Custom Transformer Enclosures | OEM/ODM Design & UL/NEMA Certified Manufacturing | CHBEB

Introduction

When a transformer enclosure fails, it’s never just a box issue — it’s a performance, safety, and certification problem. A trusted OEM/ODM partner ensures your enclosure protects, cools, and complies with every standard, adding real engineering value from CAD design to global certification.

Design Driven by Demand: The Core Value and Engineering Elements of OEM/ODM

Every project starts with a purpose — and a demand. Whether it’s for desert heat, coastal humidity, or Compact substations and custom transformer enclosures are made to fit the rules and conditions of the location.

What is OEM/ODM and how can it help you save money and time when bringing a product to market?

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) models are key parts of the transformer supply chain. OEM focuses on making things to client specifications, while ODM adds engineering and design skills to create new solutions from start.

For transformer firms, this two-part service means:

- Shared tools and modular engineering help keep costs down.

- Ready compliance documents help you get to market faster.

- Scaling up from prototype to mass production is easy.

- Standards stay consistent around the world.

OEM/ODM is more than outsourcing — it brings technical knowledge into your supply chain to ensure every enclosure fits your brand and certification goals.

Core Engineering: Balancing Heat Dissipation, IP Protection, and Corrosion Resistance

Custom enclosures are more than just metal shells. They are designed systems that control airflow, heat, and stress on the environment.

Three main design problems determine how well an enclosure works:

- Getting rid of heat

Transformers always make heat. Engineers employ CFD (Computational Fluid Dynamics) models to improve the design of vents, the flow of air inside, and the routes for natural and forced cooling. A good thermal balance keeps the winding from breaking down and keeps the electrical efficiency steady. - Protection for IP

IP (Ingress Protection)1 ratings tell you how well the case protects against dust, rain, and accidental touch. Outdoor units usually have an IP54 to IP65 rating. They use waterproof gaskets and permeable membranes to keep condensation from forming while still letting pressure equalize. - Resistance to Corrosion

Hot-dip galvanizing, zinc-aluminum plating, or marine-grade powder coating are all examples of anti-corrosive coatings that are needed in coastal or chemical environments. ASTM B117 salt-spray testing checks the longevity of a coating after years of exposure.

A well-planned enclosure isn’t just created; it’s meant to last by balancing electrical safety, environmental durability, and appearance.

Manufacturing and Compliance: Key Steps for Quality and Global Market Access

Each step of the fabrication process, from design validation to powder coating, affects how effectively the finished product works in the field and how well it passes certification.

Fabrication Process: From Material Selection to Powder Coating Technology

1. Choosing the right materials

Depending on the project’s needs, materials usually include cold-rolled steel, aluminum, or stainless steel (304/316).

2. Laser cutting and CNC bending

Precision manufacturing reduces gaps, distortion, and sharp edges to keep IP and NEMA ratings consistent.

3. Assembly and welding

MIG/TIG welding or rivet bonding ensures clean seams and strong structure. All joints are inspected for cracks or holes before surface treatment.

4. Surface preparation and powder coating

Surfaces are cleaned, sandblasted, and chemically treated (phosphate or chromate). Powder coating is then cured at 180–200 °C to create a durable and color-stable finish.

5. Final check and testing

Each enclosure is tested for size, door alignment, IP water spray, and grounding continuity.

The end result is a strong, rust-proof container that looks good and performs well.

Quality Assurance: UL, NEMA Ratings, and the “First-Time Pass” Compliance Strategy

Global markets demand conformity with several certification systems:

| Region | Standard | Key Requirements |

|---|---|---|

| North America | UL 50 / NEMA 250 | Enclosure construction, gasket integrity, corrosion resistance |

| Europe | IEC 62208 / EN 60529 | Electrical insulation, ingress protection, dielectric strength |

| Middle East & Asia | GCC, SASO, GB Standards | Temperature rise limits, earthing reliability, mechanical strength |

Getting a “First-Time Pass” rating on a certification test shows that design control is strong. This means:

- Pre-certification testing (salt spray, impact, dielectric)

- Strict documentation control for materials and processes

- Continuous feedback between manufacturing and QC teams for improvement

OEM/ODM providers may deliver enclosures ready for UL, CE, or IEC labeling, cutting weeks off client approval time.

Partnership and Delivery: Custom Project Workflow, Lead Times, and Quick Q&A

Strong relationships convert complicated technical jobs into solutions that can be predicted and scaled. Communication, accuracy, and clear goals are key to the success of custom enclosure manufacture.

The Custom Project Workflow: Six Critical Stages from Blueprint to Final Delivery

- Design Input & Feasibility Review – The client provides drawings or performance targets. Engineers verify mechanical fit, IP class, cooling requirements, and compliance feasibility.

- 3D CAD Modeling & Simulation – Detailed CAD designs are created with airflow and strength simulations. Prototypes may be 3D-printed for dimensional validation.

- Prototype Fabrication & Testing – One or two units are built to test fit, finish, and performance under IP or temperature-rise conditions.

- Client Approval & Mass Production – After approval, batch manufacturing begins under standardized work instructions and inspection checkpoints.

- Final QC & Certification Support – Each unit is inspected according to UL/NEMA or IEC standards, and compliance reports are generated for client submission.

- Packaging & Delivery – Enclosures are packaged with vibration protection and moisture-proof wrapping, shipped domestically or exported with HS coding and certificate of origin.

Lead Time

- Standard prototypes: 7–15 days

- Batch production: 25–40 days (depending on quantity and coating process)

- Export logistics: 10–20 days (sea or air freight)

Project Delivery Q&A

Q1: Can you match my existing transformer design?

Yes. OEM services can reproduce enclosures directly from your CAD drawings or samples while maintaining IP, NEMA, and certification consistency.

Q2: Do you provide certification support?

All products can be built and pre-tested for UL, CE, and IEC standards, complete with inspection and traceability reports to streamline client approval.

Q3: What’s the minimum order quantity?

Typically 1–5 units for prototype, scalable to full production batches once the design is approved.

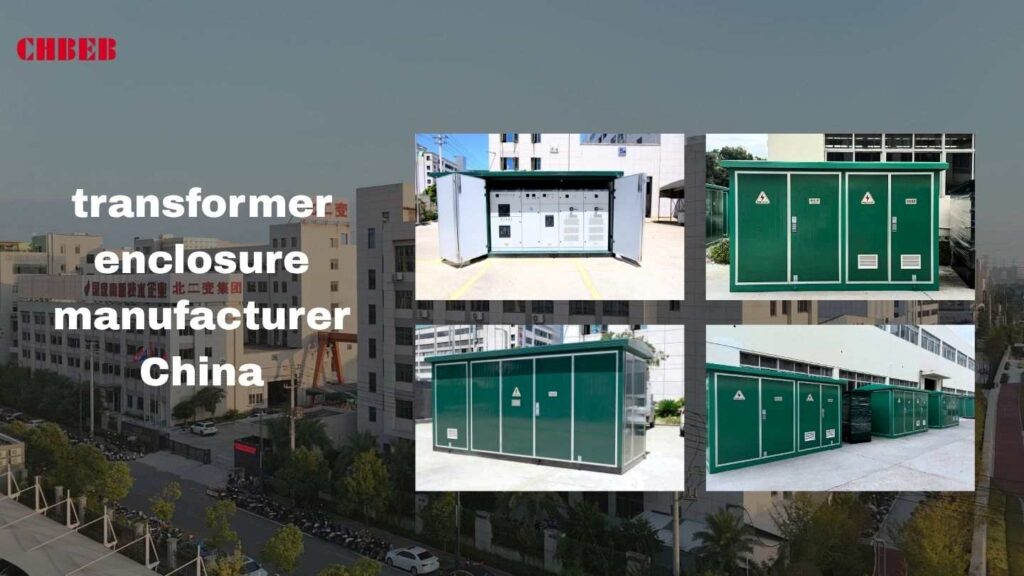

⚙️ CHBEB — Reliable Partner for OEM/ODM Transformer Enclosure Solutions

Behind every compliant, high-performance transformer enclosure is not just steel and paint — it’s engineering precision and manufacturing discipline.

With over 60 years of transformer expertise, CHBEB provides full-spectrum OEM/ODM services from CAD design to certification-ready mass production.

What Makes CHBEB Different

- Engineering Integration: In-house R&D runs CFD airflow simulations, structural analysis, and pre-certification testing to ensure long-term performance under all IP/NEMA conditions.

- Smart Manufacturing: CNC cutting, laser welding, and automated powder-coating lines deliver micron-level accuracy and repeatable quality.

- Global Compliance: Products are designed to meet UL 50, NEMA 250, IEC 62208, and EN 60529 standards, supported by full material traceability and documentation.

- Durability That Lasts: Marine-grade coatings, 316 stainless or galvanized steel options, and salt-spray testing guarantee reliability in coastal or industrial environments.

- Worldwide Delivery: With factories in Wenzhou and Nanjing, plus a logistics center in Beijing, CHBEB ensures fast OEM fulfillment and exports to over 30 countries across Asia, Africa, Russia, and the Middle East.

From prototype to production, CHBEB helps transformer manufacturers, EPC contractors, and utilities turn complex enclosure requirements into certified, globally accepted products — built to perform, built to last.

👉 Looking for a partner who combines Chinese manufacturing strength with global engineering standards? Contact CHBEB for a tailored technical proposal or download our full catalog today.

Frequently Asked Questions (FAQ): Custom Transformer Enclosures

Q1. OEM vs. ODM2 enclosures — what’s the real difference?

OEM: You provide drawings and specs — we manufacture exactly to print.

ODM: You provide functional goals — we co-engineer structure, cooling, and compliance.

Tip: Finished design? Go OEM. Need technical input and testing? Choose ODM.

Q2. How long does a custom enclosure take?

Prototype: 7–15 days

Batch production: 25–40 days

Export: 10–20 days

Locking coating and gasket specs early saves time and ensures fast certification.

Q3. Which coating is most durable — powder or liquid?

Powder coating forms a tougher, UV-resistant finish with minimal VOC emissions.

Liquid paint suits complex shapes or special finishes.

For coastal sites, combine a zinc-rich primer and polyester powder topcoat, validated through ASTM B117 salt-spray testing.

Q4. How to ensure UL compliance?

Design according to UL 50 / UL 50E and NEMA 250 construction rules.

We perform dielectric, corrosion, and impact tests, and provide pre-certification data to achieve first-time pass results.

Q5. What’s the best material for outdoor enclosures?

Hot-dip galvanized steel for inland areas.

Aluminum (5052/6061) for lightweight structures.

Stainless 316 for coastal or chemical environments.

All coatings validated through salt-spray and adhesion testing.

Q6. IP vs. NEMA — what’s the difference?

IP ratings (IEC 60529) measure dust and water ingress.

NEMA 250 covers ingress plus corrosion and mechanical strength.

Approximate guide: NEMA 3R ≈ IP24, NEMA 4 ≈ IP66, NEMA 4X ≈ IP66 with corrosion protection.

Q7. Can you produce directly from my CAD drawings?

Yes. We accept STEP/IGES/DWG/DXF files, review for DFM improvements (bend reliefs, airflow, gasket compression), and return updated GA drawings before fabrication.

Conclusion

Transformer enclosures aren’t just sheet metal—they are thermal, ingress, corrosion, and compliance systems that determine uptime and certification outcomes. If your target market requires UL/NEMA or IEC/IP performance, the path to “first-time pass” is clear: define the environment, rating, and lead time; share CAD or targets; then validate via CFD, material/coating selection, and pre-cert testing.

Whether you choose OEM (build-to-print) or ODM (co-engineered), pick a partner who proves these three things up front: (1) a documented compliance plan for UL 50 / NEMA 250 or IEC 62208 / EN 60529, (2) process capability from laser/CNC to marine-grade finishing, and (3) predictable lead times from prototype (7–15 days) to batch (25–40 days). That is how enclosure projects launch on schedule, pass certification the first time, and remain reliable in desert heat or coastal humidity.

Have drawings? We can manufacture to print. Have performance goals? We can co-design the airflow, gasket stack-up, and coatings, then supply the pre-cert data pack you’ll need for UL/CE submission—so your enclosure is ready to ship, install, and perform from day one.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group