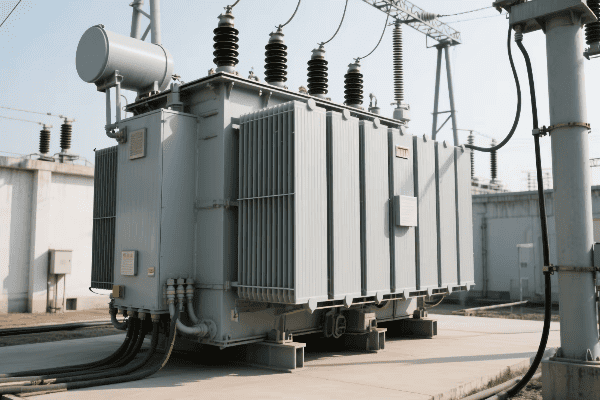

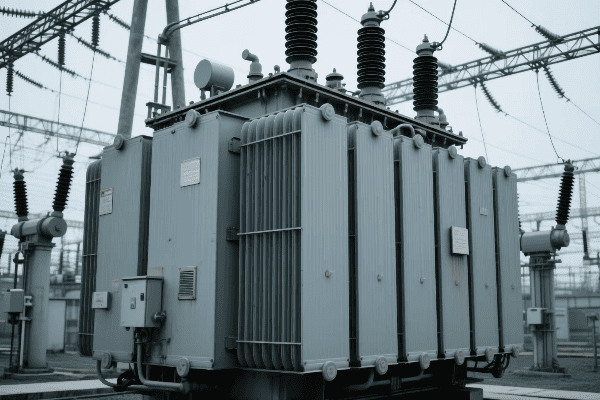

How Can Large Power Transformer Efficiency Be Maximized in High-Voltage Applications?

Power loss in large transformers can cost millions. But what if we could capture every watt? Let’s explore how to maximize efficiency in high-voltage applications.

Large power transformers in high-voltage applications can maximize efficiency through advanced core materials, optimized winding designs, and intelligent cooling systems. These improvements reduce energy losses, enhance performance, and increase the overall reliability of power transmission networks.

As we delve deeper into this topic, we’ll uncover the key factors and technologies that are revolutionizing transformer efficiency. Get ready to discover how these giants of the power industry are becoming leaner and more powerful than ever before.

What Are the Key Factors in Understanding Large Power Transformer Efficiency for High-Voltage Applications?

Have you ever wondered what makes some transformers more efficient than others? It’s like unlocking a complex puzzle, where each piece plays a crucial role.

The key factors in large power transformer efficiency for high-voltage applications include core material quality, winding design, insulation systems, cooling methods, and load management. These elements work together to minimize losses and maximize power transfer in high-voltage environments.

Let’s break down these factors to understand how they contribute to transformer efficiency:

Core Material: The Heart of the Transformer

The core is like the engine of a car – its quality directly impacts performance.

Types of Core Materials:

- Silicon Steel

- Amorphous Metals

| Material | Advantages | Disadvantages |

|---|---|---|

| Silicon Steel | Cost-effective, widely available | Higher core losses |

| Amorphous Metals | Ultra-low losses | Higher initial cost |

Winding Design: The Arteries of Power Flow

Windings are like the circulatory system, distributing power throughout the transformer.

Key Considerations:

- Conductor material (copper vs. aluminum)

- Winding configuration (disc, helical, etc.)

Insulation Systems: The Protective Shield

Insulation is the transformer’s armor, protecting against electrical breakdown and energy losses.

Types of Insulation:

- Oil-based

- Solid (paper, resin-impregnated)

Cooling Methods: Keeping Your Cool

Efficient cooling is crucial for maintaining optimal performance.

Common Cooling Techniques:

- Oil Natural Air Natural (ONAN)

- Oil Forced Air Forced (OFAF)

Load Management: Balancing Act

Proper load management is like conducting an orchestra – ensuring each component performs at its best.

Strategies:

- Smart grid integration

- Peak load management

By understanding these key factors, we can begin to see how each element plays a vital role in maximizing transformer efficiency. It’s a complex interplay of materials, design, and management that ultimately determines how well these critical components perform in our power transmission networks.

How Can We Measure and Evaluate Efficiency in Large Power Transformers for High-Voltage Environments?

Measuring transformer efficiency is like trying to gauge the performance of a marathon runner – it requires careful observation and precise tools.

Efficiency in large power transformers for high-voltage environments is measured through load and no-load loss tests, temperature rise tests, and advanced monitoring systems. These methods provide crucial data on energy losses, thermal performance, and overall efficiency under various operating conditions.

Let’s explore the methods we use to measure and evaluate transformer efficiency:

Load Loss Tests: Real-World Performance Check

Load loss tests are like putting a transformer through its paces on a treadmill.

Key Tests:

- Short-Circuit Test

- Temperature Rise Test

| Test Type | What It Measures | Why It’s Important |

|---|---|---|

| Short-Circuit | Copper losses | Indicates efficiency under load |

| Temperature Rise | Heat distribution | Ensures safe operation and longevity |

No-Load Loss Tests: Baseline Efficiency

No-load tests are like checking a car’s fuel consumption while it’s idling.

Key Tests:

- Open-Circuit Test

- Exciting Current Test

Advanced Monitoring Systems: Real-Time Efficiency Tracking

Modern transformers are equipped with sophisticated monitoring systems, much like health trackers we wear.

Key Technologies:

- Online Dissolved Gas Analysis (DGA)

- Partial Discharge Monitoring

Efficiency Calculation: Putting It All Together

Once we have all this data, we can calculate the overall efficiency of the transformer.

Efficiency Formula:

Efficiency (%) = (Output Power / Input Power) × 100

Factors Considered:

- Core losses

- Winding losses

- Auxiliary losses (cooling systems, etc.)

Comparative Analysis: Benchmarking Performance

To truly understand how well a transformer is performing, we need to compare it to industry standards and other similar units.

Benchmarking Tools:

- IEEE Standards

- Historical Data Analysis

By employing these measurement and evaluation techniques, we gain a comprehensive understanding of a large power transformer’s efficiency in high-voltage environments. This knowledge is crucial for optimizing performance, planning maintenance, and ensuring the reliability of our power transmission systems.

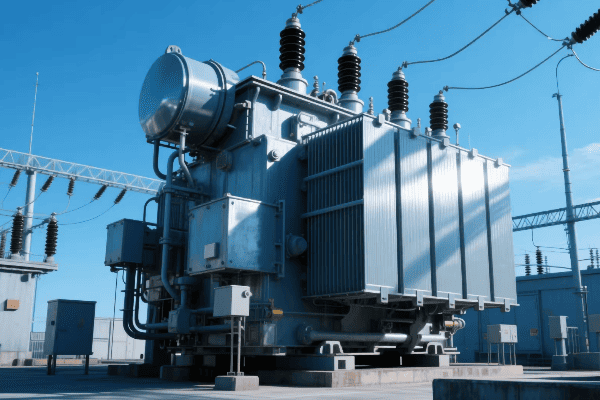

What Advanced Technologies and Design Strategies Are Enhancing Large Power Transformer Efficiency?

Imagine transformers that are not just passive components but intelligent, adaptive systems. This isn’t science fiction – it’s the cutting edge of transformer technology.

Advanced technologies enhancing large power transformer efficiency include nanotechnology-enhanced core materials, superconducting windings, smart monitoring systems, and advanced cooling techniques. These innovations significantly reduce losses, improve thermal management, and extend the operational lifespan of transformers.

Let’s explore the exciting world of advanced technologies and design strategies:

Nanotechnology-Enhanced Core Materials

Nanotechnology is giving transformers superpowers at the atomic level.

Innovations:

- Nanocrystalline Core Materials

- Nano-fluid Insulation

| Technology | Benefits | Challenges |

|---|---|---|

| Nanocrystalline Cores | Significantly reduced losses | Higher production costs |

| Nano-fluid Insulation | Better heat dissipation | Long-term stability concerns |

Superconducting Windings

Superconducting technology in transformer windings is creating a highway with no speed limits for electricity.

Key Features:

- High-Temperature Superconductors (HTS)

- Cryogenic Cooling Systems

Smart Monitoring Systems

Modern transformers are equipped with intelligent monitoring systems, acting like a constant health check-up.

Technologies:

- Internet of Things (IoT) Integration

- Artificial Intelligence (AI) Analysis

Advanced Cooling Techniques

Innovative cooling strategies are giving transformers their own high-tech air conditioning systems.

Cooling Innovations:

- Phase Change Materials (PCMs)

- Forced Oil-Water Cooling (OFWF)

Amorphous Metal Cores

Amorphous metal cores are like giving transformers a flexible skeleton that adapts to magnetic fields effortlessly.

Advantages:

- Ultra-Low Core Losses

- Improved Efficiency at All Load Levels

Hybrid Insulation Systems

Combining different insulation materials creates a synergy that enhances overall performance.

Types:

- Solid-Liquid Hybrid Systems

- Eco-friendly Insulation Options

These advanced technologies and design strategies are pushing the boundaries of what’s possible in large power transformer efficiency. By incorporating these innovations, we’re not just improving performance – we’re reimagining the very nature of power transmission.

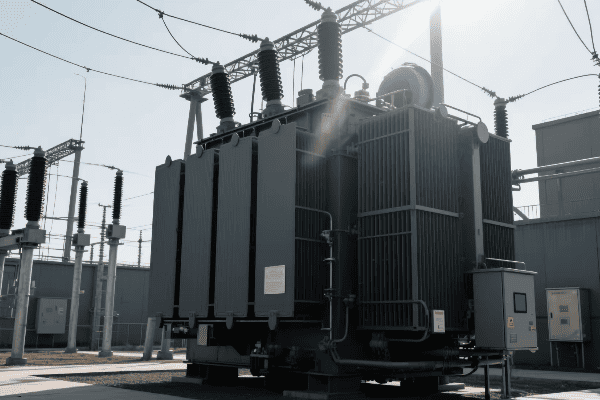

What Are the Best Practices for Optimizing Large Power Transformer Operation in High-Voltage Performance?

Optimizing transformer operations is like conducting a symphony – every element must be in perfect harmony for peak performance.

Best practices for optimizing large power transformer operation in high-voltage performance include implementing dynamic load management, regular maintenance schedules, advanced cooling strategies, and real-time monitoring systems. These practices ensure peak efficiency, extend transformer lifespan, and maintain reliable power distribution.

Let’s explore the best practices that keep our transformers running at their peak:

Dynamic Load Management

Managing transformer loads is like conducting an orchestra – it requires finesse and precision.

Strategies:

- Adaptive Load Shifting

- Smart Grid Integration

| Practice | Benefits | Implementation Challenges |

|---|---|---|

| Adaptive Load Shifting | Reduced peak stress | Requires advanced control systems |

| Smart Grid Integration | Improved overall efficiency | High initial investment |

Proactive Maintenance Schedules

Regular maintenance is like giving your transformer a health check-up.

Approaches:

- Condition-Based Maintenance

- Predictive Analytics

Advanced Cooling Strategies

Efficient cooling is crucial for maintaining optimal transformer performance.

Techniques:

- Intelligent Cooling Control

- Hybrid Cooling Technologies

Real-Time Monitoring Systems

Modern monitoring systems act like a constant health tracker for your transformer.

Key Technologies:

- Online Dissolved Gas Analysis (DGA)

- Thermal Imaging

Optimized Tap Changer Operation

Managing tap changers is like adjusting the gears on a bicycle – it ensures smooth operation under varying conditions.

Best Practices:

- Automated Tap Changing

- Wear Monitoring

Power Quality Management

Maintaining power quality is essential for the entire system’s health.

Strategies:

- Harmonic Filtering

- Reactive Power Compensation

Environmental Adaptation

Adapting to environmental conditions is like dressing appropriately for the weather.

Considerations:

- Climate-Specific Designs

- Eco-Friendly Practices

By implementing these best practices, we can significantly optimize the operation of large power transformers in high-voltage applications. It’s a holistic approach that considers every aspect of transformer operation, from the microscopic level of materials to the macroscopic level of network management.

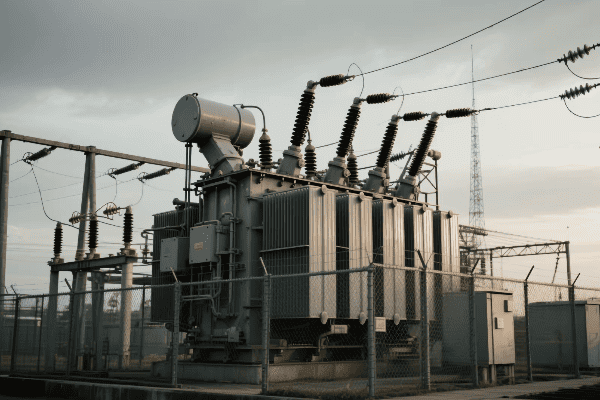

How Do Efficient Large Power Transformers Impact Grid Stability and Reliability in High-Voltage Systems?

Efficient transformers are like the unsung heroes of our power grid, silently working to keep our lights on and our world running smoothly.

Efficient large power transformers significantly enhance grid stability and reliability in high-voltage systems by reducing power losses, improving voltage regulation, and increasing overall system capacity. This leads to fewer outages, better power quality, and more resilient energy infrastructure.

Let’s explore the far-reaching effects of transformer efficiency on our power grids:

Reduced Power Losses

Efficient transformers are like well-maintained pipes in a water system – they deliver more of what’s flowing through them.

Benefits:

- Lower Transmission Losses

- Improved Energy Economics

| Impact Area | Benefits | Long-term Effects |

|---|---|---|

| Transmission Losses | Increased energy delivery | More sustainable power distribution |

| Energy Economics | Cost savings for utilities | Potential for grid expansion |

Enhanced Voltage Regulation

Better voltage regulation from efficient transformers is like having a steady hand on the steering wheel of our power grid.

Advantages:

- Stable Voltage Levels

- Reduced Stress on Grid Components

Increased System Capacity

Efficient transformers give our power grids more breathing room, like widening a highway to accommodate more traffic.

Key Impacts:

- Higher Load Handling Capability

- Deferred Infrastructure Upgrades

Improved Power Quality

High-efficiency transformers contribute to cleaner power, much like a water filtration system ensures purer water.

Enhancements:

- Reduced Harmonics

- Balanced Power Factor

Enhanced Grid Resilience

Efficient transformers make our power grids more resilient, like reinforcing a building to withstand natural disasters.

Resilience Factors:

- Better Overload Capacity

- Improved Fault Tolerance

Facilitating Renewable Integration

Efficient transformers are key to integrating renewable energy sources, acting like a bridge between traditional and green power.

Integration Benefits:

- Smoother Power Flow Management

- Enhanced Grid Flexibility

By improving the efficiency of large power transformers, we’re not just enhancing individual components – we’re strengthening the entire power distribution network. This leads to a more stable, reliable, and sustainable energy future for all.

Conclusion

Maximizing large power transformer efficiency in high-voltage applications is crucial for a reliable and sustainable energy future. By focusing on advanced materials, smart technologies, and best practices, we can significantly improve performance and grid stability.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group