Oil-Immersed Transformers Guide: Definition, Components, Principle & Maintenance

A Detailed Look at Oil-Immersed Transformers: From Basic Definition to Key Parts

Intro (PAS): Choosing the wrong transformer can lead to power outages, overheating, and expensive downtime. These hazards are worse when purchasers don’t understand the basics of oil. Find out how they function, which pieces are important, and how to keep them in good shape so you don’t make mistakes and have reliable performance over time.

What Is an Oil-Immersed Transformer? — Idea and How It Works

PAS lead: A lot of teams mix up oil-immersed with other designs, which leads to mis-specification. Not knowing “why oil?” makes decisions worse. Understanding the idea and the principle helps you choose safe, effective tools for tough jobs.

What does it mean and what makes it special? Why does it need “oil”?

An oil-immersed transformer moves energy between circuits using electromagnetic induction1. Its active elements are completely submerged in insulating oil. The oil does three important things:

- Insulation keeps the dielectric strength between high-voltage parts high, which stops flashover.

- Cooling: Takes heat from the windings and core and sends it to the radiators to be released.

- Protection: It keeps moisture and oxygen out, which slows down the aging and oxidation of insulation.

Oil-immersed units are prevalent in heavy industry, utility substations, and high-capacity power plants because they cool and insulate better.

How it works: Using electromagnetic induction in real life

According to Faraday’s Law, AC current in the main winding makes a magnetic flux in the laminated core, which makes voltage in the secondary winding. Oil immersion provides safe insulation and good heat removal, which keeps efficiency stable and extends service life.

- AC in primary → magnetic flux that changes direction in core

- Flux linkage → voltage in the secondary circuit

- Oil and paper system: stable under load in terms of thermal and dielectric properties

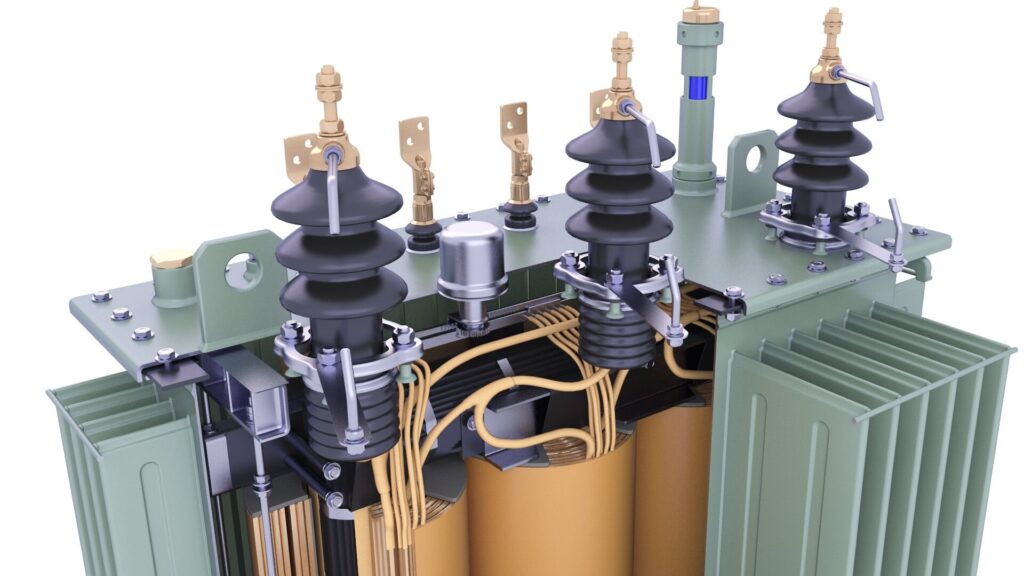

Breaking Down the Main Parts: Oil, Core, Windings, and Other Important Parts

PAS lead: Rating alone doesn’t usually cause underperformance; it’s usually parts that are left out. You can learn how to check, maintain, and specify things for long, reliable service by learning about oil, core, windings, and auxiliaries.

The “Core Medium” of Transformer Oil2

Transformer oil is more than just a coolant; it’s the living substance that keeps the system safe and stable:

- Electrical insulator: Stops electrified items from arcing within.

- Cooling medium: transfers heat to radiators or coolers so it can be released.

- Moisture barrier: Keeps dampness from getting into cellulose (paper) insulation.

- Condition indicator: Dissolved Gas Analysis3 (DGA) and dielectric tests show problems and wear and tear.

Depending on the voltage class, environmental policy, and fire safety needs, the selection ranges from mineral oils to synthetic/ester oils.

The “Heart” of the Transformer: Core and Windings

The laminated steel core reduces eddy currents and directs magnetic flux. The windings, which might be made of copper or aluminum, convey current and move energy through the core’s flux route.

- Primary winding: Connected to the power source; creates magnetic flux.

- Secondary winding: Sends power to the load and gets induced voltage.

- Paper, varnish, spacers, and oil work together to keep the insulation system from breaking down.

Modern systems that use optimized core geometry, the right conductor, and oil immersion usually get efficiencies of above 98%.

Oil tank, radiator, and other extra parts

- Main tank: An enclosure that can withstand pressure and holds the core, windings, and oil.

- Radiators and fins make the surface area bigger so that hot oil may lose heat more easily.

- The conservator tank keeps the oil from expanding or contracting when the temperature changes.

- Silica-gel breather: It keeps moisture from getting in by drying out the air that comes in.

- Buchholz relay4: Protects early by finding gas buildup from internal problems.

- Temperature gauges and indicators: Keep an eye on the levels and temperatures of the winding and oil.

How to Choose Between Oil-Immersed and Dry-Type Transformers and Important Maintenance Tips

PAS lead: Picking the wrong kind can lead to higher costs, safety issues, and failures that could have been avoided. To choose with confidence and use securely, compare features, match applications, and do the necessary maintenance.

Advantages and Disadvantages Compared: Cooling, Insulation, Cost, and Environmental Impact

| Feature | Oil-Immersed Transformers | Dry-Type Transformers |

|---|---|---|

| Cooling | Excellent; oil circulation + radiators (ONAN/ONAF) | Moderate; air flow or resin encapsulation |

| Insulation | Oil + paper; high dielectric strength | Epoxy resin or air system |

| Initial Cost | Generally lower at high ratings | Often higher |

| Maintenance | Requires oil testing/monitoring | Lower routine maintenance |

| Fire Risk | Higher; oil is flammable | Lower; no oil |

| Environmental | Potential for oil leakage/pollution | Cleaner footprint, indoor-friendly |

For high-voltage, outdoor, or utility-scale uses, use oil-immersed. For indoor, public, or environmentally sensitive settings, use dry-type.

A Guide to Application Scenarios and Choosing

- Oil-Immersed: power plants, mining, steel, petrochemical, rural networks, and transmission/distribution substations.

- Dry-Type: Hospitals, schools, high-rises, shopping complexes, tunnels, and platforms in the ocean.

Checklist for selection:

- Match to the conditions of the place (indoor/outdoor, ambient, fire code).

- Weigh the risks of oil against the benefits of resin for safety and performance.

- Look at the total cost of ownership (TCO) instead of just the capital expenditures (CAPEX).

- Check that you are following the IEC/IEEE/ANSI standards5 for your area.

Maintenance and Questions That Are Often Asked (FAQ)

Things you need to do for maintenance:

- Set up regular oil testing for DGA, acidity, moisture, and dielectric strength.

- Check the silica-gel breather and change it when the color shows it is full.

- Keep an eye on the temperatures of the winding and oil, the loading patterns, and the cooling stage.

- Check the Buchholz relay and protection circuits, and look into any alerts right away.

- Look for leaks, rust, loose bushings, and gaskets that have worn out.

FAQ:

How long will a transformer that is submerged in oil last?

Usually 20 to 30 years, although it can last longer if you load it, cool it, and take care of the oil properly.

When is it time to change the oil in a transformer?

DGA shows problems when dielectric strength is below limits, acidity or moisture levels are too high, or both. This is after checking with trend data.

Which is safer: oil-immersed or dry-type?

Dry-type for inside or public places. Oil-immersed often works better and has more thermal headroom when the voltage is high or the job is tough outside.

What tests do you need to do on a regular basis?

Dielectric testing, DGA, moisture and acidity tests, thermography, protective relay functional checks, and tests of the turns ratio every so often.

Conclusion

In conclusion, PAS: Making bad choices can lead to downtime and safety issues. You may avoid problems by knowing how things work, what they are, and how to take care of them. Choose the proper type, keep the oil system in good shape, and your transformer will work well and safely for decades.

Learn More

Want to explore detailed specifications and models? You can download our product catalog or browse our website to learn more about CHBEB’s transformer solutions.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group