Are you concerned about the environmental impact of your power distribution system? You’re not alone. Many engineers and facility managers are seeking greener alternatives to traditional oil-filled transformers. But what if there was a solution that could significantly reduce environmental risks while enhancing safety and compliance?

Dry-type transformers offer key environmental benefits by eliminating oil, reducing fire risks, and meeting green compliance standards like RoHS and REACH. Their design supports safer indoor use, lowers maintenance impact, and aligns with LEED and sustainable infrastructure goals.

In this comprehensive guide, I’ll walk you through the environmental advantages of dry type transformers. From their inherently greener design to their role in sustainable building projects, you’ll discover why these transformers are becoming the go-to choice for environmentally conscious power distribution solutions.

Why Dry Type Transformers Are Greener by Design?

Have you ever wondered why dry type transformers are considered more environmentally friendly than their oil-filled counterparts? The answer lies in their fundamental design. But what specific features make them a greener choice for modern power distribution needs?

Dry type transformers are inherently greener due to their oil-free design. This eliminates the risk of oil leaks or spills, removes the need for oil handling and disposal, and significantly reduces the environmental footprint during operation. Their design also makes them safer for indoor and high-density urban areas.

Key Environmental Advantages of Dry Type Transformers

Let’s explore the green features of dry type transformers:

- No risk of oil leaks or spills

- No need for oil handling, storage, or disposal

- Lower environmental footprint during operation

- Safer for indoor and high-density areas

Elimination of Oil-Related Risks

The absence of oil in dry type transformers is a game-changer for environmental safety:

- Zero risk of soil or water contamination from oil leaks

- No need for costly oil containment systems

- Reduced fire hazard and associated environmental risks

I once worked on a project replacing oil-filled transformers in an environmentally sensitive area near a water source. The switch to dry type units eliminated the constant worry about potential oil spills and their devastating environmental impact.

Simplified Maintenance and Reduced Waste

Dry type transformers offer significant environmental benefits through their maintenance profile:

- No oil testing or replacement required

- Reduced waste generation throughout the transformer’s lifecycle

- Lower risk of contamination during maintenance procedures

In a recent industrial project, we calculated that switching to dry type transformers would eliminate the need to dispose of thousands of liters of transformer oil over the equipment’s lifetime, significantly reducing the facility’s environmental footprint.

Enhanced Safety in Urban Environments

The design of dry type transformers makes them ideal for densely populated areas:

- Reduced fire load in buildings

- No oil smoke or fumes in case of failure

- Safer installation in multi-story buildings and underground facilities

I recall a project for a high-rise office building where the use of dry type transformers allowed for safer, more flexible installation options, reducing the overall environmental impact of the building’s power infrastructure.

Lower Carbon Footprint in Manufacturing and Transportation

The production and transportation of dry type transformers often have a lower environmental impact:

- No need for oil production and transportation

- Generally lighter weight, reducing transportation emissions

- Simpler manufacturing process with fewer environmentally sensitive materials

Here’s a quick comparison of environmental aspects:

| Aspect | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Oil Spill Risk | None | Present |

| Maintenance Waste | Minimal | Significant (oil disposal) |

| Fire Safety | High | Moderate |

| Urban Suitability | Excellent | Limited |

| Manufacturing Impact | Lower | Higher |

By choosing dry type transformers, you’re not just selecting a piece of equipment; you’re making a decision that positively impacts the environment throughout the transformer’s entire lifecycle. From manufacturing to installation, operation, and eventual decommissioning, dry type transformers offer a greener alternative at every stage.

Fire Safety Advantages: F1 and Self-Extinguishing Materials?

Are you worried about fire risks associated with electrical equipment in your facility? You’re not alone. Fire safety is a top concern for many building managers and engineers. But did you know that dry type transformers offer significant fire safety advantages over traditional oil-filled units?

Dry type transformers excel in fire safety due to their F1 class insulation and self-extinguishing materials. The absence of flammable oil significantly reduces fire load, making them compliant with strict NFPA and IEC fire zone restrictions. This makes them ideal for hospitals, schools, and high-rise buildings where fire safety is paramount.

Key Fire Safety Features of Dry Type Transformers

Let’s explore the fire safety advantages in detail:

- F1 class insulation (IEC 60076-11)

- Self-extinguishing resin (halogen-free)

- No flammable oil = lower fire load

- Compliant with NFPA / IEC fire zone restrictions

F1 Class Insulation: The Gold Standard in Fire Safety

F1 class insulation is a game-changer for transformer fire safety:

- Highest fire safety classification for transformers

- Limited combustibility and flame propagation

- Minimal emission of toxic gases in case of fire

I once worked on a hospital renovation project where F1 class dry type transformers were essential. Their superior fire safety characteristics not only met stringent regulations but also provided peace of mind for the hospital administration, knowing that patient safety was enhanced.

Self-Extinguishing Materials: Active Fire Prevention

The use of self-extinguishing resins adds an extra layer of fire protection:

- Actively resists flame spread

- Halogen-free composition reduces toxic emissions

- Contributes to overall building fire safety

In a recent data center project, we chose dry type transformers with self-extinguishing resins. This decision was crucial in meeting the client’s strict fire safety requirements and insurance standards for critical infrastructure.

Reduced Fire Load: A Safer Building Environment

The absence of oil significantly reduces the fire load in buildings:

- No risk of oil-fueled fires

- Lower overall fire risk for the facility

- Simplified fire protection systems in transformer rooms

I recall a high-rise office project where using dry type transformers allowed us to place electrical rooms on higher floors. This was possible due to the reduced fire load, offering more flexible building design options while maintaining stringent safety standards.

Compliance with Fire Zone Restrictions

Dry type transformers easily meet strict fire safety regulations:

- Compliant with NFPA 70 requirements for indoor installations

- Meet IEC standards for fire-resistant electrical equipment

- Ideal for use in designated fire zones within buildings

Here’s a comparison of fire safety aspects:

| Aspect | Dry Type (F1 Class) | Oil-Filled Transformer |

|---|---|---|

| Fire Resistance | High | Moderate |

| Toxic Emissions | Minimal | Potentially High |

| Fire Load | Low | High |

| Indoor Use Safety | Excellent | Limited |

| Compliance with Fire Codes | Easy | Often Challenging |

By choosing F1 class dry type transformers with self-extinguishing materials, you’re not just buying a transformer; you’re investing in the safety of your facility and its occupants. These transformers provide a level of fire safety that is unmatched by traditional oil-filled units, making them the preferred choice for environments where safety cannot be compromised.

RoHS, REACH, and Other Green Compliance Standards?

Are you struggling to navigate the complex world of environmental compliance for your electrical equipment? You’re not alone. Many professionals find it challenging to keep up with evolving green standards. But what if your transformer choice could simplify this process and ensure you’re meeting all necessary environmental regulations?

Dry type transformers are designed to meet stringent environmental standards including RoHS and REACH. They typically use compliant materials free from restricted substances like lead, mercury, and cadmium. Many are manufactured in ISO 14001 certified facilities, ensuring environmental management best practices throughout production.

Green Compliance Checklist for Dry Type Transformers

When selecting a dry type transformer, look for these key compliance features:

✅ RoHS-compliant (no lead, mercury, cadmium, etc.)

✅ REACH-compliant materials

✅ Halogen-free insulation system

✅ UL / CE / ISO 14001 certified manufacturing

RoHS Compliance: Eliminating Hazardous Substances

RoHS (Restriction of Hazardous Substances) compliance is crucial for environmental safety:

- Ensures the transformer is free from restricted substances

- Reduces environmental impact during manufacturing and disposal

- Supports global efforts to reduce electronic waste

I once worked on a project exporting transformers to the European Union. RoHS compliance was non-negotiable, and our dry type units easily met these stringent requirements, simplifying the export process and ensuring market access.

REACH Compliance: Safe Chemical Management

REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance demonstrates responsible chemical use:

- Ensures safe use of chemicals in transformer production

- Provides transparency about substances used

- Supports long-term environmental and health protection

In a recent project for a multinational corporation, REACH compliance was a key factor in their supplier selection process. Our ability to provide fully compliant dry type transformers was a significant advantage in securing the contract.

Halogen-Free Insulation: A Cleaner, Safer Choice

Halogen-free insulation systems offer environmental and safety benefits:

- Reduced toxic emissions in case of fire

- Lower environmental impact during production and disposal

- Improved air quality in indoor installations

I recall a data center project where the client specifically requested halogen-free transformers to align with their strict environmental policies. This choice not only met their green requirements but also enhanced the overall safety of their facility.

Certified Manufacturing Processes

Transformers produced in certified facilities ensure environmental best practices:

- ISO 14001 certification guarantees environmental management standards

- UL and CE certifications often include environmental considerations

- Demonstrates commitment to sustainable manufacturing practices

Here’s a comparison of environmental compliance aspects:

| Compliance Aspect | Typical Dry Type Transformer | Traditional Oil-Filled Transformer |

|---|---|---|

| RoHS Compliance | Fully Compliant | May Require Special Versions |

| REACH Compliance | Generally Compliant | Varies |

| Halogen-Free | Often Standard | Rarely Available |

| Certified Manufacturing | Common (ISO 14001) | Varies |

By choosing dry type transformers that meet these green compliance standards, you’re not just purchasing equipment; you’re making a statement about your commitment to environmental responsibility. These transformers help you meet regulatory requirements, support sustainable practices, and contribute to a cleaner, safer environment for all.

Ideal for Green Buildings and LEED Projects?

Are you involved in green building projects or aiming for LEED certification? You might be wondering how your choice of electrical equipment can contribute to these goals. What if I told you that the right transformer selection could significantly boost your project’s green credentials?

Dry type transformers are ideal for green buildings and LEED projects due to their energy efficiency, reduced environmental impact, and safety features. They contribute to LEED credits in Energy & Atmosphere categories, support indoor air quality targets, and improve overall building energy performance ratings.

How Dry Type Transformers Support Green Building Initiatives

Let’s explore how these transformers fit into various green building scenarios:

| Project Type | Transformer Feature | Green Certification Support |

|---|---|---|

| LEED Building | Low-loss + no oil | Contributes to Energy & Atmosphere credits |

| Hospital | Fire safe, no emissions | Supports indoor air quality targets |

| Data Center | High-efficiency + compact | Improves energy performance ratings |

LEED Buildings: Boosting Energy & Atmosphere Credits

Dry type transformers can significantly contribute to LEED certification:

- Energy efficiency reduces overall building power consumption

- No-oil design aligns with sustainable site development goals

- Low electromagnetic emissions support healthy indoor environments

I recently worked on a LEED Gold office building project where the use of high-efficiency dry type transformers directly contributed to achieving additional points in the Energy & Atmosphere category. This helped push the project from Silver to Gold certification status.

Hospitals: Enhancing Safety and Air Quality

In healthcare settings, dry type transformers offer unique advantages:

- Fire safety features crucial for patient areas

- No oil means no risk of contamination

- Low noise operation supports healing environments

During a major hospital expansion project, we implemented dry type transformers throughout the facility. This choice not only met strict safety regulations but also supported the hospital’s goals for improved indoor air quality and patient comfort.

Data Centers: Maximizing Efficiency and Reliability

For data centers, dry type transformers provide essential benefits:

- High efficiency reduces overall energy costs

- Compact design allows for better space utilization

- Improved reliability with lower maintenance needs

In a recent hyperscale data center project, the use of advanced dry type transformers played a crucial role in achieving the facility’s aggressive power usage effectiveness (PUE) targets, directly impacting its green certification level.

Green Building Performance Metrics

Here’s how dry type transformers can impact various green building metrics:

- Energy Efficiency: Can reduce losses by up to 60% compared to standard units

- Indoor Environmental Quality: Zero emissions contribute to better air quality

- Innovation in Design: Advanced models can serve as showcase green technology

- Sustainable Sites: No oil eliminates risks of soil or water contamination

Consider this comparison for green building applications:

| Aspect | Dry Type Transformer | Oil-Filled Alternative |

|---|---|---|

| LEED Credit Potential | High | Limited |

| Indoor Air Quality Impact | Positive | Potential Concern |

| Energy Efficiency | Very High | Moderate to High |

| Safety in Green Spaces | Excellent | Good |

| Lifecycle Environmental Impact | Low | Moderate |

By choosing dry type transformers for your green building or LEED project, you’re not just selecting a piece of equipment; you’re making a strategic decision that aligns with and enhances your overall sustainability goals. These transformers offer a perfect blend of efficiency, safety, and environmental responsibility, making them an ideal choice for projects where green credentials are a priority.

Reduced Maintenance = Lower Environmental Impact?

Have you ever considered how equipment maintenance affects your facility’s environmental footprint? Many overlook this aspect, but it’s a crucial factor in long-term sustainability. So, how can the choice of a transformer impact your maintenance needs and, by extension, your environmental impact?

Dry type transformers significantly reduce maintenance requirements compared to oil-filled units. This translates to lower environmental impact through reduced waste generation, eliminated risk of oil contamination, and a longer service life. The simplicity of their maintenance regime also means fewer resources are needed over the transformer’s lifecycle.

Key Environmental Benefits of Reduced Maintenance

Let’s explore how the low-maintenance nature of dry type transformers contributes to environmental protection:

- No oil testing or replacement

- No risk of oil contamination

- No need for containment pits

- Long service life reduces waste generation

Elimination of Oil-Related Maintenance

The absence of oil in dry type transformers removes several maintenance-related environmental risks:

- No periodic oil testing or filtration required

- Eliminates the need for oil disposal and replacement

- Reduces the risk of spills during maintenance procedures

I recall a project where we replaced oil-filled transformers with dry types in a water treatment facility. The elimination of oil-related maintenance not only reduced costs but also removed the constant worry about potential contamination of the water supply.

Simplified Inspection and Cleaning Procedures

Dry type transformers require minimal maintenance:

- Simple visual inspections are often sufficient

- Occasional cleaning with compressed air or vacuum

- No need for specialized oil handling equipment

In a recent data center project, the simplified maintenance of dry type transformers was a key factor in their selection. This not only reduced the environmental impact of maintenance activities but also minimized the risk of human error during servicing.

Extended Service Life and Reduced Waste

The durability of dry type transformers contributes to waste reduction:

- Typical lifespan of 20-30 years, often longer than oil-filled units

- Fewer replacements mean less manufacturing and disposal waste

- Many components are recyclable at end-of-life

I worked on an industrial facility upgrade where we calculated the lifecycle impact of switching to dry type transformers. The reduced need for replacements and maintenance over a 25-year period resulted in a significant reduction in waste generation and resource consumption.

Environmental Impact of Maintenance Activities

Consider these environmental aspects of transformer maintenance:

| Aspect | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Waste Generation | Minimal | Significant (oil, filters) |

| Contamination Risk | Very Low | Moderate to High |

| Resource Consumption | Low | Higher (oil, parts) |

| Frequency of Intervention | Low | Regular |

| End-of-Life Disposal | Simpler, More Recyclable | Complex, Potential Hazardous Waste |

Case Study: Long-Term Environmental Impact

In a recent project for a large commercial complex, we conducted a 20-year environmental impact assessment comparing dry type and oil-filled transformers. Here are some key findings:

- Waste Reduction: The dry type option generated 95% less maintenance-related waste over its lifetime.

- Carbon Footprint: Reduced maintenance activities led to a 30% lower carbon footprint from service-related travel and operations.

- Water Protection: Elimination of oil removed the risk of water contamination, a critical factor for the nearby wetland ecosystem.

This study clearly demonstrated the long-term environmental benefits of choosing low-maintenance dry type transformers.

By opting for dry type transformers, you’re not just simplifying your maintenance routine; you’re making a choice that has far-reaching positive impacts on the environment. From reduced waste generation to lower risk of contamination, the benefits accumulate over the transformer’s entire lifecycle, contributing significantly to your facility’s overall environmental performance.

A Sustainable Choice for the Future of Power Distribution?

Are you wondering how your transformer choices today will impact the future of power distribution? As we move towards a more sustainable world, it’s crucial to consider how our infrastructure decisions align with long-term environmental goals. But how exactly do dry type transformers fit into this vision of a greener future?

Dry type transformers represent a sustainable choice for future power distribution needs. They align with global decarbonization goals, integrate well with renewable energy infrastructure, and are increasingly preferred in urban planning and ESG-driven procurement. Their eco-friendly design makes them ideal for the evolving landscape of sustainable power systems.

Key Aspects of Dry Type Transformers in Future Sustainability

Let’s explore how dry type transformers contribute to sustainable power distribution:

Alignment with Global Decarbonization Goals

Dry type transformers support the transition to a low-carbon economy:

- Higher efficiency reduces overall energy consumption and related emissions

- No oil means no risk of greenhouse gas emissions from leaks or disposal

- Longer lifespan reduces the carbon footprint associated with manufacturing and replacement

I recently consulted on a city-wide energy upgrade project where the switch to high-efficiency dry type transformers was projected to reduce the city’s carbon emissions by thousands of tons annually, directly contributing to their climate action plan.

Integration with Renewable Energy Infrastructure

These transformers are well-suited for renewable energy systems:

- Can handle the variable loads typical of solar and wind power

- Compact design ideal for offshore wind platforms and solar farms

- Environmental safety crucial for remote or sensitive installation sites

In a large-scale solar farm project, we implemented dry type transformers specifically designed for renewable applications. Their ability to handle fluctuating loads and withstand outdoor conditions was crucial for the project’s success and long-term sustainability.

Urban Planning and Smart City Initiatives

Dry type transformers are becoming a preferred choice in urban development:

- Safer for high-density areas due to reduced fire risk

- Lower noise levels suitable for residential and mixed-use zones

- Compact design allows for more flexible urban substation planning

During a recent smart city planning initiative, the use of dry type transformers allowed for more integrated power distribution within the urban landscape. Their safety and compact nature enabled innovative designs that blended substations seamlessly into the cityscape.

ESG-Driven Procurement Trends

Environmental, Social, and Governance (ESG) considerations are driving transformer choices:

- No-oil design aligns with environmental protection goals

- Improved safety features support social responsibility aspects

- Transparency in materials and manufacturing supports governance objectives

I’ve observed a growing trend among corporate clients where ESG factors are becoming primary drivers in equipment selection. In several recent projects, the environmental benefits of dry type transformers were key in meeting the clients’ sustainability reporting requirements.

Public Sector Leadership

Government and public institutions are increasingly mandating eco-friendly options:

- Many public projects now require "non-oil" electrical equipment

- Educational institutions leading in adopting sustainable technologies

- Healthcare facilities prioritizing patient and environmental safety

In a recent government infrastructure project, the specification explicitly called for dry type transformers as part of their commitment to sustainable and safe public facilities.

Here’s a comparison of how dry type transformers align with future sustainability trends:

| Sustainability Aspect | Dry Type Transformer | Traditional Oil-Filled |

|---|---|---|

| Carbon Footprint | Lower | Higher |

| Renewable Energy Compatibility | Excellent | Good |

| Urban Integration | Highly Suitable | Challenging |

| ESG Alignment | Strong | Moderate |

| Future-Proofing | High | Moderate |

By choosing dry type transformers, you’re not just making a decision for today; you’re investing in a sustainable future for power distribution. These transformers represent a forward-thinking approach that aligns with global environmental goals, adapts to the changing landscape of energy generation, and meets the evolving demands of urban development and corporate responsibility.

As we look to the future, the role of dry type transformers in creating a more sustainable and resilient power infrastructure becomes increasingly clear. Their environmental benefits, safety features, and adaptability make them an ideal choice for those looking to build power systems that will stand the test of time while minimizing environmental impact.

Conclusion

Dry type transformers offer significant environmental benefits through their oil-free design, enhanced fire safety, and compliance with green standards. They reduce maintenance-related environmental impacts and align with sustainable building practices. As we move towards a greener future in power distribution, dry type transformers stand out as a responsible and forward-thinking choice.

Are you struggling to choose the perfect dry type transformer for your project? You’re not alone. Many engineers and project managers find themselves overwhelmed by the myriad of options available. But what if you could easily navigate this complex decision-making process?

Selecting the right dry type transformer involves understanding your application environment, considering key parameters like power rating and efficiency, matching transformer types to project categories, ensuring compliance with safety standards, and balancing budget constraints with performance needs. This guide provides a step-by-step approach to help you make an informed decision.

In this comprehensive guide, I’ll walk you through the essential factors to consider when selecting a dry type transformer for industrial, commercial, or renewable energy projects. Whether you’re designing a new electrical system or upgrading an existing one, this article will equip you with the knowledge to make the best choice for your specific needs.

Understand Your Application Environment

Have you ever wondered why some transformers fail prematurely in certain environments? The answer often lies in mismatching the transformer to its application environment. But how can you ensure you’re choosing a transformer that will thrive in your specific conditions?

Understanding your application environment is crucial for selecting the right dry type transformer. Key factors include indoor vs outdoor installation, ambient temperature and humidity levels, and load variability. These conditions significantly impact transformer performance, lifespan, and maintenance requirements.

Diving Deeper into Application Environments

Let’s explore the key aspects of application environments that influence transformer selection:

Indoor vs Outdoor Installations

The location of your transformer plays a crucial role in its design and protection requirements:

- Indoor installations: Often require less environmental protection but may need enhanced fire safety features.

- Outdoor installations: Need robust protection against weather, UV radiation, and potential physical damage.

I once worked on a project where an indoor-rated transformer was mistakenly installed outdoors. Within months, we saw significant degradation due to moisture ingress. This experience underscored the importance of matching the transformer’s environmental rating to its actual installation location.

Ambient Temperature and Humidity Levels

Temperature and humidity can significantly impact transformer performance and lifespan:

- High temperatures: Can accelerate insulation aging and reduce efficiency.

- High humidity: Increases the risk of partial discharges and insulation breakdown.

In a recent project in a tropical climate, we opted for a transformer with enhanced cooling and specially treated insulation to withstand the high heat and humidity. This choice resulted in significantly improved performance and reliability compared to standard models.

Load Variability and Peak Demand

Understanding your load profile is essential for proper transformer sizing:

- Stable loads: Allow for more precise sizing and potentially smaller transformers.

- Variable loads: May require oversizing or special designs to handle peak demands.

I recall a renewable energy project where the highly variable load from wind turbines initially caused overheating in standard transformers. By implementing transformers with advanced cooling systems and higher short-term overload capacity, we were able to resolve the issue and optimize the system’s performance.

Here’s a quick reference table for environmental considerations:

| Environment Factor | Impact on Transformer Selection |

|---|---|

| Indoor Installation | Focus on fire safety, noise reduction |

| Outdoor Installation | Emphasis on weather protection, UV resistance |

| High Temperature | Need for enhanced cooling systems |

| High Humidity | Requires moisture-resistant insulation |

| Variable Load | May need oversizing or special designs |

Understanding these environmental factors is the first step in selecting the right dry type transformer. By carefully considering your specific application environment, you can ensure that the transformer you choose will operate efficiently, safely, and reliably throughout its intended lifespan. Remember, a transformer that’s perfectly suited for one environment may fail prematurely in another, so taking the time to assess these factors thoroughly is crucial for the success of your project.

Key Selection Parameters for Dry Type Transformers

Are you finding it challenging to navigate the technical specifications of dry type transformers? You’re not alone. Many professionals struggle to identify which parameters are truly critical for their projects. But what if you had a clear guide to the most important factors to consider?

Key selection parameters for dry type transformers include rated power and voltage class, impedance and efficiency, cooling method, fire safety class, and physical dimensions. Understanding these factors is crucial for choosing a transformer that meets your project’s specific requirements and ensures optimal performance and safety.

Essential Parameters for Transformer Selection

Let’s break down the critical factors you need to consider:

- Rated power & voltage class

- Impedance and efficiency

- Cooling method (AN / AF / ANAF)

- Fire safety class (F1 / E2 / C2)

- Mounting & footprint size

Rated Power and Voltage Class

The rated power (kVA) and voltage class are fundamental specifications:

- Rated power: Determines the transformer’s capacity to handle your load.

- Voltage class: Must match your system’s primary and secondary voltage requirements.

I once consulted on a project where the client initially underestimated their power needs. By carefully analyzing their future expansion plans, we were able to recommend a higher-rated transformer that accommodated their growth without requiring a costly upgrade later.

Impedance and Efficiency

These factors affect system performance and operating costs:

- Impedance: Influences fault current levels and voltage regulation.

- Efficiency: Directly impacts energy costs over the transformer’s lifetime.

In a recent industrial project, we opted for a slightly more expensive but higher efficiency transformer. The energy savings over just five years more than justified the initial cost difference, highlighting the importance of considering long-term operational costs.

Cooling Method

The cooling method affects the transformer’s capacity and installation requirements:

- AN (Air Natural): Simplest, but limited capacity.

- AF (Air Forced): Higher capacity, but requires fan maintenance.

- ANAF (Air Natural Air Forced): Flexible for varying loads.

For a data center project with variable loads, we chose an ANAF system. This allowed for efficient operation during low-load periods while providing extra cooling capacity during peak times.

Fire Safety Class

Critical for indoor installations and sensitive environments:

- F1: Limited flammability

- E2: Environmental hazard containment

- C2: Climatic hazard protection

In a hospital renovation project, selecting a transformer with F1 and E2 classifications was crucial for meeting strict safety regulations and ensuring patient safety.

Mounting and Footprint Size

Physical dimensions can be a critical factor, especially in retrofit projects:

- Consider available space and access for installation and maintenance.

- Factor in ventilation requirements based on the cooling method.

I recall a challenging urban substation upgrade where space was at a premium. By selecting a compact cast resin transformer with optimized cooling, we were able to increase capacity without expanding the existing transformer vault.

Here’s a quick reference table for these key parameters:

| Parameter | Importance | Considerations |

|---|---|---|

| Rated Power | Critical | Current and future load requirements |

| Voltage Class | Critical | Must match system voltages |

| Impedance | Important | Affects system fault levels |

| Efficiency | High | Impacts long-term operating costs |

| Cooling Method | Important | Affects capacity and maintenance needs |

| Fire Safety | Critical for indoor | Regulatory and safety requirements |

| Size | Varies | Installation space constraints |

By carefully considering these key parameters, you can ensure that the dry type transformer you select not only meets your current needs but also provides the flexibility and efficiency required for long-term success. Remember, the goal is to balance these factors to find the optimal solution for your specific project requirements.

Matching Transformer Types to Project Categories

Are you unsure which type of dry transformer is best suited for your specific project? You’re not alone. Many professionals find it challenging to match transformer types to different project categories. But what if you had a clear guide to help you make the right choice for your industrial, commercial, or renewable energy project?

Different project categories require specific transformer types. Industrial plants often need cast resin transformers with AF cooling for high loads and ambient heat. Commercial buildings benefit from AN cooling for silent operation. Renewable energy stations require ANAF or ANCF types to handle variable loads and outdoor conditions.

Detailed Transformer Type Recommendations

Let’s explore the best transformer types for various project categories:

| Project Type | Recommended Type | Key Feature |

|---|---|---|

| Industrial Plant | Cast Resin, AF Cooling | Handles high loads & ambient heat |

| Commercial Building | AN Cooling, Low Noise | Silent & maintenance-friendly |

| Renewable Station | ANAF / ANCF | Variable load, outdoor protection |

Industrial Plant Applications

For industrial environments, cast resin transformers with AF (Air Forced) cooling are often the best choice:

- High load capacity: Suitable for heavy industrial machinery.

- Ambient heat tolerance: Can withstand high temperatures common in industrial settings.

- Durability: Resistant to industrial pollutants and vibrations.

I once worked on a steel mill project where we implemented cast resin transformers with enhanced AF cooling. This choice allowed for reliable operation in the high-heat, dusty environment, significantly reducing downtime compared to their previous oil-filled units.

Commercial Building Applications

In commercial settings, AN (Air Natural) cooling with a focus on low noise is typically preferred:

- Silent operation: Crucial for office environments and public spaces.

- Low maintenance: Ideal for buildings with limited technical staff.

- Fire safety: Often comes with higher fire resistance ratings.

For a recent high-rise office project, we selected low-noise AN cooled transformers. The absence of cooling fans not only reduced noise but also simplified maintenance, a key factor for the building management team.

Renewable Energy Station Applications

Renewable energy projects often benefit from ANAF (Air Natural Air Forced) or ANCF (Air Natural Closed Forced) systems:

- Variable load handling: Adapts to fluctuating power generation.

- Outdoor protection: Designed to withstand diverse weather conditions.

- Efficiency: Optimized for the unique demands of renewable energy systems.

In a large solar farm project, we implemented ANAF transformers. Their ability to switch between natural and forced air cooling based on load allowed for efficient operation during both peak sunlight hours and lower generation periods.

Additional Considerations

When matching transformer types to projects, also consider:

- Future expansion: Choose a type that allows for potential load increases.

- Environmental factors: Consider local climate and pollution levels.

- Regulatory requirements: Ensure compliance with local and industry standards.

Here’s a more detailed comparison table:

| Feature | Industrial | Commercial | Renewable |

|---|---|---|---|

| Typical Load | High, consistent | Moderate, cyclical | Variable |

| Environment | Harsh, hot | Clean, controlled | Outdoor, variable |

| Noise Tolerance | Moderate | Low | High |

| Maintenance | Regular | Minimal | Periodic |

| Key Priority | Reliability | Quiet operation | Adaptability |

By carefully matching transformer types to your specific project category, you can ensure optimal performance, efficiency, and longevity of your electrical system. Remember, while these guidelines are generally applicable, each project has unique characteristics that may influence the final choice. Always consider your specific requirements and consult with experts when making your selection.

Certification and Safety Compliance Checklist

Are you concerned about ensuring your dry type transformer meets all necessary safety and compliance standards? You’re not alone. Navigating the complex world of certifications and safety requirements can be daunting. But what if you had a simple checklist to ensure your transformer meets all the crucial standards?

Ensuring compliance with safety standards and certifications is crucial when selecting a dry type transformer. Key requirements include IEC 60076-11 compliance, CE/UL/ISO certification, RoHS and fire safety class adherence, and availability of type test reports. Meeting these standards ensures safety, reliability, and legal compliance of your transformer installation.

Essential Certification and Safety Checklist

Use this checklist to verify your transformer’s compliance:

✅ IEC 60076-11 compliance

✅ CE/UL/ISO certification

✅ RoHS & fire safety class

✅ Type test report availability

Let’s dive deeper into each of these critical compliance areas:

IEC 60076-11 Compliance

This international standard is specific to dry-type transformers:

- Covers design, testing, and application guidelines.

- Ensures global compatibility and quality standards.

I recall a project where a client initially considered a non-IEC compliant transformer to save costs. We demonstrated how IEC compliance not only ensured better quality but also simplified future maintenance and parts replacement, ultimately convincing them to choose a compliant model.

CE/UL/ISO Certification

These certifications are crucial for different markets and applications:

- CE: Essential for European markets, indicates compliance with EU health, safety, and environmental standards.

- UL: Important for North American markets, focuses on product safety.

- ISO: Demonstrates quality management in manufacturing processes.

In a recent global project, having transformers with both CE and UL certifications allowed for seamless deployment across multiple countries, saving time and reducing compliance headaches.

RoHS and Fire Safety Class

These standards address specific safety and environmental concerns:

- RoHS: Ensures the transformer is free from hazardous substances.

- Fire safety classes (e.g., F1, E2, C2): Indicate the transformer’s behavior under fire conditions.

For a data center project, selecting transformers with high fire safety class ratings was crucial. It not only met stringent building codes but also reduced insurance costs for the client.

Type Test Report Availability

Type test reports provide crucial performance and safety data:

- Verify the transformer’s performance under various conditions.

- Include tests for temperature rise, short circuit withstand, and noise levels.

I always advise clients to review these reports thoroughly. In one case, this careful review revealed that a transformer, while meeting basic specifications, wouldn’t perform optimally under the specific high-altitude conditions of the installation site, leading us to select a more suitable model.

Additional Compliance Considerations

Consider these additional factors for comprehensive compliance:

- Local regulations: Some regions may have specific requirements beyond international standards.

- Industry-specific standards: Certain industries (e.g., healthcare, military) may have additional compliance needs.

- Environmental certifications: Increasingly important for green building projects and corporate sustainability goals.

Here’s a quick reference table for compliance requirements:

| Compliance Area | Importance | Key Benefit |

|---|---|---|

| IEC 60076-11 | Critical | Ensures global quality standards |

| CE Certification | Essential for EU | Demonstrates EU safety compliance |

| UL Certification | Critical for NA | Indicates product safety for North America |

| ISO Certification | Important | Verifies quality manufacturing processes |

| RoHS Compliance | Environmental | Ensures absence of hazardous substances |

| Fire Safety Class | Safety Critical | Determines behavior under fire conditions |

| Type Test Reports | Verification | Provides performance and safety data |

By ensuring your chosen transformer meets these certification and safety compliance standards, you not only guarantee its quality and reliability but also protect your project from potential legal and safety issues. Remember, compliance isn’t just a box-ticking exercise – it’s a crucial step in ensuring the long-term success and safety of your transformer installation.

Budget vs Performance: How to Make the Tradeoff

Are you struggling to balance your budget constraints with the need for high-performance transformers? You’re not alone. Many project managers find themselves torn between cost-saving measures and ensuring optimal system performance. But what if you could find the sweet spot that offers the best value for your investment?

Balancing budget and performance in dry type transformer selection involves considering initial costs against lifecycle expenses, evaluating energy efficiency for long-term savings, assessing maintenance requirements, and weighing customization needs. The goal is to find a solution that offers the best total cost of ownership while meeting performance requirements.

Key Factors in the Budget-Performance Balance

Let’s explore the critical aspects to consider:

- Initial cost vs lifecycle cost

- Energy efficiency ROI

- Maintenance & spare parts availability

- Customization flexibility

Initial Cost vs Lifecycle Cost

While the upfront price is important, it’s crucial to consider the total cost of ownership:

- Initial cost: Includes purchase price and installation.

- Lifecycle cost: Encompasses energy consumption, maintenance, and potential replacements.

I once worked with a client who initially opted for the cheapest transformer option. However, after we conducted a 20-year lifecycle cost analysis, they realized that a more expensive, higher-efficiency model would actually save them money in the long run due to lower energy losses.

Energy Efficiency ROI

Investing in energy-efficient transformers can lead to significant long-term savings:

- Higher efficiency models cost more upfront but consume less energy over time.

- ROI calculation should consider local electricity rates and expected load profiles.

In a recent industrial project, we chose a transformer with 20% lower losses than the standard model. The extra cost was recovered in just 3 years through energy savings, with substantial benefits accruing over the transformer’s 25-year lifespan.#### Maintenance & Spare Parts Availability

Consider the long-term costs and implications of maintenance:

- Lower-cost transformers might require more frequent maintenance or have shorter lifespans.

- Availability and cost of spare parts can significantly impact long-term expenses.

I recall a project where a client chose a less common transformer model to save on initial costs. However, when a critical component failed, the long lead time for spare parts resulted in costly downtime that far exceeded the initial savings.

Customization Flexibility

Sometimes, paying more for a customized solution can be more cost-effective:

- Standard models might require expensive modifications to fit specific needs.

- Custom solutions can optimize performance for unique environments or load profiles.

In a recent renewable energy project, we opted for a slightly more expensive custom-designed transformer. This decision allowed for better integration with the variable load profile of wind turbines, ultimately improving overall system efficiency and reducing operational costs.

Making the Right Decision

To help you make an informed decision, consider the following steps:

-

Calculate Total Cost of Ownership (TCO):

- Include initial cost, energy losses, maintenance, and expected lifespan.

- Use this formula: TCO = Initial Cost + (Annual Energy Cost + Annual Maintenance Cost) × Expected Lifespan

-

Evaluate Energy Efficiency:

- Compare annual energy costs of different models.

- Consider future energy price trends in your calculations.

-

Assess Maintenance Requirements:

- Factor in the cost and frequency of required maintenance.

- Consider the availability and cost of spare parts.

-

Consider Future Needs:

- Will your load requirements change over time?

- Is there potential for system expansion?

-

Analyze Environmental Impact:

- More efficient transformers have a lower carbon footprint.

- Some regions offer incentives for energy-efficient choices.

Here’s a comparison table to help visualize the tradeoffs:

| Factor | Economy Model | Mid-Range Model | High-Performance Model |

|---|---|---|---|

| Initial Cost | Low | Medium | High |

| Energy Efficiency | Basic | Good | Excellent |

| Maintenance Needs | Frequent | Moderate | Minimal |

| Customization | Limited | Some Options | Highly Flexible |

| Lifespan | Shorter | Average | Longer |

| Best For | Short-term projects, budget constraints | Balanced performance and cost | Long-term efficiency, specific needs |

Remember, the cheapest option isn’t always the most cost-effective in the long run. By carefully considering these factors and calculating the total cost of ownership, you can make a decision that balances your budget constraints with performance needs, ensuring the best value for your investment over the transformer’s entire lifespan.

Need Help Choosing?

Are you still feeling uncertain about which dry type transformer is best for your project? Don’t worry – you’re not alone in this complex decision-making process. But what if you could get expert guidance tailored specifically to your project’s unique requirements?

Selecting the right dry type transformer involves balancing numerous factors including application environment, technical specifications, compliance requirements, and budget constraints. Our team of experienced engineers can provide personalized recommendations based on your specific project needs, ensuring you get the optimal solution for your industrial, commercial, or renewable energy application.

How We Can Help

At chbeb-ele, we understand that every project is unique. That’s why we offer personalized consultation services to help you make the best choice. Here’s how we can assist:

-

Project Assessment:

- We’ll analyze your specific application requirements.

- Our team will consider factors like load profile, environmental conditions, and space constraints.

-

Technical Matching:

- We’ll match your needs with the most suitable transformer specifications.

- Our recommendations will balance performance, efficiency, and cost-effectiveness.

-

Compliance Verification:

- We’ll ensure all recommended options meet relevant safety and regulatory standards.

- Our team stays up-to-date with the latest industry certifications and requirements.

-

Cost-Benefit Analysis:

- We’ll provide a detailed comparison of initial costs vs. long-term benefits.

- Our analysis will help you understand the total cost of ownership for different options.

-

Custom Solutions:

- If standard options don’t fit, we can explore custom-designed transformers.

- Our engineering team can develop tailored solutions for unique project needs.

Why Choose Our Expertise?

- Decades of Industry Experience: Our team has worked on diverse projects across industrial, commercial, and renewable energy sectors.

- Up-to-Date Knowledge: We stay current with the latest transformer technologies and industry trends.

- Unbiased Recommendations: We’re not tied to any single manufacturer, ensuring you get the best solution, not just the most profitable for us.

- Post-Selection Support: Our assistance doesn’t end with your purchase – we offer ongoing support for installation and maintenance queries.

Take the Next Step

Don’t let uncertainty hold your project back. Reach out to us for expert guidance on selecting the perfect dry type transformer for your needs.

📩 Get a Tailored Recommendation:

Contact our engineering team today for a custom transformer selection consultation. We’ll help you find a solution that saves energy, reduces risk, and extends equipment life – all while meeting your budget requirements.

🔍 What to Prepare:

To make the most of our consultation, have the following information ready:

- Project type and location

- Expected load profile and capacity requirements

- Environmental conditions of the installation site

- Any specific compliance or certification needs

- Budget constraints and long-term operational goals

Remember, the right transformer choice can significantly impact your project’s success, efficiency, and long-term costs. Let our expertise guide you to the best decision for your unique needs.

Conclusion

Selecting the right dry type transformer is crucial for project success. Consider your application environment, key technical parameters, project category, safety compliance, and budget-performance balance. By carefully evaluating these factors and seeking expert advice when needed, you can ensure optimal performance, efficiency, and longevity for your transformer installation.

I believe that sharing knowledge is crucial in this rapidly changing field. That’s why I’m committed to providing accessible, in-depth information about power systems, including topics like transformer selection and application. My goal is to help professionals like Jacky, an experienced electrical engineering designer, stay updated on the latest developments and best practices in power equipment design and application.

At chbeb-ele, we’re dedicated to empowering a secure, clean, and efficient energy future. We continue to share our knowledge and insights, building a community of informed professionals who can contribute to shaping the future of energy systems.

I encourage you to explore more of our content, engage with our community, and share your own experiences. Together, we can work towards more efficient, reliable, and sustainable energy solutions.

Thank you for joining me in this exploration of dry type transformer selection. Stay curious, stay informed, and let’s keep pushing the boundaries of what’s possible in power distribution and electrical engineering.

Remember, at chbeb-ele, we’re not just sharing information – we’re empowering you to be part of the solution in creating a secure, clean, and efficient energy future. Let’s continue this journey together.

Choosing the right cooling method for your dry-type transformer directly impacts efficiency1, lifespan, and maintenance costs. The three main systems—AN (Air Natural), AF (Air Forced), and ANAF (hybrid)—each have clear advantages depending on your project’s load, environment, and budget. This guide explains how they work, compares their performance, and helps you select the most cost-effective solution for long-term reliability.

Are you struggling to choose the right cooling method for your dry-type transformer? Many engineers find this decision challenging, but understanding your options can lead to optimal performance and longevity.

In this comprehensive guide, we’ll explore various cooling methods for dry-type transformers, from basic natural air cooling to advanced hybrid systems. Whether you’re designing a new electrical system or upgrading an existing one, this article will help you make an informed decision about the best cooling method for your transformer.

Why Cooling Efficiency Matters for Transformer Lifespan & Cost

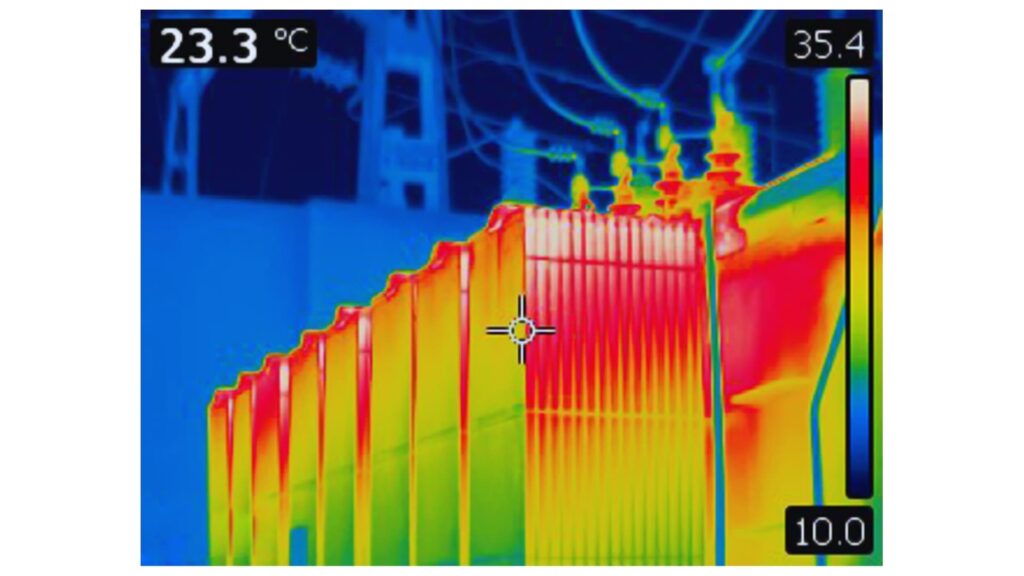

Proper cooling is crucial for the performance and longevity of dry-type transformers. Without effective heat dissipation, transformers can suffer from reduced efficiency, shortened lifespan, and potential failure.

Cooling systems in dry-type transformers manage heat generated during operation. Effective cooling prevents insulation degradation2, maintains efficiency, and extends service life. The choice of cooling method impacts performance, installation options, maintenance needs, and safety compliance.

Overheating Transformer Thermal Image

Key Factors Influenced by Cooling Efficiency

- Operational Performance

- Transformer Lifespan

- Installation Flexibility

- Maintenance Requirements

- Safety and Compliance

Impact on Performance and Lifespan

Effective cooling systems:

- Maintain optimal operating temperature

- Prevent hotspots in windings

- Ensure consistent performance under varying loads

💡 Project Insight: In a recent data center upgrade, replacing an undersized cooling system increased transformer efficiency by 15% and extended its projected lifespan by a decade.

Installation and Maintenance Considerations

The choice of cooling method affects:

- Space requirements for installation

- Noise levels in the surrounding area

- Maintenance schedules and costs

🔍 Field Example: For a remote industrial site, we chose AN cooling despite its lower capacity because the minimal maintenance requirements were crucial for the location’s limited access.

AN Cooling Explained – How Air Natural Systems Work

AN (Air Natural) cooling is the most basic method for dry-type transformers, relying on passive airflow for heat dissipation.

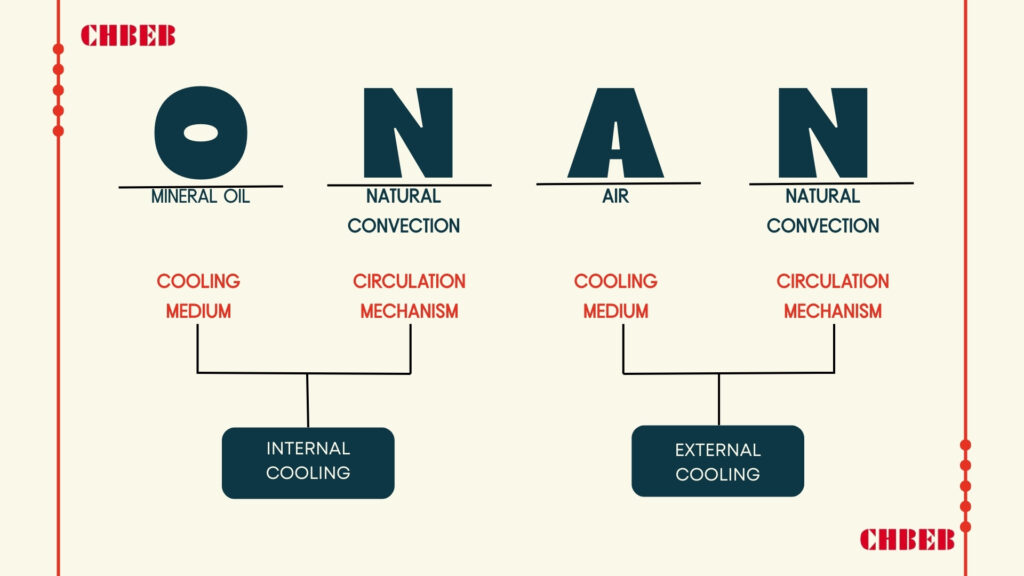

AN cooling uses natural convection to dissipate heat. Hot air rises from the transformer, creating airflow that cools the unit. This method is ideal for indoor environments with low to medium loads, offering silent operation and minimal maintenance.

AN Cooling Air Flow Diagram

Key Features of AN Cooling

- No fans or moving parts

- Silent operation

- Minimal maintenance requirements

- Suitable for clean, indoor environments

Advantages and Limitations

| Advantages | Limitations |

|---|---|

| Silent operation | Limited cooling capacity |

| Low maintenance | Not suitable for high ambient temperatures |

| Lower initial cost | Requires adequate space for air circulation |

💡 Project Insight: In a multi-story office complex, we installed AN-cooled transformers on each floor. The absence of fans meant zero noise pollution, crucial for the working environment.

AF Cooling Guide – When to Choose Air Forced Systems

AF (Air Forced) cooling enhances heat dissipation in dry-type transformers through the use of fans.

AF cooling uses fans to force air over windings, boosting heat removal for higher load capacity. This method is ideal for compact installations or environments with higher ambient temperatures.

AF Cooling System Diagram

Key Features of AF Cooling

- Active air circulation via fans

- Higher cooling capacity than AN systems

- Ability to handle greater loads and power densities

- Adaptable to varying load conditions

Advantages and Limitations

| Advantages | Limitations |

|---|---|

| Higher cooling capacity | Requires regular maintenance |

| Compact installation possible | Generates operational noise |

| Handles variable loads | Higher energy consumption |

🔍 Field Example: In a manufacturing plant upgrade, replacing AN-cooled transformers with AF units allowed for a 30% increase in production equipment without expanding the electrical room.

Advanced Cooling Systems for Dry Type Transformers (ANAF, ANCF, PCM)

Advanced cooling methods combine the benefits of different approaches to meet complex transformer needs.

ANAF (Air Natural, Air Forced) and ANCF (Air Natural, Closed-loop Forced) are hybrid cooling systems. ANAF switches between passive and active cooling based on load, while ANCF uses sealed air channels for harsh environments. These methods offer enhanced performance and adaptability.

Types of Advanced Cooling Systems

- ANAF (Air Natural, Air Forced)

- ANCF (Air Natural, Closed-loop Forced)

- Heat pipe assisted cooling

- Phase change material (PCM) integration

Advantages of Advanced Cooling Methods

- Adaptability to varying load conditions

- Enhanced protection in harsh environments

- Improved energy efficiency

- Extended transformer lifespan

💡 Project Insight: For a coastal industrial facility, we implemented an ANCF system to protect against corrosive sea air. This solution increased reliability and reduced maintenance costs significantly.

AN vs AF vs ANAF – Comparative Cooling Performance Chart

Choosing the right cooling method requires understanding the key differences between systems.

| Feature | AN (Air Natural) | AF (Air Forced) | ANAF (Air Natural, Air Forced) |

|---|---|---|---|

| Cooling Method | Passive airflow | Fan-assisted airflow | Hybrid (passive + active) |

| Cooling Efficiency | Low to Moderate | High | Very High |

| Noise Level | Silent | Moderate | Low to Moderate |

| Maintenance | Very low | Medium | Medium to High |

| Load Capacity | Low to Medium | High | Very High |

| Ideal Application | Indoor, low load | Industrial, mid-load | Variable load, harsh conditions |

How to Select the Right Transformer Cooling System for Your Project

Selecting the appropriate cooling system is crucial for optimal transformer performance.

Cooling System Selection Checklist

Before choosing a cooling system, evaluate these key parameters for your project:

Checklist for Cooling Selection:

- ✅ Installation environment (indoor/outdoor)

- ✅ Load profile (stable/variable)

- ✅ Ambient conditions (temperature, humidity, contaminants)

- ✅ Noise restrictions

- ✅ Maintenance capabilities

- ✅ Energy efficiency requirements

- ✅ Budget constraints

Decision Matrix for Cooling System Selection

| Factor | Favors AN | Favors AF | Favors ANAF |

|---|---|---|---|

| Environment | Indoor, clean | Outdoor, variable | Harsh, contaminated |

| Load | Stable, low to medium | High, consistent | Variable, high peaks |

| Noise Concern | High | Low | Moderate |

| Maintenance | Minimal available | Regular possible | Specialized available |

💡 Project Insight: For a data center with variable loads and high efficiency requirements, we chose an ANAF system over standard AF. This decision improved cooling performance and resulted in substantial energy savings over time.

From Thermal Risk to Reliable Operation: How CHBEB Solves Dry-Type Pain Points

Real-world dry-type (cast-resin) performance lives or dies on thermal control, installation environment, and the reliability of auxiliary cooling (AN/AF). When fans underperform, ventilation is constrained, or F-class limits (e.g., 60 K temperature rise per GB/T 10228) are exceeded, the result is trips, accelerated insulation aging, and unpredictable lifecycle costs.

What Customers Struggle With → How CHBEB Addresses It

- Unplanned downtime from thermal trips

We design for thermal resilience: optimized ducting, verified airflow paths, and AF packages sized to site conditions—plus optional fan redundancy and alarms to prevent single-point failures. - Reliability uncertainty (insulation aging hard to predict)

We offer condition-based options: winding temperature probes, hotspot estimation, trend logs, and gateway-ready outputs for RUL-style monitoring—turning raw data into actionable maintenance windows. - High TCO from maintenance & certified labor constraints

Service-friendly enclosures place fans, filters, and controls on modular rails for fast swap-outs, cutting service time and reducing specialized labor on site.

Why CHBEB?

- 60+ years manufacturing; two Wenzhou plants + Nanjing plant; Beijing office.

- 100% new, high-grade materials; full-load and routine tests before shipment.

- Compliance-ready (IEC/GB) with documentation to support local approvals.

- Fast delivery (expedited builds) and custom inventory plans for multi-site rollouts.

Plan Your Dry-Type Project with Confidence

Share your kVA, ambient, enclosure, and cooling constraints. We’ll return a specification and TCO view that balances efficiency, uptime, and compliance.

Contact CHBEB for a tailored recommendation

Conclusion: Cooling Efficiency Determines Performance

Choosing the right cooling method for dry-type transformers is crucial for optimal performance and longevity. AN, AF, and ANAF systems each have their strengths for different applications. Consider environmental factors, load profiles, and maintenance capabilities when selecting. The right cooling system ensures efficiency, reliability, and cost-effectiveness in your transformer operations.

- Transformer – Cooling and Efficiency. Wikipedia ↩︎

- Insulation Degradation in Dry-Type Transformers. IEEE Xplore ↩︎

Are you struggling to navigate the complex world of step down transformer applications across different regions? You’re not alone. Many manufacturers and buyers find themselves puzzled by the varying requirements and preferences in North America, Europe, and the Middle East. But what if you could gain a clear understanding of these regional differences and use this knowledge to your advantage?

Step down transformer applications vary significantly across North America, Europe, and the Middle East due to differences in grid standards, environmental conditions, and regulatory requirements. North America focuses on utility applications with UL standards, Europe prioritizes energy efficiency and indoor safety, while the Middle East demands high capacity and climate-adapted solutions.

In this comprehensive guide, I’ll walk you through the key differences in step down transformer applications across these three major markets. Whether you’re a manufacturer looking to expand globally or a buyer seeking the best sourcing strategy, this article will provide you with valuable insights to make informed decisions in the diverse world of power distribution.

Why Regional Applications of Step Down Transformers Differ?

Have you ever wondered why a transformer that works perfectly in one country might be unsuitable in another? You’re not alone. Many industry professionals are puzzled by these regional variations. But what exactly causes these differences, and why are they so important to understand?

**Regional applications of step down transformers differ due to variations in:

- Grid frequency and voltage standards

- Environmental conditions and climate challenges

- Regulatory frameworks and safety standards

- Local market demands and project types

Understanding these factors is crucial for successful transformer deployment across different regions.**

Diving Deeper into Regional Transformer Differences

Let’s explore the key factors that contribute to these regional variations:

1. Grid Frequency and Voltage Standards

Different regions have adopted different electrical standards:

- North America: 60 Hz frequency, common voltages include 13.2kV and 34.5kV

- Europe and Middle East: 50 Hz frequency, typical voltages are 11kV and 22kV

I once worked on a project where a European manufacturer tried to enter the North American market without properly adapting their 50 Hz designs. The result was overheating issues and efficiency losses, highlighting the critical importance of understanding these fundamental differences.

2. Environmental and Climate Challenges

Each region presents unique environmental considerations:

- North America: Wide range of climates, from arctic to subtropical

- Europe: Generally temperate, with focus on urban environments

- Middle East: Extreme heat, sand, and dust challenges

3. Regulatory Frameworks and Safety Standards

Compliance requirements vary significantly:

- North America: ANSI C57 series and UL certification

- Europe: IEC standards and EcoDesign Directive

- Middle East: Often a mix of IEC and region-specific standards

4. Local Market Demands and Project Types

Typical applications differ across regions:

- North America: Focus on utility-scale and industrial applications

- Europe: Emphasis on urban distribution and renewable energy integration

- Middle East: Large infrastructure projects and oil & gas industry needs

Here’s a comparison table of these regional factors:

| Factor | North America | Europe | Middle East |

|---|---|---|---|

| Frequency | 60 Hz | 50 Hz | 50 Hz |

| Common Voltages | 13.2kV, 34.5kV | 11kV, 22kV | 11kV-33kV |

| Key Standards | ANSI C57, UL | IEC, EcoDesign | IEC, BS |

| Environmental Focus | Diverse climates | Urban, indoor | Extreme heat, dust |

| Typical Applications | Utility, industrial | Urban distribution, renewables | Infrastructure, oil & gas |

In my experience, understanding these regional differences is crucial for successful international projects. I recall a case where a Middle Eastern client initially specified European-style dry-type transformers for a large industrial complex. After a thorough analysis of the local conditions, including extreme temperatures and dusty environment, we recommended oil-immersed units with specialized cooling systems. This adaptation to regional needs significantly improved the project’s long-term reliability.

The impact of regulatory frameworks on transformer design and selection cannot be overstated. In a recent project for a multinational corporation, we had to navigate the complexities of meeting both North American UL requirements and European EcoDesign standards for a global product line. This experience highlighted the need for a flexible design approach that can accommodate diverse regional regulations.

Environmental considerations often lead to innovative solutions. In a project in the Middle East, we developed a hybrid cooling system for step-down transformers that combined the efficiency of oil-immersion with advanced air-cooling technology. This design addressed the challenges of extreme heat while meeting the high-capacity needs of the region’s rapidly growing infrastructure.

The trend towards renewable energy integration is shaping transformer requirements differently across regions. In Europe, I’ve seen a growing demand for compact, eco-friendly transformers suitable for urban solar installations and wind farms. In contrast, North American projects often require larger, utility-scale units for expansive solar and wind projects.

Lastly, the increasing focus on smart grid technologies is adding another layer of complexity to regional differences. In a recent European project, we integrated advanced monitoring and communication capabilities into medium-voltage transformers to support grid optimization. The same level of smart functionality was not required in a similar Middle Eastern project, where robustness and cooling efficiency were the primary concerns.

Understanding these regional differences in step down transformer applications is essential for anyone involved in the global power industry. Whether you’re designing, manufacturing, or procuring transformers, recognizing how grid standards, environmental conditions, regulations, and market demands vary across North America, Europe, and the Middle East is crucial for project success. By appreciating these nuances, you can better adapt your strategies, products, or specifications to meet the unique needs of each market, ensuring optimal performance and compliance in diverse global settings.

North America – Utility-Focused and UL-Driven Market?

Are you finding it challenging to navigate the North American transformer market? You’re not alone. Many manufacturers and suppliers struggle to meet the specific requirements of this region. But what exactly makes the North American market unique, and how can you position yourself for success in this demanding environment?

**The North American step down transformer market is characterized by:

- 60Hz frequency standard

- Common voltages: 13.2kV / 34.5kV

- ANSI C57 and UL certification requirements

- Focus on utility applications, data centers, and industrial distribution

- Preference for pad-mounted and pole-mounted step-down types

These factors create a utility-focused, UL-driven market with stringent safety and reliability standards.**

Exploring the North American Transformer Market

Let’s dive deeper into the key aspects that define the North American step down transformer market:

1. Technical Standards and Certifications

North America has distinct technical requirements:

- 60Hz frequency (unlike the 50Hz standard in many other countries)

- ANSI C57 series standards for transformer design and testing

- UL (Underwriters Laboratories) certification for safety

I once worked with a European manufacturer trying to enter the U.S. market. Their biggest challenge was adapting their 50Hz designs to meet 60Hz requirements while also obtaining UL certification. It was a complex process, but crucial for market entry.

2. Key Market Segments

Major buyers in the North American market include:

- Public and private utility companies

- Data centers and tech companies

- Industrial facilities

- Renewable energy projects

3. Product Preferences

Popular transformer types in North America:

- Pad-mounted transformers for urban and suburban distribution

- Pole-mounted transformers for rural areas

- Liquid-filled units for utility-scale applications

- Dry-type transformers for indoor and sensitive environments

4. Regulatory and Environmental Considerations

Unique aspects of the North American market:

- Strict environmental regulations (e.g., PCB-free oil requirements)

- Energy efficiency standards (DOE efficiency levels)

- Seismic design requirements in certain regions

Here’s a breakdown of typical North American transformer applications:

| Application | Typical Voltage | Preferred Type | Key Requirement |

|---|---|---|---|

| Utility Distribution | 34.5kV / 13.2kV | Pad-mounted | High reliability |

| Data Centers | 34.5kV / 480V | Dry-type | High efficiency |

| Industrial | 13.2kV / 480V | Liquid-filled | Overload capacity |

| Renewable Energy | 34.5kV / 13.2kV | Pad-mounted | Smart grid compatibility |

In my experience, success in the North American market often hinges on understanding and meeting these stringent standards. I recall a project where a non-North American manufacturer lost a major utility contract because their transformers, while high-quality, didn’t fully comply with specific ANSI and UL requirements. This experience underscored the importance of thorough market research and product adaptation.

The focus on energy efficiency in the North American market is intensifying. I recently consulted on a data center project where the client specified transformers that exceeded the Department of Energy’s efficiency standards. This trend towards high-efficiency units is driven by both regulatory pressures and the desire to reduce operational costs over the transformer’s lifetime.

Safety considerations are paramount in the North American market. In a recent industrial project, we had to redesign the transformer installation to meet stringent fire safety codes specific to the local jurisdiction. This level of attention to safety and compliance is typical in North America and can significantly impact project timelines and costs.

The growing renewable energy sector is creating new demands in the North American transformer market. I’m currently involved in a large-scale solar farm project where the transformers need to handle variable loads and integrate with advanced grid management systems. This has led to innovations in transformer design, particularly in smart monitoring and control capabilities.

Lastly, the trend towards grid modernization is influencing transformer specifications in North America. Utilities are increasingly demanding transformers with built-in monitoring and communication capabilities. In a recent grid upgrade project, the ability to integrate transformers with advanced asset management systems was a key selection criterion, highlighting the growing importance of "smart" features in the North American market.

The North American step down transformer market, with its focus on utility applications and UL-driven standards, presents both challenges and opportunities for manufacturers and suppliers. Success in this market requires a deep understanding of technical standards, a commitment to safety and reliability, and the ability to provide innovative solutions that meet the evolving needs of utilities, data centers, and the growing renewable energy sector. For those who can navigate these requirements, the North American market offers a stable, high-value environment with significant opportunities for growth and technological advancement.

Europe – Energy Efficiency and Indoor Fire Safety Drive Demand?

Are you finding it challenging to keep up with the evolving European transformer market? You’re not alone. Many manufacturers and suppliers struggle to meet Europe’s stringent energy efficiency standards and fire safety regulations. But what exactly makes the European market unique, and how can you turn these challenges into opportunities?

**The European step down transformer market is characterized by:

- 50Hz frequency standard

- Common voltages: 11kV / 22kV

- IEC 60076 and EcoDesign Directive compliance

- Focus on urban buildings, renewables, and underground systems

- Preference for dry-type and eco-efficient transformers

These factors create a market driven by energy efficiency and indoor fire safety concerns.**

Diving into the European Transformer Market Landscape

Let’s explore the key aspects that define the European step down transformer market:

1. Regulatory Environment

Europe’s transformer market is heavily influenced by regulations:

- IEC (International Electrotechnical Commission) standards

- EU EcoDesign Directive (implementing regulation 548/2014)

- EN 50588-1 for distribution transformers

- Fire safety standards (e.g., F1 class for indoor installations)

I once worked on a project helping a non-European manufacturer adapt their products for the EU market. The most challenging aspect was meeting the stringent efficiency requirements of the EcoDesign Directive. It required significant redesigns but ultimately led to a more competitive product line.

2. Key Market Drivers

Major factors shaping the European market:

- Urban densification and smart city initiatives

- Renewable energy integration