Have you ever wondered how electricity reaches your home safely and efficiently? The answer lies in a crucial piece of equipment: the 3 phase pad mounted transformer.

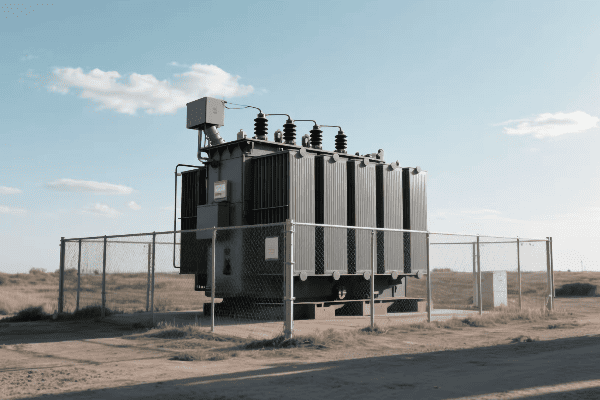

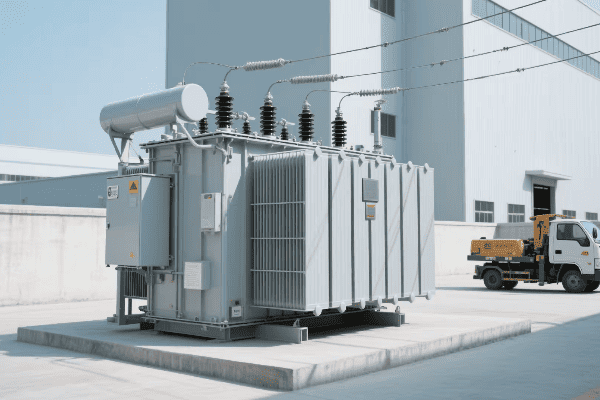

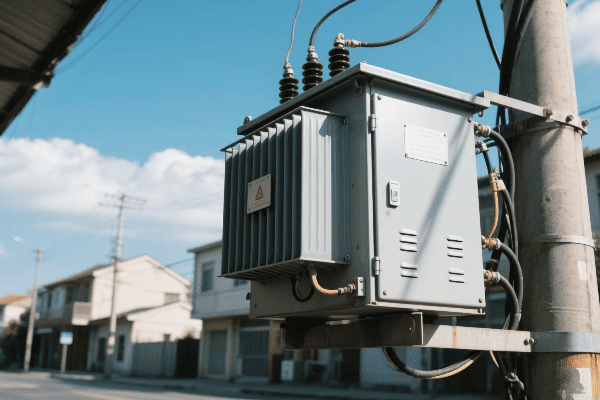

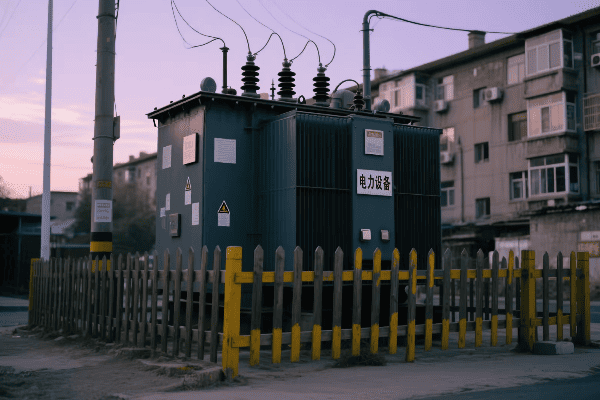

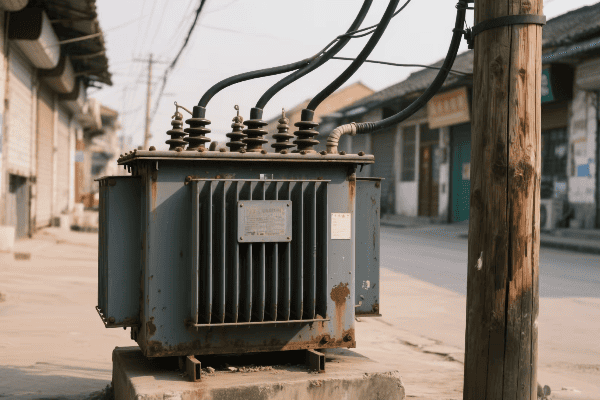

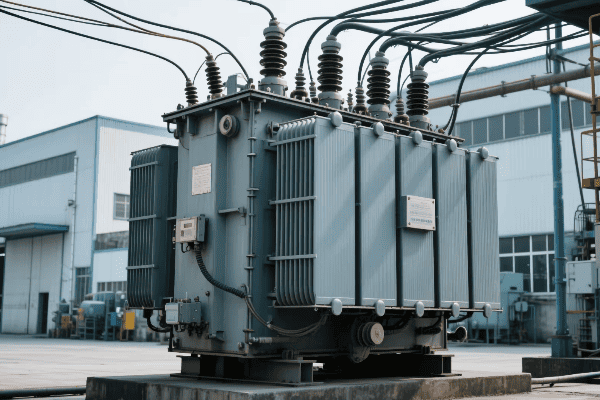

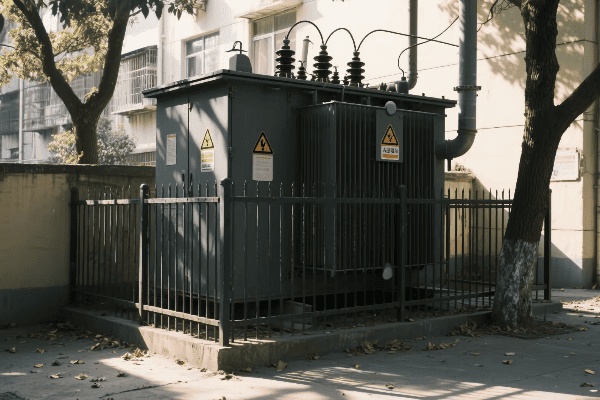

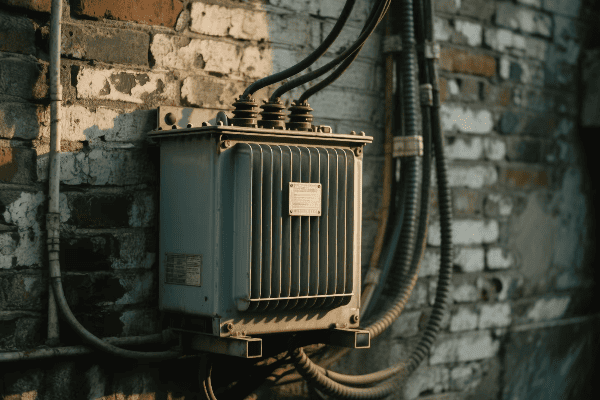

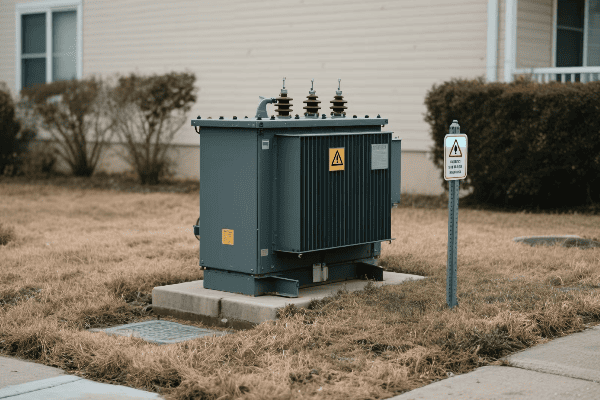

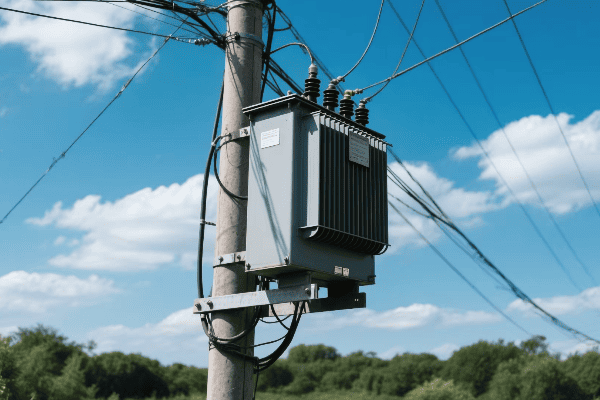

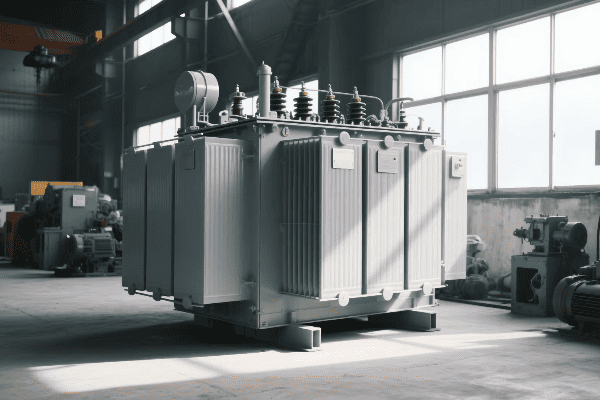

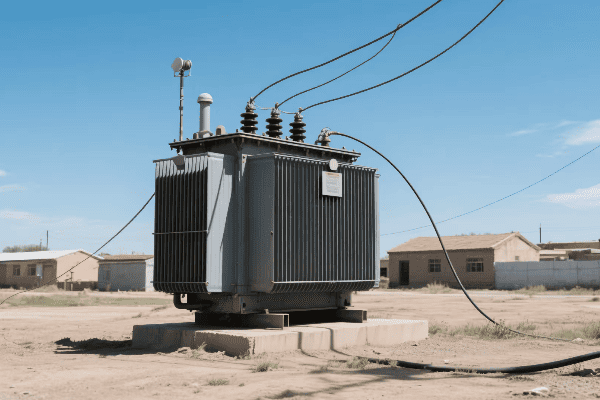

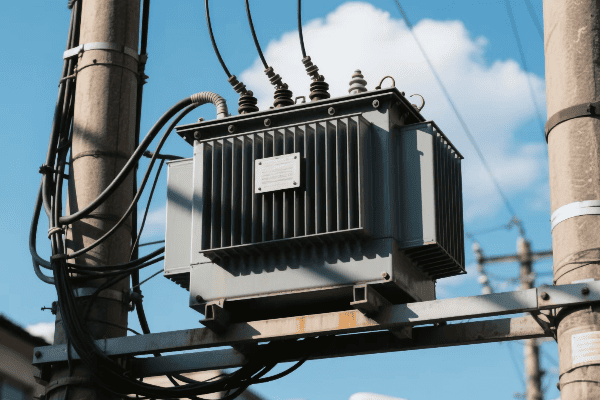

3 phase pad mounted transformers are key components in modern power distribution systems. They convert high voltage electricity to lower, usable voltages for homes and businesses. These transformers are compact, safe, and efficient, making them ideal for urban and suburban areas.

In this article, I’ll share my insights on 3 phase pad mounted transformers. My experience in designing and working with these transformers has shown me their critical role in our power infrastructure.

What Are the Unique Features and Advantages of 3 Phase Pad Mounted Transformers in Power Distribution?

When I first encountered a 3 phase pad mounted transformer, I was struck by its compact design and versatility. These transformers have revolutionized power distribution in urban areas.

3 phase pad mounted transformers offer several unique features and advantages. They are compact, aesthetically pleasing, and provide easy access for maintenance. Their enclosed design enhances safety, while their three-phase configuration allows for efficient power distribution to both residential and commercial customers.

Let’s dive deeper into these features and advantages:

Compact and Aesthetically Pleasing Design

The design of these transformers is a game-changer:

- Space-Saving: They require less space compared to pole-mounted transformers.

- Low Profile: Their height is typically less than 6 feet, reducing visual impact.

- Customizable Appearance: They can be painted or enclosed to blend with surroundings.

I once worked on a project in a historic district where we had to design a pad mounted transformer that looked like a garden shed. It was a challenge, but the result was both functional and visually appealing.

Enhanced Safety Features

Safety is a top priority in these transformers:

| Feature | Benefit |

|---|---|

| Enclosed Design | Prevents unauthorized access and protects from weather |

| Lockable Compartments | Separates high and low voltage sections for added safety |

| Dead-Front Construction | Eliminates exposed live parts, reducing risk of accidental contact |

In my career, I’ve seen how these safety features have significantly reduced accidents and improved worker safety during maintenance.

Easy Maintenance Access

Maintenance is much simpler with these transformers:

- Front and Side Panel Access: Allows easy reach to components.

- Removable Doors: Facilitates replacement of large components.

- Ground-Level Installation: Eliminates need for bucket trucks or climbing.

I remember a project where we retrofitted an old substation with pad mounted transformers. The maintenance team was thrilled with how much easier and safer their job became.

Three-Phase Configuration

The three-phase design offers several advantages:

- Balanced Load Distribution: Ideal for both residential and commercial areas.

- Higher Efficiency: Better power factor and reduced losses.

- Versatility: Can supply both single-phase and three-phase loads.

In a recent industrial park project, the three-phase configuration allowed us to efficiently power a mix of residential, commercial, and light industrial loads from the same transformer.

Environmental Considerations

These transformers are environmentally friendly:

- Oil Containment: Built-in features to prevent oil leaks.

- Reduced Noise: Quieter operation compared to pole-mounted transformers.

- Eco-Friendly Options: Some models use biodegradable fluids.

I’ve worked on projects where using eco-friendly insulating fluids was a key requirement. It’s amazing how far transformer technology has come in terms of environmental responsibility.

How Do 3 Phase Pad Mounted Transformers Enhance Efficiency and Reliability in Modern Grid Systems?

Efficiency and reliability are crucial in power distribution. I’ve seen firsthand how 3 phase pad mounted transformers have improved these aspects in modern grid systems.

3 phase pad mounted transformers enhance efficiency through reduced line losses and improved power factor. They increase reliability by providing better protection against outages and easier integration with smart grid technologies. Their design also allows for quicker repairs and replacements, minimizing downtime.

Let’s explore how these transformers boost efficiency and reliability:

Reduced Line Losses

Line losses are a significant concern in power distribution:

- Shorter Secondary Lines: Pad mounted transformers can be placed closer to loads.

- Lower Current: Three-phase configuration allows for lower currents at the same power.

- Improved Insulation: Modern materials reduce electrical losses.

I once worked on a project where replacing old pole-mounted transformers with pad mounted units reduced line losses by almost 15%. The energy savings were substantial.

Improved Power Factor

Power factor improvement is a key advantage:

| Aspect | Benefit |

|---|---|

| Balanced Loads | Three-phase design naturally balances loads |

| Reduced Reactive Power | Less strain on the distribution system |

| Better Voltage Regulation | Stable voltage leads to more efficient power use |

In a recent commercial district upgrade, the improved power factor from pad mounted transformers allowed us to defer a costly substation upgrade.

Enhanced Protection Features

These transformers come with advanced protection:

- Integrated Fusing: Protects against overloads and short circuits.

- Surge Arresters: Built-in protection against voltage spikes.

- Thermal Monitoring: Prevents overheating and extends transformer life.

I remember a case where the integrated protection in a pad mounted transformer prevented a major outage during a severe thunderstorm. It isolated the fault quickly, minimizing the impact.

Smart Grid Integration

Pad mounted transformers are ideal for smart grid integration:

- Sensor Integration: Easy to add monitoring devices.

- Communication Capabilities: Can be equipped with data transmission features.

- Remote Operation: Some models allow for remote switching and control.

I’ve been involved in several smart grid projects where pad mounted transformers were key to implementing advanced monitoring and control systems.

Quicker Repairs and Replacements

The design of these transformers facilitates faster maintenance:

- Modular Components: Easier to replace specific parts.

- Standardized Designs: Simplifies stocking of spare parts.

- Accessible Location: No need for specialized equipment for most repairs.

In my experience, the time to repair or replace a pad mounted transformer is often less than half that of a traditional pole-mounted unit. This significantly improves grid reliability.

What Are the Key Design Elements and Safety Considerations for 3 Phase Pad Mounted Transformers?

Designing 3 phase pad mounted transformers requires careful consideration of both functionality and safety. I’ve spent years refining these designs to meet evolving industry standards and customer needs.

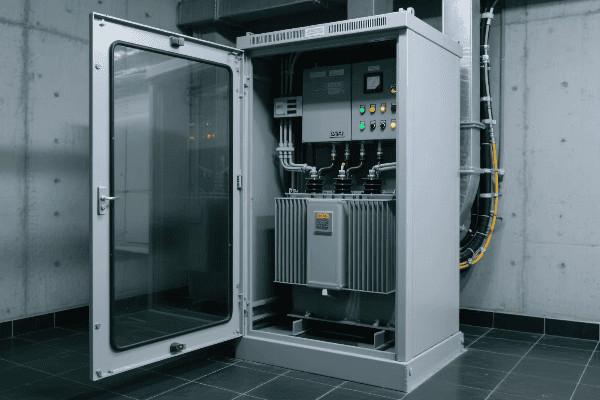

Key design elements of 3 phase pad mounted transformers include compartmentalized construction, robust insulation systems, and efficient cooling mechanisms. Safety considerations encompass tamper-resistant enclosures, internal arc containment, and proper grounding. These features ensure safe operation and maintenance in public areas.

Let’s delve into the crucial design elements and safety considerations:

Compartmentalized Construction

The internal layout is critical:

- High Voltage Compartment: Isolated section for incoming lines.

- Low Voltage Compartment: Separate area for outgoing distribution.

- Transformer Section: Houses the core and windings.

I once redesigned a transformer layout to improve compartmentalization. This change significantly enhanced safety for maintenance workers and reduced the risk of accidental contact with high voltage components.

Insulation Systems

Proper insulation is vital:

| Component | Insulation Type | Purpose |

|---|---|---|

| Windings | Oil or Dry-Type | Prevents short circuits |

| Bushings | Porcelain or Polymer | Safely conducts current through the enclosure |

| Core | Oil or Air | Provides cooling and insulation |

In a recent project, we experimented with biodegradable insulating fluids. The results were promising, offering both excellent insulation properties and environmental benefits.

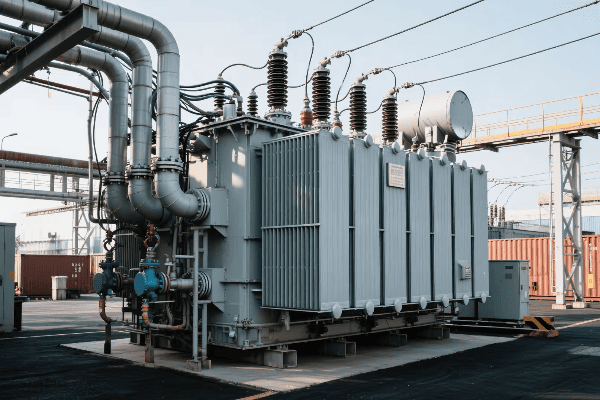

Cooling Mechanisms

Effective cooling is essential for longevity:

- Oil-Filled Designs: Use natural convection or forced oil cooling.

- Dry-Type Units: Employ air natural or forced air cooling.

- Hybrid Systems: Combine different cooling methods for optimal performance.

I’ve worked on developing cooling systems for transformers in extreme climates. In one case, we designed a custom cooling solution for a transformer in a desert environment, ensuring reliable operation in temperatures exceeding 50°C.

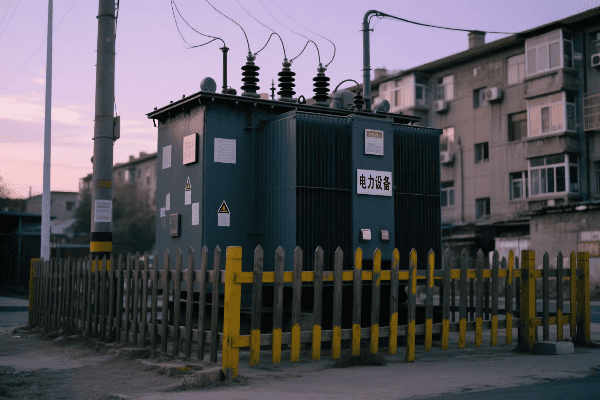

Tamper-Resistant Enclosures

Security is a top priority:

- Padlocked Doors: Prevent unauthorized access.

- Tamper-Proof Bolts: Secure access panels.

- Warning Labels: Clearly indicate dangers of entry.

I recall a project where we had to design extra secure enclosures for transformers in a high-crime area. The solution involved reinforced panels and advanced locking mechanisms.

Internal Arc Containment

Protecting against internal faults is crucial:

- Pressure Relief Devices: Safely vent internal pressure during faults.

- Reinforced Tank Design: Contains potential explosions.

- Arc-Resistant Doors: Prevent ejection of hot gases and oil.

I once witnessed a demonstration of arc containment features. The transformer contained a simulated internal fault without any external damage, showcasing the effectiveness of these safety measures.

Proper Grounding

Grounding is fundamental for safety:

- Equipment Grounding: Ensures all metal parts are at earth potential.

- System Grounding: Provides a return path for fault currents.

- Lightning Protection: Includes surge arresters and proper grounding.

In my experience, proper grounding is often overlooked but is critical for safety. I’ve seen cases where inadequate grounding led to dangerous touch potentials during fault conditions.

How Are 3 Phase Pad Mounted Transformers Integrated with Smart Grid Technologies?

The integration of 3 phase pad mounted transformers with smart grid technologies is revolutionizing power distribution. I’ve been at the forefront of this integration, witnessing the transformation of traditional grids into intelligent, responsive systems.

3 phase pad mounted transformers are integrated with smart grid technologies through advanced monitoring systems, communication capabilities, and automated control features. This integration enables real-time data collection, remote management, and improved grid responsiveness, enhancing overall efficiency and reliability.

Let’s explore how these transformers are becoming key components of smart grids:

Advanced Monitoring Systems

Modern transformers are equipped with sophisticated monitoring:

- Temperature Sensors: Track winding and oil temperatures.

- Load Monitoring: Real-time tracking of power flow.

- Dissolved Gas Analysis (DGA): Detect potential internal faults.

I recently worked on a project where we retrofitted existing pad mounted transformers with advanced monitoring systems. The utility gained unprecedented visibility into their distribution network’s performance.

Communication Capabilities

Communication is key in smart grids:

| Feature | Benefit |

|---|---|

| Wireless Connectivity | Allows remote data transmission |

| Ethernet Ports | Enables integration with utility networks |

| Protocols (e.g., DNP3, IEC 61850) | Standardizes communication across devices |

In one smart grid project, we implemented a mesh network of pad mounted transformers. This allowed for robust, self-healing communication even if individual links failed.

Automated Control Features

Automation enhances grid responsiveness:

- Remote Tap Changing: Adjust voltage levels without manual intervention.

- Fault Isolation: Automatically isolate faulty sections of the grid.

- Load Balancing: Dynamically adjust power flow for optimal distribution.

I’ve seen how these automated features can significantly reduce outage times. In one case, a smart transformer isolated a fault and rerouted power in less than a minute, minimizing the impact on customers.

Data Analytics Integration

Smart transformers generate valuable data:

- Predictive Maintenance: Use data trends to forecast potential issues.

- Load Forecasting: Analyze usage patterns for better resource planning.

- Power Quality Analysis: Identify and address power quality issues proactively.

I’ve been involved in developing analytics platforms that process data from hundreds of smart transformers. The insights gained have led to more efficient grid operations and reduced maintenance costs.

Renewable Energy Integration

These transformers play a crucial role in integrating renewables:

- Bi-Directional Power Flow: Handle power from distributed generation sources.

- Voltage Regulation: Maintain stable voltage with variable renewable inputs.

- Energy Storage Interface: Coordinate with battery systems for load balancing.

In a recent project, we designed a network of smart pad mounted transformers to manage a neighborhood with high solar panel penetration. The system successfully balanced the variable solar input with grid demand.

What Maintenance Practices and Monitoring Techniques Ensure Optimal Performance of 3 Phase Pad Mounted Transformers?

Maintaining 3 phase pad mounted transformers is crucial for their longevity and performance. Over the years, I’ve developed and implemented various maintenance strategies to keep these vital components running efficiently.

Optimal performance of 3 phase pad mounted transformers is ensured through regular inspections, proactive maintenance, and advanced monitoring techniques. Key practices include oil analysis, thermal imaging, partial discharge monitoring, and periodic electrical testing. These methods help detect potential issues early and prevent unexpected failures.

Let’s dive into the essential maintenance practices and monitoring techniques:

Regular Visual Inspections

Visual checks are the first line of defense:

- External Condition: Check for rust, dents, or leaks.

- Bushing Integrity: Inspect for cracks or contamination.

- Oil Levels: Verify proper oil levels in sight glasses.

I once discovered a small oil leak during a routine inspection that, if left unchecked, could have led to a major failure. Never underestimate the power of a thorough visual check.

Oil Analysis

Oil testing provides crucial insights:

| Test | Purpose | Frequency |

|---|---|---|

| Dissolved Gas Analysis (DGA) | Detect internal faults | Annually or semi-annually |

| Oil Quality Tests | Check for contamination and degradation | Annually |

| Furan Analysis | Assess paper insulation condition | Every 3-5 years |

I remember a case where routine DGA revealed an early-stage winding fault. We were able to schedule a repair before it led to a catastrophic failure.

Thermal Imaging

Infrared scanning can reveal hidden issues:

- Hot Spot Detection: Identify overheating components.

- Connection Integrity: Check for loose or corroded connections.

- Cooling Efficiency: Assess the performance of cooling systems.

During a summer heatwave, thermal imaging helped us identify several transformers operating near their thermal limits. We implemented emergency cooling measures to prevent outages.

Partial Discharge Monitoring

PD monitoring is crucial for insulation health:

- Online Monitoring: Continuous tracking of partial discharges.

- Periodic Testing: Scheduled PD measurements during maintenance.

- Trend Analysis: Track PD levels over time to predict insulation degradation.

I’ve seen how effective PD monitoring can be. In one instance, we detected increasing PD levels in a transformer, allowing us to schedule a rewind before a major failure occurred.

Electrical Testing

Periodic electrical tests ensure optimal performance:

- Turns Ratio Test: Verify the accuracy of voltage transformation.

- Winding Resistance Measurement: Check for winding damage or connection issues.

- Insulation Resistance Test: Assess the overall insulation condition.

I recall a project where regular electrical testing revealed a gradual shift in turns ratio. This early detection allowed us to adjust tap settings and maintain proper voltage output.

Smart Monitoring Systems

Advanced monitoring enhances maintenance strategies:

- Real-Time Data Collection: Continuous monitoring of key parameters.

- Predictive Analytics: Use AI to forecast potential issues.

- Remote Diagnostics: Analyze transformer health from a central location.

I’ve been involved in implementing smart monitoring systems that have revolutionized maintenance practices. These systems have helped utilities transition from time-based to condition-based maintenance, significantly reducing costs and improving reliability.

Environmental Protection Measures

Protecting the environment is an integral part of maintenance:

- Oil Containment: Regular checks of oil containment systems.

- Leak Detection: Use of sensors to quickly identify and address leaks.

- Eco-Friendly Practices: Proper disposal of old oil and components.

In a recent project, we upgraded the oil containment systems of several urban transformers. This not only protected the environment but also improved the utility’s public image.

Conclusion

3 phase pad mounted transformers are essential for modern power distribution. Their unique design, smart grid integration, and proper maintenance ensure efficient, reliable, and safe power delivery in urban and suburban areas.

Have you ever wondered why we need different types of transformers in our electrical grid? The answer lies in the unique roles of power and distribution transformers.

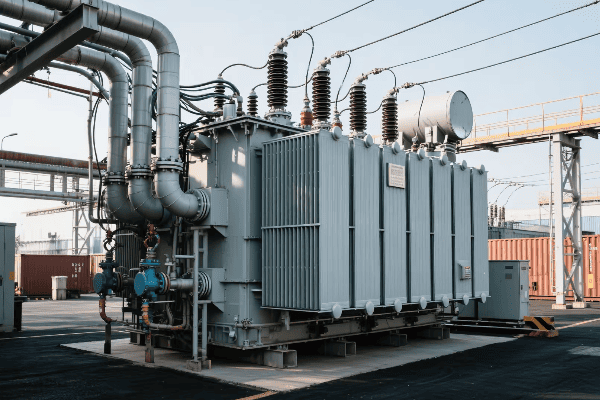

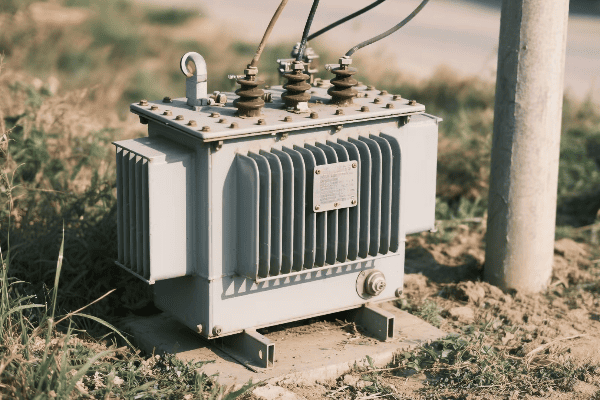

Power transformers and distribution transformers serve distinct functions in the electrical grid. Power transformers handle high voltages and large power capacities, typically found in power plants and substations. Distribution transformers operate at lower voltages and are used to supply power directly to consumers.

In this article, I’ll explain the key differences between power and distribution transformers. My experience in designing and working with both types has taught me the crucial distinctions that impact their applications in the electrical grid.

How Do Power Transformers and Distribution Transformers Differ in Their Voltage Handling Capabilities?

When I first started working with transformers, I was amazed by the vast difference in voltage levels they could handle. This difference is fundamental to their roles in the power system.

Power transformers typically handle voltages from 69 kV up to 765 kV or higher, facilitating long-distance power transmission. Distribution transformers, on the other hand, step down voltages to levels suitable for end-users, usually from 4 kV to 34.5 kV on the primary side to 120/240 V on the secondary side.

Let’s dive deeper into the voltage handling capabilities of these transformers:

Power Transformers: High Voltage Champions

Power transformers are designed for high voltage applications. I once worked on a project involving a 500 kV power transformer. The sheer size and complexity of its insulation system were impressive.

- Primary Voltage Range: Typically 69 kV to 765 kV or higher

- Secondary Voltage Range: Often steps down to sub-transmission voltages (e.g., 69 kV to 138 kV)

- Insulation Requirements: Extensive and complex due to high voltages

Distribution Transformers: Bringing Power to Consumers

Distribution transformers operate at much lower voltages. In a recent residential project, we used transformers that stepped down 12.47 kV to 120/240 V for household use.

| Aspect | Primary Side | Secondary Side |

|---|---|---|

| Voltage Range | 4 kV to 34.5 kV | 120/240 V to 480 V |

| Insulation | Less complex | Standard for low voltage |

| BIL (Basic Impulse Level) | Lower than power transformers | Designed for end-user safety |

Voltage Regulation Capabilities

The ability to regulate voltage differs between these transformer types:

- Power Transformers: Often equipped with on-load tap changers for voltage regulation

- Distribution Transformers: Usually have off-load tap changers or no tap changers at all

I remember a case where we had to retrofit a power transformer with an advanced on-load tap changer to improve voltage stability in a growing industrial area.

Impact on System Design

The voltage handling capabilities of these transformers significantly impact overall system design:

- Power Transformers: Key in determining transmission line voltages and substation configurations

- Distribution Transformers: Influence the layout and capacity of local distribution networks

In my experience, understanding these voltage capabilities is crucial for effective power system planning and operation.

What Are the Distinct Roles of Power Transformers and Distribution Transformers in the Electrical Grid?

Understanding the roles of power and distribution transformers is key to grasping how our electrical grid functions. I’ve seen firsthand how these different transformers work together to keep our lights on.

Power transformers play a crucial role in bulk power transmission, facilitating the transfer of large amounts of electricity over long distances. Distribution transformers are the final link in the power delivery chain, stepping down voltage to levels suitable for homes and businesses.

Let’s explore the distinct roles of these transformers:

Power Transformers: The Backbone of Transmission

Power transformers are vital in the transmission network. I once worked on upgrading a substation where the power transformer was the centerpiece of the entire operation.

- Step-Up Transformation: At power plants, increasing generator voltage for efficient transmission

- Bulk Power Transfer: Enabling the movement of large amounts of power across the grid

- Interconnection: Facilitating power exchange between different regions or countries

Distribution Transformers: Bringing Power to the People

Distribution transformers are the unsung heroes of our local power supply. In a recent urban development project, I saw how crucial these transformers were in powering an entire neighborhood.

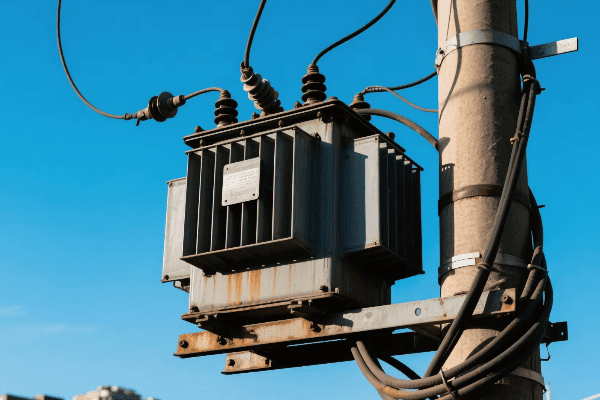

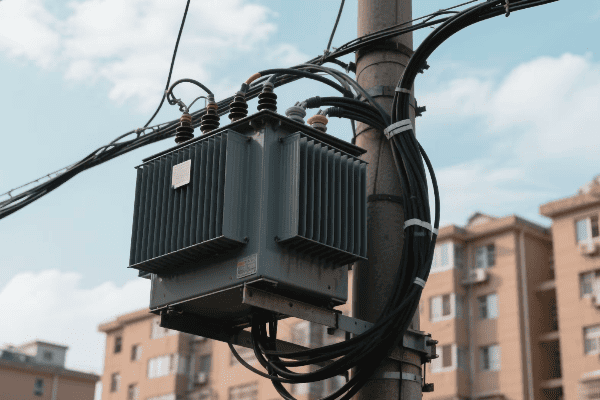

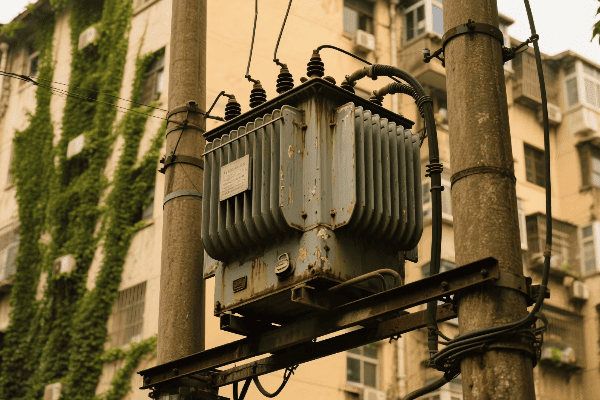

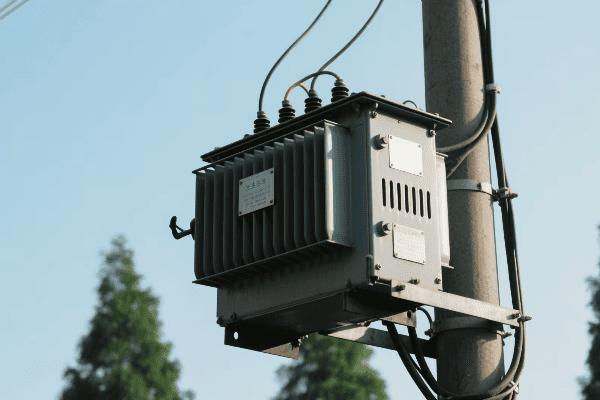

| Function | Power Transformer | Distribution Transformer |

|---|---|---|

| Location | Power plants, Substations | Neighborhoods, Poles, Pad-mounted |

| Power Capacity | Typically > 10 MVA | Usually < 5 MVA |

| End Users | Other substations, Large industries | Homes, Small businesses |

System Stability and Reliability

Both types of transformers contribute to system stability, but in different ways:

- Power Transformers: Crucial for overall grid stability and power flow control

- Distribution Transformers: Essential for local voltage regulation and power quality

I recall a project where we had to carefully coordinate the protection settings of power and distribution transformers to ensure seamless operation during fault conditions.

Energy Loss Considerations

The role of these transformers in managing energy losses is significant:

- Power Transformers: Focus on minimizing losses for large-scale efficiency

- Distribution Transformers: Balancing efficiency with cost for widespread deployment

In my experience, even small improvements in distribution transformer efficiency can lead to significant energy savings across the grid.

Future Grid Integration

As our grid evolves, so do the roles of these transformers:

- Power Transformers: Adapting to integrate large-scale renewable energy sources

- Distribution Transformers: Evolving to handle bi-directional power flow in smart grids

I’m currently involved in a project exploring how distribution transformers can better accommodate distributed energy resources like rooftop solar panels.

How Do Design and Construction Features Vary Between Power and Distribution Transformers?

The design and construction of power and distribution transformers reflect their distinct roles and operating conditions. I’ve had the opportunity to work on both types, and the differences are fascinating.

Power transformers are typically larger, custom-designed units with advanced cooling systems and robust mechanical structures to handle high voltages and power levels. Distribution transformers are smaller, often standardized units designed for cost-effective production and easier installation in various locations.

Let’s explore the key design and construction differences:

Core and Winding Design

The core and winding designs vary significantly:

-

Power Transformers:

- Often use shell-type cores for better mechanical strength

- Complex winding arrangements to handle high currents

- Advanced insulation systems for high voltage stress

-

Distribution Transformers:

- Typically use simpler core-type designs

- More standardized winding arrangements

- Insulation designed for lower voltage applications

I once worked on a power transformer design that used a novel core material to reduce losses. The complexity of integrating this material into the large core structure was a significant engineering challenge.

Cooling Systems

Cooling system design is a critical difference:

| Aspect | Power Transformer | Distribution Transformer |

|---|---|---|

| Cooling Methods | ONAN, ONAF, OFAF, ODAF | Mainly ONAN |

| Oil Volume | Large oil volumes | Smaller oil volumes or dry-type |

| Radiators | Often extensive radiator banks | Simple radiators or tanks |

In a recent project, we had to design a custom cooling system for a large power transformer located in an extremely hot climate. The solution involved a combination of forced oil and forced air cooling (OFAF) with additional heat exchangers.

Tap Changers

Tap changer designs differ significantly:

-

Power Transformers:

- Often equipped with on-load tap changers (OLTC)

- Complex mechanisms for voltage regulation under load

- Wide range of tap positions

-

Distribution Transformers:

- Usually have off-load tap changers or no tap changers

- Simpler designs with fewer tap positions

- Manual adjustment when de-energized

I remember a challenging project where we had to retrofit an OLTC onto an existing power transformer to improve voltage regulation in a rapidly growing industrial area.

Bushings and Terminals

The design of bushings and terminals also varies:

-

Power Transformers:

- Large, complex bushings for high voltage insulation

- Often oil-filled or SF6 gas-filled bushings

- Robust terminal designs for high current capacity

-

Distribution Transformers:

- Simpler, smaller bushings

- Often solid or polymer-type insulators

- Standardized terminal configurations for easy connection

In my experience, the design of power transformer bushings can be as complex as the transformer itself, especially for ultra-high voltage applications.

Monitoring and Protection

The level of monitoring and protection differs:

-

Power Transformers:

- Extensive monitoring systems (temperature, gas, partial discharge)

- Complex protection schemes

- Often include online monitoring and diagnostics

-

Distribution Transformers:

- Basic overload and short-circuit protection

- Simple temperature monitoring

- Generally rely on external protection devices

I’ve been involved in implementing advanced monitoring systems for power transformers that can predict potential failures weeks in advance, significantly improving reliability and maintenance planning.

What Are the Efficiency and Loss Considerations for Power Transformers vs. Distribution Transformers?

Efficiency and loss considerations are crucial in transformer design and operation. I’ve spent a significant part of my career optimizing these aspects for both power and distribution transformers.

Power transformers typically have higher efficiency ratings due to their larger size and the critical nature of their role in the grid. Distribution transformers, while also designed for efficiency, must balance performance with cost-effectiveness for widespread deployment. Both types focus on minimizing core and winding losses, but the approaches differ.

Let’s delve into the efficiency and loss considerations for both types:

Types of Losses

Both transformer types experience two main types of losses:

-

No-Load Losses (Core Losses):

- Occur whenever the transformer is energized

- Caused by the magnetization and demagnetization of the core

-

Load Losses (Copper Losses):

- Vary with the load on the transformer

- Caused by resistance in the windings

In my experience, balancing these losses is a key challenge in transformer design.

Efficiency Ratings

Efficiency ratings differ between the two types:

| Aspect | Power Transformer | Distribution Transformer |

|---|---|---|

| Typical Efficiency | 99.5% – 99.9% | 98% – 99% |

| Rated Load | Often designed for optimal efficiency at 50-70% load | Typically optimized for 35-50% load |

| Efficiency Standards | IEC 60076-20, IEEE C57.12.00 | DOE 10 CFR Part 431, EU Ecodesign |

I once worked on a project to upgrade a substation’s power transformers. By choosing high-efficiency units, we were able to reduce energy losses by over 20%, resulting in significant cost savings for the utility.

Core Material and Design

The choice of core material significantly impacts efficiency:

-

Power Transformers:

- Often use higher grade silicon steel or amorphous metals

- Complex core designs to minimize flux path length

- Larger core cross-sections to reduce flux density

-

Distribution Transformers:

- Balancing cost and performance with silicon steel grades

- Simpler core designs for ease of manufacturing

- Optimized core sizes for standard ratings

In a recent distribution transformer design project, we experimented with different core materials to find the optimal balance between efficiency and cost.

Winding Design and Materials

Winding design also plays a crucial role in efficiency:

-

Power Transformers:

- Often use continuously transposed conductors (CTC) to reduce eddy current losses

- Complex winding geometries to optimize current distribution

- Sometimes use exotic materials like superconductors for ultra-high efficiency

-

Distribution Transformers:

- Simpler winding designs for cost-effective production

- Focus on optimizing conductor sizes and arrangements

- Sometimes use aluminum instead of copper for cost savings

I’ve been involved in projects where we used advanced simulation tools to optimize winding designs, resulting in significant reductions in load losses.

Cooling System Efficiency

The efficiency of the cooling system is another important factor:

-

Power Transformers:

- Advanced cooling systems (OFAF, ODAF) for better heat dissipation

- Use of low-loss cooling fans and pumps

- Sometimes employ directed oil flow techniques for targeted cooling

-

Distribution Transformers:

- Simpler ONAN cooling sufficient for most applications

- Design focus on natural convection efficiency

- Sometimes use special tank designs to enhance cooling without active components

In a recent power transformer project, we implemented a smart cooling control system that adjusted cooling intensity based on load and ambient conditions, significantly improving overall efficiency.

How Do Maintenance and Monitoring Requirements Differ for Power and Distribution Transformers?

Maintenance and monitoring are critical for ensuring the longevity and reliability of transformers. In my years of working with both power and distribution transformers, I’ve seen how these requirements can vary significantly.

Power transformers typically require more intensive and frequent maintenance due to their critical role and complex design. They often have advanced monitoring systems for real-time performance tracking. Distribution transformers, being simpler and more numerous, usually have less intensive maintenance schedules and rely more on periodic inspections and testing.

Let’s explore the differences in maintenance and monitoring requirements:

Routine Maintenance Schedules

The frequency and depth of routine maintenance differ:

-

Power Transformers:

- Often have monthly, quarterly, and annual maintenance schedules

- Involve comprehensive checks of all major components

- May require planned outages for detailed inspections

-

Distribution Transformers:

- Typically have annual or bi-annual inspection schedules

- Focus on external condition checks and basic electrical tests

- Often maintained on a "run to failure" basis in some utilities

I once managed a maintenance program for a fleet of power transformers where we implemented a condition-based maintenance approach. This significantly reduced unnecessary maintenance while improving reliability.

Oil Testing and Analysis

Oil testing is a crucial aspect of transformer maintenance:

| Aspect | Power Transformer | Distribution Transformer |

|---|---|---|

| Frequency | Often quarterly or bi-annual | Typically annual or less frequent |

| Tests Performed | Comprehensive DGA, furan analysis, oil quality tests | Basic oil quality tests, sometimes DGA |

| Sampling Points | Multiple sampling points for detailed analysis | Usually single sampling point |

In a recent project, we introduced online DGA monitoring for critical power transformers. This allowed us to detect a developing fault early, preventing a potential failure that could have cost millions in downtime.

Electrical Testing

Electrical testing requirements vary:

-

Power Transformers:

- Regular power factor testing

- Winding resistance and ratio tests

- Insulation resistance and polarization index tests

- Sometimes include frequency response analysis (FRA)

-

Distribution Transformers:

- Basic insulation resistance tests

- Turn ratio tests at longer intervals

- Often rely on load current and voltage measurements for performance indication

I recall a case where regular FRA testing on a power transformer helped us identify a minor core displacement early, allowing for timely corrective action.

Monitoring Systems

The complexity of monitoring systems differs significantly:

-

Power Transformers:

- Often equipped with online monitoring systems

- Real-time tracking of temperatures, gas levels, partial discharges

- Integration with SCADA systems for remote monitoring

- Sometimes include advanced analytics for predictive maintenance

-

Distribution Transformers:

- Usually limited to basic overload and short-circuit protection

- Some modern units include simple temperature and load monitoring

- Increasingly incorporating smart grid functionalities in urban areas

I’ve been involved in implementing advanced monitoring systems for power transformers that use AI algorithms to predict potential failures. This technology has revolutionized our approach to transformer maintenance.

Physical Inspections

The nature of physical inspections varies:

-

Power Transformers:

- Detailed visual inspections of all components

- Regular checks of cooling systems, bushings, and tap changers

- Thermographic surveys to detect hot spots

-

Distribution Transformers:

- Often limited to external visual inspections

- Check for oil leaks, corrosion, and damage to bushings

- Inspection of connections and grounding

In my experience, regular and thorough physical inspections are invaluable. I once discovered a minor oil leak during a routine inspection of a power transformer, which, if left unchecked, could have led to a major failure.

Bushing Maintenance

Bushing maintenance is another area of difference:

-

Power Transformers:

- Regular testing of bushing power factor and capacitance

- Oil level checks in oil-filled bushings

- Sometimes require specialized equipment for testing and maintenance

-

Distribution Transformers:

- Visual inspection of bushing condition

- Cleaning of bushing surfaces to prevent flashovers

- Simpler replacement procedures when necessary

I remember a project where we had to develop a custom maintenance procedure for ultra-high voltage bushings on a power transformer. The complexity of these components often surprises even experienced engineers.

Tap Changer Maintenance

Tap changer maintenance requirements differ significantly:

-

Power Transformers:

- Regular maintenance of on-load tap changers (OLTC)

- Oil filtering or replacement in OLTC compartments

- Mechanical wear checks and contact resistance measurements

-

Distribution Transformers:

- Infrequent checks of off-load tap changers

- Usually limited to ensuring proper tap position and connection integrity

In my career, I’ve seen how neglected OLTC maintenance can lead to severe issues. We once had to perform an emergency repair on a power transformer OLTC that had failed due to lack of proper maintenance, causing a significant outage.

Documentation and Record Keeping

The approach to documentation varies:

-

Power Transformers:

- Detailed maintenance logs and test reports

- Comprehensive historical records for trend analysis

- Often use specialized asset management software

-

Distribution Transformers:

- Basic maintenance records, often part of a broader distribution system database

- Less emphasis on individual transformer history due to large numbers

I’ve implemented digital record-keeping systems for power transformer fleets, which greatly improved our ability to predict and prevent failures through trend analysis.

Conclusion

Power and distribution transformers, while both crucial to the electrical grid, have distinct differences in voltage handling, roles, design, efficiency, and maintenance needs. Understanding these differences is key to effective grid management and operation.

Have you ever wondered why some pad mounted transformers fail prematurely? The answer often lies beneath the surface, in the concrete pad they’re installed on.

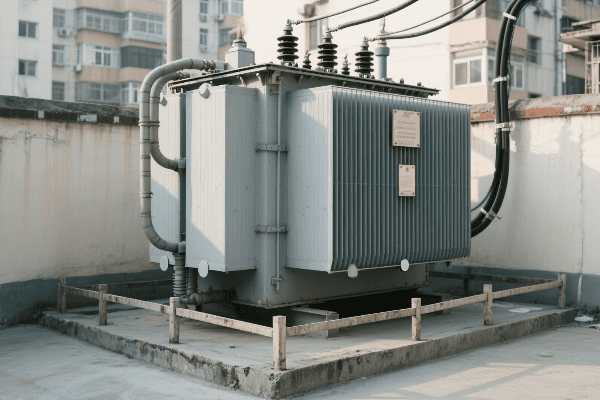

Proper installation of concrete pads for pad mounted transformers is crucial for utility companies. It ensures transformer stability, longevity, and safety. Best practices include correct pad design, proper site preparation, adherence to safety regulations, and consideration of environmental factors.

In this article, I’ll share my insights on concrete pad installation for pad mounted transformers. I’ve seen firsthand how a well-designed pad can make all the difference in transformer performance and maintenance.

What Are the Key Considerations for Designing and Preparing a Concrete Pad for Pad Mounted Transformers?

When I first started working with pad mounted transformers, I underestimated the importance of the concrete pad. I quickly learned that a poorly designed pad can lead to a host of problems.

Key considerations for concrete pad design include load-bearing capacity, dimensions, drainage, conduit placement, and soil conditions. The pad must support the transformer’s weight, allow for proper cable entry, and ensure adequate drainage to prevent water accumulation.

Let’s dive deeper into these key considerations:

Load-Bearing Capacity

The pad’s load-bearing capacity is crucial. I once worked on a project where an undersized pad cracked under the transformer’s weight. We had to replace both the pad and the transformer, a costly mistake that could have been avoided with proper design.

- Transformer Weight: Pads must support the full weight of the transformer.

- Oil Weight: For oil-filled transformers, factor in the oil weight.

- Safety Factor: Include a safety margin for additional loads.

Dimensions and Thickness

Pad dimensions are critical. In a recent project, we designed a pad with extended dimensions to accommodate future transformer upgrades. This foresight saved the utility company significant costs down the line.

| Aspect | Consideration |

|---|---|

| Length and Width | Must extend beyond transformer footprint |

| Thickness | Depends on soil conditions and transformer weight |

| Reinforcement | Steel rebar for added strength |

Drainage and Slope

Proper drainage is essential. I remember a site where poor drainage led to water pooling around the transformer. We had to retrofit a drainage system, which was much more expensive than if it had been included in the initial design.

- Slope: Typically 1% away from the transformer.

- Surrounding Area: Grade the area to direct water away.

- Drainage Channels: Consider adding channels in flood-prone areas.

Conduit Placement

Conduit placement requires careful planning. In one project, we used a template to ensure precise conduit placement. This made cable installation much easier and reduced the risk of damage to the cables during installation.

- Primary Conduits: For incoming high-voltage cables.

- Secondary Conduits: For outgoing low-voltage cables.

- Future Expansion: Include spare conduits for potential upgrades.

Soil Conditions

Soil conditions significantly impact pad design. I once worked on a site with expansive clay soil. We had to design a special pad with a deeper foundation to prevent movement and cracking.

- Soil Testing: Conduct geotechnical surveys.

- Compaction: Ensure proper soil compaction before pouring concrete.

- Frost Heave: In cold climates, consider frost heave protection.

How Does Proper Concrete Pad Installation Affect the Performance and Longevity of Pad Mounted Transformers?

Early in my career, I saw a transformer fail due to a poorly installed pad. It was a wake-up call that showed me how crucial proper installation is.

Proper concrete pad installation significantly impacts transformer performance and longevity. It ensures stability, prevents water ingress, facilitates heat dissipation, and enables easy maintenance access. A well-installed pad can extend a transformer’s lifespan and reduce the risk of failures.

Let’s explore how proper installation affects transformers:

Stability and Vibration Reduction

A properly installed pad provides stability. I once worked on a project in a seismic zone. We designed a pad with special anchoring systems that significantly improved the transformer’s ability to withstand earthquakes.

- Level Surface: Prevents transformer tilting.

- Vibration Absorption: Reduces operational vibrations.

- Seismic Protection: In earthquake-prone areas, proper installation is crucial.

Water Protection

Water is a transformer’s enemy. Good pad installation helps. In a coastal project, we used a raised pad design with special sealants. It successfully protected the transformer from saltwater corrosion and flooding.

| Aspect | Benefit |

|---|---|

| Elevation | Keeps transformer above flood levels |

| Slope | Directs water away from the transformer |

| Sealant | Prevents water ingress through conduit entries |

Heat Dissipation

Proper pad installation aids in heat dissipation. I remember a case where poor air circulation led to transformer overheating. By redesigning the pad with better clearance, we solved the issue and extended the transformer’s life.

- Air Circulation: Adequate clearance allows airflow.

- Thermal Mass: Concrete acts as a heat sink.

- Surface Treatment: Reflective coatings can reduce heat absorption.

Maintenance Access

A well-designed pad facilitates maintenance. In one project, we incorporated a built-in oil containment system into the pad design. It not only met environmental regulations but also made oil changes and spill cleanups much easier.

- Working Space: Ensures enough room for technicians.

- Equipment Access: Allows for easy replacement of components.

- Oil Containment: Proper design can include oil containment features.

Long-Term Cost Savings

Proper installation leads to cost savings. I’ve seen utilities save millions in the long run by investing in proper pad installation upfront. It’s a classic case of "pay now or pay more later."

- Reduced Failures: Fewer transformer failures mean less downtime.

- Extended Lifespan: Well-supported transformers last longer.

- Lower Maintenance Costs: Easier access reduces maintenance time and costs.

What Safety Measures and Regulations Should Utility Companies Follow During Concrete Pad Installation?

Safety is paramount in utility work. I’ve seen the consequences of neglecting safety measures, and it’s not pretty.

Utility companies must follow strict safety measures and regulations during concrete pad installation. These include adherence to OSHA standards, proper equipment usage, electrical safety protocols, and environmental protection measures. Compliance ensures worker safety and prevents accidents.

Let’s delve into the key safety measures and regulations:

OSHA Compliance

OSHA standards are crucial. I once consulted on a project where strict adherence to OSHA standards prevented a potentially serious accident during excavation. It reinforced the importance of these regulations.

- Personal Protective Equipment (PPE): Hard hats, safety boots, gloves.

- Fall Protection: When working at heights.

- Trench Safety: For excavation work.

Equipment Safety

Proper equipment usage is essential. In a recent project, we implemented a comprehensive equipment safety program. It reduced accidents and improved overall efficiency.

| Equipment | Safety Measure |

|---|---|

| Concrete Mixers | Regular maintenance, proper operation training |

| Excavators | Certified operators, clear communication protocols |

| Power Tools | Proper grounding, GFCI protection |

Electrical Safety

Electrical safety is paramount. I remember a close call where a worker almost contacted a live wire. Our strict electrical safety protocols prevented what could have been a fatal accident.

- De-energization: Ensure all nearby power sources are off.

- Lockout/Tagout: Use proper procedures to prevent accidental energization.

- Grounding: Properly ground all equipment.

Environmental Protection

Environmental considerations are important. In an urban project, we used innovative low-noise equipment and dust control measures. It helped maintain good relations with the surrounding community.

- Spill Prevention: Have containment measures for concrete and chemicals.

- Dust Control: Use water sprays to minimize dust.

- Noise Reduction: Schedule noisy work during appropriate hours.

Site Security

Securing the site is crucial. I’ve seen how proper site security can prevent vandalism and theft. In one project, our security measures deterred copper thieves, saving the utility company significant costs.

- Fencing: Erect temporary fencing around the work area.

- Signage: Clear warning signs about the construction.

- Access Control: Limit site access to authorized personnel only.

How Can Utility Companies Optimize the Concrete Pad Layout for Efficient Transformer Maintenance and Access?

Efficient maintenance is key to transformer longevity. I’ve seen how a well-designed pad layout can make a huge difference in maintenance operations.

Utility companies can optimize concrete pad layout by ensuring adequate working space, strategic placement of access points, incorporation of oil containment features, and consideration of future expansion. An optimized layout facilitates easier maintenance, reduces downtime, and improves overall efficiency.

Let’s explore ways to optimize pad layout:

Working Space

Adequate working space is crucial. In a recent project, we designed a pad with extra clearance on one side. This "maintenance alley" greatly improved the efficiency of routine checks and repairs.

- Clearance: Allow enough room around all sides of the transformer.

- Access Paths: Clear paths for maintenance vehicles and equipment.

- Staging Areas: Designate areas for tools and replacement parts.

Strategic Access Points

Placement of access points is key. I once redesigned a pad layout to relocate the control cabinet. This simple change reduced maintenance time by 30% by improving accessibility.

| Access Point | Consideration |

|---|---|

| Cable Entry | Easy access for cable replacement |

| Oil Drain | Accessible for oil changes |

| Control Cabinet | Clear view and easy reach |

Oil Containment

Incorporating oil containment features is important. In an environmentally sensitive area, we designed a pad with an integrated oil containment system. It not only met regulations but also simplified maintenance procedures.

- Containment Basin: Built into the pad design.

- Drainage System: For safe oil removal.

- Capacity: Sized to contain the full volume of transformer oil.

Future Expansion

Planning for the future is wise. I worked on a substation where we implemented a modular pad design. When the utility needed to upgrade the transformer years later, the expansion was straightforward and cost-effective.

- Oversized Pad: Allow room for larger transformers.

- Extra Conduits: Install spare conduits for future needs.

- Modular Design: Enable easy expansion of the pad.

Ergonomic Considerations

Ergonomics can improve maintenance efficiency. In one project, we incorporated ergonomic features like adjustable work platforms. It significantly reduced strain on maintenance workers and improved their efficiency.

- Height: Design the pad height for comfortable working postures.

- Surface Texture: Non-slip surfaces for safety.

- Lighting: Consider built-in lighting for nighttime maintenance.

What Are the Environmental and Aesthetic Considerations in Concrete Pad Design for Urban and Suburban Areas?

In urban and suburban areas, transformers can’t just be functional – they need to blend in. I’ve worked on projects where environmental and aesthetic considerations were just as important as technical specs.

Environmental and aesthetic considerations in concrete pad design include using eco-friendly materials, implementing green spaces, noise reduction measures, and visual camouflage techniques. These factors help utilities meet regulations, improve community relations, and enhance the overall urban landscape.

Let’s explore these considerations:

Eco-Friendly Materials

Using sustainable materials is increasingly important. In a recent urban project, we used recycled concrete for the pad. It not only met performance standards but also helped the utility meet its sustainability goals.

- Recycled Concrete: Reduces environmental impact.

- Permeable Surfaces: Allows water to seep through, reducing runoff.

- Low-Carbon Cement: Reduces the carbon footprint of the installation.

Green Space Integration

Incorporating green spaces can improve aesthetics. I once designed a pad that included a small rain garden. It not only looked great but also helped manage stormwater runoff.

| Feature | Benefit |

|---|---|

| Planting Areas | Softens the visual impact |

| Green Walls | Vertical gardens on screening walls |

| Bioswales | Natural drainage and filtration |

Noise Reduction

Minimizing noise is crucial in residential areas. In a suburban project, we used special vibration-dampening mounts on the pad. It significantly reduced noise complaints from nearby residents.

- Sound-Absorbing Materials: Use in pad and enclosure design.

- Vibration Dampening: Install vibration isolators.

- Strategic Placement: Position transformers away from sensitive areas.

Visual Camouflage

Blending the transformer into its surroundings is an art. I worked on a project in a historic district where we designed a pad and enclosure that mimicked a traditional garden shed. It preserved the area’s character while housing modern equipment.

- Color Matching: Use colors that complement the environment.

- Artistic Enclosures: Collaborate with local artists for creative designs.

- Landscaping: Use plants to screen the transformer.

Community Engagement

Involving the community can lead to better outcomes. In one project, we partnered with a local school to create an educational garden around the transformer pad. It turned a potential eyesore into a community asset.

- Public Consultations: Gather input on design preferences.

- Educational Signage: Inform the public about the transformer’s role.

- Local Partnerships: Work with local organizations for maintenance of surrounding areas.

Conclusion

Proper concrete pad installation is crucial for pad mounted transformers. It ensures stability, safety, and longevity while addressing environmental and aesthetic concerns. Utility companies must consider all aspects for optimal performance and community acceptance.

Have you ever wondered why some power transformers seem to last forever while others fail prematurely? The secret often lies beneath the surface, in the concrete pad they’re installed on.

Proper installation of concrete pads for pad mounted transformers is crucial for utility companies. It ensures transformer stability, longevity, and safety. Best practices include correct pad design, proper site preparation, adherence to safety regulations, and consideration of environmental factors.

In this article, I’ll share my insights on concrete pad installation for pad mounted transformers. I’ve seen firsthand how a well-designed pad can make all the difference in transformer performance and maintenance.

What Are the Key Considerations for Designing and Preparing a Concrete Pad for Pad Mounted Transformers?

When I first started working with pad mounted transformers, I underestimated the importance of the concrete pad. I quickly learned that a poorly designed pad can lead to a host of problems.

Key considerations for concrete pad design include load-bearing capacity, dimensions, drainage, conduit placement, and soil conditions. The pad must support the transformer’s weight, allow for proper cable entry, and ensure adequate drainage to prevent water accumulation.

Let’s dive deeper into these key considerations:

Load-Bearing Capacity

The pad’s load-bearing capacity is crucial:

- Transformer Weight: Pads must support the full weight of the transformer.

- Oil Weight: For oil-filled transformers, factor in the oil weight.

- Safety Factor: Include a safety margin for additional loads.

I once worked on a project where an undersized pad cracked under the transformer’s weight. We had to replace both the pad and the transformer, a costly mistake that could have been avoided with proper design.

Dimensions and Thickness

Pad dimensions are critical:

| Aspect | Consideration |

|---|---|

| Length and Width | Must extend beyond transformer footprint |

| Thickness | Depends on soil conditions and transformer weight |

| Reinforcement | Steel rebar for added strength |

In a recent project, we designed a pad with extended dimensions to accommodate future transformer upgrades. This foresight saved the utility company significant costs down the line.

Drainage and Slope

Proper drainage is essential:

- Slope: Typically 1% away from the transformer.

- Surrounding Area: Grade the area to direct water away.

- Drainage Channels: Consider adding channels in flood-prone areas.

I remember a site where poor drainage led to water pooling around the transformer. We had to retrofit a drainage system, which was much more expensive than if it had been included in the initial design.

Conduit Placement

Conduit placement requires careful planning:

- Primary Conduits: For incoming high-voltage cables.

- Secondary Conduits: For outgoing low-voltage cables.

- Future Expansion: Include spare conduits for potential upgrades.

In one project, we used a template to ensure precise conduit placement. This made cable installation much easier and reduced the risk of damage to the cables during installation.

Soil Conditions

Soil conditions significantly impact pad design:

- Soil Testing: Conduct geotechnical surveys.

- Compaction: Ensure proper soil compaction before pouring concrete.

- Frost Heave: In cold climates, consider frost heave protection.

I once worked on a site with expansive clay soil. We had to design a special pad with a deeper foundation to prevent movement and cracking.

How Does Proper Concrete Pad Installation Affect the Performance and Longevity of Pad Mounted Transformers?

Early in my career, I saw a transformer fail due to a poorly installed pad. It was a wake-up call that showed me how crucial proper installation is.

Proper concrete pad installation significantly impacts transformer performance and longevity. It ensures stability, prevents water ingress, facilitates heat dissipation, and enables easy maintenance access. A well-installed pad can extend a transformer’s lifespan and reduce the risk of failures.

Let’s explore how proper installation affects transformers:

Stability and Vibration Reduction

A properly installed pad provides stability:

- Level Surface: Prevents transformer tilting.

- Vibration Absorption: Reduces operational vibrations.

- Seismic Protection: In earthquake-prone areas, proper installation is crucial.

I once worked on a project in a seismic zone. We designed a pad with special anchoring systems that significantly improved the transformer’s ability to withstand earthquakes.

Water Protection

Water is a transformer’s enemy. Good pad installation helps:

| Aspect | Benefit |

|---|---|

| Elevation | Keeps transformer above flood levels |

| Slope | Directs water away from the transformer |

| Sealant | Prevents water ingress through conduit entries |

In a coastal project, we used a raised pad design with special sealants. It successfully protected the transformer from saltwater corrosion and flooding.

Heat Dissipation

Proper pad installation aids in heat dissipation:

- Air Circulation: Adequate clearance allows airflow.

- Thermal Mass: Concrete acts as a heat sink.

- Surface Treatment: Reflective coatings can reduce heat absorption.

I remember a case where poor air circulation led to transformer overheating. By redesigning the pad with better clearance, we solved the issue and extended the transformer’s life.

Maintenance Access

A well-designed pad facilitates maintenance:

- Working Space: Ensures enough room for technicians.

- Equipment Access: Allows for easy replacement of components.

- Oil Containment: Proper design can include oil containment features.

In one project, we incorporated a built-in oil containment system into the pad design. It not only met environmental regulations but also made oil changes and spill cleanups much easier.

Long-Term Cost Savings

Proper installation leads to cost savings:

- Reduced Failures: Fewer transformer failures mean less downtime.

- Extended Lifespan: Well-supported transformers last longer.

- Lower Maintenance Costs: Easier access reduces maintenance time and costs.

I’ve seen utilities save millions in the long run by investing in proper pad installation upfront. It’s a classic case of "pay now or pay more later."

What Safety Measures and Regulations Should Utility Companies Follow During Concrete Pad Installation?

Safety is paramount in utility work. I’ve seen the consequences of neglecting safety measures, and it’s not pretty.

Utility companies must follow strict safety measures and regulations during concrete pad installation. These include adherence to OSHA standards, proper equipment usage, electrical safety protocols, and environmental protection measures. Compliance ensures worker safety and prevents accidents.

Let’s delve into the key safety measures and regulations:

OSHA Compliance

OSHA standards are crucial:

- Personal Protective Equipment (PPE): Hard hats, safety boots, gloves.

- Fall Protection: When working at heights.

- Trench Safety: For excavation work.

I once consulted on a project where strict adherence to OSHA standards prevented a potentially serious accident during excavation. It reinforced the importance of these regulations.

Equipment Safety

Proper equipment usage is essential:

| Equipment | Safety Measure |

|---|---|

| Concrete Mixers | Regular maintenance, proper operation training |

| Excavators | Certified operators, clear communication protocols |

| Power Tools | Proper grounding, GFCI protection |

In a recent project, we implemented a comprehensive equipment safety program. It reduced accidents and improved overall efficiency.

Electrical Safety

Electrical safety is paramount:

- De-energization: Ensure all nearby power sources are off.

- Lockout/Tagout: Use proper procedures to prevent accidental energization.

- Grounding: Properly ground all equipment.

I remember a close call where a worker almost contacted a live wire. Our strict electrical safety protocols prevented what could have been a fatal accident.

Environmental Protection

Environmental considerations are important:

- Spill Prevention: Have containment measures for concrete and chemicals.

- Dust Control: Use water sprays to minimize dust.

- Noise Reduction: Schedule noisy work during appropriate hours.

In an urban project, we used innovative low-noise equipment and dust control measures. It helped maintain good relations with the surrounding community.

Site Security

Securing the site is crucial:

- Fencing: Erect temporary fencing around the work area.

- Signage: Clear warning signs about the construction.

- Access Control: Limit site access to authorized personnel only.

I’ve seen how proper site security can prevent vandalism and theft. In one project, our security measures deterred copper thieves, saving the utility company significant costs.

How Can Utility Companies Optimize the Concrete Pad Layout for Efficient Transformer Maintenance and Access?

Efficient maintenance is key to transformer longevity. I’ve seen how a well-designed pad layout can make a huge difference in maintenance operations.

Utility companies can optimize concrete pad layout by ensuring adequate working space, strategic placement of access points, incorporation of oil containment features, and consideration of future expansion. An optimized layout facilitates easier maintenance, reduces downtime, and improves overall efficiency.

Let’s explore ways to optimize pad layout:

Working Space

Adequate working space is crucial:

- Clearance: Allow enough room around all sides of the transformer.

- Access Paths: Clear paths for maintenance vehicles and equipment.

- Staging Areas: Designate areas for tools and replacement parts.

In a recent project, we designed a pad with extra clearance on one side. This "maintenance alley" greatly improved the efficiency of routine checks and repairs.

Strategic Access Points

Placement of access points is key:

| Access Point | Consideration |

|---|---|

| Cable Entry | Easy access for cable replacement |

| Oil Drain | Accessible for oil changes |

| Control Cabinet | Clear view and easy reach |

I once redesigned a pad layout to relocate the control cabinet. This simple change reduced maintenance time by 30% by improving accessibility.

Oil Containment

Incorporating oil containment features is important:

- Containment Basin: Built into the pad design.

- Drainage System: For safe oil removal.

- Capacity: Sized to contain the full volume of transformer oil.

In an environmentally sensitive area, we designed a pad with an integrated oil containment system. It not only met regulations but also simplified maintenance procedures.

Future Expansion

Planning for the future is wise:

- Oversized Pad: Allow room for larger transformers.

- Extra Conduits: Install spare conduits for future needs.

- Modular Design: Enable easy expansion of the pad.

I worked on a substation where we implemented a modular pad design. When the utility needed to upgrade the transformer years later, the expansion was straightforward and cost-effective.

Ergonomic Considerations

Ergonomics can improve maintenance efficiency:

- Height: Design the pad height for comfortable working postures.

- Surface Texture: Non-slip surfaces for safety.

- Lighting: Consider built-in lighting for nighttime maintenance.

In one project, we incorporated ergonomic features like adjustable work platforms. It significantly reduced strain on maintenance workers and improved their efficiency.

What Are the Environmental and Aesthetic Considerations in Concrete Pad Design for Urban and Suburban Areas?

In urban and suburban areas, transformers can’t just be functional – they need to blend in. I’ve worked on projects where environmental and aesthetic considerations were just as important as technical specs.

Environmental and aesthetic considerations in concrete pad design include using eco-friendly materials, implementing green spaces, noise reduction measures, and visual camouflage techniques. These factors help utilities meet regulations, improve community relations, and enhance the overall urban landscape.

Let’s explore these considerations:

Eco-Friendly Materials

Using sustainable materials is increasingly important:

- Recycled Concrete: Reduces environmental impact.

- Permeable Surfaces: Allows water to seep through, reducing runoff.

- Low-Carbon Cement: Reduces the carbon footprint of the installation.

In a recent urban project, we used recycled concrete for the pad. It not only met performance standards but also helped the utility meet its sustainability goals.

Green Space Integration

Incorporating green spaces can improve aesthetics:

| Feature | Benefit |

|---|---|

| Planting Areas | Softens the visual impact |

| Green Walls | Vertical gardens on screening walls |

| Bioswales | Natural drainage and filtration |

I once designed a pad that included a small rain garden. It not only looked great but also helped manage stormwater runoff.

Noise Reduction

Minimizing noise is crucial in residential areas:

- Sound-Absorbing Materials: Use in pad and enclosure design.

- Vibration Dampening: Install vibration isolators.

- Strategic Placement: Position transformers away from sensitive areas.

In a suburban project, we used special vibration-dampening mounts on the pad. It significantly reduced noise complaints from nearby residents.

Visual Camouflage

Blending the transformer into its surroundings is an art:

- Color Matching: Use colors that complement the environment.

- Artistic Enclosures: Collaborate with local artists for creative designs.

- Landscaping: Use plants to screen the transformer.

I worked on a project in a historic district where we designed a pad and enclosure that mimicked a traditional garden shed. It preserved the area’s character while housing modern equipment.

Community Engagement

Involving the community can lead to better outcomes:

- Public Consultations: Gather input on design preferences.

- Educational Signage: Inform the public about the transformer’s role.

- Local Partnerships: Work with local organizations for maintenance of surrounding areas.

In one project, we partnered with a local school to create an educational garden around the transformer pad. It turned a potential eyesore into a community asset.

Conclusion

Proper concrete pad installation is crucial for pad mounted transformers. It ensures stability, safety, and longevity while addressing environmental and aesthetic concerns. Utility companies must consider all aspects for optimal performance and community acceptance.

Have you ever wondered why power outages still happen in our high-tech world? The answer might lie in outdated power distribution technology. But there’s a solution on the horizon.

Electronic Power Transformers (EPTs) are revolutionizing power distribution systems. They combine traditional transformer functions with advanced power electronics, offering improved efficiency, power quality, and grid stability. EPTs are key components in the development of smart grids and modern power systems.

In this article, I’ll explain how Electronic Power Transformers are changing the game. As someone who’s worked with both traditional and electronic transformers, I’ve seen firsthand the impact of this technology.

How Do Electronic Power Transformers Differ from Traditional Transformers in Design and Function?

When I first encountered an Electronic Power Transformer, I was amazed by its complexity compared to traditional transformers. It was like comparing a smartphone to a landline.

Electronic Power Transformers differ from traditional transformers by incorporating power electronic converters. They use high-frequency switching to transform voltage, allowing for more compact designs and additional functionalities like active power flow control and harmonic mitigation.

Let’s dive deeper into the differences between EPTs and traditional transformers:

Core Design

The core design of EPTs is fundamentally different:

- Traditional Transformers: Use large iron cores for 50/60 Hz operation.

- EPTs: Employ smaller, high-frequency cores.

I remember working on a project where space was a major constraint. The compact design of the EPT allowed us to fit it into a space half the size of what a traditional transformer would have required.

Power Conversion Process

The power conversion process in EPTs is more complex:

| Stage | Traditional Transformer | Electronic Power Transformer |

|---|---|---|

| Input | AC directly to core | AC to DC conversion |

| Transformation | Magnetic field in core | High-frequency switching |

| Output | AC from secondary winding | DC to AC conversion |

This multi-stage conversion in EPTs allows for greater control over the output. In one project, we were able to maintain a stable output voltage despite significant input fluctuations, something that would have been challenging with a traditional transformer.

Frequency Operation

The frequency operation is a key differentiator:

- Traditional Transformers: Operate at grid frequency (50/60 Hz).

- EPTs: Use high-frequency switching (typically kHz range).

The high-frequency operation of EPTs results in smaller magnetic components. I’ve seen EPTs that are 30% lighter than their traditional counterparts with the same power rating.

Control Capabilities

EPTs offer superior control capabilities:

- Voltage Regulation: EPTs can provide precise voltage control.

- Power Factor Correction: They can adjust power factor in real-time.

- Harmonic Mitigation: EPTs can actively filter out harmonics.

In a recent industrial project, we used an EPT to solve both voltage regulation and harmonic issues that were plaguing the client’s sensitive equipment. It was like killing two birds with one stone.

Fault Handling

Fault handling is another area where EPTs shine:

- Traditional Transformers: Rely on external protection devices.

- EPTs: Can limit fault currents internally.

I once worked on a grid upgrade where the increased fault current levels were a major concern. By using EPTs, we were able to limit fault currents without additional equipment, simplifying the overall system design.

What Are the Key Advantages of Electronic Power Transformers in Smart Grid Applications?

Smart grids are the future of power distribution, and Electronic Power Transformers are playing a crucial role. I’ve seen firsthand how EPTs can transform a traditional grid into a smart, responsive system.

Electronic Power Transformers offer several key advantages in smart grid applications. These include real-time voltage regulation, power flow control, enhanced communication capabilities, and improved power quality. EPTs enable more efficient integration of renewable energy sources and support advanced grid management functions.

Let’s explore the advantages of EPTs in smart grid applications:

Real-Time Voltage Regulation

EPTs excel at voltage regulation:

- Traditional Transformers: Use tap changers, slow response.

- EPTs: Provide instantaneous voltage adjustment.

I once worked on a project integrating a large solar farm into the grid. The EPTs we used could adjust voltage in milliseconds, compensating for the rapid fluctuations in solar output.

Power Flow Control

EPTs offer unprecedented control over power flow:

| Aspect | Traditional Transformer | Electronic Power Transformer |

|---|---|---|

| Active Power | No control | Can control direction and magnitude |

| Reactive Power | Limited control via tap changers | Full four-quadrant control |

This level of control is game-changing. In a recent microgrid project, we used EPTs to balance loads between different renewable sources and storage systems, optimizing the overall system efficiency.

Enhanced Communication

EPTs are designed for the digital age:

- Data Collection: EPTs can gather detailed operational data.

- Network Integration: They can easily integrate with SCADA systems.

- Remote Control: EPTs allow for remote operation and adjustment.

I remember a utility project where the ability to remotely adjust EPT settings saved countless truck rolls, significantly reducing operational costs.

Improved Power Quality

Power quality improvement is a major advantage of EPTs:

- Harmonic Mitigation: EPTs can actively filter out harmonics.

- Voltage Balancing: They can balance voltages in three-phase systems.

- Flicker Reduction: EPTs can mitigate voltage flicker.

In an industrial park project, the installation of EPTs resolved long-standing power quality issues that had been affecting sensitive manufacturing processes.

Renewable Energy Integration

EPTs facilitate the integration of renewable energy sources:

- Voltage Support: They can provide voltage support for intermittent sources.

- Frequency Regulation: EPTs can help maintain grid frequency.

- Fault Ride-Through: They enhance the grid’s ability to handle faults.

I’ve worked on several wind farm integration projects where EPTs were crucial in meeting grid code requirements, allowing for higher penetration of wind power.

How Do Electronic Power Transformers Enhance Power Quality and System Reliability?

Power quality and system reliability are critical in our increasingly digital world. I’ve seen how poor power quality can wreak havoc on sensitive equipment and how unreliable power can cost businesses millions.

Electronic Power Transformers enhance power quality and system reliability through active voltage regulation, harmonic mitigation, and fault current limiting. They provide rapid response to power disturbances, maintain stable voltage profiles, and improve overall grid resilience.

Let’s delve into how EPTs enhance power quality and system reliability:

Active Voltage Regulation

EPTs offer superior voltage regulation:

- Fast Response: Can adjust voltage in cycles rather than seconds.

- Wide Range: Typically can regulate voltage ±10% or more.

- Independence: Each phase can be regulated independently.

I once worked on a project in an area with frequent voltage sags. The EPTs we installed maintained a stable voltage profile, protecting sensitive industrial equipment from damage and downtime.

Harmonic Mitigation

Harmonics are a growing concern in modern power systems:

| Harmonic Order | Traditional Transformer | Electronic Power Transformer |

|---|---|---|

| Low Order | Passive filtering | Active cancellation |

| High Order | Limited mitigation | Effective reduction |

In a data center project, the EPTs we used reduced total harmonic distortion from over 8% to less than 3%, significantly improving the efficiency and reliability of the IT equipment.

Fault Current Limiting