Vetting Chinese Transformer Manufacturers 2025 | Debunking “Top 100” & Choosing the Right Partner | CHBEB

The “Top 100” Myth Debunked: Your Ultimate Guide to Vetting Chinese Transformer Manufacturers

Introduction

There is illusory confidence in endless “Top 100” lists. Buyers look for names, but then they run across problems like mismatches, delays, and hidden fees. The answer is a vetting system that puts needs first and uses evidence to match providers to your scope, standards, and risk tolerance.

Why There Isn’t a Single “Best” Ranking: Debunking the Myth

Ranking tables don’t take into account your voltage class, kVA, losses, environment, timing, or after-sales needs. Too much dependency might cause overspec or failure. To address this, you need to figure out what “best” means for your project and then compare vendors based on those exact standards.

Search Intent Analysis: What Is the “Best” Transformer for You?

Distribution, GSU, step-up/step-down, rectifier, furnace, and traction are all functions.

Spec anchors include kVA, voltage class, impedance, cooling, assured losses, and noise.

Commercial anchors: Capex vs. Opex, delivery timeframe, warranty/service SLAs, and location constraints.

The Chinese Transformer Market: Top Players by Application Segment

Chinese Transformer Supplier Divides by Use

| Application Segment | Typical Supplier Profile | What They’re Good At | Key Watchouts |

|---|---|---|---|

| Utility / UHV & HVDC1 | State-owned groups, national labs | EHV/UHV, type tests, large bays | Longer planning cycles |

| Renewables (Wind/Solar GSUs) | Export-oriented mid-tier | Fast lead times, IEC docs, flexible MOQs | Validate loss guarantees |

| Industrial / Process | Regional specialists | MV distribution, custom accessories | After-sales capacity |

| Data Centers / Metro / Hospitals | Dry-type specialists | Low fire-load, low noise, indoor design | Thermal management & ventilation |

📌 Regional Outlook: Chinese transformer makers are big suppliers for Belt & Road markets, which include Southeast Asia, Africa, the Middle East, and Russia, in addition to their own projects. In these areas, affordable prices, reliable logistics, and established IEC certificates are frequently the most important factors. This makes mid-tier and regional firms attractive candidates.

Evaluate and Vet: How to Find Your Perfect Partner

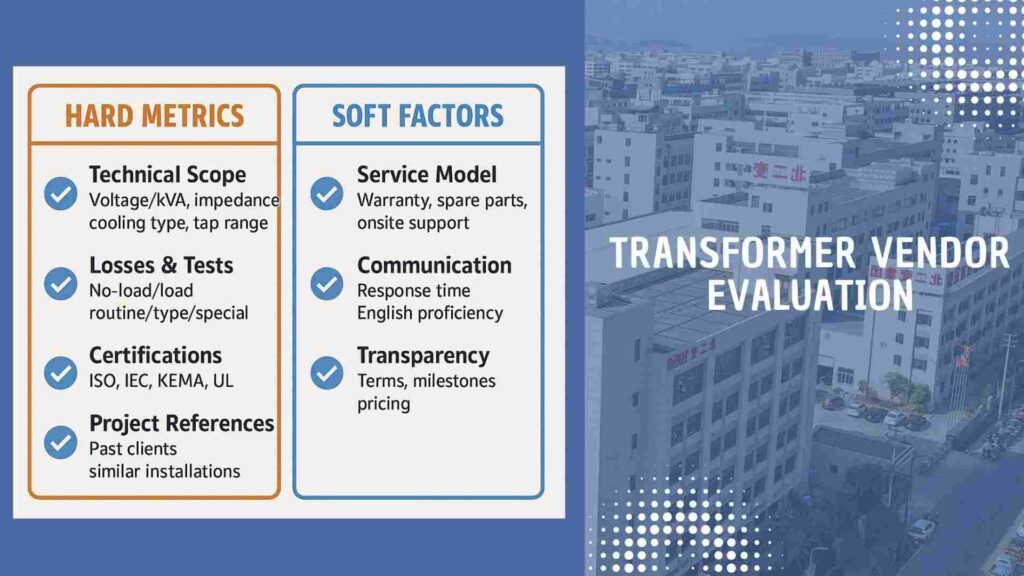

Hard Metrics: Technical Strength, Quality Certifications, and Experience on Projects

Voltage/kVA, impedance, temperature rise, cooling (AN/AF/ONAN/ONAF/ODAF), and tap range are all parts of the technical scope.

Losses and tests: No-load/load losses are guaranteed, and there are routine, type, and special tests with acceptance criteria.

ISO9001/14001/45001, IEC compliance, CE, and sectoral certifications (such KEMA2/UL) when they are needed.

References: installations with similar duties, grid/EPC projects, FAT reports, and clients that can be reached.

💡 Keep in mind that these factors are most important for EPC contractors, utilities, and big infrastructure buyers who need to follow the rules very closely.

Soft factors: service, communication, and clear pricing

Service model: warranty conditions, how long it takes to get spare parts, and when they can come to your site.

Communication: how quickly engineers respond, how well they write in English, and how they handle changes.

Transparency: explicit Incoterms, milestone plan, fines, and itemized offers.

The Rise of Smart and High-Efficiency Transformers: Trends to Watch in 2025

Higher efficiency classes: stricter loss targets are pushing upgrades to the core and winding.

Digitalization: sensors, thermal modeling, partial discharge, and diagnostics from afar.

Eco-fluids and safety: natural esters that are safe for the environment and fire.

Contracting shift: More customers are making payments based on performance testing and losses.

A Safe and Effective Way to Buy Things

Five Steps to Check Out a Transformer Supplier

- Define and RFQ: List kVA, voltage, losses, cooling, standards, FAT scope, and delivery.

- Evaluate and Compare: Make sure that technical offers, credentials, and references are all in line with one other; make sure that all offers are the same.

- Audit & Validate: Check certificates with the people who gave them to you, do an on-site or video audit, and make a quality control plan before the award.

- Contract and Safeguards: Set milestones, LDs, and a list of spare parts to protect against losses.

- Build, FAT, and Handover: Approve the drawings, watch the FAT, and make sure the packing, insurance, and customs documents are all in order.

Risk Management: Important Things to Know About Payment Security and Quality Control

Safety of payments: Use L/C or milestone payments that are linked to drawings, FAT, or shipment. Use an escrow account for spare parts.

QC checkpoints: ITP with hold/witness points; third-party (SGS/TÜV) inspections before shipping.

Control of documents: changes to drawings, material certificates, test records, and warranty contacts.

Logistics and insurance: checked packing specs, shock/tilt indications, all-risk freight protection, and a checklist for receiving.

FAQ – Chinese Transformer Makers 2025

Q1: Which company makes the best Chinese transformers?

There isn’t one “best” for everyone. Your kVA, voltage, standards, and budget will help you find the perfect partner. State-owned companies are good for UHV, whereas mid-tier suppliers are good for industrial and renewable consumers.

Q2: How can I check out a transformer provider in China?

Check IEC and ISO certifications, make sure the project references are real, and check the certificates with the people who gave them. Third-party audits, such as SGS or TÜV, provide you even more peace of mind.

Q3: How much does a transformer usually cost in China in 2025?

FOB China, distribution transformers cost between $20 and $45 per kVA. For instance, a 1000 kVA 11/0.4 kV unit usually costs between $25,000 and $40,000 FOB. CIF quotes change depending on where they are going.

Q4: How long does it take to get in-stock and custom transformers?

In stock: 2 to 4 weeks, which is great for projects that need to be done quickly.

Depending on the design and testing, custom constructions can take 10 to 14 weeks or longer.

Q5: Do Chinese transformer vendors allow OEM customization?

Yes. Many manufacturers offer OEM/private-label builds with custom ratings, tap changers, and extras.

Conclusion

There is no universal “Top 100” transformer supplier list—only the right partner for your specific project. Define what “best” means for you in terms of capacity, voltage class, efficiency, certifications, delivery, and service model.

Then, apply a structured vetting process:

- Check hard metrics — kVA, voltage, losses, IEC/ISO/KEMA compliance, and proven project references.

- Weigh soft factors — service guarantees, communication, and transparent pricing.

- Secure safeguards — milestone payments, third-party inspections, and itemized contracts.

✅ Final takeaway: The best choice is not a name on a ranking, but the supplier that minimizes your risks and maximizes your ROI. With clear criteria and disciplined procurement, buyers can source reliable oil-immersed, dry-type, or low-loss transformers from China—on budget, on time, and with confidence.

Learn More

Looking for the right dry-type transformer for your project? Download our latest product catalog or browse our product categories to find reliable solutions tailored to your needs.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group