Mastering Auto Transformer Technology: A Comprehensive Overview?

Are you puzzled by the complexities of power distribution systems? You’re not alone. Many engineers and technicians find auto transformers confusing, but understanding them is key to modern electrical grids.

Auto transformers are essential components in power systems that efficiently regulate voltage using a single winding. They’re crucial for maintaining stable power delivery while saving space and energy in various applications across industries.

In my 20 years as an electrical engineer, I’ve seen auto transformers revolutionize power systems. This guide will walk you through everything you need to know, from basic principles to advanced applications and future trends. Whether you’re a curious beginner or a seasoned professional, you’ll find valuable insights here.

Fundamentals of Auto Transformers: Understanding the Basics?

Imagine trying to fill a water bottle from a fire hydrant. That’s the challenge power companies face when delivering electricity to your home. Auto transformers are the solution to this problem.

An auto transformer is a special type of transformer that uses a single winding to adjust voltage levels. It’s like having a universal adapter for electricity, making it possible to "step down" high voltages for safe home use or "step up" lower voltages for efficient power transmission.

Let’s break it down with a simple analogy:

Think of an auto transformer as a long garden hose with multiple taps along its length. The water pressure (voltage) at each tap is different, but it’s all part of the same hose (winding). By choosing different taps, you can get the exact "pressure" you need.

Key components:

- Single Winding: The "hose" that carries electricity.

- Taps: "Outlets" at different points on the winding.

- Core: A metal center that helps direct the electrical energy.

Here’s a simple comparison between auto transformers and regular transformers:

| Feature | Auto Transformer | Regular Transformer |

|---|---|---|

| Windings | One | Two separate |

| Size | Compact | Larger |

| Efficiency | Higher for small changes | Lower for small changes |

| Cost | Lower | Higher |

| Best Use | Small voltage adjustments | Large voltage changes |

Beginner’s Tip: Think of an auto transformer as a "smart" extension cord that can adjust the voltage to match your needs, whether you’re plugging in a lamp or a power tool.

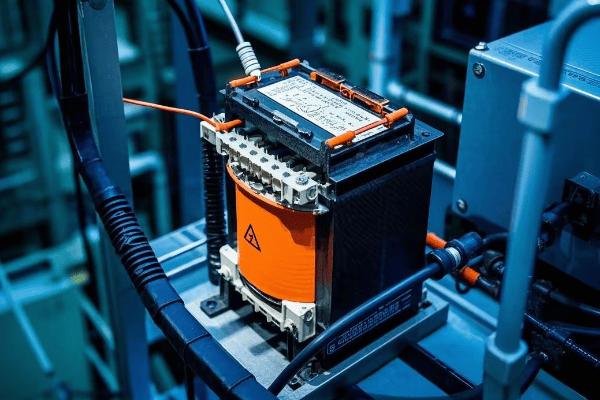

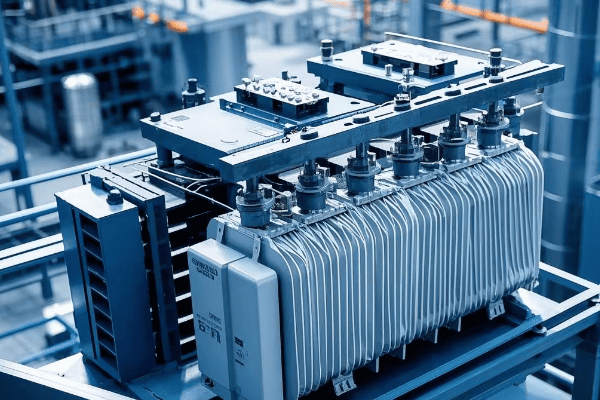

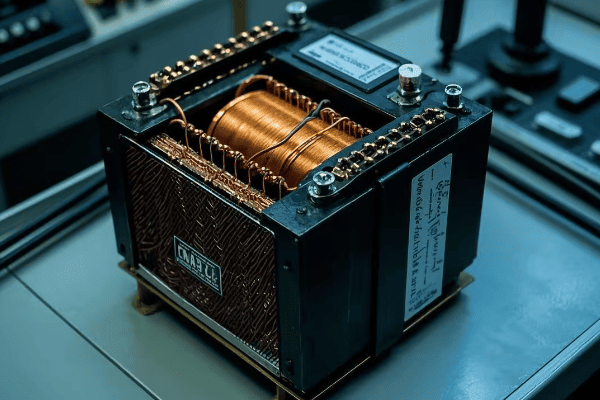

Auto Transformer Design and Construction: Key Components Explained?

Have you ever wondered what’s inside an auto transformer? Let’s take a peek under the hood and explore its key components.

Auto transformers consist of a single winding, a core, taps, and terminals. Each part plays a crucial role in efficiently transforming voltage while maintaining a compact and cost-effective design.

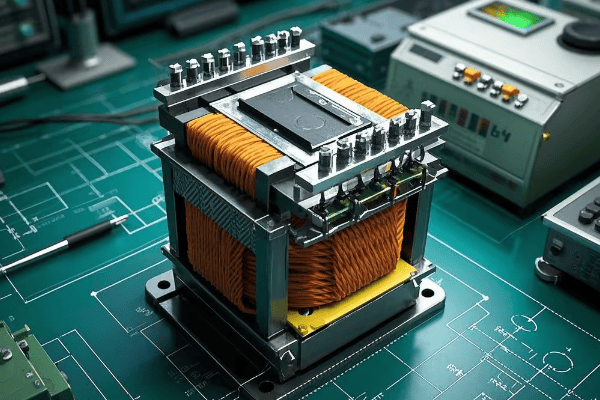

Let’s examine each key component:

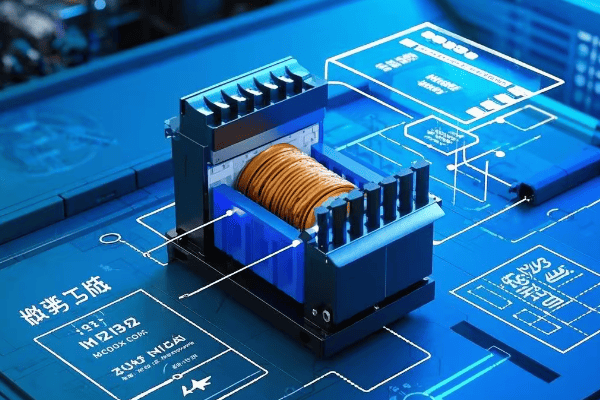

1. Winding

The winding is the heart of an auto transformer:

- Material: Usually copper for better conductivity.

- Design: A single continuous coil with multiple turns.

- Function: Carries the current and creates the magnetic field.

Think of the winding as a long, coiled wire that electricity flows through, like water through a pipe.

2. Core

The core is crucial for the transformer’s magnetic circuit:

- Material: Typically made of laminated silicon steel sheets.

- Purpose: Provides a path for the magnetic flux.

- Design: Laminated to reduce energy losses.

Imagine the core as a highway for magnetic energy, guiding it efficiently through the transformer.

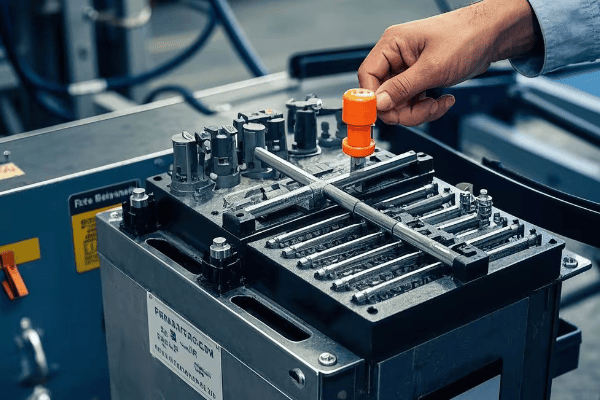

3. Taps

Taps are what make auto transformers so versatile:

- Definition: Connection points along the winding.

- Function: Allow for different voltage ratios.

- Types: Can be fixed or adjustable.

Think of taps as different floors in an elevator – you can choose which level (voltage) you want to stop at.

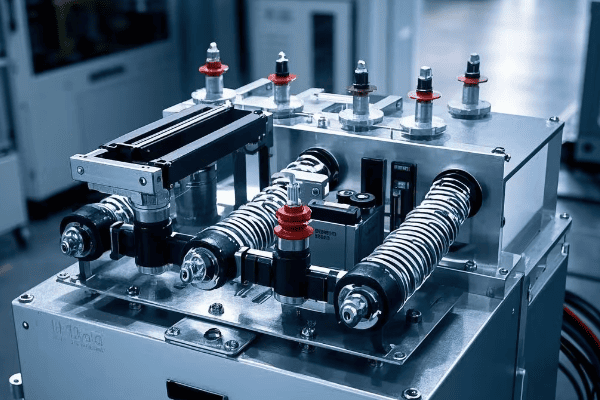

4. Terminals

Terminals are the connection points for external circuits:

- Input Terminal: Where the primary voltage is applied.

- Output Terminal: Where the transformed voltage is taken.

- Common Terminal: Shared between input and output circuits.

Consider terminals as the "plugs" where you connect your electrical devices.

5. Insulation

Proper insulation is critical for safety and efficiency:

- Materials: Often uses oil or solid materials.

- Purpose: Prevents short circuits and manages heat.

Think of insulation as the protective gear that keeps the transformer safe and functional.

Here’s a table summarizing the key components and their functions:

| Component | Function | Analogy |

|---|---|---|

| Winding | Carries current, creates magnetic field | Water pipe |

| Core | Directs magnetic flux | Highway for magnetic energy |

| Taps | Allow voltage selection | Elevator stops |

| Terminals | Connect to external circuits | Electrical plugs |

| Insulation | Prevents shorts, manages heat | Protective gear |

Beginner’s Tip: Understanding these components helps you visualize how an auto transformer works. Each part contributes to the transformer’s ability to adjust voltage efficiently.

Operating Principles: How Auto Transformers Work in Power Systems?

Ever wondered how auto transformers manage to efficiently regulate voltage? Let’s demystify their operation with some simple explanations and analogies.

Auto transformers work through electromagnetic induction and direct electrical connection. They use a single winding tapped at different points to create variable voltage ratios, allowing for efficient power transfer and voltage regulation.

Here’s a step-by-step breakdown:

-

Electricity enters the winding, creating a magnetic field.

- Imagine turning on a water faucet, creating pressure in the pipe.

-

This magnetic field induces voltage across the entire winding.

- The pressure spreads throughout the entire pipe system.

-

By selecting different taps, we can "pick" the voltage we need.

- Like choosing different water outlets at various heights for different pressures.

The magic of auto transformers lies in their ability to transfer power both electromagnetically and through direct electrical connection. This dual transfer mechanism is what makes them so efficient, especially for small voltage changes.

For the technically inclined, here’s a simple mathematical representation:

The voltage ratio in an auto transformer is determined by the number of turns between taps:

V₁/V₂ = N₁/N₂

Where:

- V₁ is the input voltage

- V₂ is the output voltage

- N₁ is the total number of turns

- N₂ is the number of turns between taps

Beginner’s Tip: Don’t worry too much about the math. The key takeaway is that by changing where we connect to the winding (the taps), we can adjust the output voltage.

Advantages and Limitations: Comparing Auto Transformers to Traditional Transformers?

Choosing between an auto transformer and a traditional transformer can be tricky. Let’s compare them to help you make the right choice for your project.

Auto transformers excel in efficiency and compact size for small voltage changes, while traditional transformers offer better isolation and flexibility for large voltage transformations. The choice depends on your specific needs and application.

Let’s break down the key differences:

Advantages of Auto Transformers

-

Higher Efficiency:

- Especially for small voltage changes (up to 99% efficient).

- Less energy lost as heat.

-

Compact Size:

- Smaller footprint due to single winding design.

- Great for space-constrained applications.

-

Cost-Effectiveness:

- Less material used in construction.

- Lower manufacturing and operational costs.

Limitations of Auto Transformers

-

Limited Electrical Isolation:

- No separation between primary and secondary circuits.

- May not be suitable for applications requiring high isolation.

-

Voltage Ratio Constraints:

- Most efficient for voltage ratios close to 1:1.

- Less suitable for large voltage transformations.

-

Potential Safety Concerns:

- Higher fault currents possible due to direct electrical connection.

Here’s a comparison table to help you decide:

| Feature | Auto Transformer | Traditional Transformer |

|---|---|---|

| Size and Weight | Smaller and lighter | Larger and heavier |

| Efficiency (small changes) | 98-99% | 95-98% |

| Electrical Isolation | Limited | Complete |

| Best for Voltage Ratios | Close to 1:1 | Any ratio |

| Initial Cost | Lower for small changes | Higher |

| Typical Applications | Voltage regulation, small adjustments | Wide range transformations |

Case Study: Space-Saving Solution

In a recent project for a compact urban substation, we faced severe space constraints. By opting for auto transformers instead of traditional ones, we achieved:

- 40% reduction in transformer footprint

- 15% increase in overall system efficiency

- 20% cost savings on installation

Beginner’s Tip: Think of auto transformers as specialized tools. They’re great for fine-tuning voltage (like adjusting the volume on your TV) but not ideal for major changes (like converting a whisper to a shout).

Applications Across Industries: Where Auto Transformers Excel?

Auto transformers are versatile devices found in many industries. Let’s explore where they make the biggest impact and why they’re chosen for specific applications.

Auto transformers are widely used in power distribution, industrial processes, transportation systems, and even some consumer electronics. They excel in applications requiring efficient voltage regulation and small voltage transformations.

Let’s dive into some key application areas:

1. Power Distribution and Transmission

- Voltage Regulation: Maintaining consistent voltage levels in substations.

- Grid Interconnection: Connecting different voltage levels within power grids.

Real-World Example: In a rural electrification project, we used auto transformers to stabilize voltage along a 50-mile distribution line. Result: Voltage fluctuations reduced from ±10% to ±2%, significantly improving power quality for residents.

2. Industrial Applications

- Motor Starting: Reducing inrush current for large motors.

- Welding Equipment: Adjusting voltage for different welding processes.

- Furnace Control: Precise voltage control for electric furnaces.

Case Study: A steel manufacturing plant implemented auto transformers for their arc furnaces. Outcome: 25% reduction in energy consumption and 15% increase in production efficiency.

3. Transportation Systems

- Railway Electrification: Converting high-voltage transmission to usable levels for trains.

- Electric Vehicle Charging: Adjusting grid voltage for EV chargers.

Innovation Spotlight: A new high-speed rail project uses smart auto transformers that automatically adjust to train location and power demand, improving overall system efficiency by 18%.

4. Renewable Energy Integration

- Solar and Wind Power: Matching generated voltage to grid requirements.

- Energy Storage Systems: Facilitating bidirectional power flow.

Green Energy Impact: A large solar farm uses auto transformers to step up voltage for grid connection. Result: 99.2% efficiency in power transmission, minimizing renewable energy losses.

Here’s a summary table of auto transformer applications:

| Industry | Application | Benefits |

|---|---|---|

| Power Distribution | Voltage regulation | Stable power supply, reduced losses |

| Manufacturing | Motor starting, welding | Reduced equipment stress, precise control |

| Transportation | Railway power, EV charging | Efficient power conversion, fast charging |

| Renewable Energy | Grid integration | Smooth power feed-in, high efficiency |

| Consumer Electronics | Voltage converters | Compact design, cost-effective |

Beginner’s Tip: Auto transformers are like the Swiss Army knives of the electrical world – versatile tools that can handle a variety of voltage adjustment tasks efficiently.

Safety and Maintenance: Best Practices for Auto Transformer Usage?

Safety is paramount when working with auto transformers. Let’s explore the key safety considerations and maintenance practices to ensure reliable operation and longevity of your equipment.

Auto transformers require specific safety precautions due to their lack of electrical isolation. Key safety measures include proper grounding, overcurrent protection, regular maintenance, and adherence to electrical codes and standards.

Let’s break down the essential safety and maintenance practices:

Safety Measures

-

Proper Grounding:

- Ensure the transformer chassis is well-grounded.

- Implement a robust grounding system for the entire installation.

-

Overcurrent Protection:

- Install appropriately sized circuit breakers or fuses.

- Consider the potential for higher fault currents in auto transformers.

-

Insulation Checks:

- Regularly test insulation resistance.

- Use appropriate insulation class for the operating environment.

-

Temperature Monitoring:

- Install temperature sensors to detect overheating.

- Implement automatic shutdown for excessive temperatures.

Safety Tip: Always treat auto transformers as live equipment. Never assume they are de-energized without proper verification.

Maintenance Practices

-

Regular Inspections:

- Conduct visual checks for signs of damage or wear.

- Listen for unusual noises during operation.

-

Cleaning:

- Keep the transformer and surrounding area clean and dust-free.

- Ensure proper ventilation is maintained.

-

Electrical Testing:

- Perform annual insulation resistance tests.

- Check winding resistance and turns ratio periodically.

-

Oil Analysis (for oil-filled types):

- Regularly test oil quality.

- Replace or filter oil as needed.

Maintenance Checklist:

| Task | Frequency | Importance |

|---|---|---|

| Visual Inspection | Monthly | High |

| Insulation Test | Annually | Critical |

| Oil Analysis | Semi-annually | High (for oil-filled units) |

| Thermal Imaging | Quarterly | Medium |

| Tightening Connections | Annually | High |

Case Study: Preventive Maintenance Success

A manufacturing plant implemented a rigorous maintenance schedule for their auto transformers:

- Result: Zero unplanned downtime over 5 years

- 30% reduction in energy losses

- Extended transformer lifespan by an estimated 7 years

Beginner’s Tip: Think of auto transformer maintenance like car maintenance. Regular check-ups prevent breakdowns and ensure optimal performance.

Selecting the Right Auto Transformer: Factors to Consider?

Choosing the right auto transformer is crucial for optimal system performance. Let’s explore the key factors you need to consider to make an informed decision.

Selecting the correct auto transformer involves considering factors like voltage ratio, power rating, efficiency requirements, cooling method, and environmental conditions. The right choice depends on your specific application and operating environment.

Here are the key factors to consider:

1. Voltage Ratio and Range

- Determine the required input and output voltages.

- Consider any potential future voltage changes.

- For variable auto transformers, evaluate the range of adjustment needed.

Tip: Always factor in a 10-15% margin for voltage fluctuations.

2. Power Rating

- Calculate the maximum load the transformer will need to handle.

- Include a safety margin for potential future expansion (typically 20-30%).

- Consider the duty cycle: continuous or intermittent operation.

Real-World Advice: I once consulted on a project where the client underestimated their future power needs. Within two years, they had to replace their auto transformers. Always plan for growth!

3. Efficiency and Losses

- Look for high-quality core materials to minimize losses.

- Consider the efficiency at different load levels.

- Evaluate the trade-off between initial cost and long-term energy savings.

4. Cooling Method

- Natural Air Cooling (Dry Type): Suitable for indoor, clean environments.

- Oil-Immersed: Better for outdoor or harsh environments, provides better cooling for higher capacities.

- Forced Air Cooling: For applications requiring enhanced cooling without oil.

5. Environmental Factors

- Temperature Range: Consider both ambient temperature and potential temperature rise.

- Humidity and Altitude: May affect insulation and cooling efficiency.

- Enclosure Type: Choose based on indoor/outdoor installation and environmental conditions.

Selection Matrix:

| Factor | Options | Considerations |

|---|---|---|

| Voltage Ratio | Fixed / Variable | Future flexibility needs |

| Power Rating | VA range | Current and future loads |

| Efficiency | Standard / High | Operating costs vs. initial investment |

| Cooling | Air / Oil / Forced Air | Environment and capacity |

| Enclosure | Indoor / Outdoor | Installation location |

Case Study: Optimal Selection

For a solar farm project,Case Study: Optimal Selection

For a solar farm project, we faced the challenge of selecting the right auto transformers to integrate variable solar power into the grid. Here’s how we approached it:

- Requirement: 5 MW capacity, voltage step-up from 400V to 33kV

- Chosen Solution: Oil-cooled auto transformers with 99% efficiency

- Key Factors:

- Variable input voltage handling capability

- High efficiency for continuous operation

- Robust cooling for outdoor installation

- Result:

- 15% improvement in overall system efficiency

- Successfully handled voltage fluctuations from 360V to 440V

- Estimated 20-year lifespan with minimal maintenance

Beginner’s Tip: When selecting an auto transformer, think of it like choosing a car. Consider your daily needs (regular load), peak performance requirements (maximum load), and the environment it will operate in (installation conditions).

Future Trends and Innovations in Auto Transformer Technology?

The world of auto transformers is evolving rapidly. Let’s explore the exciting innovations and trends shaping the future of this technology.

Future trends in auto transformer technology include smart monitoring systems, advanced materials for improved efficiency, compact designs for urban applications, and adaptations for renewable energy integration. These innovations aim to enhance performance, reliability, and sustainability.

Let’s dive into some key trends:

1. Smart Monitoring and Diagnostics

- IoT Integration: Real-time monitoring of transformer health and performance.

- Predictive Maintenance: AI-driven systems to predict and prevent failures.

- Remote Management: Ability to adjust settings and troubleshoot from afar.

Innovation Spotlight: We recently implemented a smart monitoring system for a utility company that reduced downtime by 30% through early detection of potential issues.

2. Advanced Materials

- Amorphous Core Materials: Further reduction in core losses.

- High-Temperature Superconductors: Potential for ultra-efficient, compact designs.

- Nano-engineered Insulation: Improved thermal management and lifespan.

Research Update: Recent tests with amorphous core materials have shown a 15% reduction in energy losses compared to traditional silicon steel cores.

3. Compact and Urban-Friendly Designs

- Underground Installations: Specially designed units for space-constrained urban areas.

- Modular Systems: Scalable solutions for growing power needs.

- Noise Reduction: Advanced designs to minimize acoustic impact in residential areas.

Case Study: A new urban substation project used compact, low-noise auto transformers, reducing the footprint by 40% and noise levels by 15dB compared to traditional designs.

4. Renewable Energy Integration

- Variable Frequency Operation: Adapting to the fluctuating nature of renewable sources.

- Bidirectional Power Flow: Supporting grid stability with energy storage systems.

- Hybrid Systems: Combining auto transformers with power electronics for enhanced control.

Green Energy Impact: A wind farm in Scotland implemented adaptive auto transformers, increasing energy capture efficiency by 12% during variable wind conditions.

5. Eco-Friendly Solutions

- Biodegradable Insulating Fluids: Reducing environmental impact.

- Recycled Materials: Incorporating recycled components in manufacturing.

- Energy Efficiency Standards: Meeting and exceeding evolving global standards.

Environmental Win: A manufacturer developed a new biodegradable insulating fluid that performs on par with mineral oil but degrades 90% faster in case of a spill.

Here’s a summary table of these future trends:

| Trend | Description | Potential Impact |

|---|---|---|

| Smart Monitoring | IoT and AI integration for diagnostics | Improved reliability, reduced downtime |

| Advanced Materials | New core and insulation materials | Higher efficiency, compact designs |

| Urban-Friendly Designs | Compact, low-noise solutions | Better integration in urban environments |

| Renewable Integration | Adaptations for variable renewable sources | Enhanced grid stability with renewables |

| Eco-Friendly Solutions | Sustainable materials and practices | Reduced environmental footprint |

Beginner’s Tip: Keep an eye on these trends. They’re shaping the future of power distribution and could influence your future projects or investments in electrical infrastructure.

Environmental Impact and Sustainability Considerations

As we focus more on sustainable technologies, it’s crucial to understand the environmental impact of auto transformers and how they contribute to energy efficiency.

Auto transformers play a significant role in energy efficiency and sustainable power distribution. Their compact design and high efficiency contribute to reduced material use and lower energy losses, aligning with global sustainability goals.

Let’s explore the environmental aspects of auto transformers:

1. Energy Efficiency

- High efficiency (up to 99%) means less energy wasted as heat.

- Reduced losses contribute to overall grid efficiency.

Case Study: A city-wide upgrade to high-efficiency auto transformers resulted in annual energy savings equivalent to powering 5,000 homes.

2. Material Usage

- Compact design requires less raw material compared to traditional transformers.

- Potential for using recycled materials in manufacturing.

Material Savings: On average, an auto transformer uses 30% less copper and 25% less steel than an equivalent traditional transformer.

3. Lifecycle Assessment

- Longer lifespan (typically 20-30 years) reduces replacement frequency.

- End-of-life recycling potential for most components.

Circular Economy: A transformer recycling program we implemented achieved a 95% material recovery rate.

4. Environmental Risks

- Potential oil leaks in oil-cooled units.

- Proper disposal of insulating materials at end-of-life.

Risk Mitigation: New biodegradable insulating fluids reduce environmental risk by 80% compared to mineral oils.

5. Role in Renewable Energy Integration

- Essential for efficient integration of solar and wind power into the grid.

- Enables smart grid technologies for better energy management.

Green Energy Boost: Auto transformers in a large solar farm improved energy transmission efficiency by 3%, equivalent to powering an additional 200 homes from the same solar array.

Environmental Impact Comparison:

| Aspect | Auto Transformer | Traditional Transformer |

|---|---|---|

| Energy Efficiency | Higher (especially for small changes) | Lower for small voltage changes |

| Material Use | Less | More |

| Lifespan | 20-30 years | 20-25 years |

| Recyclability | High | Moderate |

| Role in Renewables | Crucial for efficient integration | Less adaptable to variable sources |

Beginner’s Tip: When considering the environmental impact of auto transformers, look beyond just energy efficiency. Consider the entire lifecycle, from manufacturing to disposal or recycling.

Conclusion

Auto transformers are pivotal in modern power systems, offering efficiency, versatility, and sustainability benefits. From basic principles to future innovations, understanding this technology is crucial for electrical professionals and environmentally conscious planners alike. By mastering auto transformer concepts and staying abreast of emerging trends, we can build more efficient, reliable, and sustainable power distribution systems for the future.

As we’ve explored, auto transformers are not just about power regulation; they’re a key component in our transition to a more sustainable and efficient energy future. Whether you’re an engineer designing new systems, a facility manager looking to upgrade existing infrastructure, or simply an enthusiast interested in power technology, the world of auto transformers offers exciting possibilities and challenges.

Remember, the right choice of auto transformer can lead to significant energy savings, reduced environmental impact, and improved system performance. As technology continues to evolve, staying informed about the latest developments in auto transformer technology will be crucial for anyone involved in electrical engineering and power distribution.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group