Optimizing Three Phase Pad Mounted Transformer Efficiency for Industrial Settings?

Is your industrial facility struggling with high energy costs? The culprit might be hiding in plain sight. Inefficient three phase pad mounted transformers could be silently draining your profits.

Optimizing three phase pad mounted transformer efficiency in industrial settings involves proper sizing, regular maintenance, and implementing energy-saving technologies. Key strategies include load management, cooling system upgrades, and using high-efficiency core materials. These improvements can significantly reduce energy losses and operational costs.

In this article, I’ll guide you through the essentials of optimizing your three phase pad mounted transformers. Whether you’re a plant manager or an energy consultant, you’ll find valuable insights to boost your facility’s energy efficiency and cut costs.

Three Phase Transformers Explained: Powering Your Industrial World?

Have you ever wondered how your factory’s massive machines get their power? The answer lies in those big green boxes outside – your three phase pad mounted transformers. But how exactly do they work?

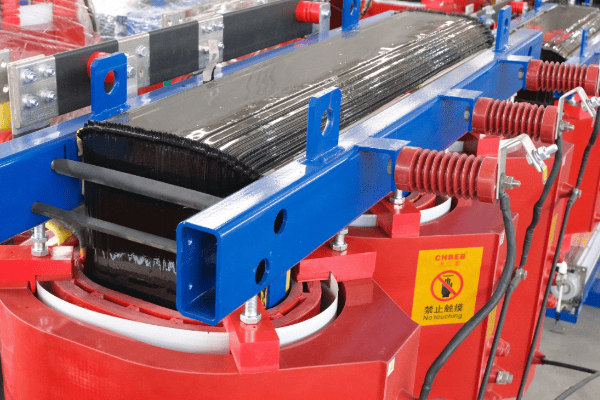

Three phase pad mounted transformers are crucial for industrial power distribution. They convert high voltage electricity from utility lines to usable levels for industrial equipment. These transformers use three separate phases of power, allowing for more efficient and stable energy transmission in high-demand settings.

Let’s break down the key components and functions of these power workhorses:

The Basics: What Makes It ‘Three Phase’?

Three phase power is the backbone of industrial electricity supply.

Key Aspects:

- Three separate electrical waves

- 120-degree phase difference between each wave

- More efficient power transmission than single phase

Core Components: The Heart of the Transformer

The transformer’s core is where the magic of voltage conversion happens.

Core Elements:

- Laminated steel construction

- Three legs for three phases

- Designed to minimize energy losses

Windings: The Power Converters

Windings are responsible for stepping voltage up or down.

Winding Types:

- Primary windings (high voltage side)

- Secondary windings (low voltage side)

- Delta or Wye configurations

Cooling Systems: Keeping It Cool Under Pressure

Efficient cooling is crucial for transformer performance and longevity.

Cooling Methods:

- Oil-immersed designs

- Forced air cooling

- Water cooling for larger units

| Component | Function | Efficiency Impact |

|---|---|---|

| Core | Magnetic flux transfer | High – Core losses affect overall efficiency |

| Windings | Voltage transformation | Medium – Copper losses occur here |

| Cooling System | Heat dissipation | Medium – Affects operational efficiency |

| Insulation | Electrical isolation | Low – Quality affects long-term efficiency |

I remember my first encounter with a three phase pad mounted transformer in an industrial setting. It was during my early days as an electrical engineer, and I was tasked with assessing the power distribution system of a large manufacturing plant.

As I approached the transformer, I was struck by its size and complexity. The plant manager, noticing my interest, began explaining how crucial this piece of equipment was to their operations. "This transformer," he said, "is what allows us to run all our heavy machinery simultaneously without overloading the system."

Intrigued, I decided to dive deeper into understanding its operation. I started by examining the nameplate, which provided key information about its capacity and voltage ratings. The three phase nature of the transformer was evident from the three sets of bushings protruding from the top.

One of the most fascinating aspects was the core design. When we opened the transformer for inspection, I saw the three-legged core structure, each leg corresponding to one phase of power. The plant’s chief electrician explained how this design allowed for more efficient power transmission compared to three single phase transformers.

The windings were another point of interest. The primary windings, connected to the high voltage input, were wound around each leg of the core. The secondary windings, providing the lower voltage output for the plant’s equipment, were similarly arranged. The electrician pointed out how the winding configuration – in this case, a delta-wye arrangement – helped in voltage regulation and harmonic suppression.

What really caught my attention was the cooling system. This particular transformer used an oil-immersed design with external radiators. The oil served a dual purpose: insulating the windings and dissipating heat. I learned that maintaining the proper oil level and quality was crucial for the transformer’s efficiency and longevity.

During our inspection, we noticed that one of the cooling fans wasn’t operating correctly. The plant manager explained that this had led to slightly higher operating temperatures, potentially reducing efficiency. This incident highlighted the importance of regular maintenance in keeping these transformers running at peak performance.

As we concluded our tour, I realized the complexity and importance of these often-overlooked pieces of equipment. Three phase pad mounted transformers are not just simple voltage converters; they are sophisticated systems that require careful design, operation, and maintenance to power our industrial world efficiently.

This experience sparked my interest in transformer efficiency, leading me to specialize in this field. I’ve since worked on numerous projects optimizing industrial power systems, always remembering that first encounter that showed me the critical role these transformers play in our industrial infrastructure.

Understanding the basics of three phase transformers is crucial for anyone involved in industrial operations or energy management. These devices are the unsung heroes of our factories, silently ensuring that power flows smoothly to keep production lines running. By grasping their fundamental principles, we can make informed decisions about their selection, operation, and maintenance, ultimately leading to more efficient and reliable industrial power systems.

Energy Savings 101: Simple Ways to Boost Your Transformer’s Efficiency?

Are you watching your energy bills climb higher each month? Your transformer might be the hidden culprit. But don’t worry, there are simple ways to turn this power-hungry beast into an efficiency champion.

Boosting transformer efficiency involves both operational and maintenance strategies. Key methods include proper load management, regular oil testing and filtration, upgrading to high-efficiency cores, and implementing smart monitoring systems. These steps can significantly reduce energy losses and extend the transformer’s lifespan.

Let’s explore some straightforward ways to enhance your transformer’s efficiency:

Load Management: Finding the Sweet Spot

Proper load management is crucial for optimal transformer efficiency.

Efficiency Strategies:

- Balancing loads across phases

- Avoiding underloading or overloading

- Implementing peak load shifting

Regular Maintenance: The Power of Prevention

Consistent maintenance is key to maintaining high efficiency.

Maintenance Musts:

- Routine oil testing and filtration

- Checking and tightening connections

- Cleaning cooling systems regularly

Upgrade Opportunities: Embracing New Technologies

Sometimes, upgrading components can lead to significant efficiency gains.

Potential Upgrades:

- High-efficiency core materials

- Advanced cooling systems

- Smart monitoring and control systems

Insulation Integrity: The Silent Efficiency Killer

Maintaining proper insulation is often overlooked but crucial for efficiency.

Insulation Care:

- Regular thermal imaging inspections

- Monitoring partial discharge activity

- Timely replacement of degraded insulation

Environmental Factors: Controlling the Surroundings

The transformer’s environment plays a significant role in its efficiency.

Environmental Considerations:

- Proper ventilation around the transformer

- Protection from direct sunlight and extreme weather

- Maintaining optimal ambient temperature

| Efficiency Measure | Potential Savings | Implementation Difficulty |

|---|---|---|

| Load Management | 2-5% energy savings | Medium – Requires load analysis |

| Regular Maintenance | 1-3% efficiency improvement | Low – Can be integrated into routines |

| Component Upgrades | 5-10% efficiency boost | High – Significant investment required |

| Insulation Care | 1-2% loss reduction | Medium – Specialized equipment needed |

| Environmental Control | 1-3% performance improvement | Low to Medium – Site-dependent |

I recall a project where we tackled efficiency issues in a manufacturing plant’s transformer. The facility was experiencing higher than expected energy costs, and the plant manager was at his wit’s end trying to figure out why.

Our first step was to analyze the transformer’s loading pattern. We discovered that the transformer was significantly underloaded most of the time, only reaching its optimal efficiency range during peak production hours. This underloading was causing unnecessary core losses.

To address this, we implemented a load management strategy. We worked with the plant’s production team to redistribute some of their energy-intensive processes to off-peak hours. This not only balanced the transformer’s load but also took advantage of lower electricity rates during off-peak times.

Next, we turned our attention to maintenance. The plant had been following a basic maintenance schedule, but it wasn’t comprehensive enough. We introduced regular oil testing and filtration. During our first thorough oil analysis, we found early signs of insulation breakdown, which we were able to address before it became a major issue.

One of the most impactful changes we made was upgrading the transformer’s core. The existing core was made of standard silicon steel. We replaced it with a high-efficiency amorphous metal core. This upgrade alone resulted in a 3% reduction in core losses, which translated to significant energy savings over time.

We also focused on the cooling system. The existing fans were old and inefficient. We replaced them with modern, variable-speed fans controlled by a smart monitoring system. This not only improved cooling efficiency but also reduced the energy consumed by the cooling system itself.

Insulation integrity was another area we addressed. Using thermal imaging, we identified several hotspots that indicated potential insulation problems. By addressing these issues promptly, we prevented further degradation and potential failures.

The environmental factors around the transformer were also considered. We improved ventilation around the unit and installed shading to protect it from direct sunlight. These simple changes helped maintain a more consistent operating temperature, reducing stress on the cooling system.

One of the most interesting aspects of this project was implementing a smart monitoring system. This system provided real-time data on the transformer’s performance, allowing for proactive maintenance and immediate response to any efficiency drops.

The results of these combined efforts were impressive. Over the course of a year, the plant saw a 7% reduction in energy losses related to their transformer. This translated to substantial cost savings and a significant decrease in their carbon footprint.

This experience taught me that improving transformer efficiency is not about one big change, but rather a combination of several strategic improvements. It’s about understanding the transformer as a system and optimizing each component.

For plant managers and engineers looking to boost their transformer’s efficiency, my advice is to start with the basics: proper loading, regular maintenance, and keeping an eye on insulation health. These steps alone can lead to noticeable improvements. Then, as budget allows, consider more significant upgrades like core replacements or smart monitoring systems.

Remember, an efficient transformer is not just about saving money – it’s about improving the reliability and sustainability of your entire operation. Every percentage point of improved efficiency contributes to a more robust and environmentally friendly industrial process.

Signs of a Struggling Transformer: What Every Plant Manager Should Know?

Is your transformer trying to tell you something? Ignoring its subtle cries for help could lead to catastrophic failure and costly downtime. But how can you spot the warning signs before it’s too late?

Recognizing signs of a struggling transformer is crucial for preventing failures and maintaining efficiency. Key indicators include unusual noises, oil leaks, overheating, decreased performance, and abnormal test results. Regular monitoring and prompt response to these signs can prevent major breakdowns and extend the transformer’s lifespan.

Let’s explore the critical signs that your transformer might be in distress:

Unusual Noises: The Transformer’s Cry for Help

Transformers typically operate quietly. Any new or unusual sound is a red flag.

What to Listen For:

- Humming louder than usual

- Crackling or popping sounds

- Sudden changes in operational noise

Oil Leaks: The Silent Threat

Oil leaks can indicate serious problems and lead to transformer failure.

Leak Indicators:

- Oil stains on the transformer body

- Puddles around the base

- Decreasing oil levels in gauges

Overheating: When Things Get Too Hot

Excessive heat is a major enemy of transformer efficiency and longevity.

Heat Warning Signs:

- Hot spots on the transformer surface

- Discolored paint or bubbling finish

- Tripping of temperature alarms

Performance Issues: The Efficiency Decline

A drop in performance can indicate internal problems.

Performance Red Flags:

- Voltage fluctuations

- Increased energy losses

- Frequent circuit breaker trips

Abnormal Test Results: The Hidden Troubles

Regular testing can reveal issues before they become visible problems.

Key Test Indicators:

- Changes in dissolved gas analysis results

- Declining insulation resistance

- Abnormal power factor test results

| Warning Sign | Potential Cause | Recommended Action |

|---|---|---|

| Unusual Noises | Loose windings, core issues | Immediate inspection |

| Oil Leaks | Gasket failure, tank cracks | Repair and oil top-up |

| Overheating | Cooling system failure, overloading | Load review, cooling check |

| Performance Issues | Internal faults, aging | Electrical testing |

| Abnormal Test Results | Insulation degradation, contamination | Detailed analysis, possible repair |

I remember a particularly eye-opening experience early in my career when I was called to a manufacturing plant experiencing intermittent power issues. The plant manager was frustrated, as these issues were causing production delays, but they couldn’t pinpoint the source of the problem.

As we approached the main transformer, I immediately noticed something was off. There was a subtle but distinct change in the humming sound coming from the unit. To the untrained ear, it might have gone unnoticed, but this change in pitch was my first clue that something wasn’t right.

Upon closer inspection, we found small oil stains at the base of the transformer. These stains weren’t obvious at first glance, hidden behind some equipment, which explained why they had been overlooked during routine checks. This discovery prompted a more thorough examination.

Using a thermal imaging camera, we scanned the transformer’s surface. The images revealed several hotspots, particularly around the top of the tank. This indicated potential issues with the windings or insulation.

We decided to conduct a series of tests, starting with a dissolved gas analysis (DGA) of the transformer oil. The results were alarming – they showed elevated levels of ethylene and acetylene, gases typically associated with arcing within the transformer.

Further electrical tests revealed that the transformer’s efficiency had declined significantly. It was operating well below its rated capacity, explaining the plant’s power issues and increased energy costs.

This combination of signs – the unusual noise, oil leaks, hotspots, and abnormal test results – all pointed to a transformer on the brink of failure. We immediately recommended taking the transformer offline for repairs.

The root cause turned out to be a combination of factors: aging insulation, a small internal fault that had been gradually worsening, and a partially blocked cooling duct. If left unchecked, this could have led to a catastrophic failure, potentially causing a plant-wide shutdown and posing safety risks.

This experience taught me the importance of being attentive to even the subtlest signs of transformer distress. It also highlighted the value of regular, comprehensive inspections and testing. Many of these issues could have been caught earlier with a more rigorous maintenance program.

For plant managers and maintenance teams, I always emphasize the importance of developing a keen eye (and ear) for these warning signs. Regular walk-throughs, listening for changes in sound, looking for oil stains, and feeling for unusual heat can go a long way in catching problems early.

I also stress the importance of keeping detailed records of transformer performance and test results. These historical data can be invaluable in spotting gradual changes that might otherwise go unnoticed.

Remember, a transformer doesn’t typically fail without warning. It often gives us clues – sometimes subtle, sometimes obvious – that something is amiss. By learning to recognize and respond to these signs promptly, we can prevent minor issues from escalating into major problems, ensuring the reliability and efficiency of our industrial power systems.

In the world of industrial operations, where every minute of downtime can mean significant losses, being proactive about transformer health is not just good practice – it’s essential for maintaining productivity and safety.

Green Power: How Efficient Transformers Help Your Factory and the Environment?

Are you looking to reduce your factory’s carbon footprint while also cutting costs? The solution might be right under your nose – in your transformer yard. Efficient transformers are not just good for your bottom line; they’re a powerful tool in the fight against climate change.

Efficient transformers significantly reduce energy losses, lowering both operational costs and environmental impact. They minimize wasted energy, reduce greenhouse gas emissions, and decrease the demand on power generation facilities. By upgrading to high-efficiency transformers, factories can contribute to sustainability goals while improving their energy performance.

Let’s explore how efficient transformers can make your factory greener and more cost-effective:

Energy Loss Reduction: Every Watt Counts

Efficient transformers minimize energy losses, directly impacting your carbon footprint.

Key Benefits:

- Lower core losses during idle periods

- Reduced copper losses under load

- Decreased overall energy consumption

Sustainable### Sustainable Materials: Building a Greener Future

Modern efficient transformers often use more environmentally friendly materials.

Green Material Choices:

- Biodegradable transformer oils

- Recyclable core and winding materials

- Low-emission insulation options

Load Management: Optimizing Power Use

Efficient transformers enable better load management, reducing waste.

Efficiency Strategies:

- Smart load distribution

- Peak shaving capabilities

- Integration with renewable energy sources

Longer Lifespan: Reducing Environmental Impact

Efficient transformers typically last longer, reducing the need for replacements.

Longevity Factors:

- Better heat management

- Reduced stress on components

- Advanced monitoring for preventive maintenance

Compliance and Incentives: Meeting Green Standards

Efficient transformers help meet environmental regulations and can qualify for incentives.

Regulatory Advantages:

- Compliance with energy efficiency standards

- Potential for green energy credits

- Improved corporate sustainability ratings

| Efficiency Aspect | Environmental Benefit | Economic Benefit |

|---|---|---|

| Energy Loss Reduction | Lower CO2 emissions | Reduced electricity costs |

| Sustainable Materials | Less environmental impact | Potential tax incentives |

| Load Management | Optimized energy use | Better power quality |

| Longer Lifespan | Reduced waste | Lower replacement costs |

| Compliance | Meeting green standards | Avoiding penalties, gaining incentives |

I recall a project where we helped a large manufacturing plant upgrade their transformer system to improve efficiency and reduce their environmental impact. The plant manager was initially skeptical about the investment, focusing mainly on the upfront costs rather than long-term benefits.

We started by conducting a comprehensive energy audit of their existing transformer system. The results were eye-opening. Their old transformers were operating at an efficiency of only 95%, which might sound high, but in the world of industrial power, those 5% losses translated to significant energy waste and unnecessary CO2 emissions.

We proposed replacing their aging units with new, high-efficiency transformers boasting an efficiency rating of 98.5%. The difference might seem small on paper, but the impact was substantial. We calculated that this upgrade would reduce their annual energy losses by over 100,000 kWh – equivalent to the yearly electricity consumption of about 10 average homes.

One of the most interesting aspects of this project was the choice of materials. We opted for transformers using biodegradable ester fluids instead of traditional mineral oil. This not only reduced the environmental risk in case of leaks but also improved the transformer’s fire safety rating, an added bonus for the plant’s insurance considerations.

The core of the new transformers was made from advanced amorphous metal, which significantly reduced no-load losses. This was particularly important for this plant, as their production schedule included periods of low activity where transformers would be largely idle.

We also implemented a smart load management system. This system could dynamically adjust the transformer’s output based on the plant’s varying power needs throughout the day. During peak production hours, it ensured optimal power distribution, while during off-hours, it minimized wastage.

One unexpected benefit came from the transformers’ ability to handle harmonic currents more effectively. This improved overall power quality, reducing stress on other electrical equipment in the plant and potentially extending their lifespan as well.

The plant manager was particularly impressed with the monitoring capabilities of the new system. Real-time efficiency data allowed for proactive maintenance, preventing issues before they could impact production or energy consumption.

About a year after the installation, we conducted a follow-up assessment. The results exceeded even our optimistic projections. The plant had reduced its energy consumption related to transformer losses by nearly 70%. This translated to a significant reduction in their carbon footprint – equivalent to taking about 15 cars off the road each year.

The financial benefits were equally impressive. The energy savings alone meant the new transformers would pay for themselves in just over four years. Additionally, the plant qualified for several green energy incentives, further offsetting the initial investment.

But perhaps the most satisfying outcome was the change in the plant manager’s perspective. What started as a reluctant investment in "green technology" became a cornerstone of the company’s sustainability strategy. They began to look at other areas of their operation where similar efficiency improvements could be made.

This experience reinforced my belief in the power of efficient transformers not just as energy-saving devices, but as catalysts for broader environmental consciousness in industrial settings. It showed that with the right approach, economic and environmental benefits can go hand in hand.

For factory owners and managers considering similar upgrades, my advice is to look beyond the initial costs. Consider the long-term savings, both financial and environmental. Efficient transformers are not just about reducing electricity bills; they’re about future-proofing your operation in a world increasingly focused on sustainability.

Remember, every kilowatt-hour saved is a step towards a greener future. By investing in efficient transformer technology, factories can play a significant role in reducing industrial energy consumption and combating climate change, all while improving their bottom line.

From Installation to Operation: Maximizing Your Transformer’s Performance?

Are you getting the most out of your industrial transformer? Many factory managers overlook the critical steps from installation to daily operation that can make or break a transformer’s performance. Let’s change that.

Maximizing transformer performance involves careful attention from installation through operation. Key factors include proper sizing, correct installation practices, regular maintenance, and optimal operational strategies. By focusing on these areas, industries can ensure their transformers operate at peak efficiency, reducing costs and improving reliability.

Let’s explore the crucial steps to ensure your transformer performs at its best:

Proper Sizing: The Foundation of Efficiency

Choosing the right size transformer is crucial for optimal performance.

Sizing Considerations:

- Accurate load calculations

- Future growth projections

- Peak demand analysis

Installation Best Practices: Setting Up for Success

Correct installation is vital for long-term performance and safety.

Key Installation Steps:

- Proper foundation preparation

- Correct electrical connections

- Adequate ventilation and cooling setup

Regular Maintenance: Keeping Performance High

Consistent maintenance is essential for sustained efficiency.

Maintenance Musts:

- Scheduled oil testing and filtration

- Thermal imaging inspections

- Tightening of connections and bushings

Operational Strategies: Day-to-Day Excellence

How you operate your transformer can significantly impact its performance.

Operational Tips:

- Load balancing across phases

- Monitoring and managing power factor

- Implementing energy-saving practices during off-peak hours

Monitoring and Upgrades: Staying Ahead of the Curve

Keeping an eye on performance and upgrading when necessary ensures long-term efficiency.

Monitoring and Upgrade Strategies:

- Implementing smart monitoring systems

- Analyzing performance trends

- Upgrading components as technology improves

| Performance Aspect | Impact on Efficiency | Implementation Difficulty |

|---|---|---|

| Proper Sizing | High – Foundational for efficiency | Medium – Requires careful planning |

| Correct Installation | High – Affects long-term performance | Medium – Needs skilled technicians |

| Regular Maintenance | Medium – Prevents efficiency decline | Low – Can be routinely scheduled |

| Operational Strategies | Medium – Optimizes daily performance | Low – Involves operational changes |

| Monitoring and Upgrades | High – Ensures continued efficiency | Medium – Requires ongoing investment |

I remember a particularly challenging project involving a food processing plant that was struggling with frequent power issues and high energy costs. Upon investigation, we discovered that many of their problems stemmed from poorly managed transformers, right from installation to daily operation.

Our first step was to reassess the sizing of their main transformers. We found that due to recent expansions, the plant had outgrown its transformer capacity. The units were constantly operating near their maximum load, leading to increased losses and reduced efficiency. We worked with the plant engineers to accurately calculate current and projected loads, then sized new transformers to meet these needs with room for future growth.

During the installation of the new transformers, we paid close attention to every detail. We ensured a proper foundation was laid, capable of supporting the weight and providing stability. The electrical connections were made with precision, using high-quality materials to minimize connection losses. We also redesigned the transformer yard to improve ventilation, crucial for maintaining optimal operating temperatures.

One interesting challenge we faced was integrating the new transformers with the plant’s existing power distribution system. We implemented a phased installation approach to minimize production downtime, carefully planning each step to ensure a smooth transition.

Once the new transformers were in place, we established a comprehensive maintenance program. This included regular oil testing and filtration schedules, thermal imaging inspections to catch hotspots early, and periodic tightening of all connections. We trained the plant’s maintenance team on these procedures, emphasizing the importance of consistency in these routines.

For day-to-day operations, we worked with the plant managers to implement new strategies for load management. This included balancing loads across all three phases of the transformers and adjusting production schedules to better manage peak demand periods. We also installed power factor correction equipment to improve overall system efficiency.

One of the most impactful changes was the implementation of a smart monitoring system. This allowed real-time tracking of the transformers’ performance, including load levels, temperatures, and efficiency metrics. The system was set up to alert maintenance staff of any anomalies, enabling proactive interventions before minor issues could escalate.

About six months after these changes were implemented, the results were clear. The plant saw a 15% reduction in energy losses related to their transformer system. Power quality improved significantly, reducing issues with sensitive production equipment. The frequency of unplanned downtime due to electrical issues dropped by over 80%.

An unexpected benefit came in the form of improved safety. With the new installation and monitoring systems in place, potential hazards were identified and addressed much more quickly, creating a safer working environment.

The plant manager was particularly impressed with how these improvements affected their bottom line. The energy savings alone meant the project would pay for itself faster than initially projected. Moreover, the increased reliability had a positive impact on production efficiency, further boosting the plant’s profitability.

This experience reinforced my belief in the importance of a holistic approach to transformer management. It’s not enough to simply install a good transformer and forget about it. From proper sizing and installation to ongoing maintenance and smart operational strategies, every step plays a crucial role in maximizing performance.

For industrial managers looking to improve their transformer efficiency, my advice is to view it as an ongoing process rather than a one-time task. Start with ensuring your transformers are properly sized and installed, then focus on developing robust maintenance routines and smart operational practices. Keep an eye on emerging technologies and be willing to invest in upgrades that can improve efficiency and reliability.

Remember, a well-managed transformer is not just a piece of equipment – it’s a key asset in your industrial operation. By giving it the attention it deserves, from installation through its entire operational life, you can ensure it performs at its best, contributing to a more efficient, reliable, and cost-effective industrial process.

Conclusion

Optimizing three phase pad mounted transformer efficiency in industrial settings is crucial for reducing energy costs and environmental impact. From understanding basics to implementing advanced strategies, proper management of these vital components can significantly enhance industrial operations and sustainability.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group