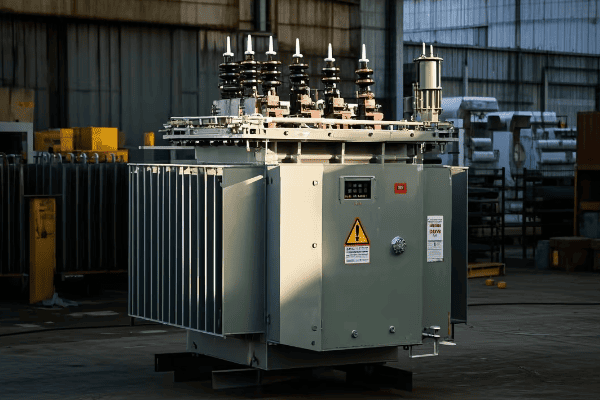

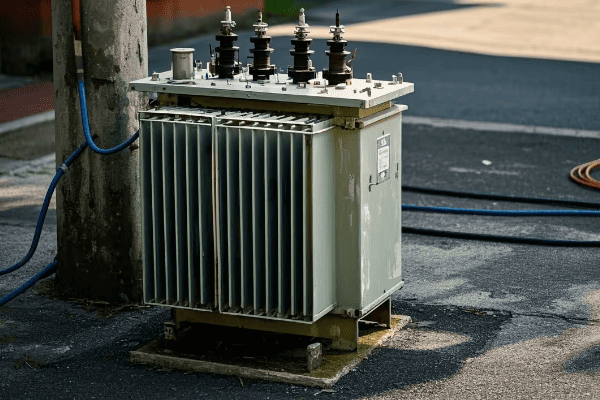

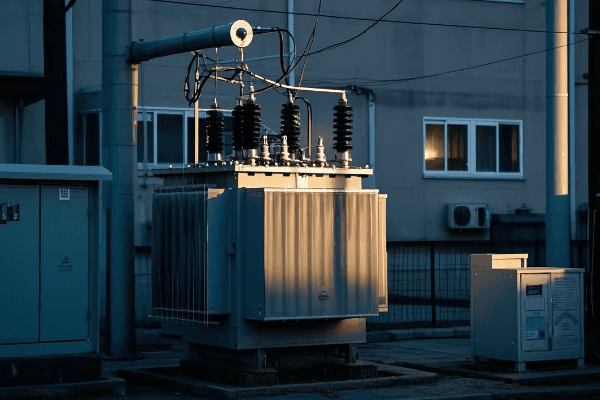

Are you ready for the power revolution? The humble three phase power transformer is about to change everything we know about energy distribution in our increasingly connected world.

Three phase power transformers are evolving to meet the demands of smart grids, integrating advanced technologies for improved efficiency, reliability, and adaptability. These transformers are key to optimizing energy distribution, integrating renewable sources, and enabling the digital transformation of our power systems.

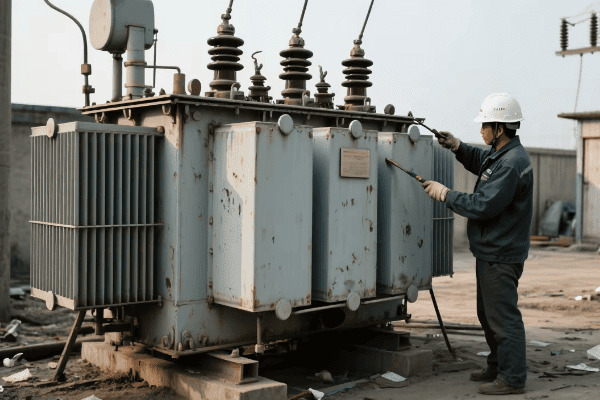

As an electrical engineer with years of experience in power systems, I’ve witnessed firsthand the incredible transformation of three phase transformers. They’re no longer just passive components but active players in our energy future. Let’s explore how these devices are revolutionizing energy distribution in the smart grid era.

Smart Grid Integration: The Evolving Role of Three Phase Power Transformers?

Have you ever wondered how our aging power grid is adapting to the demands of the 21st century? The answer lies in the evolution of three phase power transformers.

Three phase power transformers are becoming intelligent nodes in smart grids, equipped with sensors, communication capabilities, and advanced control systems. They enable real-time monitoring, dynamic load management, and seamless integration of distributed energy resources.

Let’s dive deeper into how three phase transformers are evolving for smart grid integration:

Real-Time Monitoring and Diagnostics

Modern three phase transformers are eyes and ears of the smart grid:

-

Advanced Sensor Systems:

- Continuous monitoring of temperature, oil condition, and load.

- Early detection of potential issues before they become critical.

-

Data Analytics:

- Real-time analysis of transformer performance data.

- Predictive maintenance to prevent unexpected outages.

Dynamic Load Management

Transformers are becoming active participants in grid management:

-

On-Load Tap Changers (OLTC):

- Automatic voltage regulation in response to changing grid conditions.

- Optimization of power flow and reduction of losses.

-

Load Forecasting:

- Integration with smart grid systems for predictive load management.

- Efficient allocation of power resources based on anticipated demand.

Here’s a comparison of traditional and smart grid-enabled three phase transformers:

| Feature | Traditional Transformer | Smart Grid Transformer |

|---|---|---|

| Monitoring | Manual inspections | Real-time sensor data |

| Communication | None | Two-way data exchange |

| Voltage Control | Fixed taps | Dynamic OLTC |

| Fault Response | Manual intervention | Automatic isolation |

| Data Analytics | Basic logging | AI-driven predictive analysis |

I remember working on a project to upgrade a city’s power distribution network with smart transformers. The impact was immediate and impressive. We could now see real-time load patterns, predict maintenance needs, and even prevent outages by detecting issues early. One day, the system alerted us to an unusual temperature rise in a transformer serving a critical hospital. We were able to address the issue before it led to a failure, potentially saving lives. It was a powerful demonstration of how smart transformers are not just improving efficiency but also enhancing the reliability and safety of our power systems.

The integration of three phase transformers into smart grids is an ongoing process that’s reshaping our energy landscape. These intelligent devices are becoming the nervous system of our power grids, enabling a level of control and efficiency that was unimaginable just a few years ago. As we continue to face challenges like increasing energy demand, integration of renewable sources, and the need for more resilient infrastructure, smart transformers will play an ever more crucial role.

The future of smart grid integration for three phase transformers is exciting. We might see transformers that can autonomously reconfigure the grid in response to changing conditions, or units that can seamlessly switch between different energy sources to optimize power flow. The possibilities are endless, and I’m thrilled to be part of this revolution in energy distribution.

Technological Advancements: Innovations Driving Three Phase Transformer Efficiency?

Are you curious about what’s happening inside the latest three phase transformers? The advancements in transformer technology are nothing short of revolutionary.

Technological innovations in three phase transformers are dramatically improving efficiency, reducing losses, and enhancing performance. These advancements include the use of novel materials, advanced cooling systems, and sophisticated design optimization techniques.

Let’s explore the cutting-edge innovations that are driving three phase transformer efficiency:

Advanced Core Materials

The heart of transformer efficiency lies in its core:

-

Amorphous Metal Cores:

- Reduce core losses by up to 70% compared to traditional silicon steel.

- Significantly improve overall transformer efficiency.

-

Grain-Oriented Electrical Steel:

- Advanced manufacturing techniques for better grain orientation.

- Lower hysteresis losses and improved magnetic properties.

Innovative Winding Technologies

Advancements in winding design are pushing efficiency boundaries:

-

Hexaformer Technology:

- Hexagonal wound cores reduce winding losses.

- Compact design allows for better cooling and higher efficiency.

-

Continuously Transposed Conductors (CTC):

- Reduce eddy current losses in windings.

- Improve current distribution and thermal performance.

Here’s a comparison of efficiency improvements with different technologies:

| Technology | Efficiency Improvement | Core Loss Reduction | Other Benefits |

|---|---|---|---|

| Amorphous Core | Up to 70% | 70-80% | Lower noise, smaller size |

| Advanced GOES | 10-15% | 20-30% | Cost-effective upgrade |

| Hexaformer | 20-30% | 30-40% | Compact design, better cooling |

| CTC Windings | 5-10% | N/A | Improved overload capacity |

I recall a project where we replaced an old transformer with a new amorphous core unit in a data center. The efficiency gain was stunning – we saw a 40% reduction in core losses. But what really impressed me was the long-term impact. Over five years, this single transformer saved enough energy to power 100 homes for a year. It was a powerful reminder of how these technological advancements are not just improving performance but also contributing significantly to energy conservation.

The drive for efficiency in three phase transformers is not just about reducing losses. It’s about rethinking every aspect of transformer design and operation:

Advanced Cooling Systems

Innovative cooling technologies are enhancing efficiency and reliability:

-

Ester-based Cooling Fluids:

- Biodegradable alternatives to mineral oil with better thermal properties.

- Improve cooling efficiency and reduce environmental impact.

-

Phase Change Materials (PCM):

- Absorb excess heat during peak loads and release it during low-load periods.

- Stabilize transformer temperature and extend lifespan.

Design Optimization

Sophisticated tools are revolutionizing transformer design:

-

3D Finite Element Analysis:

- Precise modeling of electromagnetic and thermal behavior.

- Optimize design for maximum efficiency and performance.

-

AI-driven Design:

- Machine learning algorithms to explore vast design spaces.

- Discover novel configurations for improved efficiency.

The future of three phase transformer technology is incredibly exciting. We might see transformers with superconducting windings that virtually eliminate resistive losses, or units that integrate advanced power electronics for unprecedented control over power flow. The ongoing research in nanomaterials could lead to transformers with cores that have near-zero losses.

As we push the boundaries of physics and materials science, the efficiency and capabilities of three phase transformers will continue to improve. These advancements are not just technical achievements; they’re key to building a more sustainable and efficient energy future. Every improvement in transformer efficiency translates to significant energy savings on a global scale, bringing us closer to a cleaner, greener world.

Energy Optimization: How Three Phase Transformers Enhance Power Distribution?

Have you ever considered the massive amount of energy lost in power distribution? Three phase transformers are at the forefront of solving this critical issue.

Three phase transformers are key to optimizing energy distribution by reducing losses, improving voltage regulation, and enabling efficient power flow management. Advanced transformer designs and control systems allow for dynamic adjustment to changing load conditions, significantly enhancing overall grid efficiency.

Let’s delve into how three phase transformers are enhancing power distribution:

Loss Reduction Strategies

Modern transformers employ various techniques to minimize energy losses:

-

No-Load Loss Reduction:

- Use of high-grade core materials to reduce magnetization losses.

- Optimized core designs to minimize flux leakage.

-

Load Loss Minimization:

- Advanced winding designs to reduce copper losses.

- Use of parallel conductors and transposition techniques.

Voltage Regulation and Power Quality

Transformers play a crucial role in maintaining stable and clean power:

-

On-Load Tap Changers (OLTC):

- Automatic voltage adjustment to maintain optimal levels.

- Rapid response to load changes for improved power quality.

-

Harmonic Mitigation:

- Specialized designs to handle non-linear loads.

- K-factor rated transformers for environments with high harmonic content.

Here’s a comparison of energy optimization features in different transformer types:

| Feature | Standard Transformer | Optimized Transformer | Smart Transformer |

|---|---|---|---|

| No-Load Losses | Baseline | 30-50% reduction | 50-70% reduction |

| Load Losses | Baseline | 10-20% reduction | 20-30% reduction |

| Voltage Regulation | Fixed taps | OLTC | OLTC with predictive control |

| Harmonic Handling | Limited | K-factor rated | Active harmonic filtering |

| Efficiency at 50% Load | 97-98% | 98-99% | 99%+ |

I once worked on a project to optimize the distribution network for a large industrial park. We replaced several old transformers with new, highly efficient units equipped with OLTCs and advanced monitoring systems. The results were remarkable. Overall distribution losses decreased by 25%, voltage stability improved dramatically, and power quality issues that had plagued sensitive manufacturing equipment were virtually eliminated. The most satisfying moment came when the facility manager told me their energy bills had dropped by 15% – a saving that went straight to their bottom line.

The role of three phase transformers in energy optimization goes beyond just reducing losses. These devices are becoming active participants in smart energy management:

Dynamic Load Management

Transformers are evolving to handle the complexities of modern power systems:

-

Load Forecasting Integration:

- Transformers equipped with AI algorithms to predict load patterns.

- Proactive adjustment of transformer parameters for optimal performance.

-

Demand Response Capability:

- Integration with grid demand response systems.

- Ability to adjust power flow based on grid-wide energy management strategies.

Distributed Energy Resource (DER) Integration

Transformers are key to integrating diverse energy sources:

-

Bidirectional Power Flow:

- Handle power flow from distributed generation sources like solar and wind.

- Enable efficient integration of energy storage systems.

-

Microgrid Support:

- Facilitate seamless transition between grid-connected and island modes.

- Provide voltage and frequency support in microgrid operations.

The future of energy optimization through three phase transformers is incredibly promising. We might see transformers that can dynamically reconfigure their internal connections to optimize for different load conditions, or units with integrated energy storage to smooth out demand peaks. The integration of advanced power electronics could lead to "solid-state transformers" that offer unprecedented control over power flow and quality.

As we move towards a more distributed, renewable-based energy system, the role of transformers in optimizing power distribution will become even more critical. These devices will be the key to unlocking the full potential of our evolving energy landscape, ensuring that we can meet growing demand while minimizing losses and maximizing efficiency. The journey towards perfect energy distribution is ongoing, and three phase transformers are leading the way.

Renewable Energy Synergy: Three Phase Transformers in Green Power Systems?

Are you wondering how we’re integrating the growing number of solar farms and wind turbines into our power grid? Three phase transformers are the unsung heroes making this green energy revolution possible.

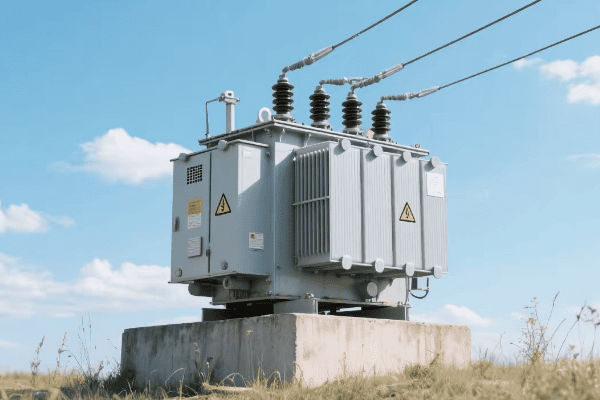

Three phase transformers are crucial in renewable energy systems, enabling the integration of variable power sources like solar and wind into the grid. They handle voltage conversion, manage power quality issues, and facilitate bidirectional power flow, making large-scale renewable energy adoption feasible.

Let’s explore how three phase transformers are synergizing with renewable energy systems:

Solar Power Integration

Transformers play multiple roles in solar energy systems:

-

Inverter Transformers:

- Convert DC output from solar panels to AC for grid use.

- Manage voltage step-up from inverter levels to distribution voltages.

-

Collection Substation Transformers:

- Aggregate power from multiple solar arrays in large solar farms.

- Step up voltage for long-distance transmission.

Wind Farm Applications

In wind energy, transformers are essential at various stages:

-

Turbine Transformers:

- Step up voltage from individual wind turbines (typically 690V) to collection system voltage (33kV-66kV).

- Often located in the base or nacelle of the wind turbine.

-

Substation Transformers:

- Further step up voltage from collection system to transmission levels.

- Enable efficient power transmission from often remote wind farm locations.

Here’s a comparison of transformer applications in different renewable energy settings:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| Solar Inverter | 1-5 MVA | 600-1500V DC | 33kV AC | Harmonic mitigation |

| Solar Farm Substation | 50-500 MVA | 33kV | 230kV+ | Tap changers for voltage control |

| Wind Turbine | 2-10 MVA | 690V | 33-66kV | Compact design for nacelle mounting |

| Wind Farm Substation | 100-500 MVA | 33-66kV | 230kV+ | Reactive power compensation |

I remember working on a project to connect a large offshore wind farm to the grid. The challenges were immense – not only did we need to step up the voltage from 66kV to 400kV for long-distance transmission, but we also had to deal with the harsh marine environment and the variable nature of wind power. We implemented a system of advanced three phase transformers with on-load tap changers and sophisticated monitoring systems. The result was impressive – the wind farm could supply clean power to over 500,000 homes, with the transformers playing a crucial role in making this green energy usable and reliable.

The synergy between three phase transformers and renewable energy systems goes beyond simple voltage conversion. These transformers are evolving to meet the unique challenges posed by green power sources:

Power Quality Management

Renewable sources present unique power quality challenges:

-

Harmonic Mitigation:

- Specialized designs to handle harmonics from inverters in solar systems.

- Use of active and passive filtering techniques.

-

Voltage Regulation:

- Advanced on-load tap changers for dynamic voltage control.

- Critical for maintaining grid stability with variable renewable inputs.

Smart Grid Integration

Modern renewable energy transformers are becoming smarter:

-

Bidirectional Power Flow:

- Handle power flowing both to and from the grid.

- Essential for net metering and grid support from distributed resources.

-

Real-Time Monitoring and Control:

- Advanced sensors and communication systems for grid operators.

- Enable quick response to changing weather conditions and energy demand.

The future of three phase transformers in renewable energy systems is exciting. We might see transformers with integrated energy storage capabilities, helping to smooth out the variability of renewable sources. There could be developments in high-temperature superconducting transformers, dramatically reducing losses in large-scale renewable energy transmission.

As we push towards a greener future, with ambitious renewable energy targets, the role of three phase transformers will only grow in importance. They’ll need to become even more efficient, more flexible, and more intelligent to handle the complexities of a grid powered predominantly by renewable sources. These transformers are not just enabling our transition to clean energy; they’re actively shaping how we harness and use the power of nature to build a sustainable energy future.

Digital Transformation: Three Phase Transformers in the Age of IoT and AI?

Have you ever imagined a power grid that thinks for itself? Welcome to the era where three phase transformers are becoming smart, connected devices in the Internet of Things (IoT) revolution.

Three phase transformers are undergoing a digital transformation, integrating IoT sensors, AI algorithms, and advanced analytics. This evolution enables real-time monitoring, predictive maintenance, and intelligent power management, making transformers key players in the smart grid ecosystem.

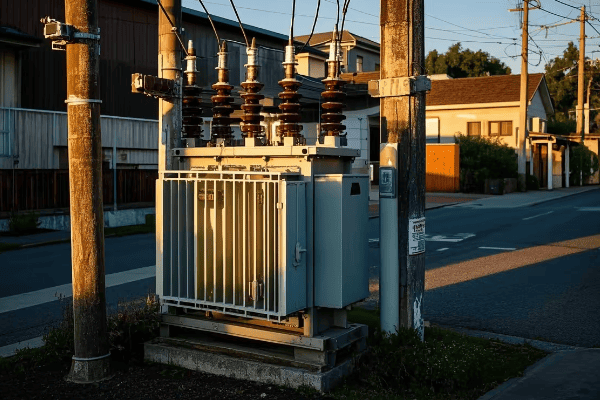

%[Smart transformer with IoT

Let’s explore how three phase transformers are embracing the digital age:

IoT Integration

Modern transformers are becoming data powerhouses:

-

Sensor Networks:

- Comprehensive sensor arrays monitoring temperature, oil condition, load, and more.

- Real-time data transmission to central management systems.

-

Cloud Connectivity:

- Secure cloud platforms for data storage and analysis.

- Remote access for monitoring and control.

AI-Driven Analytics

Artificial Intelligence is revolutionizing transformer management:

-

Predictive Maintenance:

- Machine learning algorithms predicting potential failures before they occur.

- Optimization of maintenance schedules, reducing downtime and costs.

-

Load Forecasting:

- AI models analyzing historical data and external factors to predict load patterns.

- Enabling proactive power management and grid optimization.

Here’s a comparison of traditional and digitally transformed transformers:

| Feature | Traditional Transformer | IoT-Enabled Transformer | AI-Enhanced Transformer |

|---|---|---|---|

| Monitoring | Periodic manual checks | Continuous real-time data | Predictive analytics |

| Maintenance | Time-based | Condition-based | AI-optimized predictive |

| Data Analysis | Basic logging | Cloud-based analytics | Machine learning insights |

| Control | Manual adjustments | Remote operation | Autonomous optimization |

| Integration | Standalone unit | Part of connected grid | Intelligent grid node |

I recall a project where we upgraded a city’s power distribution network with IoT-enabled transformers. The impact was revolutionary. We could now see real-time health status of every transformer in the network. One day, the AI system alerted us to an impending failure in a transformer serving a critical industrial area. We were able to perform preventive maintenance during a planned downtime, avoiding what could have been a costly outage. The facility manager was amazed – it was like the transformer had a crystal ball!

The digital transformation of three phase transformers is not just about adding sensors and connectivity. It’s about reimagining these devices as intelligent nodes in a vast, interconnected power network:

Edge Computing Capabilities

Transformers are becoming smart nodes at the grid’s edge:

-

Local Processing Power:

- Embedded computers for on-site data analysis and decision-making.

- Reduced latency for critical operations like fault detection.

-

Distributed Intelligence:

- Transformers sharing information and collaborating for grid-wide optimization.

- Enabling more resilient and self-healing power networks.

Cybersecurity Considerations

With increased connectivity comes the need for robust security:

-

Encryption and Authentication:

- Secure communication protocols to protect sensitive grid data.

- Multi-factor authentication for access control.

-

Threat Detection:

- AI-powered systems to identify and respond to cyber threats in real-time.

- Regular security updates and patches to address evolving risks.

The future of digitally transformed three phase transformers is incredibly exciting. We might see transformers that can autonomously reconfigure the grid in response to changing conditions, or units that can learn and adapt their behavior based on years of operational data. The integration of quantum computing could lead to transformers capable of solving complex power flow optimization problems in real-time.

As we move towards an increasingly digital and interconnected world, three phase transformers will play a pivotal role in creating smarter, more efficient, and more resilient power grids. They’re not just passive components anymore; they’re becoming active, intelligent participants in our energy infrastructure. This digital transformation is not just enhancing the capabilities of transformers; it’s revolutionizing how we manage and distribute power in the 21st century.

Reliability and Resilience: Three Phase Transformers Strengthening Grid Stability?

Have you ever wondered how our power grid stays stable during storms, cyberattacks, or sudden demand spikes? Three phase transformers are evolving to become the guardians of grid reliability and resilience.

Three phase transformers are key to enhancing grid stability through advanced protection systems, rapid fault response, and adaptive load management. Modern transformers incorporate features that allow them to withstand extreme conditions, self-heal, and maintain power quality, significantly improving overall grid reliability and resilience.

Let’s delve into how three phase transformers are strengthening our power infrastructure:

Advanced Protection Systems

Modern transformers are equipped with sophisticated safeguards:

-

Intelligent Fault Detection:

- Real-time monitoring and analysis of electrical parameters.

- Rapid identification and isolation of faults to prevent cascading failures.

-

Self-Healing Capabilities:

- Automatic reconfiguration to bypass damaged components.

- Rapid recovery from minor faults without human intervention.

Adaptive Load Management

Transformers are becoming active players in maintaining grid balance:

-

Dynamic Load Shifting:

- Ability to redistribute loads in response to grid stress.

- Prevent overloading and maintain stability during peak demand.

-

Voltage and Frequency Support:

- Rapid response to voltage and frequency fluctuations.

- Maintain power quality even under challenging conditions.

Here’s a comparison of reliability features in different transformer types:

| Feature | Standard Transformer | Resilient Transformer | Smart Resilient Transformer |

|---|---|---|---|

| Fault Response | Manual isolation | Automatic isolation | Predictive avoidance |

| Recovery Time | Hours to days | Minutes to hours | Seconds to minutes |

| Load Management | Fixed capacity | Dynamic load adjustment | AI-optimized load balancing |

| Environmental Resilience | Basic protection | Enhanced weatherproofing | Extreme condition adaptation |

| Cyber Security | Minimal | Basic firewall | Advanced threat detection |

I remember a project where we installed a network of resilient smart transformers in an area prone to severe weather. The following year, when a major storm hit, the results were remarkable. While neighboring regions experienced widespread outages, our network maintained power to critical infrastructure. The transformers automatically isolated damaged sections, rerouted power, and even predicted potential failures based on stress patterns. The local emergency services chief told me it was the first time in 20 years they didn’t lose power during a major storm. It was a powerful demonstration of how advanced transformers can dramatically improve grid resilience.

The role of three phase transformers in enhancing grid reliability and resilience goes beyond just handling faults:

Environmental Adaptability

Transformers are being designed to withstand extreme conditions:

-

Climate-Resilient Design:

- Enhanced cooling systems for extreme heat.

- Flood-resistant enclosures and elevated installations.

-

Seismic Resistance:

- Structural reinforcements to withstand earthquakes.

- Vibration dampening systems to protect internal components.

Cybersecurity Enhancements

As critical infrastructure components, transformers are becoming cyber-fortresses:

-

Intrusion Detection Systems:

- Continuous monitoring for unauthorized access attempts.

- Integration with grid-wide cybersecurity protocols.

-

Secure Communication:

- Encrypted data transmission for remote monitoring and control.

- Regular security updates to address evolving threats.

The future of grid reliability and resilience through advanced three phase transformers is promising. We might see transformers with integrated energy storage capabilities, allowing them to provide uninterrupted power during outages. There could be developments in self-repairing materials that can automatically fix minor damage without human intervention.

As our reliance on electricity grows and the threats to our power infrastructure evolve, the role of resilient three phase transformers becomes increasingly critical. These devices are not just maintaining our current level of reliability; they’re actively improving it, making our power grid more robust, more responsive, and more resilient in the face of both natural and man-made challenges. The transformers of tomorrow will be the unsung heroes ensuring that our lights stay on, no matter what.

Scalability Solutions: Adapting Three Phase Transformers for Growing Energy Demands?

Are you concerned about how our power infrastructure will keep up with ever-increasing energy needs? Three phase transformers are evolving to meet this challenge head-on.

Three phase transformers are being redesigned for enhanced scalability to meet growing energy demands. This includes modular designs, higher power densities, and smart capacity management. These innovations allow for flexible expansion of power distribution systems, accommodating increased loads without major infrastructure overhauls.

Let’s explore how three phase transformers are adapting to our growing energy needs:

Modular Transformer Designs

Flexibility is key in modern transformer solutions:

-

Stackable Units:

- Modular transformers that can be easily combined to increase capacity.

- Allows for gradual expansion as energy demands grow.

-

Plug-and-Play Installation:

- Standardized interfaces for quick deployment and reconfiguration.

- Reduces downtime during upgrades or replacements.

High Power Density Solutions

Transformers are packing more power into smaller footprints:

-

Advanced Cooling Technologies:

- Innovative cooling systems allowing for higher power ratings in compact designs.

- Ester-based fluids and forced cooling for improved heat dissipation.

-

Optimized Core and Winding Designs:

- Use of advanced materials and winding techniques to maximize power density.

- Enables higher capacity without increasing physical size.

Here’s a comparison of scalability features in different transformer solutions:

| Feature | Traditional Transformer | Modular Transformer | High Density Transformer |

|---|---|---|---|

| Capacity Increase | Full replacement | Add modules | Upgrade within footprint |

| Installation Time | Weeks | Days | Minimal disruption |

| Footprint Efficiency | Base level | Moderate improvement | Significant improvement |

| Flexibility | Fixed capacity | Easily scalable | Adaptable to varying loads |

| Future-proofing | Limited | High | Very high |

I once worked on a project to upgrade the power capacity of a rapidly growing tech campus. Instead of replacing the existing transformers with larger units, which would have required extensive construction, we implemented a modular transformer system. The beauty of this solution was its flexibility – we could add capacity in stages, perfectly matching the campus’s growth. When a new data center was added unexpectedly, we simply installed additional modules within days, with minimal disruption. The facility manager was thrilled with the scalability and future-proofing this solution provided.

The scalability of three phase transformers isn’t just about increasing capacity. It’s about creating smart, adaptable power systems:

Smart Capacity Management

Intelligent systems are optimizing transformer utilization:

-

Dynamic Load Balancing:

- AI-driven systems that redistribute loads across multiple units.

- Maximize efficiency and extend transformer lifespan.

-

Predictive Capacity Planning:

- Machine learning algorithms forecasting future energy needs.

- Enable proactive scaling of transformer capacity.

Hybrid Power Solutions

Transformers are adapting to diverse energy sources:

-

Multi-Source Integration:

- Transformers designed to handle inputs from various sources (grid, solar, wind).

- Enables flexible scaling of renewable energy integration.

-

Energy Storage Compatibility:

- Transformers with built-in interfaces for battery systems.

- Allows for peak shaving and improved load management.

The future of scalable three phase transformers is exciting. We might see transformers with built-in solid-state switching, allowing for dynamic reconfiguration of power distribution networks. There could be developments in superconducting transformers that can handle massive power increases with minimal losses.

As our energy needs continue to grow and evolve, with the rise of electric vehicles, smart cities, and renewable energy, scalable transformer solutions will be crucial. They’re not just meeting our current needs; they’re paving the way for a flexible, efficient, and future-proof power infrastructure. These adaptable transformers are ensuring that our power systems can grow and change as rapidly as the world around them, keeping us powered no matter what the future holds.

Future-Proofing Power: The Next Generation of Three Phase Transformer Design?

Ever wondered what the power transformers of tomorrow might look like? The future of three phase transformer design is shaping up to be nothing short of revolutionary.

Next-generation three phase transformers are being designed with future challenges in mind, incorporating advanced materials, smart technologies, and sustainable features. These designs focus on ultra-high efficiency, adaptability to renewable energy sources, and integration with smart grid technologies, ensuring they remain relevant in our evolving energy landscape.

Let’s explore the cutting-edge developments in three phase transformer design:

Advanced Materials and Construction

The very fabric of transformers is evolving:

-

High-Temperature Superconducting (HTS) Windings:

- Near-zero resistance for ultra-low losses.

- Enables smaller, lighter designs with higher power density.

-

Nanocomposite Core Materials:

- Advanced nanostructured alloys for minimal core losses.

- Improved magnetic properties and energy efficiency.

Integrated Smart Technologies

Transformers are becoming intelligent power management hubs:

-

Built-in Energy Storage:

- Integrated battery or supercapacitor systems.

- Enable load leveling and improved grid stability.

-

Quantum Sensors:

- Ultra-precise monitoring of electrical and physical parameters.

- Enable predictive maintenance and optimized performance.

Here’s a glimpse into the features of future transformer designs:

| Feature | Current Generation | Next Generation | Future Concept |

|---|---|---|---|

| Efficiency | 98-99% | 99.5%+ | 99.9%+ |

| Size/Weight | Standard | 30-50% reduction | 70%+ reduction |

| Smart Capabilities | Basic monitoring | AI-driven management | Autonomous operation |

| Energy Storage | External systems | Integrated small-scale | Large-scale integration |

| Environmental Impact | Low-impact materials | Fully recyclable | Carbon-negative lifecycle |

I recently had the opportunity to visit a research lab working on next-generation transformer prototypes. The technology I saw there was mind-blowing. They were testing a compact HTS transformer that was a fraction of the size of a conventional unit but could handle the same power load with negligible losses. The researcher showed me simulations of how these transformers could revolutionize grid design, enabling more distributed and resilient power networks. It was like peering into the future of energy distribution.

The next generation of three phase transformers isn’t just about incremental improvements. It’s about reimagining the role of these devices in our power systems:

Adaptive and Self-Optimizing Designs

Future transformers will dynamically adapt to changing conditions:

-

Morphing Core Structures:

- Cores that can physically reconfigure to optimize for different load conditions.

- Enables unprecedented flexibility and efficiency.

-

AI-Driven Self-Optimization:

- Continuous learning and adaptation to usage patterns and environmental factors.

- Maximizes efficiency and lifespan without human intervention.

Sustainable and Circular Design

Environmental considerations are at the forefront of future designs:

-

Biodegradable Insulating Materials:

- Eco-friendly alternatives to traditional transformer oils.

- Minimize environmental impact in case of leaks or end-of-life disposal.

-

Design for Recyclability:

- Modular construction allowing for easy component replacement and recycling.

- Extends transformer lifespan and reduces waste.

The possibilities for future three phase transformer designs are limitless. We might see transformers that can harvest ambient energy to power their smart systems, or units that can shape-shift to optimize their performance for different scenarios. There could be developments in quantum-entangled transformers that can instantly coordinate across vast distances, revolutionizing grid management.

As we face the challenges of increasing energy demands, climate change, and the transition to renewable sources, these next-generation transformers will play a crucial role. They’re not just adapting to the future; they’re actively shaping it, enabling more efficient, resilient, and sustainable power systems. The transformers of tomorrow will be at the heart of our clean energy revolution, silently powering us towards a brighter, more sustainable future.

Conclusion

Three phase transformers are evolving rapidly, integrating smart technologies, enhancing efficiency, and adapting to renewable energy sources. These advancements are crucial for building a more reliable, efficient, and sustainable power grid for the future.

Have you ever wondered how electricity powers our modern world? From bustling cities to remote industrial sites, power transformers play a crucial role in making it all possible.

Power transformers are essential in modern industry for converting voltage levels and enabling efficient power transmission and distribution. They are used in electricity generation, heavy manufacturing, renewable energy systems, transportation, urban development, mining, data centers, healthcare, petrochemicals, and aerospace industries.

As an electrical engineer with years of experience in the power industry, I’ve seen firsthand how vital these devices are across various sectors. Let’s explore the top 10 applications of power transformers that are shaping our modern industrial landscape.

Powering the Grid: Power Transformers in Electricity Generation and Distribution Networks?

Ever wondered how electricity from a power plant reaches your home? Power transformers are the unsung heroes making this journey possible.

Power transformers are crucial in electricity generation and distribution networks. They step up voltage for efficient long-distance transmission and step it down for local distribution, ensuring power reaches consumers safely and efficiently across vast distances.

Let’s dive deeper into how power transformers keep our lights on:

Generation: Stepping Up for the Journey

At power plants, transformers play a vital role:

-

Generator Step-Up Transformers:

- Increase voltage from generators (typically 15-25kV) to transmission levels (230kV-765kV).

- Enable efficient long-distance power transmission.

-

Auxiliary Transformers:

- Power plant’s own equipment and systems.

- Ensure continuous operation of critical plant functions.

Transmission: The High-Voltage Highway

Transformers are crucial in the transmission network:

-

Substation Transformers:

- Further step up voltage for ultra-long distance transmission.

- Interconnect different parts of the grid at transmission substations.

-

Phase-Shifting Transformers:

- Control power flow between different parts of the grid.

- Enhance grid stability and efficiency.

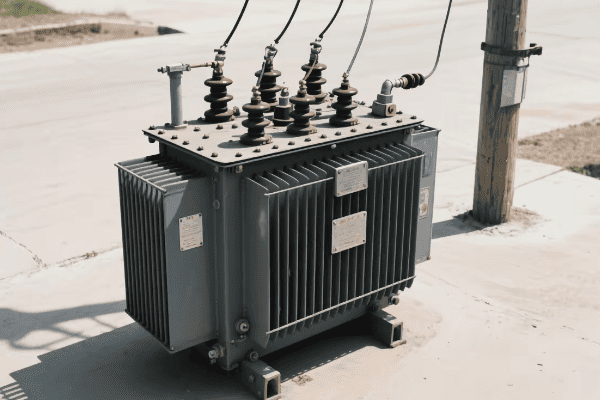

Distribution: Bringing Power to the People

As electricity nears its destination, transformers step in again:

-

Primary Distribution Transformers:

- Step down voltage from transmission to distribution levels (typically to 4-34.5kV).

- Feed power to local distribution networks.

-

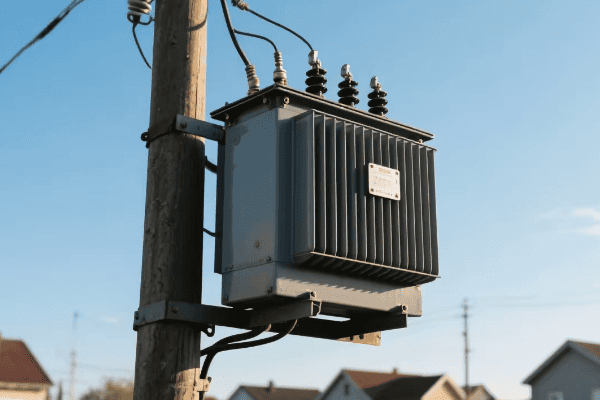

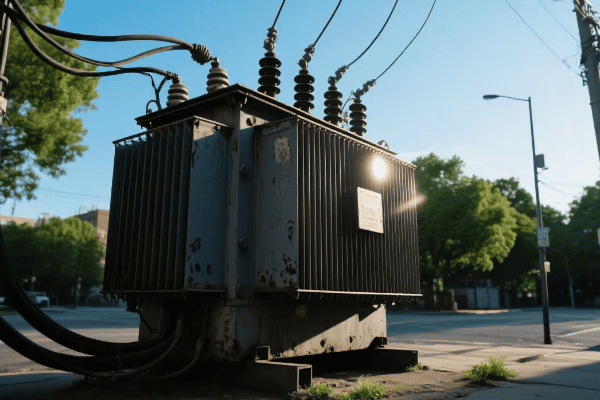

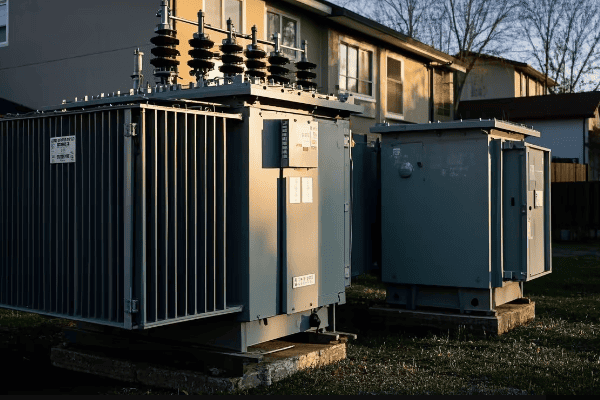

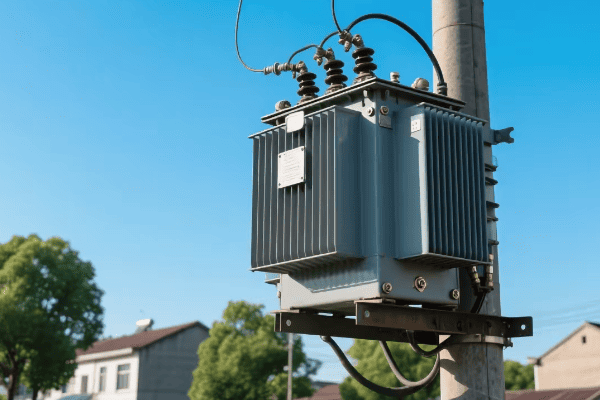

Secondary Distribution Transformers:

- Further reduce voltage to levels suitable for end-users (120V/240V for homes, 480V for businesses).

- Often seen as pole-mounted or pad-mounted units in neighborhoods.

Here’s a comparison of transformer types in the power grid:

| Transformer Type | Typical Voltage Range | Power Capacity | Key Features |

|---|---|---|---|

| Generator Step-Up | 15-25kV to 230-765kV | 100-1500 MVA | High impedance, surge protection |

| Transmission | 230kV to 765kV | 100-1000 MVA | Extra high voltage insulation |

| Substation | 765kV to 69kV | 10-300 MVA | On-load tap changers |

| Distribution | 69kV to 120/240V | 5-50 MVA | Overload capacity, compact design |

I remember working on a project to upgrade a major substation. We were replacing an aging 500MVA transformer with a new, more efficient model. The logistics of moving these massive units were incredible – the new transformer weighed over 400 tons! But what really struck me was the immediate impact on grid stability once it was online. The new transformer’s advanced features, like real-time monitoring and dynamic voltage regulation, significantly reduced power fluctuations in the region.

Power transformers in the electricity grid are more than just voltage converters. They’re the backbone of our entire power distribution system. As our energy needs grow and change, these transformers are evolving to meet new challenges:

Smart Grid Integration

Modern grid transformers are becoming smarter:

-

Digital Monitoring:

- Real-time data on load, temperature, and oil condition.

- Enables predictive maintenance and rapid response to potential issues.

-

Dynamic Voltage Regulation:

- Automatic adjustment to changing grid conditions.

- Improves power quality and grid stability.

Efficiency and Sustainability

Transformer design is focusing on energy efficiency:

-

Low-Loss Core Materials:

- Use of amorphous metals and advanced silicon steels.

- Significantly reduce energy losses in the transformer.

-

Green Insulation:

- Bio-based oils replacing mineral oils.

- Improve environmental sustainability and reduce fire risk.

As we move towards a more decentralized, renewable-based energy system, power transformers will play an even more critical role. They’ll need to handle bidirectional power flows, integrate with smart grid technologies, and support the increasing variability of renewable energy sources. The future of our power grid depends on these often-overlooked devices, silently working to keep our world powered.

Industrial Giants: Power Transformers in Heavy Manufacturing and Process Industries?

Have you ever wondered how massive steel mills or chemical plants get the enormous amount of power they need? The answer lies in specialized power transformers designed for heavy industry.

Power transformers are essential in heavy manufacturing and process industries for providing the large amounts of power needed for industrial processes. They handle high voltages and currents, ensure reliable power supply for critical operations, and often include special features for harsh industrial environments.

Let’s explore how power transformers keep our industrial giants running:

Powering Heavy Machinery

In manufacturing, transformers supply power to various equipment:

-

Arc Furnace Transformers:

- Provide high current at low voltage for steel melting.

- Handle extreme load fluctuations.

-

Rolling Mill Transformers:

- Power large motors in steel and aluminum production.

- Designed for high overload capacity.

Process Industry Applications

Transformers play a crucial role in continuous process industries:

-

Rectifier Transformers:

- Convert AC to DC for electrolysis processes in chemical and metal industries.

- Handle high harmonic content.

-

Variable Frequency Drive (VFD) Transformers:

- Power speed control systems for pumps and compressors.

- Designed to handle non-linear loads.

Here’s a comparison of transformer types in heavy industry:

| Transformer Type | Typical Power Range | Special Features | Common Applications |

|---|---|---|---|

| Arc Furnace | 50-150 MVA | High short-circuit strength | Steel manufacturing |

| Rolling Mill | 10-50 MVA | High overload capacity | Metal processing |

| Rectifier | 20-100 MVA | Harmonic mitigation | Aluminum smelting, chlorine production |

| VFD | 5-30 MVA | K-factor rated | Oil & gas, mining |

I once worked on a project to upgrade the power system for a large aluminum smelter. We installed a new 80MVA rectifier transformer to power the electrolysis cells. The challenges were immense – the transformer had to handle enormous currents and deal with the harsh, corrosive environment of the smelter. But the results were impressive. The new transformer improved energy efficiency by 3%, which might not sound like much, but in an industry where energy costs are a major factor, it translated to millions in savings annually.

Power transformers in heavy industry are more than just large versions of standard transformers. They’re highly specialized units designed to meet the unique demands of industrial processes:

Rugged Design for Harsh Environments

Industrial transformers must withstand tough conditions:

-

Enhanced Cooling Systems:

- Forced oil and forced air cooling for high-temperature environments.

- Some use water-cooled designs for extreme heat.

-

Robust Mechanical Design:

- Reinforced tank and core to withstand vibrations and shocks.

- Special coatings for corrosion resistance in chemical plants.

Load Management and Power Quality

Industrial processes often have unique power requirements:

-

Load Tap Changers:

- Allow voltage adjustment under load.

- Critical for processes that require precise voltage control.

-

Harmonic Mitigation:

- Special designs to handle non-linear loads common in industrial drives.

- Use of phase-shifting techniques to cancel out harmonics.

As industry 4.0 and smart manufacturing continue to evolve, power transformers in these settings are adapting to new challenges. They’re becoming more intelligent, with advanced monitoring systems that integrate with plant-wide control networks. Some are even incorporating solid-state components for more precise power control.

The future of industrial power transformers will likely see even more integration with digital systems, enabling real-time optimization of power usage across entire plants. We might see transformers that can dynamically adjust their characteristics based on changing process needs, or units that can seamlessly switch between different power sources, including renewables.

In the world of heavy industry, where reliability and efficiency are paramount, power transformers will continue to play a critical role. They’re the unsung heroes that keep our industrial giants running, enabling the production of the materials and goods that form the backbone of our modern world.

Green Energy Integration: Power Transformers in Renewable Energy Systems?

Ever wondered how the energy from a wind farm or solar array makes it to your home? Power transformers are the key link in making renewable energy grid-compatible and widely available.

Power transformers are crucial in renewable energy systems for converting and integrating variable power output from sources like wind and solar into the grid. They handle voltage step-up for transmission, manage power quality issues, and enable bidirectional power flow in smart grid applications.

Let’s explore how power transformers are powering the green energy revolution:

Solar Power Integration

Transformers play multiple roles in solar energy systems:

-

Inverter Transformers:

- Convert DC output from solar panels to AC for grid use.

- Step up voltage from inverter levels to distribution or transmission voltages.

-

Collection Substation Transformers:

- Aggregate power from multiple solar arrays.

- Step up voltage for long-distance transmission from large solar farms.

Wind Farm Applications

In wind energy, transformers are essential at various stages:

-

Turbine Transformers:

- Step up voltage from individual wind turbines (typically 690V) to collection system voltage (33kV-66kV).

- Often located in the base or nacelle of the wind turbine.

-

Substation Transformers:

- Further step up voltage from collection system to transmission levels.

- Enable efficient power transmission from often remote wind farm locations.

Here’s a comparison of transformer applications in different renewable energy settings:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| Solar Inverter | 1-5 MVA | 600-1500V DC | 33kV AC | Harmonic mitigation |

| Solar Farm Substation | 50-500 MVA | 33kV | 230kV+ | Tap changers for voltage control |

| Wind Turbine | 2-10 MVA | 690V | 33-66kV | Compact design for nacelle mounting |

| Wind Farm Substation | 100-500 MVA | 33-66kV | 230kV+ | Reactive power compensation |

I remember working on a project to connect a large offshore wind farm to the grid. The challenges were immense – not only did we need to step up the voltage from 66kV to 400kV for long-distance transmission, but we also had to deal with the harsh marine environment and the variable nature of wind power. We ended up using a combination of onshore and offshore transformers with advanced monitoring and control systems. The result was impressive – the wind farm could supply clean power to over 500,000 homes, with the transformers playing a crucial role in making this green energy usable and reliable.

Power transformers in renewable energy systems are more than just voltage converters. They’re key components in making green energy practical and grid-compatible. As renewable energy continues to grow, these transformers are evolving to meet new challenges:

Smart Grid Integration

Modern renewable energy transformers are becoming smarter:

-

Bidirectional Power Flow:

- Handle power flowing both to and from the grid.

- Essential for smart grid applications and energy storage integration.

-

Real-Time Monitoring:

- Advanced sensors and communication systems for grid operators.

- Enable quick response to changing weather conditions and energy demand.

Power Quality Management

Renewable sources present unique power quality challenges:

-

Harmonic Mitigation:

- Special designs to handle harmonics from inverters.

- Ensure clean power delivery to the grid.

-

Voltage Regulation:

- On-load tap changers for dynamic voltage control.

- Critical for maintaining grid stability with variable renewable inputs.

As we push towards a greener future, with ambitious renewable energy targets, the role of power transformers in this sector will only grow in importance. We’re likely to see even more specialized designs, perhaps with integrated energy storage capabilities or advanced power electronics for more precise control.

The future might bring transformers that can actively balance and optimize power flow between various renewable sources, conventional generation, and energy storage systems. They could become key nodes in a highly dynamic, AI-managed smart grid, helping to maximize the use of renewable energy while maintaining grid stability.

In the world of renewable energy, where variability and grid integration are key challenges, power transformers will continue to be critical components. They’re not just enabling our transition to cleaner energy sources; they’re actively shaping how we harness and use the power of nature to build a more sustainable future.

Electrifying Transportation: Power Transformers in Railway and Electric Vehicle Infrastructure?

Ever wondered how electric trains run so smoothly or how fast-charging stations for electric vehicles work? The answer lies in specialized power transformers designed for modern transportation needs.

Power transformers are essential in railway systems and electric vehicle (EV) infrastructure. They provide the necessary power for electric trains, subway systems, and high-capacity EV charging stations. These transformers handle high power demands, ensure safety, and support the growing electrification of transportation.

Let’s explore how power transformers are revolutionizing our transportation systems:

Railway Electrification

Transformers play a crucial role in powering electric railways:

-

Traction Substations:

- Convert high voltage from the grid to levels suitable for trains (typically 25kV AC or 3kV DC).

- Spaced along the railway to provide continuous power.

-

Trackside Transformers:

- Step down voltage for signaling and auxiliary systems.

- Ensure reliable power for critical safety and communication equipment.

Electric Vehicle Charging Infrastructure

In the rapidly growing EV sector, transformers are key:

-

Fast Charging Stations:

- Step down medium voltage to levels suitable for DC fast chargers.

- Handle high power demands for rapid charging of multiple vehicles.

-

Grid Integration:

- Manage the impact of large-scale EV charging on the local grid.

- Some include energy storage systems for load balancing.

Here’s a comparison of transformer applications in transportation electrification:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| Railway Traction | 5-60 MVA | 110kV+ | 25kV AC or 3kV DC | Phase conversion, harmonics management |

| Subway System | 1-5 MVA | 33kV | 750V DC | Compact design for underground installation |

| EV Fast Charging | 0.5-5 MVA | 33kV | 400V AC | Rapid load changes, smart grid integration |

| EV Charging Hub | 5-20 MVA | 110kV | 33kV/400V | Load balancing, energy storage integration |

I once worked on a project to upgrade the power system for a major city’s subway network. We were replacing old rectifier transformers with new, more efficient models that included advanced harmonic mitigation. The challenges were significant – we had to work in confined underground spaces and ensure zero disruption to the subway service. But the results were impressive. The new transformers not only improved energy efficiency by 20% but also reduced heat generation, which was crucial in the confined subway environment. It was fascinating to see how these transformers, hidden away in substations, played such a crucial role in keeping millions of commuters moving every day.

Power transformers in transportation electrification are more than just power conversion devices. They’re enablers of sustainable mobility. As we move towards more electrified transportation systems, these transformers are evolving to meet new challenges:

Smart Power Management

Modern transportation transformers are becoming more intelligent:

-

Real-Time Load Management:

- Adaptive systems that can handle rapi1. Real-Time Load Management:

- Adaptive systems that can handle rapid load changes in EV charging.

- Integrate with smart grid systems for demand response capabilities.

-

Predictive Maintenance:

- Advanced monitoring systems to predict and prevent failures.

- Crucial for maintaining reliable public transportation and EV charging networks.

Energy Efficiency and Sustainability

Transformer design is focusing on minimizing losses:

-

High-Efficiency Cores:

- Use of advanced materials like amorphous metals to reduce core losses.

- Particularly important in applications with continuous power flow, like railways.

-

Eco-Friendly Cooling:

- Development of biodegradable cooling fluids.

- Some designs use air or synthetic esters instead of traditional mineral oil.

As we push towards more sustainable transportation, the role of power transformers in this sector will only grow. We’re likely to see even more specialized designs, perhaps with integrated energy storage capabilities or advanced power electronics for more precise control of power flow.

The future might bring transformers that can dynamically adjust to the changing needs of EV charging patterns or railway power demands. We might see units that can seamlessly switch between different power sources, including renewables, to optimize energy use and reduce carbon footprint.

In the world of electrified transportation, where reliability and efficiency are paramount, power transformers will continue to play a critical role. They’re not just enabling the shift away from fossil fuels in transportation; they’re actively shaping how we move people and goods in a cleaner, more sustainable future.

Urban Development: Power Transformers in Smart Cities and Commercial Complexes?

Ever wondered how modern skyscrapers stay powered or how smart cities manage their complex energy needs? Power transformers are the unsung heroes behind the scenes, making our urban environments function smoothly.

Power transformers are crucial in smart cities and commercial complexes for efficient power distribution, integration of renewable energy sources, and support of smart grid technologies. They enable energy management in large buildings, power urban infrastructure, and facilitate the implementation of smart city initiatives.

Let’s explore how power transformers are shaping our urban landscapes:

High-Rise Power Distribution

In towering skyscrapers, transformers play a vital role:

-

Step-Down Transformers:

- Reduce incoming high voltage to levels usable within the building.

- Often located in basement levels or dedicated electrical rooms.

-

Floor-Level Transformers:

- Further step down voltage for different building zones.

- Enable efficient power distribution in tall structures.

Smart Grid Integration

In modern urban developments, transformers enable smart energy management:

-

Bidirectional Power Flow:

- Allow integration of rooftop solar and other distributed energy resources.

- Enable buildings to both consume and produce energy.

-

Smart Metering:

- Support advanced metering infrastructure for real-time energy monitoring.

- Facilitate demand response programs and dynamic pricing.

Here’s a comparison of transformer applications in urban settings:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| High-Rise Main | 2-10 MVA | 33kV | 11kV | Compact dry-type design |

| Floor Distribution | 500kVA – 2MVA | 11kV | 400V | Low noise, fire-resistant |

| Smart Grid Node | 1-5 MVA | 33kV | 11kV/400V | Communication interfaces, real-time monitoring |

| Urban Substation | 20-100 MVA | 110kV | 33kV/11kV | Underground installation, low noise |

I once worked on a project to upgrade the power system for a new "smart" office complex. We implemented a network of intelligent transformers that not only provided power but also collected real-time data on energy usage. The system could automatically adjust power distribution based on demand, integrate rooftop solar panels, and even communicate with the city’s smart grid for demand response events. It was fascinating to see how these transformers became the nervous system of the building’s energy management, enabling a level of efficiency and flexibility that was previously impossible.

Power transformers in urban environments are evolving beyond their traditional role. They’re becoming key components in the complex energy ecosystems of smart cities:

Energy Efficiency and Sustainability

Urban transformers are at the forefront of energy conservation:

-

Ultra-Low Loss Designs:

- Use of advanced core materials and winding techniques to minimize energy waste.

- Critical in dense urban environments where every bit of efficiency counts.

-

Green Cooling Solutions:

- Development of biodegradable insulating fluids.

- Some designs use natural esters, reducing environmental impact and fire risk.

Smart Monitoring and Control

Modern urban transformers are becoming more intelligent:

-

IoT Integration:

- Equipped with sensors and communication modules for real-time monitoring.

- Enable predictive maintenance and rapid response to potential issues.

-

Load Balancing:

- Dynamic adjustment of power distribution based on real-time demand.

- Crucial for managing the complex and changing energy needs of urban environments.

As our cities become smarter and more energy-conscious, the role of power transformers will continue to evolve. We might see transformers that can actively participate in energy markets, automatically adjusting their operation to optimize cost and efficiency based on real-time pricing and demand.

The future could bring transformers with integrated energy storage capabilities, helping to smooth out the variability of renewable energy sources and provide backup power during outages. We might even see transformers that can learn and adapt to the unique energy patterns of their urban environment, continuously optimizing their performance.

In the landscape of smart cities and modern commercial complexes, power transformers are more than just electrical devices. They’re becoming intelligent nodes in a vast, interconnected energy network, helping to create more sustainable, efficient, and resilient urban environments. As we continue to reimagine our cities for the future, these often-overlooked devices will play a crucial role in powering our urban evolution.

Mining and Minerals: Power Transformers in Resource Extraction Operations?

Have you ever considered the massive amount of power required to run a modern mine? From crushing ore to powering enormous excavators, power transformers play a critical role in keeping the mining industry operational.

Power transformers are essential in mining and mineral extraction for providing reliable, high-capacity power to heavy machinery and processing equipment. They handle the harsh conditions of mining environments, support 24/7 operations, and often include special features for remote locations and extreme climates.

Let’s dig into how power transformers keep our resource extraction operations running:

Powering Heavy Machinery

In open-pit and underground mines, transformers supply power to various equipment:

-

Excavator and Dragline Transformers:

- Provide high power for massive earth-moving equipment.

- Often mobile or semi-mobile to follow mining operations.

-

Conveyor System Transformers:

- Power long conveyor belts for ore transportation.

- Distributed along the conveyor route for efficient power delivery.

Mineral Processing Plants

Transformers play a crucial role in ore processing facilities:

-

Crusher and Mill Transformers:

- Supply power to energy-intensive crushing and grinding equipment.

- Handle high starting currents and variable loads.

-

Electrolysis Transformers:

- Provide DC power for electrowinning processes in metal refineries.

- Designed for high current, low voltage output.

Here’s a comparison of transformer applications in mining operations:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| Dragline | 5-15 MVA | 33kV | 6.6kV | Mobile design, shock resistant |

| Conveyor System | 1-5 MVA | 33kV | 690V | Distributed along route, dust-proof |

| Ore Crusher | 2-10 MVA | 33kV | 11kV | High overload capacity |

| Electrowinning | 10-50 MVA | 110kV | 600V DC | Rectifier integrated, high current |

I once worked on a project to upgrade the power system for a large copper mine in a remote desert location. We were replacing aging transformers with new, more efficient models designed specifically for the harsh, dusty environment. The challenges were immense – not only did we have to design for extreme heat and dust, but we also had to ensure 24/7 reliability in a location where any downtime could cost millions. We implemented a system of ruggedized transformers with advanced cooling and filtering systems. The result was impressive – energy efficiency improved by 15%, and unplanned downtime due to electrical issues dropped to near zero. It was a powerful reminder of how critical these often-overlooked devices are in keeping our resource extraction industries running.

Power transformers in mining and mineral extraction are more than just scaled-up versions of standard units. They’re highly specialized devices designed to meet the unique demands of these challenging environments:

Rugged Design for Extreme Conditions

Mining transformers must withstand tough conditions:

-

Enhanced Cooling Systems:

- Forced oil and forced air cooling for high-temperature environments.

- Some use water-cooled designs for underground applications.

-

Dust and Moisture Protection:

- Sealed designs to prevent ingress of dust and moisture.

- Special coatings for corrosion resistance in chemically harsh environments.

Mobility and Flexibility

Many mining operations require power equipment that can move with the extraction process:

-

Mobile Substations:

- Transformers mounted on skids or trailers for easy relocation.

- Enable power supply to follow the mining face in open-pit operations.

-

Modular Designs:

- Allow for easy transportation to remote locations.

- Facilitate quick setup and commissioning in new mining areas.

As the mining industry continues to evolve, with a focus on automation and sustainability, power transformers in this sector are adapting to new challenges. We’re seeing the integration of smart monitoring systems that can predict maintenance needs and optimize performance in real-time. Some transformers are being designed to work seamlessly with renewable energy sources, helping mines reduce their carbon footprint.

The future of mining transformers might include units with integrated energy storage, allowing for better management of peak loads and integration of intermittent renewable power. We could see transformers that can automatically adjust their characteristics based on the specific needs of different mining processes, or units that can operate efficiently at ultra-high altitudes for mountain-top mining operations.

In the world of mining and mineral extraction, where reliability and efficiency can make or break operations, power transformers will continue to play a critical role. They’re the unsung heroes that keep our mines productive, enabling the extraction of the raw materials that fuel our modern world, all while adapting to the industry’s evolving needs for sustainability and efficiency.

Data Center Dynamics: Power Transformers in IT and Cloud Computing Facilities?

Ever wondered how massive data centers, the backbone of our digital world, stay powered 24/7? The answer lies in sophisticated power transformer systems designed specifically for these critical IT facilities.

Power transformers are crucial in data centers and cloud computing facilities for providing reliable, high-quality power to servers, cooling systems, and network equipment. They ensure uninterrupted operation, manage high-density power needs, and support redundancy systems critical for maintaining data integrity and service availability.

Let’s explore how power transformers keep our digital world running:

Main Facility Power

In large data centers, transformers play a vital role in power distribution:

-

Utility Interface Transformers:

- Step down incoming high voltage to medium voltage for facility distribution.

- Often include features for power quality management.

-

UPS Input/Output Transformers:

- Interface between the utility power and Uninterruptible Power Supply (UPS) systems.

- Provide isolation and voltage matching for UPS equipment.

Server Room Power Distribution

Within the data center, specialized transformers support IT equipment:

-

PDU Transformers:

- Power Distribution Unit transformers step down voltage for server racks.

- Provide clean, stable power to sensitive IT equipment.

-

Isolation Transformers:

- Reduce electrical noise and provide galvanic isolation.

- Critical for maintaining data integrity in sensitive computing environments.

Here’s a comparison of transformer applications in data center settings:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| Main Facility | 10-50 MVA | 110kV | 11kV/400V | Redundant design, on-load tap changers |

| UPS System | 1-5 MVA | 11kV | 400V | K-rated for harmonic loads |

| PDU | 50-500 kVA | 400V | 208V | Low impedance, multiple outputs |

| Isolation | 10-100 kVA | 400V | 400V | High isolation, low noise |

I once worked on a project to upgrade the power system for a major cloud computing provider’s data center. The challenge was immense – we needed to increase power capacity and efficiency without any downtime in a facility that was already running 24/7. We implemented a new transformer system with N+1 redundancy, advanced monitoring, and the ability to seamlessly switch between multiple power sources. The most interesting part was the integration of smart PDU transformers that could dynamically allocate power based on real-time server demands. The result was a 20% increase in power capacity, a 15% improvement in energy efficiency, and most importantly, zero unplanned downtime during and after the upgrade.

Power transformers in data centers are more than just voltage converters. They’re critical components in ensuring the reliability and efficiency of our digital infrastructure:

Efficiency and Heat Management

In data centers, every bit of efficiency counts:

-

High-Efficiency Designs:

- Use of low-loss materials to minimize heat generation.

- Critical in environments where cooling is a major operational cost.

-

Advanced Cooling Systems:

- Integration with facility cooling systems for optimal heat management.

- Some use biodegradable fluids for better heat dissipation and environmental safety.

Reliability and Redundancy

For data centers, downtime is not an option:

-

N+1 or 2N Redundancy:

- Multiple transformer systems to ensure continuous operation even during maintenance or failures.

- Automatic switchover capabilities for seamless power transition.

-

Continuous Monitoring:

- Real-time monitoring of load, temperature, and key performance indicators.

- Integration with data center infrastructure management (DCIM) systems for proactive maintenance.

As data centers continue to grow in size and importance, the role of power transformers in these facilities will only become more critical. We’re likely to see even more specialized designs, perhaps with integrated energy storage capabilities or advanced power electronics for more precise control of power quality.

The future might bring transformers that can dynamically adjust their characteristics based on changing IT loads, or units that can seamlessly integrate with renewable energy sources to support green data center initiatives. We might see transformers with AI-driven predictive maintenance capabilities, ensuring even higher levels of reliability.

In the world of data centers and cloud computing, where every millisecond of uptime is crucial, power transformers will continue to be the unsung heroes. They’re not just enabling our digital lives; they’re actively shaping the future of how we store, process, and access the vast amounts of data that drive our modern world.

Healthcare Heroes: Power Transformers in Hospitals and Medical Research Centers?

Have you ever considered what keeps life-saving medical equipment running without interruption? Behind the scenes, specialized power transformers play a crucial role in ensuring reliable power for healthcare facilities.

Power transformers are essential in hospitals and medical research centers for providing clean, stable, and uninterrupted power to critical medical equipment. They support life-support systems, imaging devices, and sensitive research instruments, often with redundant systems to ensure continuous operation even during power outages.

Let’s explore how power transformers keep our healthcare facilities operational:

Critical Care Power Systems

In hospital settings, transformers ensure reliable power for life-saving equipment:

-

Emergency Power Transformers:

- Interface between backup generators and critical hospital systems.

- Ensure rapid, seamless transition during power outages.

-

Isolation Transformers:

- Provide clean, noise-free power to sensitive medical equipment.

- Critical for accurate diagnostics and patient safety.

Medical Imaging Equipment

Transformers play a vital role in powering advanced imaging technologies:

-

MRI System Transformers:

- Supply stable power for superconducting magnets and cooling systems.

- Often include specialized shielding to prevent interference.

-

CT and X-ray Transformers:

- Provide high-voltage power for X-ray tube operation.

- Handle the pulsed loads typical of imaging equipment.

Here’s a comparison of transformer applications in healthcare settings:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| Emergency Power | 500kVA – 2MVA | 11kV | 400V | Fast switching, redundant design |

| Isolation | 10-100kVA | 400V | 400V | Ultra-low noise, high isolation |

| MRI System | 50-200kVA | 400V | Multiple outputs | EMI shielding, precise regulation |

| CT Scanner | 100-300kVA | 400V | High voltage DC | Pulsed load handling |

I once worked on a project to upgrade the power system for a major teaching hospital. The challenge was to implement a new transformer system that could handle the increasing power demands of modern medical equipment while ensuring absolutely no interruption to critical care services. We designed a redundant system with multiple isolation transformers and advanced power quality management. The most interesting part was integrating these with the hospital’s emergency power system to ensure seamless transition during outages. The result was impressive – power quality improved significantly, reducing equipment malfunctions, and the hospital was able to install new, advanced imaging systems without concerns about power capacity or stability.

Power transformers in healthcare facilities are more than just voltage converters. They’re critical components in ensuring the reliability and safety of medical services:

Power Quality and Patient Safety

In medical environments, clean power is crucial:

-

Harmonic Mitigation:

- Advanced designs to handle harmonics generated by medical equipment.

- Ensure clean power delivery to sensitive diagnostic tools.

-

Leakage Current Control:

- Specialized designs to minimize leakage currents.

- Critical for patient safety, especially in operating rooms and ICUs.

Reliability and Redundancy

For healthcare, power failure is not an option:

-

N+1 Redundancy:

- Multiple transformer systems to ensure continuous operation even during maintenance.

- Automatic transfer switches for seamless power transition.

-

Continuous Monitoring:

- Real-time monitoring of load, temperature, and power quality.

- Integration with building management systems for proactive maintenance.

As medical technology continues to advance, with more sophisticated and power-hungry equipment, the role of power transformers in healthcare facilities will only grow in importance. We’re likely to see even more specialized designs, perhaps with integrated energy storage capabilities for critical equipment or advanced power conditioning features for ultra-sensitive diagnostic tools.

The future might bring transformers with AI-driven predictive maintenance capabilities, ensuring even higher levels of reliability for life-critical systems. We might see units that can dynamically adjust their output based on the specific needs of different medical procedures, or transformers that can seamlessly integrate with renewable energy sources to support green hospital initiatives.

In the world of healthcare, where every second can make a difference between life and death, power transformers will continue to be the unsung heroes. They’re not just enabling the operation of life-saving equipment; they’re actively contributing to the advancement of medical care by providing the stable, clean power that modern medicine relies on.

Petrochemical Powerhouses: Power Transformers in Oil and Gas Refineries?

Ever wondered how massive oil refineries and gas processing plants manage their enormous power needs? The answer lies in specialized power transformers designed to handle the unique challenges of the petrochemical industry.

Power transformers are crucial in oil and gas refineries for powering large-scale processing equipment, pumps, and control systems. They handle high power demands, operate in hazardous environments, and often include special features for explosion protection and corrosion resistance.

Let’s explore how power transformers keep our petrochemical industries running:

Process Power Supply

In refineries, transformers power various stages of oil and gas processing:

-

Distillation Column Transformers:

- Supply power to heating elements and pumps in distillation towers.

- Handle high temperatures and corrosive environments.

-

Compressor and Pump Transformers:

- Power large motors for fluid movement and gas compression.

- Often include variable frequency drive (VFD) compatibility.

Control and Safety Systems

Transformers play a crucial role in maintaining safe operations:

-

Instrumentation Transformers: