Dry-Type Transformer Cost 2025: Price Guide & Supplier Analysis | CHBEB

Introduction

It’s hard to figure out how to budget for dry-type transformers. Prices change based on the materials and demand, and suppliers give varying quotes. One mistake leads to spending too much and delays. This guide makes it easier to understand 2025 prices, drivers, and supplier strategy so you can make a choice with confidence.

Dry-Type Transformer Price Landscape in 2025: Key Drivers

When transformer costs go up more than expected, projects collapse. Quotes are affected by materials, technology, and following the rules. You can prevent hidden costs and make accurate budgets if you know price ranges and drivers.

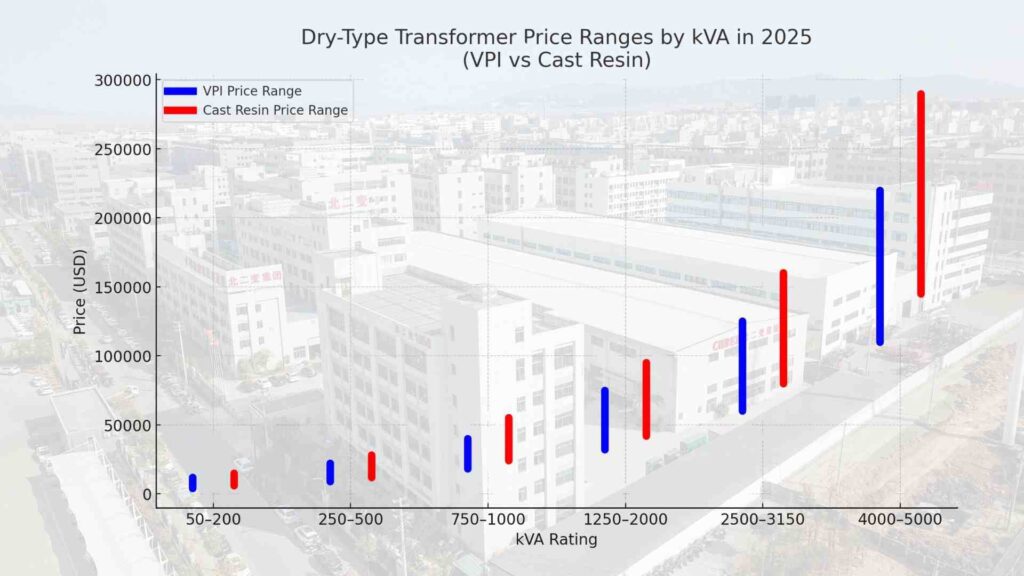

How Much Does a Dry-Type Transformer Cost by kVA in 2025?

The price changes the most based on the voltage class and capacity (kVA). The ranges below are for typical three-phase systems that are shipped directly from the factory. Shipping, taxes, testing, and installation are not included.

| kVA Rating | HV Range | VPI Price (USD) | Cast-Resin1 Price (USD) | Typical Uses |

|---|---|---|---|---|

| 50–200 | 6–11 kV | $4,000–$12,000 | $6,000–$15,000 | Shops, small offices |

| 250–500 | 6–15 kV | $9,000–$22,000 | $12,000–$28,000 | Campuses, retail |

| 750–1,000 | 10–20 kV | $18,000–$40,000 | $24,000–$55,000 | Factories, mid-size plants |

| 1,250–2,000 | 11–24 kV | $32,000–$75,000 | $42,000–$95,000 | Hospitals, metro stations |

| 2,500–3,150 | 11–33 kV | $60,000–$125,000 | $80,000–$160,000 | Industrial feeders |

| 4,000–5,000 | 13.8–35 kV | $110,000–$220,000 | $145,000–$290,000 | Utilities, heavy industry |

- Impact of technology: Cast-resin usually costs 15–30% more than VPI because of the fire safety and epoxy casting.

- Voltage effect: When you move up to 22–35 kV, the strength and clearances of the insulation normally get up by 8–20%.

- Regional differences: North America tends to be higher (UL/CSA), whereas Asia tends to be lower (localized supply chains).

What Will Affect the Prices of Dry-Type Transformers in 2025?

Small design changes might quickly change the pricing. Knowing these things stops budget shocks from happening.

- Copper is a better conductor than aluminum because it makes things work better and can handle short circuits better (around 20–40% more expensive).

- Quality of core steel: Grain-oriented or amorphous cores cut no-load losses by 10–15% of capital expenses.

- Insulation and resin: Higher-class (like Class H) and low-smoke resins make things safer and more expensive.

- Accessories like RTDs, temp relays, forced-air blowers, heaters, and sound kits add about 5–25%.

- Compliance testing: IEC/IEEE type tests, UL/CE, and FAT documents take more time and money.

- Freight and tariffs: Ocean freight, import fees, cranes, and permissions can change the price by 10% to 25%.

- Lead time and FX: Quotes are affected by rush orders and currency changes. Longer lead times usually get better prices.

For example, a 1,000 kVA cast-resin unit in Europe may cost $45,000 ex-works, but shipping, customs, and FAT testing can make the total cost more than $60,000.

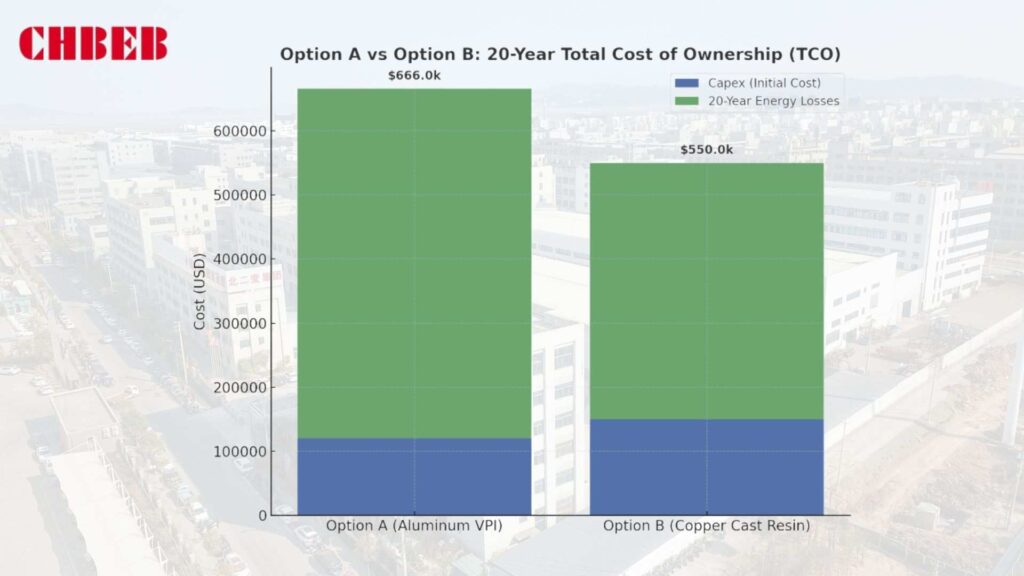

Total Cost of Ownership (TCO) and a Guide for Suppliers

A low price up front can be a trap. Over the course of 20 years, losses, downtime, and insufficient support cost more. Calculating TCO and checking out suppliers helps keep lifetime value.

What is the real total cost of ownership (TCO) for dry-type transformers?

TCO = Purchase Price + Installation + Energy Losses + Maintenance + Downtime − Residual Value

- Energy losses: No-load runs all the time; load losses go up with current and harmonics.

- Lower than oil-filled, however fans, RTDs, and windings need to be checked on a regular basis.

- Risk of downtime: One outage in a hospital or metro can cost more than the purchase price.

- Residual value: Premium items that are fully certified keep their resale value.

For example, Option A (Aluminum VPI) costs $120,000 and loses around 12 kW, while Option B (Copper Cast-Resin) costs $150,000 and loses about 9 kW. Option B saves over $140,000 in energy over 20 years at $0.12 per kilowatt-hour, which more than makes up for the $30,000 disparity in capital expenditures..

Don’t buy based on sticker price; lifetime cost is more important than losses.

How to Pick the Best Dry-Type Transformer Supplier in 2025

A bad supplier can cause delays, extra expenditures, and problems with compliance. Match your strengths to your risk profile and your timetable.

- Global giants like Hitachi Energy, Siemens, and Schneider have proven technology, good documentation, and spare parts available all over the world. However, they cost more and take longer to get.

- Regional champions (Eaton, Toshiba, TBEA): faster delivery, knowledge of local codes, and prices that are comparable. Check the depth of QA.

- OEM/ODM experts (Daelim, niche makers): make custom builds for small spaces, low noise, and tough sites; check factories and ask for type-test results with FAT witness choices.

Checklist for suppliers:

- IEC/IEEE compliance with routine and type test reports; UL/CE as needed

- Guaranteed no-load and load losses with penalty clauses

- Temperature rising class, cooling stages, and control of hot spots

- Noise level guaranteed at a certain distance (in cities)

- Terms of warranty, service SLAs, replacement parts and training in your area

- Look at projects with the same kVA/voltage and surroundings.

Warning signs: confusing drawings, missing test data, “equivalent” exchanges after the purchase order, ambiguous warranties, and pressure for big prepayments.

Put loss assurances in the contract as a practical recommendation. Small discrepancies in no-load can add up to tens of thousands over the term of the contract.

Conclusion

In 2025, the cost of a dry-type transformer is driven mainly by kVA rating, voltage level, materials/technology (e.g., copper vs2. aluminum; VPI vs. cast-resin), and compliance requirements (IEC/IEEE, UL/CE). Looking only at the sticker price can be misleading—lower upfront cost may mean higher energy losses, more downtime, and unexpected maintenance over the life of the unit.

For engineers & technical buyers

Evaluate the Total Cost of Ownership (TCO): Purchase + Installation + Energy Losses + Maintenance + Downtime − Residual Value. Higher-efficiency designs (e.g., copper windings or cast-resin insulation) can reduce losses and often save six-figure amounts on energy over a 20-year horizon.

For project owners & procurement managers

- Don’t compare on price alone—request type/routine test reports and ensure IEC/IEEE compliance.

- Ask for guaranteed losses with penalty clauses and clear warranty/service terms.

- Consider lead time, documentation quality, and after-sales support as part of value.

By looking beyond initial quotes and focusing on long-term performance, you’ll secure a transformer that is safe, efficient, and cost-effective. Partnering directly with a source factory like CHBEB can combine competitive pricing with faster delivery and international-standard quality, giving you confidence from specification to commissioning.

- Cast Resin Transformers — All About Circuits ↩︎

- Copper vs. Aluminum in Transformer Windings — ScienceDirect ↩︎

Learn More

Want to explore more transformer solutions? Download our latest product catalog or browse our product categories to find the right transformer for your project.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group