall a case where a transformer was experiencing unusual heating. By understanding the internal layout, we quickly identified that the issue was related to a partial blockage in the oil circulation path, not a winding problem as initially suspected.

For example, in a recent project involving transformers for a coastal area, we specified special materials for the internal components to resist corrosion from salt air. This attention to the internal structure based on environmental factors significantly extended the expected lifespan of the units.

As we move on to discuss how distribution transformers work in the power grid, keep these internal components in mind. Understanding how they interact is key to grasping the overall function and efficiency of these essential devices in our power distribution systems.

How a Distribution Transformer Works in the Power Grid?

Have you ever wondered how electricity from a distant power plant safely reaches your home at the right voltage? The journey involves several steps, but distribution transformers play a crucial role in the final stage. But how exactly do these devices function within the larger power grid?

A distribution transformer works by stepping down medium voltage electricity from the power grid to lower voltages suitable for end-users. It receives power from distribution lines (typically 6kV to 33kV) and converts it to 230V or 400V for residential and commercial use. The transformer is positioned at the end of the distribution network, often serving as the last voltage transformation point before consumer connection. It operates continuously, adjusting to load variations and maintaining a relatively constant output voltage through its design and sometimes with the help of tap changers.

Key Aspects of Distribution Transformer Operation

Let’s break down how these transformers function in the grid:

- Position in the Power Distribution Chain

- Voltage Transformation Process

- Load Management and Efficiency

- Protection and Safety Features

- Integration with Smart Grid Systems

Position in the Power Distribution Chain

The final link in power delivery:

- Receives power from medium-voltage distribution lines

- Typically located near end-users (neighborhoods, commercial areas)

- Serves as the interface between utility infrastructure and consumer systems

I recently toured a local substation and followed the power flow to nearby neighborhoods. It was fascinating to see how distribution transformers acted as the crucial transition point, making grid power usable for homes and businesses.

Voltage Transformation Process