High-Voltage Step-Up Transformers | The Core Technology, Parameters, and Total Lifecycle Value | CHBEB

Introduction

When step-up transformers1 are used incorrectly or not enough, projects run the danger of being inefficient and getting fines. These issues cause downtime, instability, and further losses. For energy projects, a high-voltage step-up transformer makes sure that connections are safe, performance is stable, and the lifecycle value is maximized.

The Product Core: A Summary and Important Technical Features

Ignoring important technical details might cause transformers to not fit together, work less efficiently, and be dangerous. Buyers may make sure that the design meets project needs and is reliable and compliant by knowing what the product’s purpose and limits are.

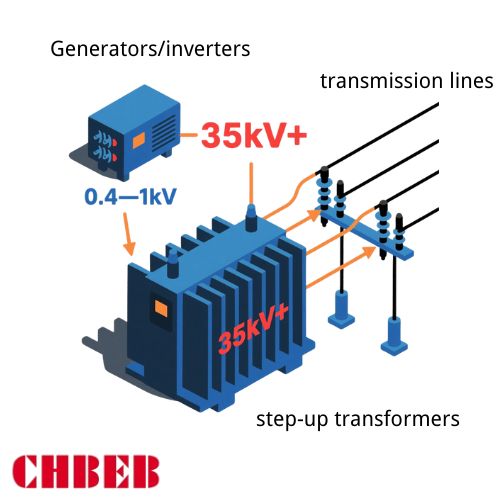

Product Introduction: Why a High-Voltage Step-Up Transformer Is Necessary

Most of the time, generators and inverters make low or medium voltage that can’t be sent. A high-voltage step-up transformer elevates this to 35 kV or more, keeps the voltage stable, and makes sure that the system meets utility regulations.

- Voltage elevation: Changes the outputs of LV/MV generators into HV levels so they can be sent more quickly.

- Isolation: Keeps source circuits separate from the utility, which keeps everyone safe and makes it easier to fix problems.

- System stability: It controls harmonics, helps with protective schemes, and keeps the grid balanced.

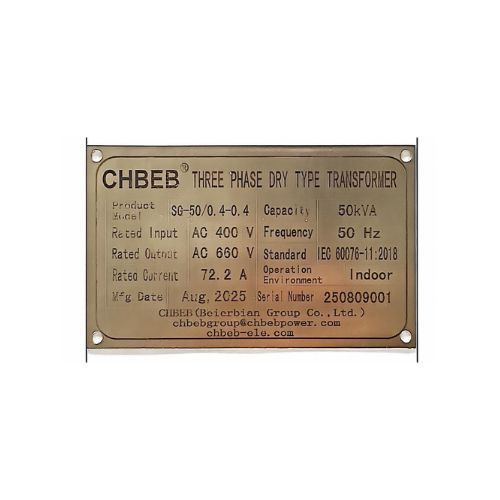

A Look at the Specs: Knowing the Value of Important Parameters

If you don’t pay attention to the main criteria, you could end up paying too much or not doing enough. Taking into account the most important parameters ensures a well-designed product, fewer losses, and a long service life.

- Power rating (kVA/MVA): This must match the peak load and growing margin.

- Primary and secondary voltage: Make sure the generator output meets utility HV standards (11–35kV+).

- Vector group2: This tells you how to handle harmonics, phase shift, and neutral availability.

- Impedance (%Z)3: This controls the levels of faults and the voltage.

- Cooling class: The ONAN/ONAF settings set the temperature rise and how long the product will last.

- Losses (no-load/load): Directly affect operating costs over the course of decades.

- BIL (Basic Insulation Level)4 protects against surges and switching occurrences.

How We Make Sure Your Project Is a Success with Applications and Services

When transformers aren’t matched to the right applications or aren’t supported after delivery, projects fail. We make sure that every project meets its performance and financial goals by using the correct application knowledge, cost analysis, and service.

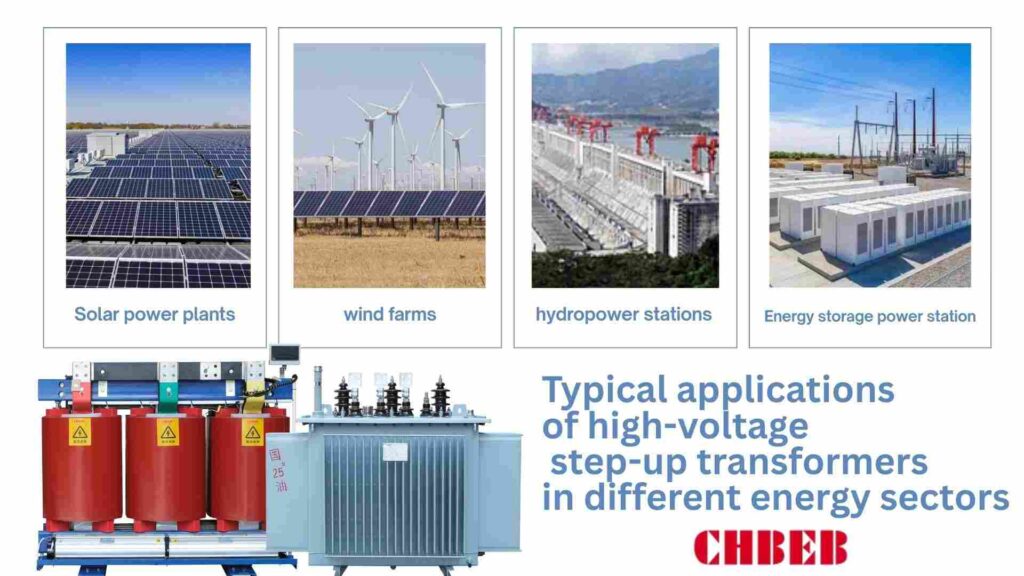

Common Uses: Where Our Products Are Very Important

High-voltage step-up transformers are very important in many fields. Using something wrong can make it less efficient and reliable, but using it correctly can make it safer and more reliable.

- Step inverter or generator outputs up to HV for transmission in utility-scale solar and wind.

- Industrial cogeneration: Safely connects CHP units to networks with medium to high voltage.

- Hydropower and thermal plants: Raise the voltage efficiently for grid export.

- Battery energy storage: lets HV systems send power in both directions.

Looking at more than just the price: using Total Cost of Ownership (TCO)5 to assess an investment

When you buy based on pricing alone, you risk hidden expenses like larger losses and downtime. Calculating the total cost of ownership makes sure that things will be useful and profitable in the long run.

TCO = Capital Expenditures + Installation + Losses + Maintenance + Downtime − Residual Value

- Energy losses: Monetize guaranteed no-load/load losses throughout 20 years of operation.

- Better designs mean less frequent inspections and lower costs for spare parts.

- Risk of downtime: Reliable units don’t go down, which can offset savings made up front.

- Residual value: Quality transformers keep their worth when they are sold or used again.

Customization and Service: Our Expert Solution for Your Project

Every project has its own needs, and not customizing can lead to a bad fit. We change designs and offer lifecycle support to make sure success with experienced engineering and timely service.

- Flexibility in design: Adjust winding material, impedance, and vector groups to fit the needs of the project.

- Adapting to the environment: Solutions for deserts, coastal areas, or high elevations.

- Service throughout the lifecycle: from testing and installing at the factory to monitoring and maintenance help.

- Quick help: Teams that respond quickly make sure that projects don’t have to stop for long.

Conclusion

Reliable grid integration depends on selecting the right high-voltage step-up transformer—not only by reading the nameplate, but by verifying what’s inside. Buyers secure safe, efficient, and future-ready outcomes when they combine technical fit, lifecycle economics, and supplier transparency.

What to do to get it right

- Match the specs: Align voltage ratio, kVA/MVA, impedance (%Z), vector group and tap range with project and utility requirements.

- Evaluate TCO: Compare no-load/load losses, expected maintenance, and downtime risk—not just upfront price.

- Verify the build quality: Require factory routine/type test reports, allow FAT (factory acceptance tests), and use third-party inspections where needed to prevent hidden compromises.

- Lock in reliability: Specify warranty terms, response SLAs, and a critical spares list (fans, bushings, gaskets, relays) to protect uptime.

In short: the right transformer isn’t defined by the lowest quote, but by technical compliance, lifecycle cost control, and proof of quality—ensuring the unit you buy performs exactly as promised for decades.

- Transformer — Wikipedia ↩︎

- Transformer Vector Groups — All About Circuits ↩︎

- Transformer Impedance and Fault Studies — IEEE Xplore ↩︎

- Transformer Insulation and BIL Studies — ScienceDirect ↩︎

- Total Cost of Ownership in Electrical Distribution — Schneider Electric ↩︎

Learn More About Our Transformers

Want to explore more transformer solutions? Download our latest product catalog or browse our product categories to find the right fit for your project.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group