In-Depth Analysis: The Core Value and Applications of Cast Resin Transformers | CHBEB

Cast Resin Transformer: Definition, Types, Benefits, Applications, Maintenance

Introduction

If you pick the wrong transformer, you could have safety problems, downtime, and exorbitant expenditures. Buyers often can’t decide between oil-based and dry-based solutions. Cast resin transformers are a safe, environmentally sustainable, and low-maintenance choice that works well for current projects in Southeast Asia, Africa, and the Middle East.

Technical Guide: Definition, Principles & Unique Advantages of Cast Resin Transformers

People are taking longer to make decisions because they are confused about cast resin transformers. If purchasers don’t comprehend clearly, they can spend too much or pick the wrong models. Here is how they function and why they are important.

What is a cast resin transformer, and what are its core concepts?

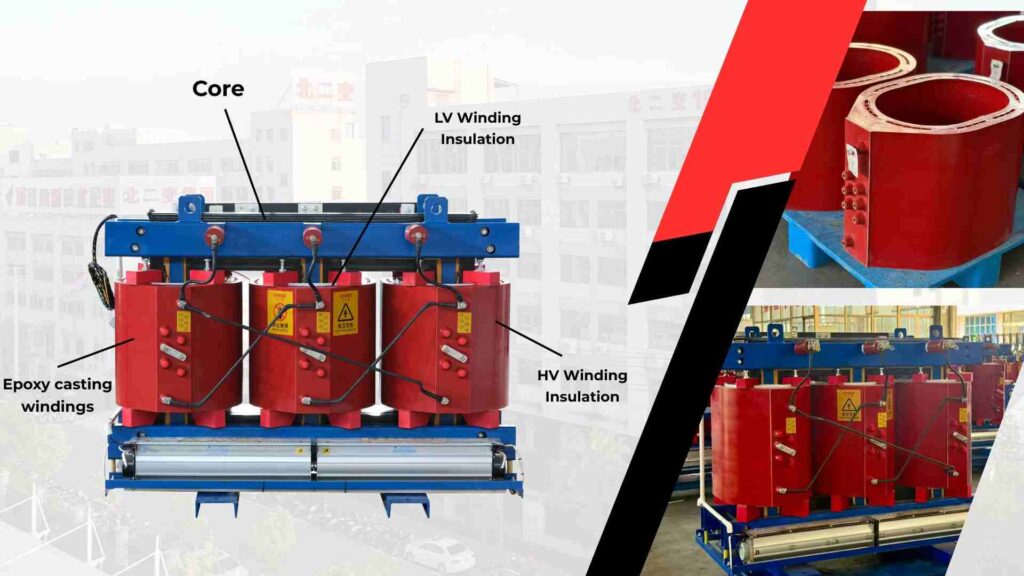

A cast resin transformer, also called an epoxy dry-type transformer or SCB transformer1, is a dry-type transformer that has its windings and core covered in epoxy resin2.

- Made via vacuum casting and making molds.

- Insulation that doesn’t catch fire and keeps moisture out.

- Gets rid of oil, which lowers the chance of leaks and fires.

👉 People in humid Southeast Asia generally choose cast resin over other materials to avoid problems caused by moisture.

Five main benefits of cast resin technology that make it better than other technologies

Why do so many people choose cast resin? Here are the five most important reasons:

- Epoxy resin is flame-resistant, so it is quite safe from fire.

- Great electrical performance; it can handle partial discharge3 and short circuits.

- No oil or regular fluid testing is needed, so it’s easy to take care of.

- Good for the environment—uses less energy and doesn’t pollute.

- Small and sturdy—resin encapsulation gives them exceptional mechanical integrity.

👉 These benefits make them a good alternative for hospitals, data centers, and metro projects.

Applications Guide: From Types to Scenarios, Find Your Ideal Match

Buyers often get confused when they don’t know what kinds of things are available and how to use them. If you guess wrong about someone’s ability or the situation, you could end up with a costly mismatch. Here are the categories and examples of how to use them.

SCB Series and Other Special Models Are Common Classifications

The SCB series (standard epoxy cast resin dry-type transformer) is the one that people use the most. There are other types, such as:

- SCB10/11—made to use less energy

- SCB14 has a low partial discharge and is very reliable.

- Special models made for usage in mining, maritime, or renewable energy

👉 Buyers should choose the proper SCB model based on the load profile and standards of their project.

Common Uses: Projects That Need to Pick Cast Resin Transformers

Cast resin transformers are great for places that need a lot of safety and dependability:

- Shopping malls, hospitals, and office towers are examples of indoor installations.

- Chemical facilities and refineries are areas where fires are likely to happen.

- Infrastructure projects include airports, metros, and data centers.

- IP54/IP65 protective enclosures for outdoor areas

👉 Cast resin units are preferred in African electrification schemes because they require less maintenance and are safe.

Maintenance Guide: The Truth About “Maintenance-Free” and Daily Care

A lot of people think that “maintenance-free” means no effort at all. Here, misunderstandings can shorten the life of things and make them less reliable. You still need to take care of it every day.

No need for maintenance for life? What You Need to Know About Daily Care

Transformers made of cast resin don’t need much upkeep, but they do need some. Important care includes:

- Regularly getting rid of dust to maintain airways clear

- Testing for partial discharge every so often

- Checks for insulation resistance and withstand voltage

- Checking the temperature during high loads

👉 Buyers don’t have to monitor the oil, but they do need to plan for testing at commissioning and regular overhauls.

Emerging Chinese Manufacturers

CHBEB — Reliable Partner for Distribution Transformers

With over 60 years of transformer manufacturing expertise, CHBEB has become one of China’s most trusted distribution transformer suppliers. The company operates two factories in Wenzhou, one in Nanjing, and an office in Beijing, ensuring both strong production capacity and responsive customer support.

What makes CHBEB stand out:

- Strict Quality Commitment: All raw materials are 100% new and high-grade — no recycled or downgraded components.

- Proven Reliability: A qualified supplier for the State Grid Corporation of China, with a spotless record of zero major accidents.

- 100% Product Testing: Every unit is fully tested before delivery to guarantee safety, efficiency, and long service life.

- Fast-Track Orders: Ability to fulfill urgent orders in as little as one week, helping customers meet tight project deadlines.

- Custom Inventory Planning: Flexible stocking and supply strategies designed to align with customer procurement schedules.

- Global Outlook: Rooted in China and expanding worldwide, CHBEB actively supports local agents and partners, including assistance with market-specific certifications.

- Flexible Customization: Tailored transformer designs for utilities, contractors, and industrial clients, with reliable quality and fast delivery.

👉 Looking for a distribution transformer manufacturer that combines Chinese manufacturing strength with international standards?Contact CHBEB for a tailored solution or Download our full transformer catalog here.

Conclusion

Choosing the right cast resin transformer is not just about fire safety—it’s about ensuring long-term reliability, compliance, and cost control for your project.

✅ Key takeaway for buyers:

- Match the right SCB model to your load profile and standards.

- Verify IEC/ISO certifications and request partial discharge reports.

- Plan ahead for commissioning tests and periodic checks.

With 60+ years of experience, CHBEB supports global partners with certified solutions and proven export expertise, helping you secure reliable performance in 2025 and beyond.

📞 Contact CHBEB today for the 2025 cast resin transformer price list and technical catalog.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group