Power Transformer Construction: A Deep Dive into Key Components and Their Functions | CHBEB

Introduction

Power transformers are very important for sending and receiving power, but how they are built on the inside is still a mystery. Not knowing parts can lead to bad design, slow performance, and problems with maintenance. This book goes into great detail about how transformers are built, focusing on how each item affects safety, dependability, and long-term performance.

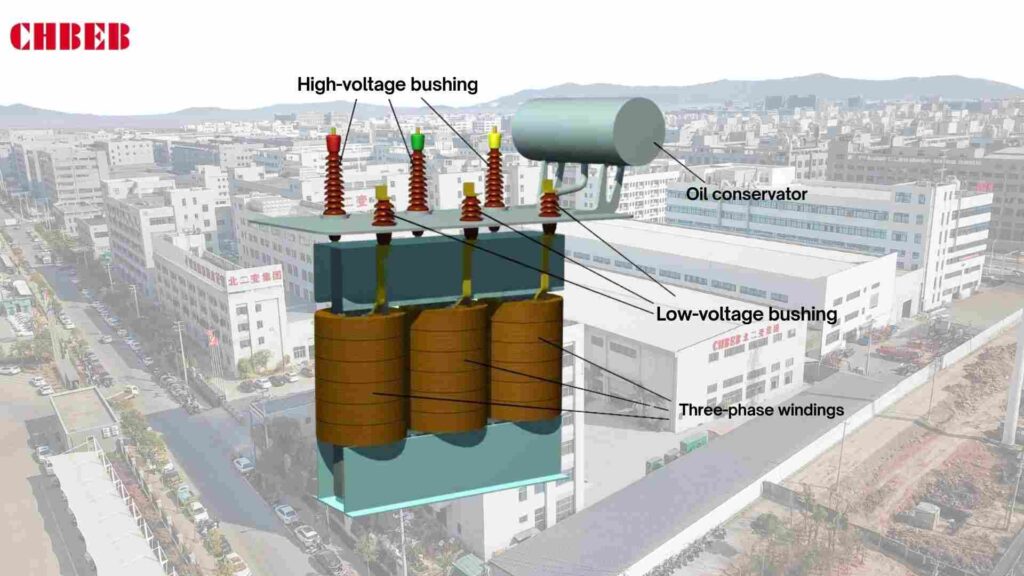

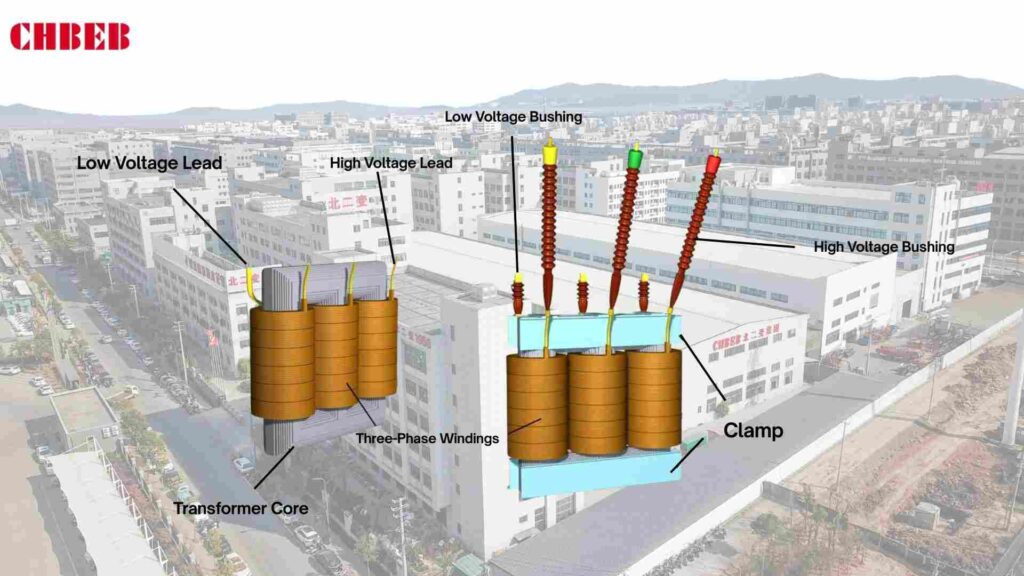

Part 1: The Main Part of How the Transformer Works

The active parts of a transformer are what make it work. The transformer can’t safely operate or convert voltage stably if the core, windings, or insulation are badly built. Both purchasers and engineers need to know about these interior parts.

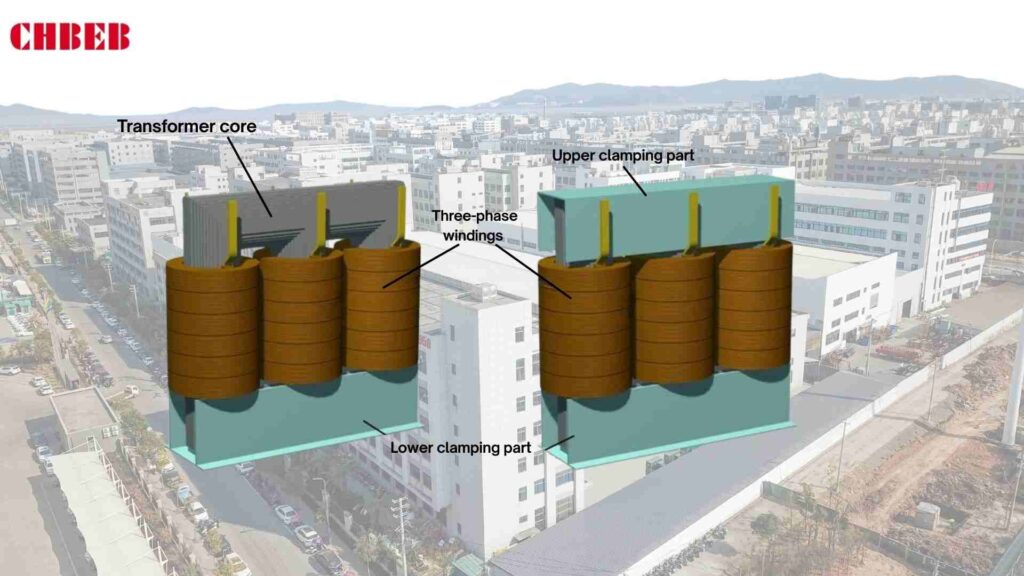

The Magnetic Core1: The Transformer’s Frame

The magnetic core makes the skeleton of the transformer and gives the flux a path. It is usually built of laminated silicon steel sheets to cut down on losses from eddy currents. Amorphous alloy cores can be employed in designs that need to be very efficient. The shape of the core (core-type or shell-type) has a direct effect on the amount of loss, the strength of the structure, and the noise.

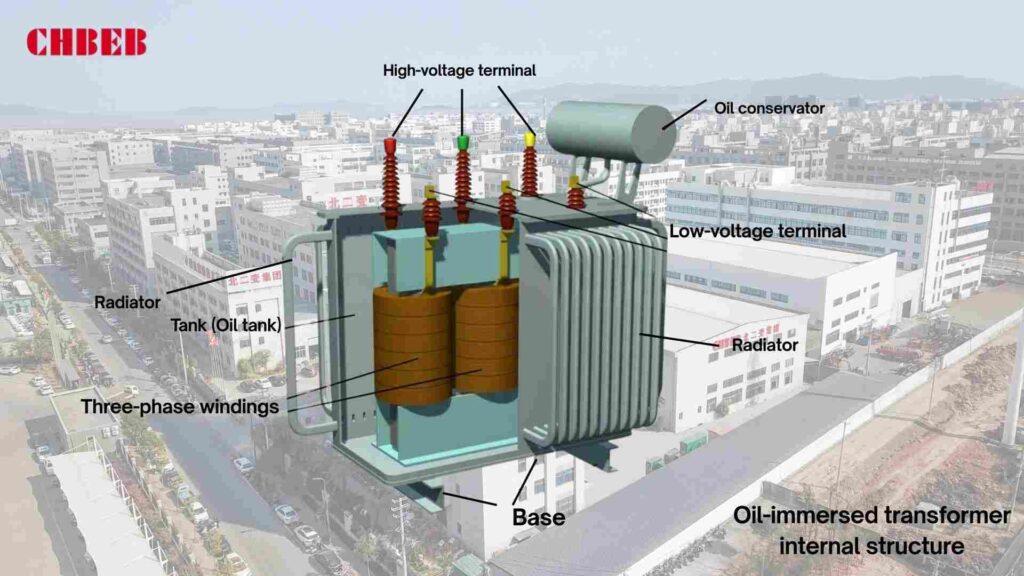

The Windings: The Transformer Core

Windings change the voltage of electrical energy. They are made of copper2 or aluminum conductors and are stacked in layers of high and low voltage. The low-voltage winding is usually closer to the core, and the high-voltage winding surrounds it. Buyers have to make a big choice between copper and aluminum since it impacts efficiency, short-circuit strength, and cost.

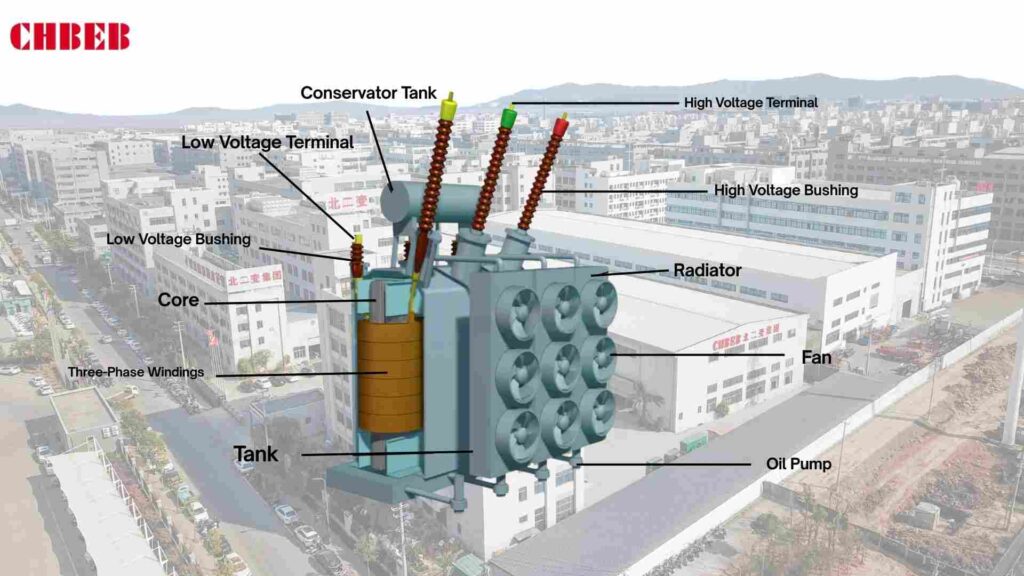

Insulation and cooling are the system’s lifeblood.

Insulation stops electrical problems from happening between the core and the windings. Pressboard, resin, and oil for liquid-filled transformers, or epoxy resin for dry-type designs are some of the materials used. Cooling systems get rid of the heat that builds up during use:

- Oil-immersed transformers: Mineral or ester oil provides both insulation and cooling. Heat dissipates through radiators or oil pumps with fans.

- Dry-type transformers3: Windings are encapsulated in epoxy resin, with natural or forced air cooling.

Both insulation and cooling affect how long something will last, how safe it is to use, and how well it can handle a load.

Part 2: The Transformer’s Systems for Support and Protection

Transformers need more than simply active parts to work. They also need external mechanisms to keep them secure and safeguard them. These parts protect against stress from the environment, electrical problems, and changes in voltage.

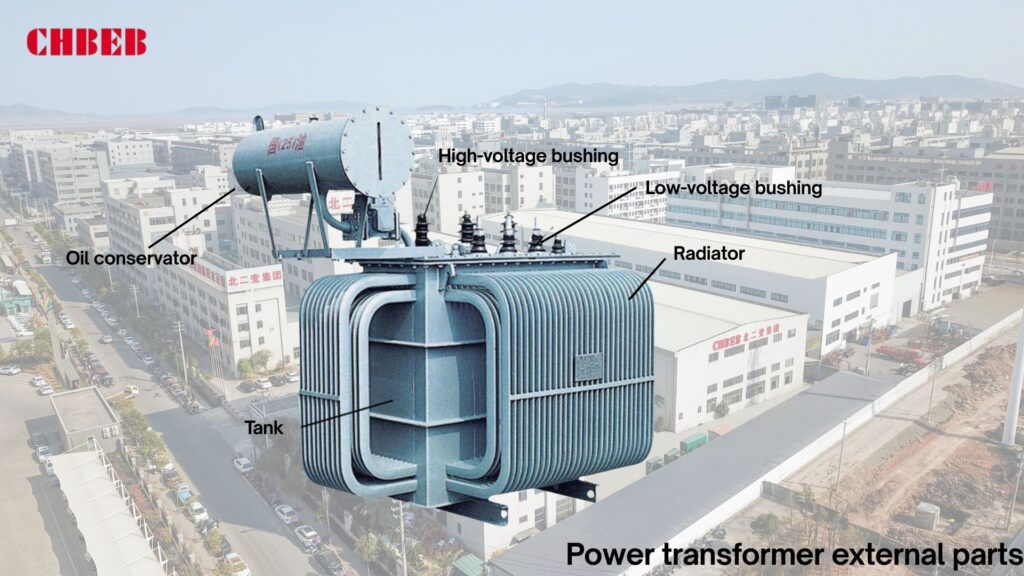

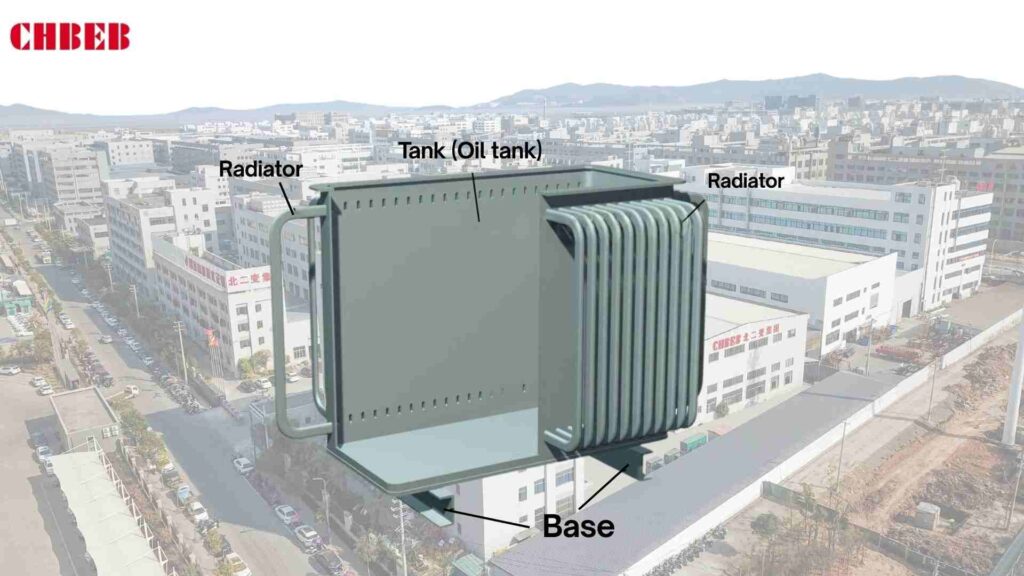

The Tank and Conservator: The Housing That Protects

The oil tank, which is sometimes called the transformer tank, holds the active parts and is filled with insulating oil. There are radiator fins or cooling pipes around the tank that let heat escape. Forced circulation is done via external oil coolers and fans on bigger units.

The conservator, or oil reservoir, makes up for the oil expanding when the temperature changes. Sealed metal bellows or bladder-type conservators are typically used in modern designs to keep oil separate from air. This keeps moisture from getting into the oil and keeps it from oxidizing. For smaller facilities, sealed tanks with corrugated fins can be utilized instead of a conservator.

The Guardian Devices: The Buchholz Relay and Breather

For transformers that are filled with oil, protection is very important:

- Buchholz relay: This device is put between the main tank and the conservator. It detects gas buildup or abrupt oil movement and sends out early fault alerts and trip signals.

- Breather: Usually filled with silica gel, it filters and dries the air that comes into the conservator. This keeps the insulation oil from being too wet.

These devices work together to protect transformers, making them last longer and keeping them safe.

The Tap Changer is the voltage regulator.

Transformers need to change the output voltage because demand and the grid change. Tap changers vary the turns ratios in the winding to control voltage::

- Off-load tap changers: You have to replace them by hand when the transformer is not working.

- On-load tap changers (OLTC) automatically alter the voltage while the system is powered on, making sure that the supply never stops.

Tap changers are very important for keeping the grid stable and safe for sensitive equipment.

Part 3: Putting It All Together: Types of Construction and Common Problems

Even with good parts, a bad overall design might cause problems. Buyers may make smart choices about how to maintain and buy transformers by learning about the many types of transformers and the problems they often have.

A Look at Structural Design: Core-Type vs. Shell-Type

- Core-Type Transformers: The windings go around the core’s limbs. This design is common for high-voltage uses and makes it easier to cool down.

- Shell-Type Transformers: The core surrounds the windings, which makes them stronger and better able to handle faults. This kind is widely utilized in power plants and other big industrial settings.

The size of the application, the voltage level, and the cost are all factors that affect the choice between core and shell kinds.

Linking Parts to Common Issues and Answers

- Core: Bad lamination can lead to a lot of noise and losses. Solution: Use tight clamping and high-quality silicon steel.

- Windings: When they get too hot, the insulation breaks down. The answer is to use the right size conductor and good insulation.

- Insulation and cooling: Hot spots happen when oil spills or air passages get blocked. The answer is to check the oil and the ventilation on a regular basis.

- Tank and conservator: Leaks happen when gaskets wear out or corrode. Routine checks and maintenance are the answer.

- Buchholz relay and breather: A broken relay or too much silica gel can make protection less effective. Solution: Testing the relay and changing the gel on a regular basis.

- Tap changer: Failures happen when contacts wear out or arc. Scheduled maintenance and oil filtering are the answers.

Maintenance staff may take action before problems happen by tying them to parts. This cuts down on downtime and extends the life of assets.

Conclusion

A power transformer is more than just copper windings inside a steel tank. Its performance depends on a careful balance of the magnetic core, windings, insulation, cooling, protective devices, and housing.

For engineers, understanding these parts means better specifications, fewer failures, and longer service life. For beginners, it’s enough to remember that every component has a role: the core carries the magnetic flow, the windings carry electricity, the insulation keeps it safe, the oil or air keeps it cool, and devices like the Buchholz relay or tap changer keep it stable and protected.

When these pieces come together with good design and proper maintenance, the result is a transformer that runs safely, efficiently, and reliably for decades—powering everything from homes and hospitals to factories and renewable plants.

- Transformer Construction — Wikipedia ↩︎

- Copper and Aluminium Windings in Transformers — ScienceDirect ↩︎

- Transformer Cooling Methods — All About Circuits ↩︎

Learn More

Want to explore more transformer solutions? Download our latest product catalog or browse our product categories to find the right transformer for your project.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

We'd like to work with you

- +86 15558785111

- chbebgroup@chbebpower.com

- +86 15558785111

What We Do

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

Latest Product

address

BeiJing

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

JiangSu

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

WenZhou

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

contact us

- chbebgroup@chbebpower.com

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group