Choosing the Right Dry Type Transformer: A Definitive Guide to Types, Applications, Specifications, and Lifetime Value

Introduction

Choosing the improper type of dry transformer1 can cause expensive downtime, safety risks, and early failure. A lot of purchasers feel confused by technical specifications and advice that doesn’t agree. This tutorial breaks it down so you can choose the transformer that is safest, most efficient, and least expensive for your needs.

What Dry Type Transformers Are and Why They Are Important

Issue: A lot of people think “dry type” means it’s just a safer transformer, but they don’t know how it works or what it’s good at.

Agitate: If you don’t know this, you might spend too much money or pick a model that doesn’t work well in your area.

Let’s start by explaining what dry type transformers are and why they are becoming more popular around the world.

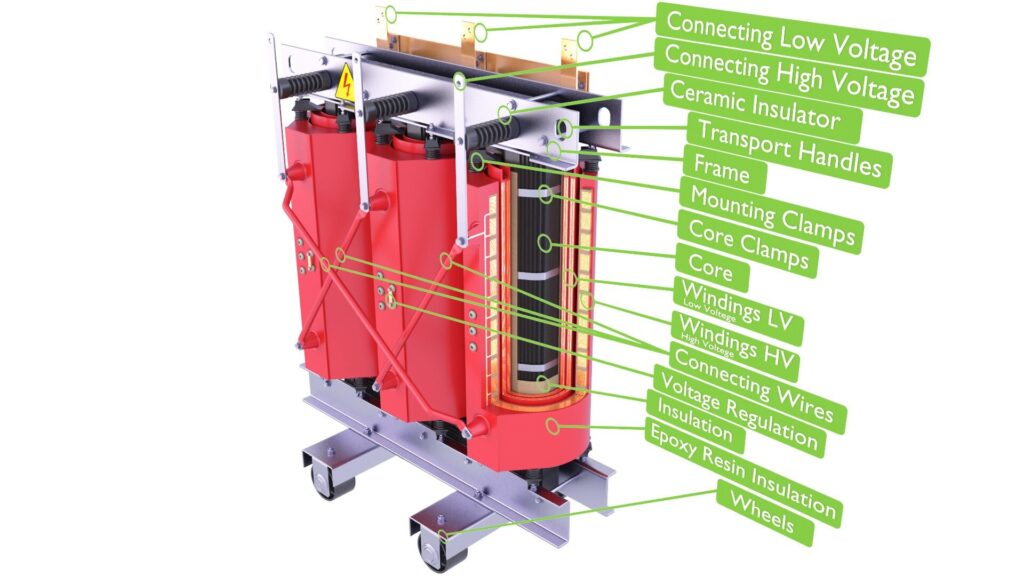

What does it mean to have a dry type transformer?

A dry type transformer doesn’t utilize mineral oil or other liquids to cool down. Instead, it uses air or solid insulation. Resin or varnish protects its windings and core, and it cools down with natural or forced air. This makes it perfect for places that are indoors or care about the environment.

The Main Benefits of Dry Type and Oil-Filled Transformers

| Feature | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Cooling Medium | Air/Solid Insulation | Mineral/Synthetic Oil |

| Fire Safety | Higher (no flammable liquid) | Lower (oil is combustible) |

| Maintenance | Lower | Higher (oil testing, leak checks) |

| Environmental Impact | Minimal risk of spills | Risk of oil contamination |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Indoor, sensitive sites | Outdoor, high-load grids |

The Most Important Types of Dry Type Transformers and Where They Work Best

Problem: Choosing the wrong type can cause it to not work as well or fail too soon.

Agitate: Not all dry type transformers work the same way in every situation.

Solution: For the best performance and longest life, match the proper type to your use.

Cast Resin Transformers (CRT)

Core Features: Windings are completely covered in epoxy resin, which makes them very resistant to moisture, dust, and chemicals.

Pros: Very durable, needs little upkeep, and is safe for tough or corrosive conditions.

Drawbacks: more expensive and can’t be fixed if the resin splits or burns.

Common Uses: Hospitals, chemical industries, underground mines, and ships.

Vacuum Pressure Impregnated (VPI) Transformers

Main Features: Windings are coated with varnish under vacuum and pressure, and then baked to make them stronger.

Pros: It’s cheaper, it lets heat escape well, and it can be fixed if it breaks.

Limitations: Not as resistant to high humidity or contamination.

Common Uses: Schools, data centers, and commercial structures.

Specialized Dry Type Transformers

K-Factor Rated: Made for data centers or factories with non-linear loads.

Harmonic Mitigation Models: Help sensitive electronics work better by lowering voltage distortion.

High-Temperature Designs: Work in places where the standard ratings are higher.

Decoding Key Specifications and Selection Parameters

Problem: If you don’t know things like the kVA rating or insulation class, you can buy the wrong thing.

Agitate: This can make things less safe, more costly to fix, or less efficient.

Before you buy, be sure you know what each setting implies.

KVA Rating: Choosing the Right Size for Current and Future Loads

kVA tells you how much load the transformer can handle. To get kVA, use this formula: kVA = (Load Voltage × Load Current) ÷ 10002

Always leave room for future growth and environmental derating.

Voltage Class: Meeting the needs of both the primary and secondary systems

To avoid problems with performance, be sure that both the supply and load voltages are compatible.

Class of insulation and rise in temperature

For example, models with 150°C rise survive longer and run cooler than models with 220°C rise.

Longer life and better performance come from a lower temperature rise.

Losses and Efficiency

No-Load Losses: Energy lost while a transformer is turned on but not doing anything.

Load losses happen when energy is lost while under load.

To be in compliance and save money, follow the efficiency criteria set by DOE 2016, NEMA TP-1, or GB 20052-2020.3

IP Rating and Enclosure

IP544: shielded from dust and splashes, therefore it’s suitable for outdoor settings that are sheltered.

NEMA 3R: Weatherproof for outside use.

Pick based on the dangers in the area.

Winding Material: Copper vs. Aluminum

| Property | Copper | Aluminum |

|---|---|---|

| Conductivity | Higher | Lower |

| Cost | Higher | Lower |

| Weight | Heavier | Lighter |

| Mechanical Strength | Higher | Lower |

Impedance

Changes the short-circuit current and the voltage regulation. If it’s too low, there’s a chance of excessive fault currents. If it’s too high, the voltage will drop when it’s loaded.

Cost of maintenance, longevity, and lifetime

Problem: A lot of people think that “dry type” means “no maintenance.”

Agitate: Ignoring things shortens life and makes failure more likely.

Follow a simple maintenance plan and think on the lifetime cost instead of the purchase price.

Common Mistakes and Signs of Trouble

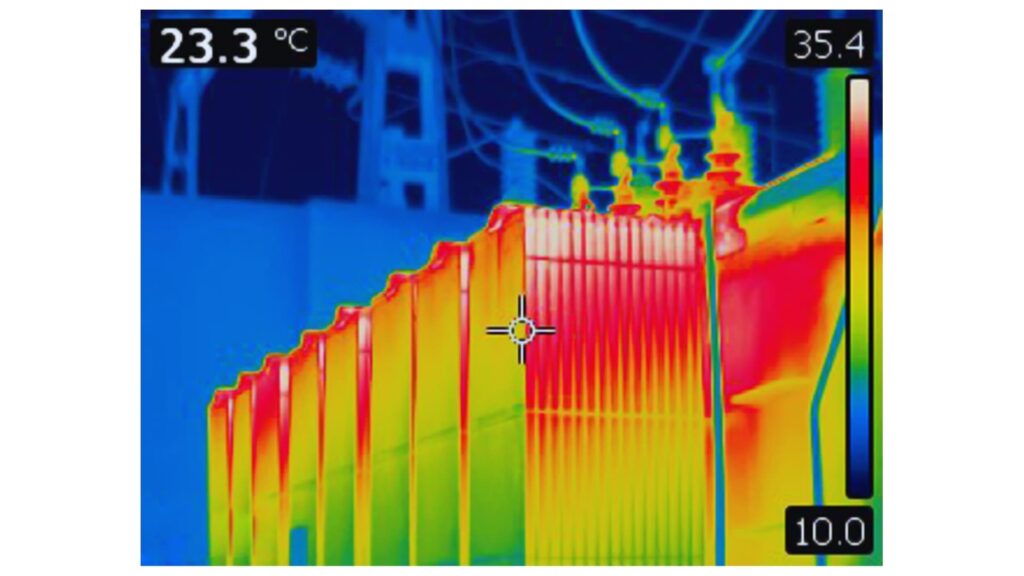

- Overheating

- Insulation cracks

- Unusual humming noise

- Discoloration of windings

The List of Important Maintenance Tasks

- Visual inspection every 6–12 months

- Cleaning dust and debris

- Tightening connections

- Infrared thermography5 for hot spots

- Insulation resistance tests

Analysis of Lifetime Cost (LCC)

Think about more than simply the purchase price. Think about installation, energy losses, maintenance, and disposal. Models with high efficiency frequently offer a better return on investment.

A process for choosing step by step

Problem: A lot of purchasers only care about price and don’t follow an organized process.

Agitate: This can cause safety problems or units that are too big or too little.

The answer is to use a planned approach..

A Flowchart for Systematic Transformer Selection

- Needs Assessment – Load profile, future expansion

- Environment Evaluation – Indoor/outdoor, humidity, dust

- Parameter Finalization – kVA, voltage, temperature rise, IP rating

- Vendor Comparison – Certifications, track record, support

Picking a Manufacturer You Can Trust

- International certifications (NEMA, IEC, GB/T)

- Proven track record in your industry

- Strong after-sales service

Conclusion

To choose the proper dry type transformer, you need to find a balance between performance, safety, and long-term expenses. Follow a plan, make sure the specs fit your space, and spend money on quality. Your electrical system will be more reliable if you do these things.

- Dry type transformer — Wikipedia ↩︎

- Transformer kVA calculation formula — Electrical Engineering Portal ↩︎

- DOE 2016 Energy Efficiency Standards — U.S. Department of Energy ↩︎

- IP Code — Wikipedia ↩︎

- Infrared thermography in electrical inspections — ScienceDirect ↩︎

Ready to Find the Perfect Dry Type Transformer?

Explore our full range of Dry Type Transformers to match your project requirements, or download our Product Catalog for detailed specifications and technical data.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group