Have you ever wondered how electricity travels safely from power plants to your home? The answer lies in a device you rarely see but heavily rely on: the electric transformer.

An electric transformer is a device that changes the voltage of electrical power. It allows electricity to be transmitted efficiently over long distances and then safely used in our homes and businesses. Transformers are the unsung heroes that make our modern electrical grid possible.

As an electrical engineer with years of experience in the power industry, I’ve seen firsthand how crucial these devices are. Let’s explore the world of electric transformers and discover why they’re so important for our modern life.

The Inner Workings of Electric Transformers: Powering Our World Behind the Scenes?

Imagine trying to pour water from a fire hose into a drinking glass. That’s similar to the challenge of getting electricity from power plants to your home. Transformers are the solution to this problem.

Electric transformers work by using electromagnetic induction to change voltage levels. They have two coils of wire around an iron core. When alternating current flows through one coil, it creates a changing magnetic field that induces a voltage in the other coil.

Let’s dive deeper into how transformers work:

The Principle of Electromagnetic Induction

This is the key to transformer operation:

- An alternating current in the primary coil creates a changing magnetic field.

- This field is concentrated by the iron core.

- The changing field induces a voltage in the secondary coil.

- The voltage in the secondary coil depends on the ratio of turns in the two coils.

Voltage Transformation

Transformers can increase or decrease voltage:

- If the secondary coil has more turns than the primary, voltage increases.

- If it has fewer turns, voltage decreases.

- The voltage ratio equals the turns ratio.

The Role of the Core

The iron core is crucial for efficient operation:

- It provides a low-reluctance path for the magnetic field.

- This concentrates the field, making the transformer more efficient.

- The core is made of thin laminations to reduce energy losses.

Here’s a simple comparison of transformers with different turn ratios:

| Primary Turns | Secondary Turns | Input Voltage | Output Voltage | Type |

|---|---|---|---|---|

| 100 | 1000 | 120 V | 1200 V | Step-up |

| 1000 | 100 | 12000 V | 1200 V | Step-down |

| 100 | 100 | 120 V | 120 V | Isolation |

I remember the first time I saw a large power transformer in action. The hum of the core, the heat from the windings, and the sheer size of the device were impressive. But what struck me most was how this massive machine was silently and efficiently changing voltage levels, enabling power to flow from the plant to homes miles away.

Understanding the inner workings of transformers helps us appreciate their crucial role in our power systems. They’re not just simple devices; they’re marvels of engineering that make our modern electrical world possible. From the massive transformers at power plants to the small ones on utility poles, they all work on the same principles to keep our lights on and our devices running.

Anatomy of a Hero: Key Components That Make Electric Transformers Tick?

Have you ever opened up a device to see how it works? While I don’t recommend doing this with a transformer, understanding its components is key to grasping its function.

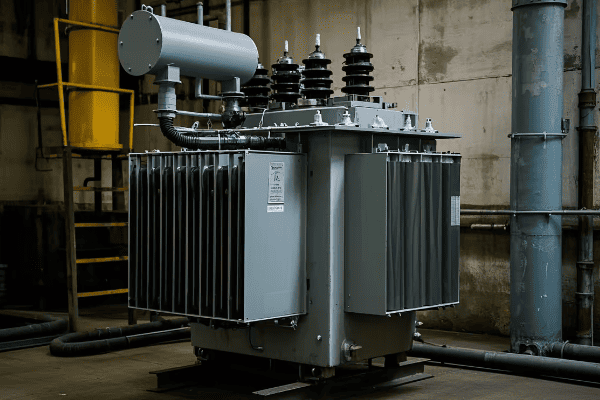

Electric transformers consist of several key components: the core, primary and secondary windings, insulation, and cooling system. Each part plays a crucial role in the transformer’s operation, working together to efficiently change voltage levels and transfer power.

Let’s break down the anatomy of a transformer:

1. The Core

The core is the heart of the transformer:

- It’s usually made of thin layers of silicon steel.

- These layers, called laminations, reduce energy losses.

- The core provides a path for the magnetic field.

2. Windings

Transformers have two sets of windings:

- Primary Winding: Connects to the input power source.

- Secondary Winding: Delivers the output power.

- The ratio of turns in these windings determines the voltage change.

3. Insulation

Insulation is crucial for safety and efficiency:

- It prevents short circuits between windings and the core.

- Common insulation materials include paper, oil, and resin.

4. Cooling System

Transformers generate heat, so cooling is essential:

- Small transformers often use air cooling.

- Larger ones use oil for both cooling and insulation.

5. Tap Changer

Some transformers have tap changers:

- These adjust the turn ratio slightly.

- They help maintain consistent output voltage.

Here’s a table summarizing the key components:

| Component | Function | Material |

|---|---|---|

| Core | Provides magnetic path | Silicon steel laminations |

| Primary Winding | Receives input power | Copper or aluminum wire |

| Secondary Winding | Delivers output power | Copper or aluminum wire |

| Insulation | Prevents short circuits | Paper, oil, resin |

| Cooling System | Manages heat | Air or oil |

| Tap Changer | Adjusts voltage ratio | Mechanical or electronic switch |

I once had the opportunity to disassemble a small distribution transformer during a training session. The precision of each component was impressive. The tightly wound coils, the carefully stacked core laminations, and the intricate insulation system all worked together in perfect harmony. It gave me a new appreciation for the engineering that goes into these devices.

Understanding the anatomy of a transformer is crucial for anyone working in the power industry. Each component plays a vital role, and they all must work together flawlessly to ensure reliable power distribution. From the core that channels the magnetic field to the cooling system that keeps everything running smoothly, every part contributes to the transformer’s ability to power our world efficiently and safely.

Efficiency Masters: How Transformers Optimize Power Distribution Networks?

Have you ever wondered how electricity travels hundreds of miles without losing all its power? The secret lies in the efficiency of transformers, the unsung heroes of our power grids.

Transformers optimize power distribution networks by minimizing energy losses during transmission and distribution. They do this by changing voltage levels, allowing power to be transmitted at high voltages and low currents, which reduces power loss. Transformers also help regulate voltage and balance loads across the network.

Let’s explore how transformers keep our power grids running efficiently:

1. Minimizing Transmission Losses

Transformers play a key role in reducing power losses during transmission:

- They step up voltage at power plants, reducing current for the same power.

- Lower current means lower I²R losses in transmission lines.

- This allows power to be transmitted efficiently over long distances.

2. Voltage Regulation

Transformers help maintain stable voltage levels throughout the grid:

- They use tap changers to adjust voltage ratios.

- This helps compensate for voltage drops along transmission lines.

- Stable voltage is crucial for the proper operation of electrical equipment.

3. Load Balancing

Transformers help balance loads across the power system:

- Distribution transformers can be sized and placed to match local power demands.

- This helps prevent overloading of certain parts of the grid.

4. Reducing Harmonics

Some specialized transformers can help reduce harmonic distortions in the power system:

- Harmonics can cause overheating and reduced efficiency.

- Transformers with special winding configurations can mitigate these issues.

Here’s a table showing how transformers improve efficiency at different stages:

| Stage | Transformer Type | Efficiency Improvement |

|---|---|---|

| Generation | Step-Up | Enables high-voltage transmission |

| Transmission | Power | Minimizes line losses |

| Sub-transmission | Step-Down | Prepares for local distribution |

| Distribution | Distribution | Matches voltage to consumer needs |

I once worked on a project to upgrade a city’s aging transformer network. We replaced old, inefficient transformers with modern, high-efficiency units. The results were striking. Overall power losses in the distribution system dropped by 15%, which translated to significant energy savings and reduced carbon emissions. It was a clear demonstration of how crucial efficient transformers are to our power infrastructure.

Transformers are more than just voltage converters. They’re the key to making our vast power grids work efficiently. By minimizing losses, regulating voltage, and enabling load balancing, transformers ensure that the electricity generated at power plants reaches consumers with minimal waste. As we continue to modernize and expand our power grids, the role of efficient transformers will only become more critical in ensuring reliable and sustainable power for all.

From Substations to Streetlights: The Diverse Family of Electric Transformers?

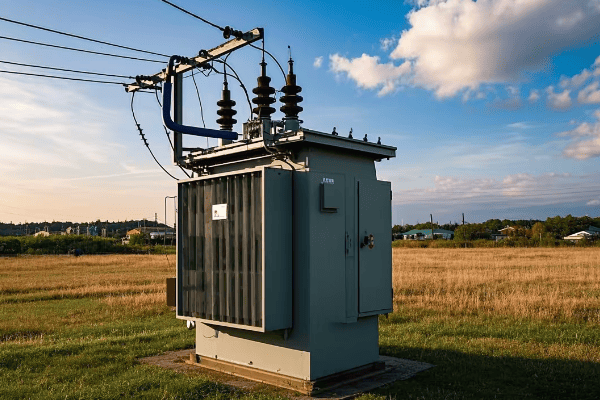

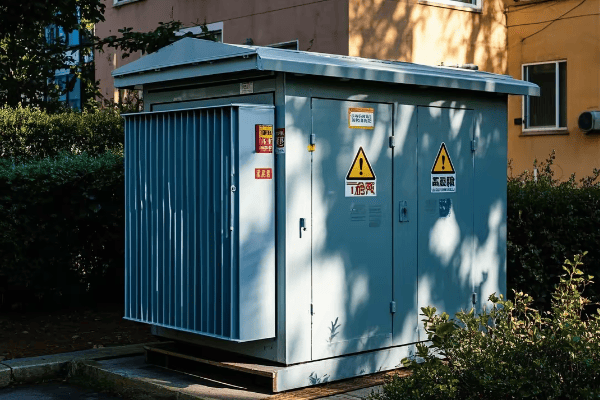

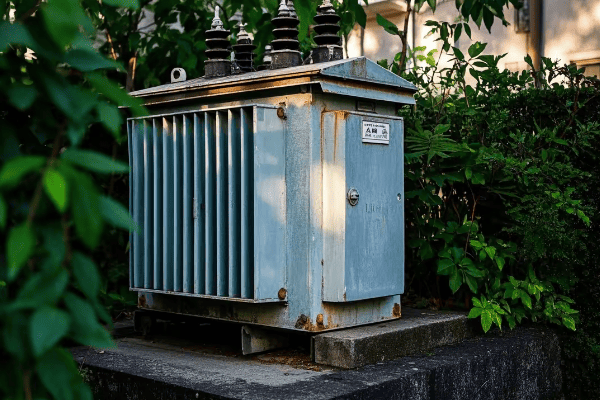

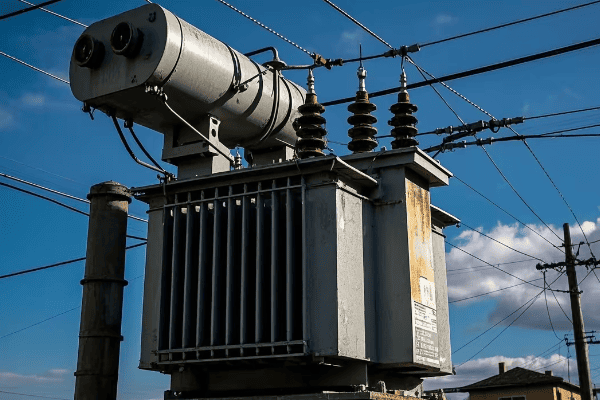

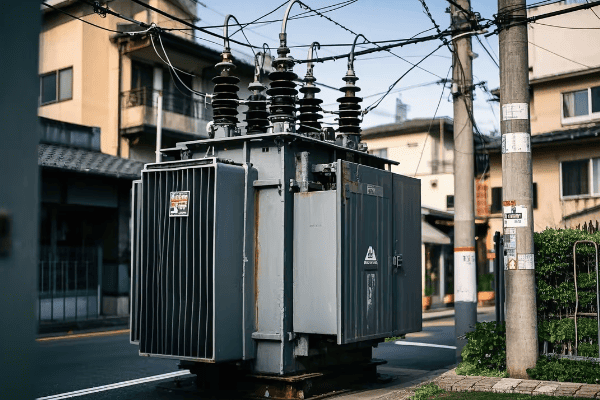

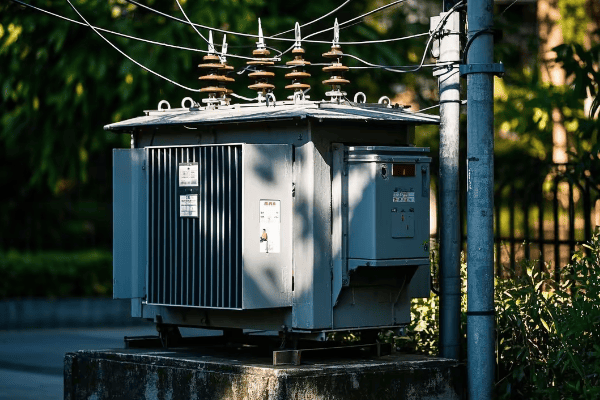

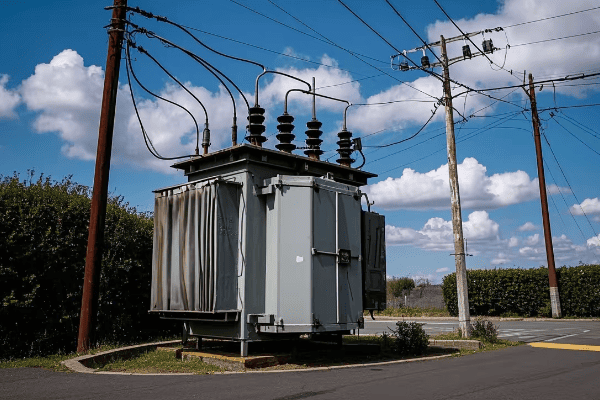

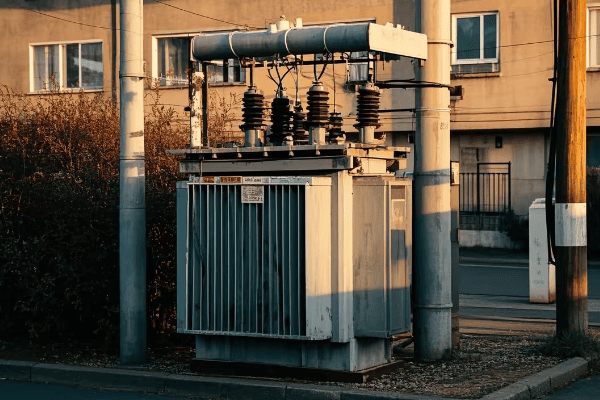

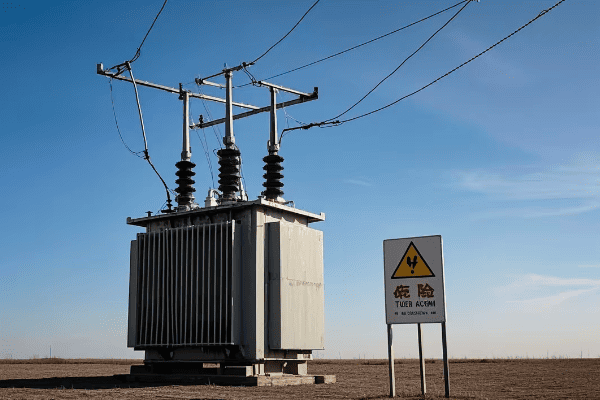

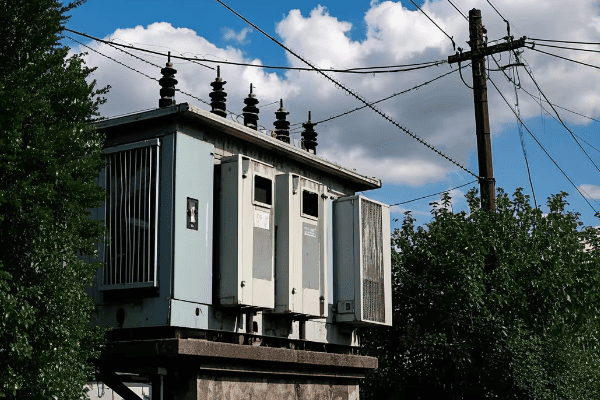

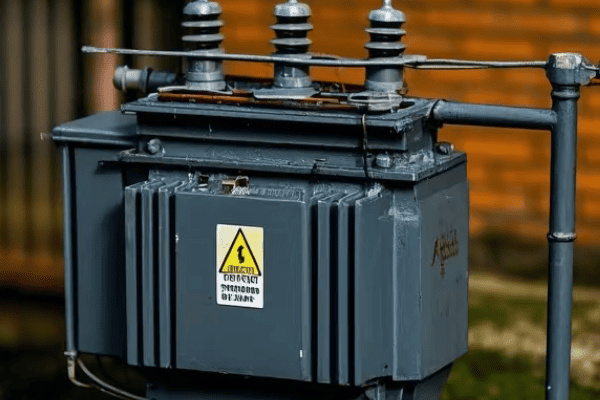

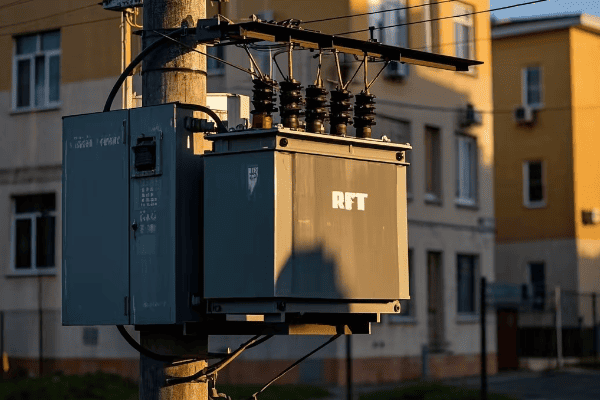

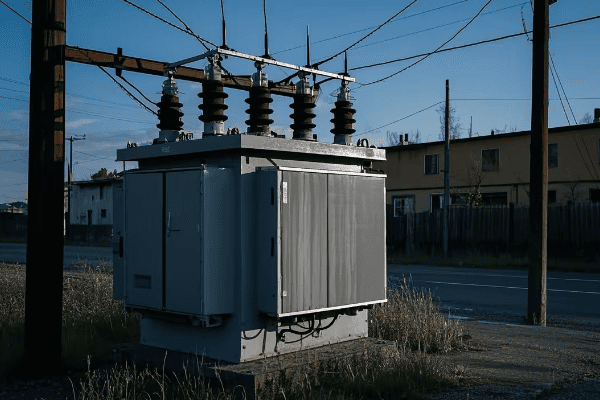

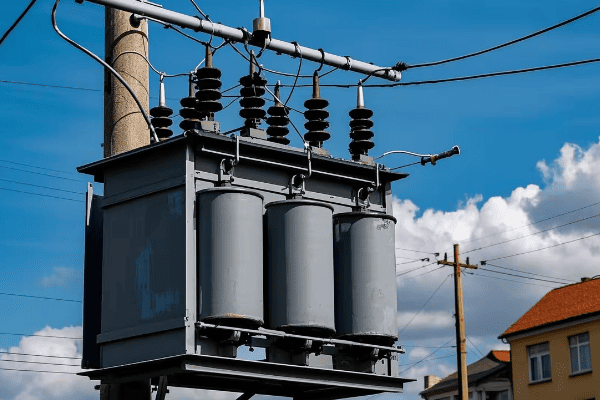

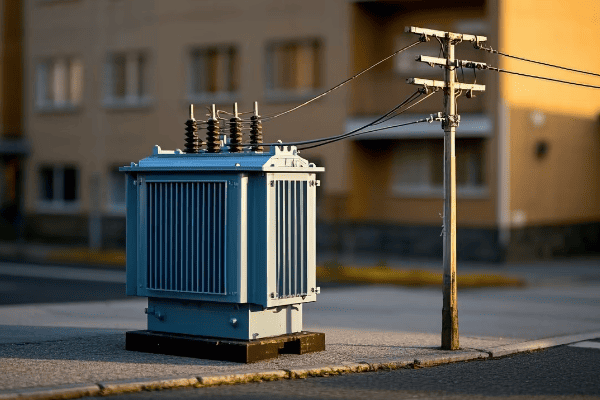

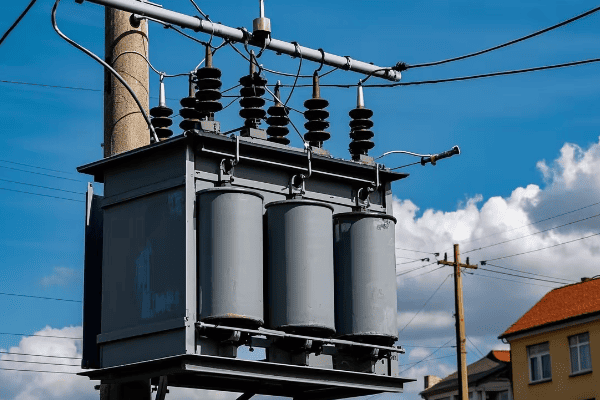

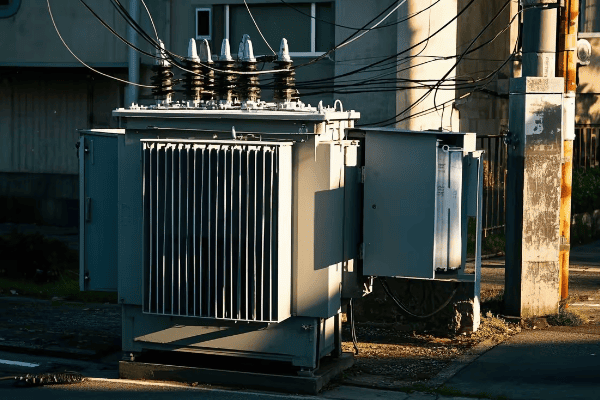

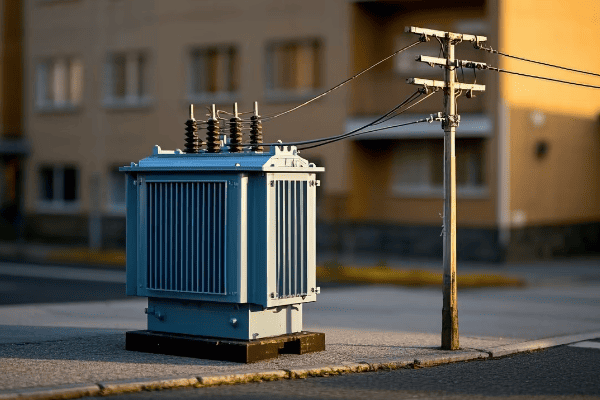

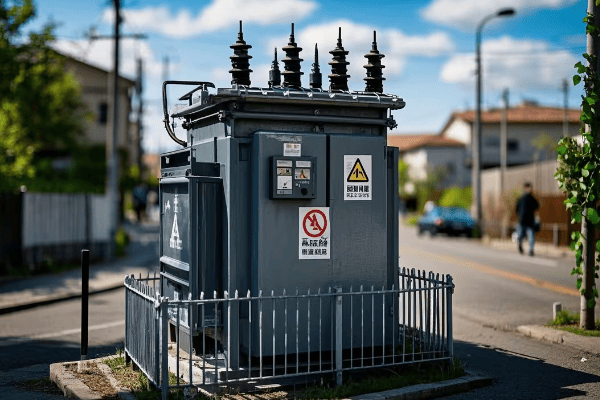

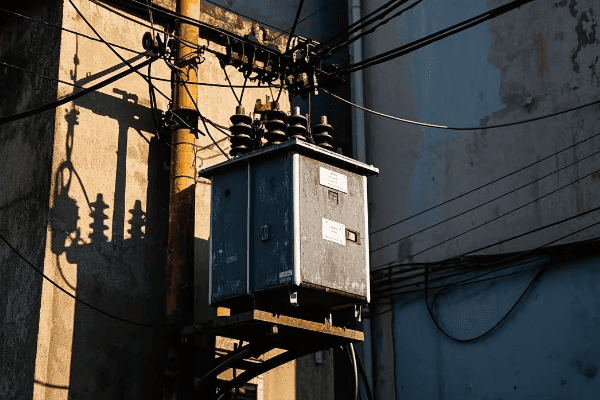

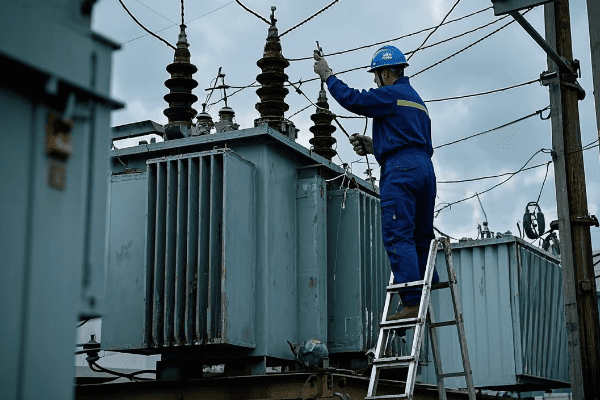

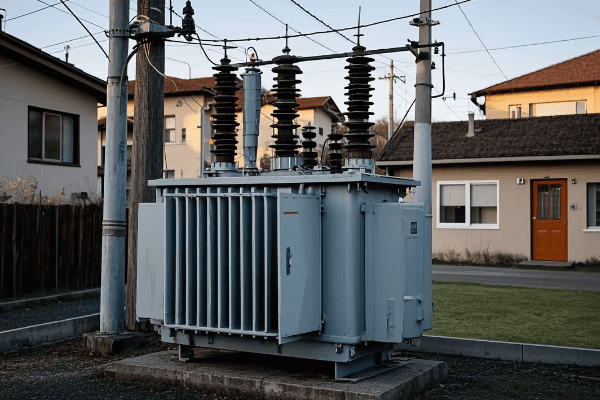

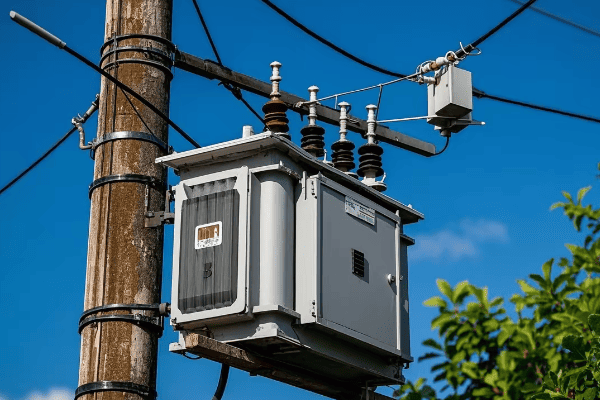

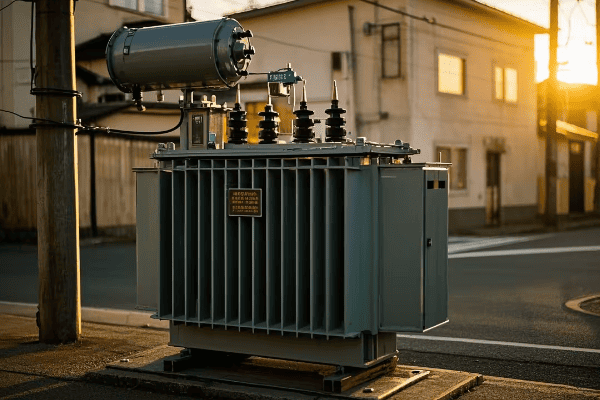

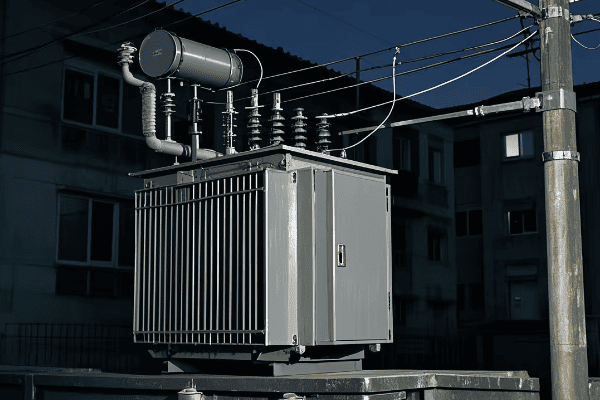

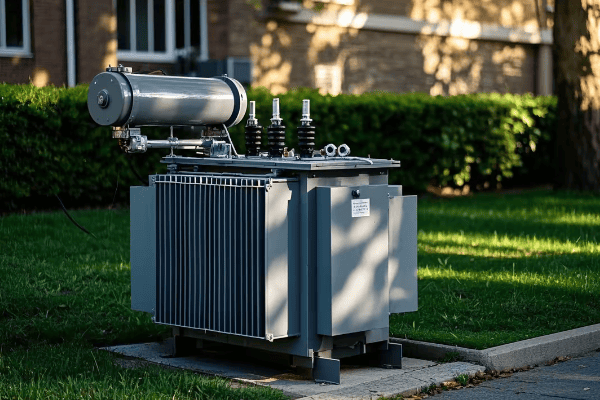

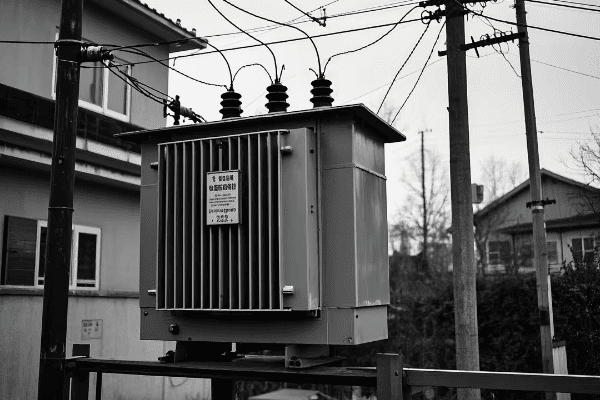

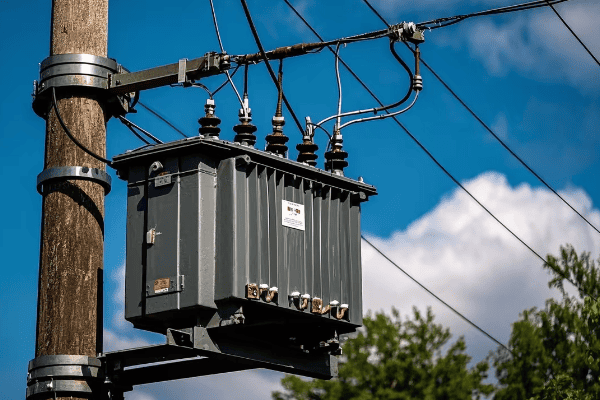

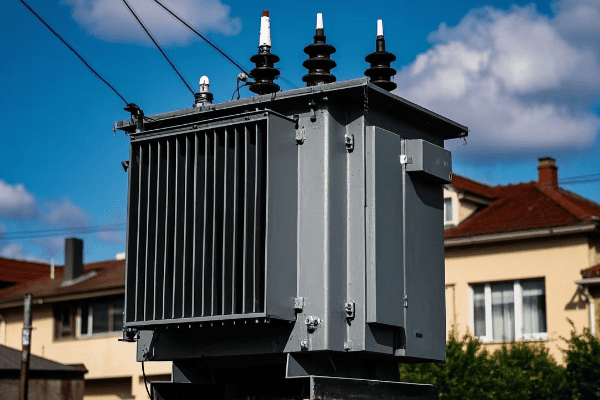

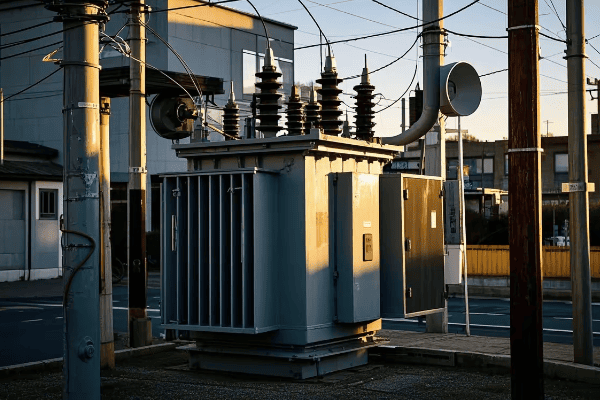

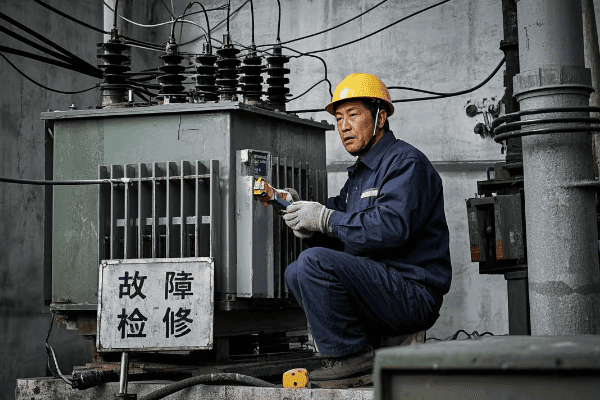

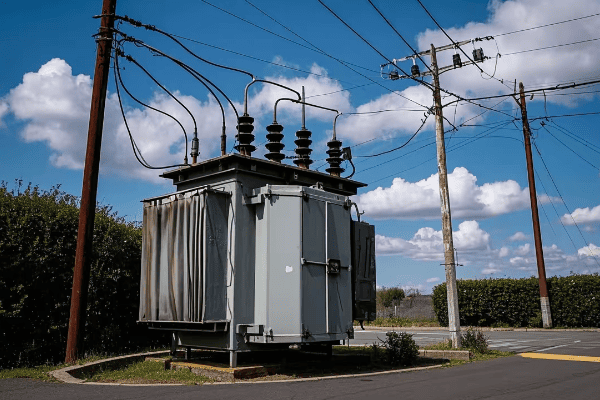

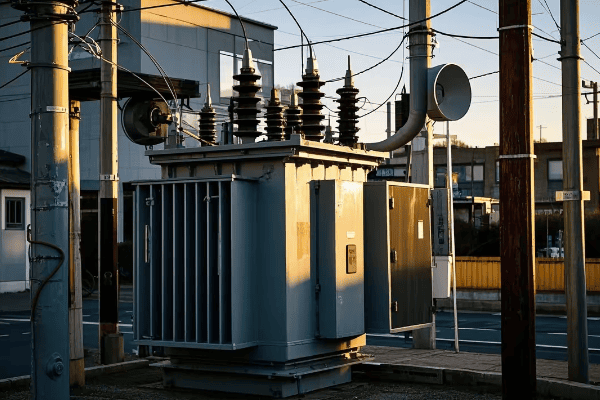

Have you ever noticed those cylindrical objects on utility poles or those large green boxes in your neighborhood? These are all different types of transformers, each with a specific job in our power distribution system.

Electric transformers come in various types, each designed for specific roles in power distribution. The main categories include power transformers for high-voltage transmission, distribution transformers for local power delivery, and special-purpose transformers for unique applications. Each type is crucial for efficient and safe power delivery.

Let’s explore the diverse family of electric transformers:

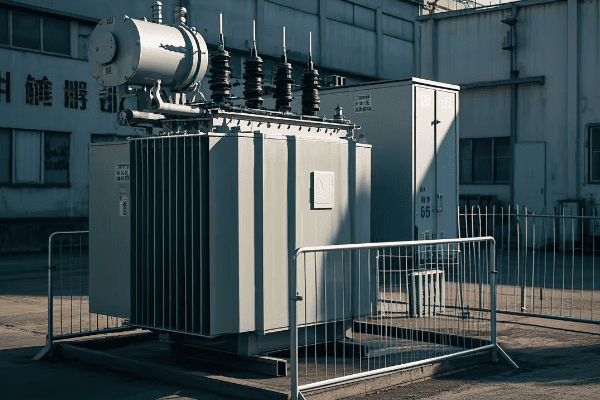

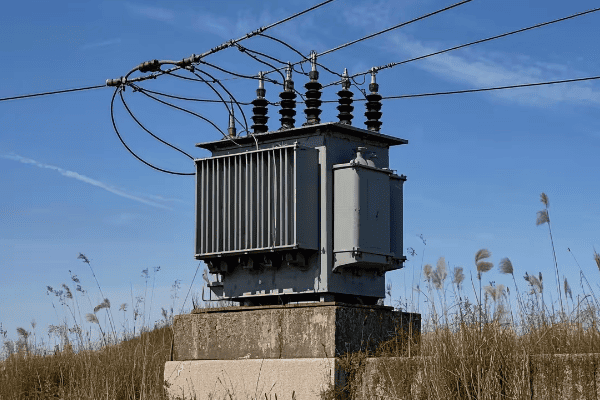

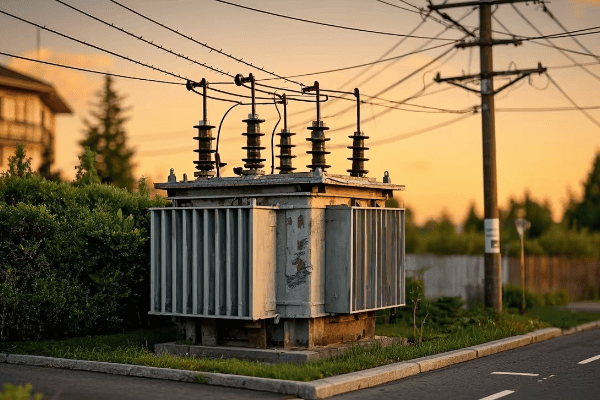

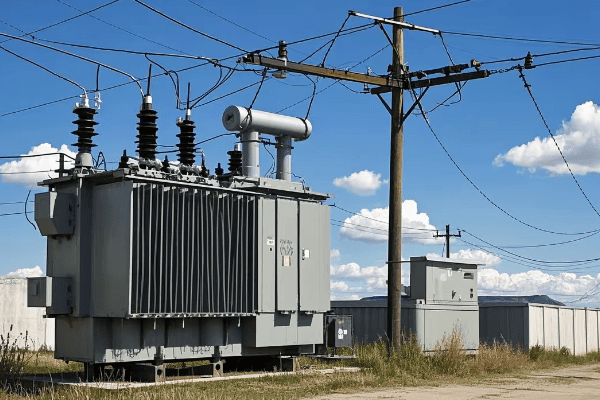

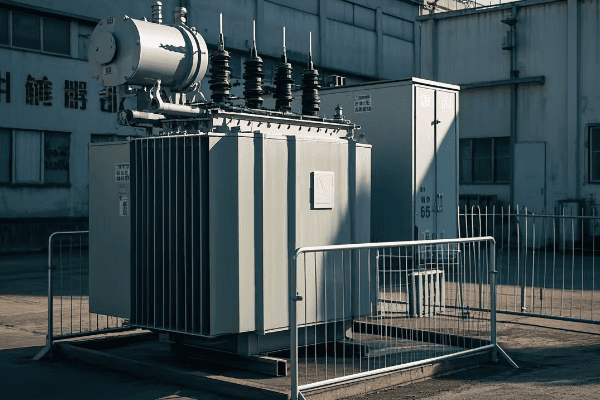

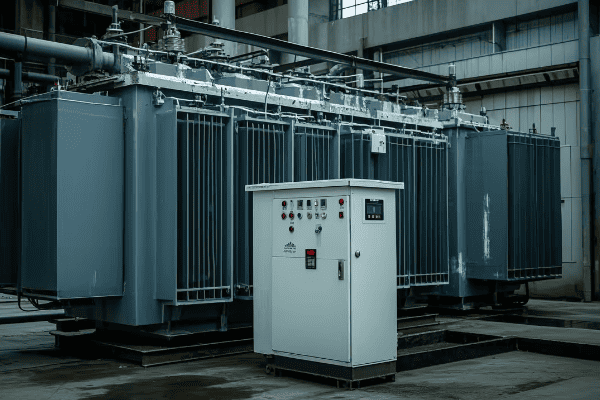

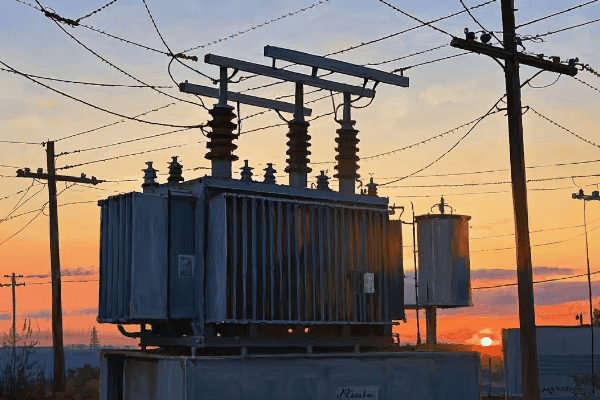

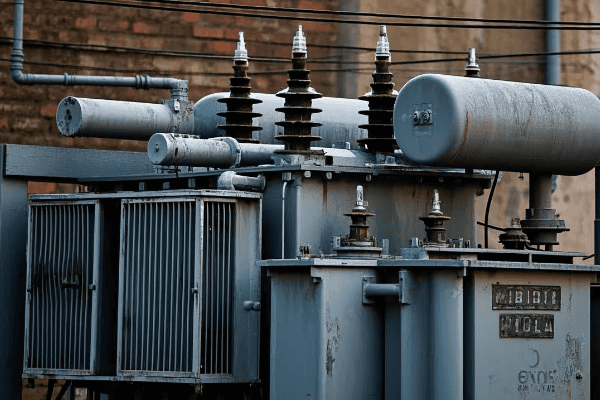

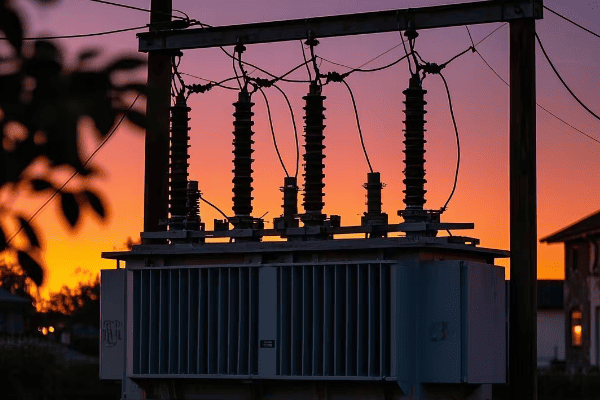

1. Power Transformers

These are the giants of the transformer world:

- Used in power plants and major substations.

- Handle very high voltages, often above 100,000 volts.

- Can be as large as a small house and weigh hundreds of tons.

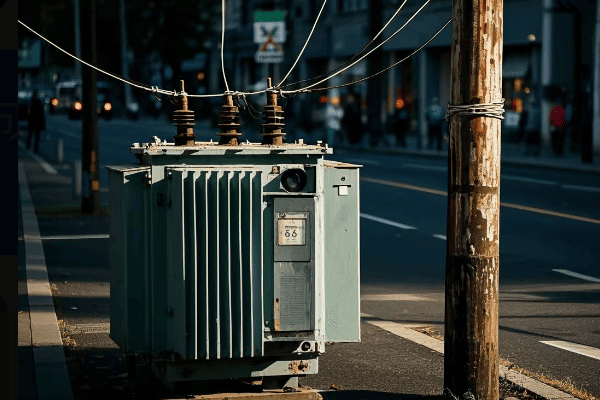

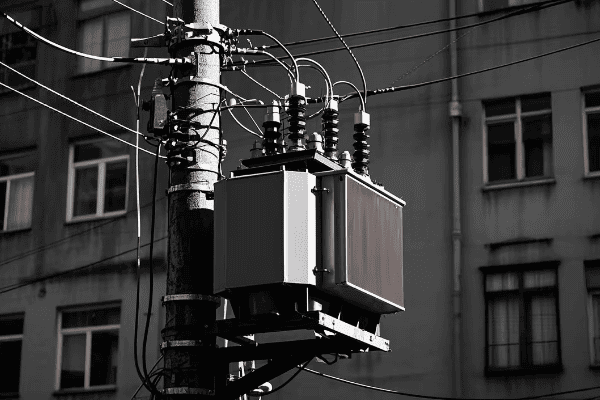

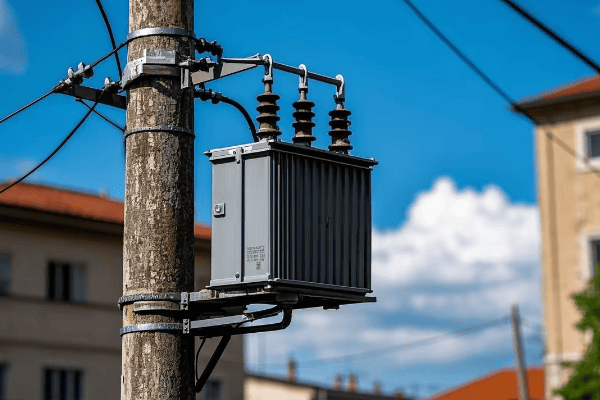

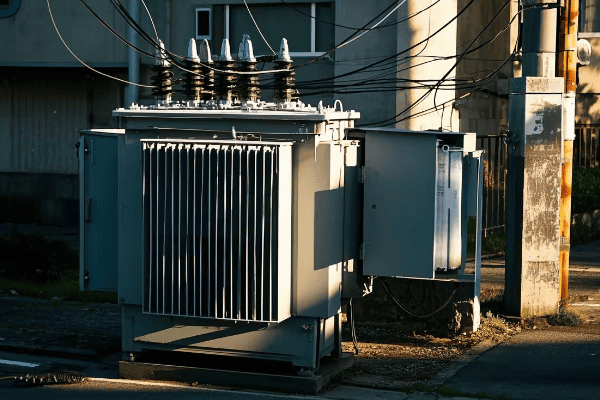

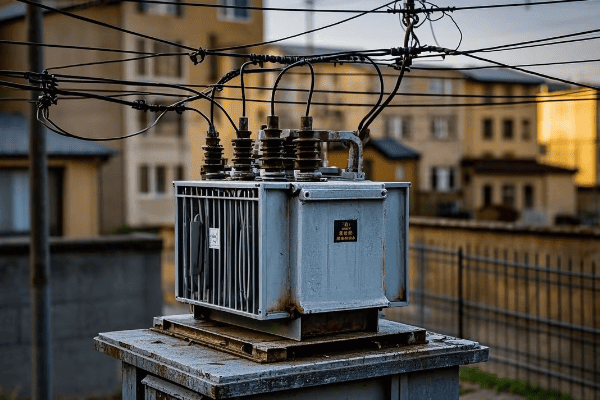

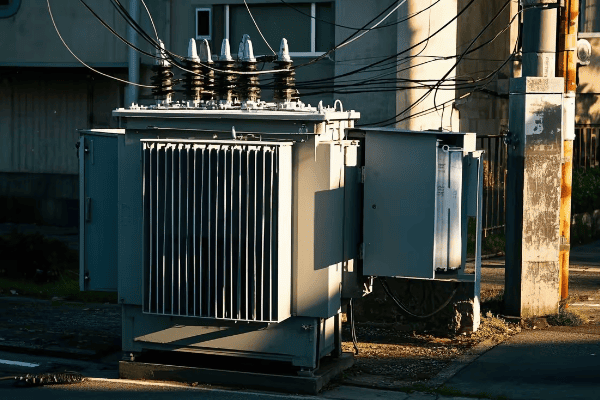

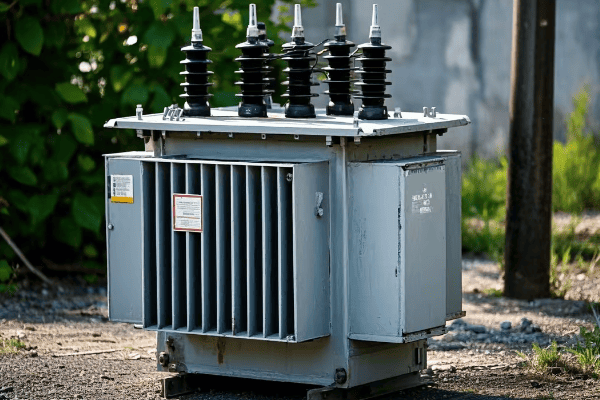

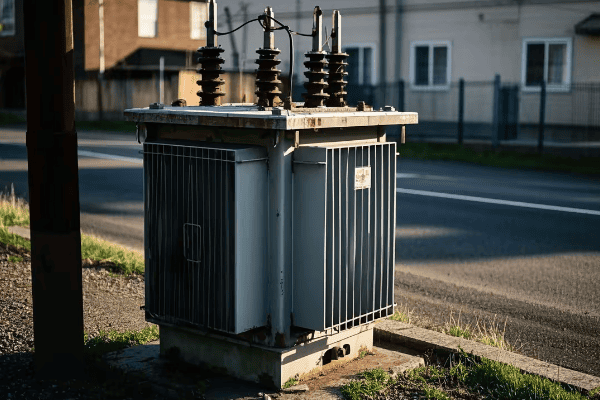

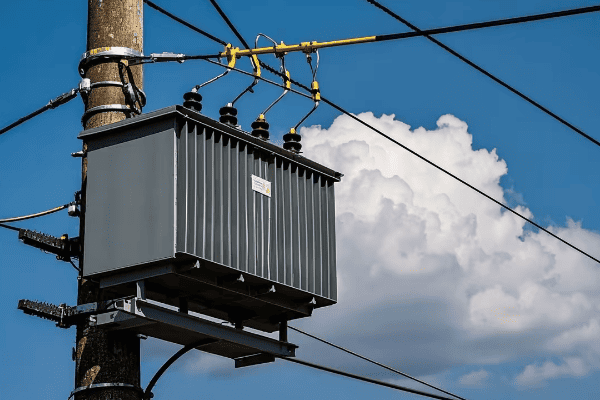

2. Distribution Transformers

These bring power to our neighborhoods:

- Found on utility poles or in ground-level boxes.

- Reduce voltage to levels safe for homes and businesses (typically 120/240 volts).

- Range in size from small pole-mounted units to larger pad-mounted transformers.

3. Instrument Transformers

These help with measuring and protecting the power system:

- Current Transformers (CTs): Measure electric current.

- Voltage Transformers (VTs): Measure voltage.

- Provide inputs for meters, relays, and other instruments.

4. Special-Purpose Transformers

These are designed for specific applications:

- Isolation Transformers: Provide electrical isolation for safety or noise reduction.

- Autotransformers: Used for small voltage adjustments.

- Rectifier Transformers: Used in high-voltage direct current (HVDC) transmission systems.

Here’s a comparison of the main transformer types:

| Type | Size | Voltage Range | Primary Use |

|---|---|---|---|

| Power | Very Large | 100kV – 1000kV+ | Transmission substations |

| Distribution | Small to Medium | 4kV – 35kV | Local power distribution |

| Instrument | Very Small | Varies | Measurement and protection |

| Special-Purpose | Varies | Varies | Specific applications |

I once worked on a project that involved almost every type of transformer mentioned above. We were upgrading a small town’s electrical infrastructure. The project included a large power transformer at the local substation, numerous distribution transformers throughout the town, and instrument transformers for the new smart metering system. We even used isolation transformers for some sensitive industrial equipment. It was like conducting an orchestra, with each transformer playing its unique part in the symphony of power distribution.

Understanding these different types of transformers is crucial for anyone involved in electrical systems. Each type has its strengths and ideal applications. By using the right transformer for each job, we ensure that our power grid remains efficient, safe, and reliable. From the massive transformers at power plants to the small ones powering your electronic devices, each plays a vital role in bringing electricity to our fingertips.

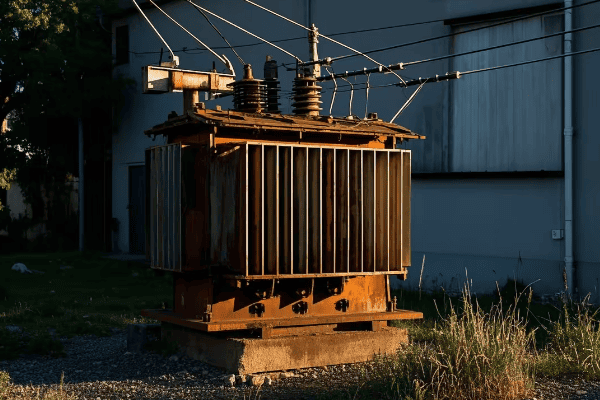

Evolution of Power: How Electric Transformers Have Adapted to Modern Energy Demands?

Remember when phones were just for calling? Now they’re smart devices that do almost everything. The same revolution is happening with transformers, and it’s changing our power grid.

Electric transformers have evolved significantly to meet modern energy demands. They’ve become more efficient, smarter, and adaptable to new energy sources. Modern transformers incorporate advanced materials, digital monitoring systems, and designs that support renewable energy integration and smart grid technologies.

Let’s explore how transformers have adapted to our changing energy landscape:

1. Improved Efficiency

Modern transformers are much more efficient than their predecessors:

- They use advanced core materials like amorphous metals to reduce energy losses.

- Improved winding designs minimize copper losses.

- Some transformers now achieve efficiency ratings over 99%.

2. Smart Monitoring Systems

Transformers are getting smarter:

- They now incorporate sensors to monitor temperature, oil condition, and load.

- These systems can predict potential failures before they occur.

- This enables predictive maintenance, reducing downtime and extending transformer life.

3. Adaptability for Renewable Energy

Transformers have evolved to support renewable energy integration:

- They can handle bidirectional power flow from distributed generation sources.

- Some are designed to cope with the variable output of wind and solar power.

- Special designs help manage harmonics introduced by renewable energy inverters.

4. Size and Weight Reduction

Modern transformers are often smaller and lighter:

- This makes installation and replacement easier, especially in urban areas.

- It also reduces transportation costs and environmental impact.

Here’s a comparison of traditional and modern transformers:

| Feature | Traditional Transformer | Modern Transformer |

|---|---|---|

| Core Material | Silicon Steel | Amorphous Metal or Advanced Silicon Steel |

| Monitoring | Basic gauges | Integrated digital monitoring systems |

| Renewable Energy Compatibility | Limited | Designed for bidirectional power flow |

| Efficiency | 95-98% | Up to 99.5% |

| Size/Weight | Larger and heavier | Compact and lighter |

I recently worked on a project to replace an old substation transformer with a modern unit. The new transformer was 30% smaller but had the same power rating. It came with an advanced monitoring system that could predict potential issues weeks in advance. The utility company was amazed at how much more they could do with this single unit. It was a clear example of how far transformer technology has come.

The evolution of transformers is not just about incremental improvements. It’s about reimagining how our power grid works. These advancements are enabling a more flexible, efficient, and reliable power system. They’re helping us integrate more renewable energy, reduce energy losses, and create smarter grids. As we continue to face new energy challenges, transformers will keep evolving, playing a crucial role in shaping the future of our power systems.

Conclusion

Electric transformers are the unsung heroes of power distribution. They efficiently change voltage levels, enable long-distance transmission, and adapt to modern energy demands. From massive substation units to small pole-mounted devices, transformers are crucial in powering our world reliably and safely.

Have you ever wondered how electricity travels safely from power plants to your home? The answer lies in a device you rarely see but heavily rely on: the electrical transformer.

An electrical transformer is a device that changes the voltage of electrical power. It allows electricity to be transmitted efficiently over long distances and then safely used in our homes and businesses. Transformers are essential for powering our modern world.

As an electrical engineer with years of experience in the power industry, I’ve seen firsthand how crucial these devices are. Let’s explore the world of electrical transformers and discover how they keep our lights on and our devices running.

The Anatomy of an Electrical Transformer: Understanding Its Core Components?

Imagine trying to understand how a car works without knowing its parts. The same goes for transformers. Knowing their components is key to grasping their function.

An electrical transformer consists of several key components: the core, primary and secondary windings, insulation, and cooling system. Each part plays a crucial role in the transformer’s operation, working together to efficiently change voltage levels.

Let’s break down the anatomy of a transformer:

1. The Core

The core is the heart of the transformer:

- It’s usually made of thin layers of silicon steel.

- These layers, called laminations, reduce energy losses.

- The core provides a path for the magnetic field.

2. Windings

Transformers have two sets of windings:

- Primary Winding: Connects to the input power source.

- Secondary Winding: Delivers the output power.

- The ratio of turns in these windings determines the voltage change.

3. Insulation

Insulation is crucial for safety and efficiency:

- It prevents short circuits between windings and the core.

- Common insulation materials include paper, oil, and resin.

4. Cooling System

Transformers generate heat, so cooling is essential:

- Small transformers often use air cooling.

- Larger ones use oil for both cooling and insulation.

Here’s a table summarizing the key components:

| Component | Function | Material |

|---|---|---|

| Core | Provides magnetic path | Silicon steel laminations |

| Primary Winding | Receives input power | Copper or aluminum wire |

| Secondary Winding | Delivers output power | Copper or aluminum wire |

| Insulation | Prevents short circuits | Paper, oil, resin |

| Cooling System | Manages heat | Air or oil |

I remember the first time I opened up a large power transformer. The complexity inside was astounding. The carefully wound coils, the massive core, and the intricate cooling systems all worked together in a delicate balance. It gave me a new appreciation for these devices that we often take for granted.

Understanding the anatomy of a transformer is just the first step. Each component plays a crucial role in the transformer’s operation, and they all work together to perform the seemingly magical task of changing voltage levels. This knowledge forms the foundation for understanding how transformers function in our power distribution systems.

Voltage Manipulation: How Transformers Step Up and Step Down Power?

Have you ever tried to pour water from a fire hose into a drinking glass? That’s similar to the challenge of getting electricity from power plants to your home. Transformers are the solution to this problem.

Transformers manipulate voltage by using the principle of electromagnetic induction. They can step up voltage for efficient long-distance transmission or step it down for safe use in homes and businesses. This ability is crucial for our modern power distribution system.

Let’s dive into how transformers change voltage levels:

1. The Basics of Voltage Manipulation

Transformers change voltage through the ratio of turns in their windings:

- If the secondary winding has more turns than the primary, voltage increases.

- If it has fewer turns, voltage decreases.

- The voltage ratio equals the turns ratio.

2. Stepping Up Voltage

At power plants, transformers increase voltage for transmission:

- This reduces current for the same power.

- Lower current means less power loss in transmission lines.

- Voltages can be stepped up to 400,000 volts or more.

3. Stepping Down Voltage

Near consumers, transformers decrease voltage for safe use:

- Substation transformers reduce transmission voltages to distribution levels.

- Local transformers further reduce voltage to 120/240 volts for homes.

4. The Role of Electromagnetic Induction

This principle is key to transformer operation:

- An alternating current in the primary winding creates a changing magnetic field.

- This field induces a voltage in the secondary winding.

- The induced voltage depends on the turns ratio.

Here’s a comparison of step-up and step-down transformers:

| Aspect | Step-Up Transformer | Step-Down Transformer |

|---|---|---|

| Location | Power plants | Substations, neighborhoods |

| Primary Purpose | Increase voltage for transmission | Decrease voltage for distribution |

| Turns Ratio | Secondary > Primary | Primary > Secondary |

| Typical Input Voltage | 10,000 – 20,000 volts | 100,000 – 500,000 volts |

| Typical Output Voltage | 100,000 – 500,000 volts | 4,000 – 25,000 volts |

I once worked on a project to upgrade a city’s power infrastructure. We installed new step-down transformers at a substation to handle increased power demand. The transformation was remarkable. We took in power at 230,000 volts and stepped it down to 13,800 volts for local distribution. It was fascinating to see how these devices could safely bring such high voltages down to levels that could power homes and businesses.

Voltage manipulation by transformers is what makes our modern power distribution system possible. Without it, we couldn’t transmit power efficiently over long distances or use it safely in our homes. Every time you plug in a device, you’re benefiting from this invisible but crucial process of voltage transformation. Transformers truly are the unsung heroes of our electrical world.

Transformer Types Unveiled: From Distribution to Power and Beyond?

Have you ever wondered why we need different types of transformers? It’s like having different tools in a toolbox – each has its specific purpose in our power distribution system.

Transformers come in various types, each designed for specific roles in power distribution. The main categories include power transformers for high-voltage transmission, distribution transformers for local power delivery, and special-purpose transformers for unique applications. Each type is crucial for efficient and safe power delivery.

Let’s explore the main types of transformers:

1. Power Transformers

These are the giants of the transformer world:

- Used in power plants and major substations.

- Handle very high voltages, often above 100,000 volts.

- Can be as large as a small house and weigh hundreds of tons.

2. Distribution Transformers

These bring power to our neighborhoods:

- Found on utility poles or in ground-level boxes.

- Reduce voltage to levels safe for homes and businesses (typically 120/240 volts).

- Range in size from small pole-mounted units to larger pad-mounted transformers.

3. Instrument Transformers

These help with measuring and protecting the power system:

- Current Transformers (CTs): Measure electric current.

- Voltage Transformers (VTs): Measure voltage.

- Provide inputs for meters, relays, and other instruments.

4. Special-Purpose Transformers

These are designed for specific applications:

- Isolation Transformers: Provide electrical isolation for safety or noise reduction.

- Autotransformers: Used for small voltage adjustments.

- Rectifier Transformers: Used in high-voltage direct current (HVDC) transmission systems.

Here’s a comparison of the main transformer types:

| Type | Size | Voltage Range | Primary Use |

|---|---|---|---|

| Power | Very Large | 100kV – 1000kV+ | Transmission substations |

| Distribution | Small to Medium | 4kV – 35kV | Local power distribution |

| Instrument | Very Small | Varies | Measurement and protection |

| Special-Purpose | Varies | Varies | Specific applications |

I once worked on a project involving almost every type of transformer mentioned above. We were upgrading a small town’s electrical infrastructure. The project included a large power transformer at the local substation, numerous distribution transformers throughout the town, and instrument transformers for the new smart metering system. We even used isolation transformers for some sensitive industrial equipment. It was like conducting an orchestra, with each transformer playing its unique part in the symphony of power distribution.

Understanding these different types of transformers is crucial for anyone involved in electrical systems. Each type has its strengths and ideal applications. By using the right transformer for each job, we ensure that our power grid remains efficient, safe, and reliable. From the massive transformers at power plants to the small ones powering your electronic devices, each plays a vital role in bringing electricity to our fingertips.

Efficiency in Action: Transformers as the Backbone of Modern Power Grids?

Have you ever wondered how electricity travels hundreds of miles without losing all its power? The secret lies in the efficiency of transformers, the unsung heroes of our power grids.

Transformers are the backbone of modern power grids, ensuring efficient power transmission and distribution. They minimize energy losses, regulate voltage, and enable the interconnection of different power systems. Without efficient transformers, our vast and complex power grids simply couldn’t function.

Let’s explore how transformers keep our power grids running efficiently:

1. Minimizing Transmission Losses

Transformers play a key role in reducing power losses during transmission:

- They step up voltage at power plants, reducing current for the same power.

- Lower current means lower I²R losses in transmission lines.

- This allows power to be transmitted efficiently over long distances.

2. Voltage Regulation

Transformers help maintain stable voltage levels throughout the grid:

- They use tap changers to adjust voltage ratios.

- This helps compensate for voltage drops along transmission lines.

- Stable voltage is crucial for the proper operation of electrical equipment.

3. System Interconnection

Transformers enable the interconnection of different power systems:

- They can match voltage levels between different parts of the grid.

- This allows power to be shared between regions or even countries.

- It improves overall grid reliability and flexibility.

4. Load Management

Transformers help balance loads across the power system:

- Distribution transformers can be sized and placed to match local power demands.

- This helps prevent overloading of certain parts of the grid.

Here’s a table showing how transformers improve efficiency at different stages:

| Stage | Transformer Type | Efficiency Improvement |

|---|---|---|

| Generation | Step-Up | Enables high-voltage transmission |

| Transmission | Power | Minimizes line losses |

| Sub-transmission | Step-Down | Prepares for local distribution |

| Distribution | Distribution | Matches voltage to consumer needs |

I once worked on a project to upgrade a city’s aging transformer network. We replaced old, inefficient transformers with modern, high-efficiency units. The results were striking. Overall power losses in the distribution system dropped by 15%, which translated to significant energy savings and reduced carbon emissions. It was a clear demonstration of how crucial efficient transformers are to our power infrastructure.

Transformers are more than just voltage converters. They’re the key to making our vast power grids work efficiently. By minimizing losses, regulating voltage, and enabling system interconnections, transformers ensure that the electricity generated at power plants reaches consumers with minimal waste. As we continue to modernize and expand our power grids, the role of efficient transformers will only become more critical in ensuring reliable and sustainable power for all.

Transformers and Green Energy: Enabling the Renewable Power Revolution?

Have you ever wondered how the energy from solar panels or wind turbines makes it to your home? The answer involves a special role for our friends, the transformers.

Transformers are crucial in integrating renewable energy sources into our power grids. They handle the variable output of renewables, enable long-distance transmission from remote generation sites, and help maintain grid stability. Modern transformers are evolving to meet the unique challenges of green energy.

Let’s explore how transformers are powering the green energy revolution:

1. Handling Variable Output

Renewable sources like wind and solar have variable output. Transformers help manage this:

- They use advanced voltage regulation to handle fluctuations.

- Some incorporate energy storage to smooth out supply.

- They’re designed to operate efficiently across a wide range of loads.

2. Enabling Long-Distance Transmission

Many renewable sources are far from population centers:

- High-voltage transformers enable efficient long-distance transmission from remote wind or solar farms.

- Some use HVDC (High Voltage Direct Current) technology for even more efficient long-distance power transfer.

3. Grid Stability

Transformers help maintain grid stability with high renewable penetration:

- They use tap changers to adjust voltage levels in real-time.

- Some advanced transformers can provide reactive power compensation.

- This helps balance the grid despite the variability of renewable sources.

4. Bidirectional Power Flow

With distributed generation, power can flow both ways:

- Modern transformers can handle power flowing from homes and businesses back to the grid.

- This is crucial for systems with rooftop solar or small wind turbines.

Here’s a comparison of transformer applications in conventional and renewable energy systems:

| Aspect | Conventional Power | Renewable Energy |

|---|---|---|

| Power Flow | Mostly one-way | Often bidirectional |

| Output Stability | Relatively stable | Highly variable |

| Location | Near population centers | Often in remote areas |

| Voltage Levels | Standardized | May vary widely |

I recently worked on a project integrating a large offshore wind farm into the grid. The challenges were significant. We needed transformers that could handle the variable output, cope with the harsh marine environment, and efficiently transmit power over long distances. The solution involved advanced transformers with dynamic voltage regulation and HVDC technology. It was a complex project, but it showed me the incredible potential of transformers in enabling our renewable energy future.

Transformers are not just adapting to the renewable revolution; they’re enabling it. They’re the bridge between green energy sources and our existing power infrastructure. As we continue to increase our reliance on renewable sources, the role of these adaptable and resilient transformers will only grow in importance. They’re helping us build a greener, more sustainable energy future, one conversion at a time.

Conclusion

Electrical transformers are the unsung heroes of our power systems. They enable efficient transmission, safe distribution, and the integration of renewable energy. From power plants to our homes, transformers ensure reliable electricity supply, powering our modern world and driving the green energy revolution.

Have you ever wondered how your sleek smartphone charges so quickly or how your laptop stays cool despite its powerful performance? The secret lies in a tiny but mighty component: the electronic transformer.

Electronic transformers are revolutionizing power conversion in modern devices. They use advanced semiconductor technology to convert and control electrical power more efficiently than traditional transformers. This innovation enables smaller, lighter, and more energy-efficient electronic devices.

As an electrical engineer with years of experience in power electronics, I’ve witnessed firsthand the impact of electronic transformers on our everyday devices. Let’s explore how these small wonders are changing the game in power conversion technology.

Electronic vs. Traditional Transformers: A New Era in Power Conversion Technology?

Remember those bulky chargers we used to have? The shift to sleek, efficient power adapters is thanks to electronic transformers. But how do they differ from their traditional counterparts?

Electronic transformers use semiconductor switches and high-frequency operation to convert power, unlike traditional transformers that rely on electromagnetic induction. This allows electronic transformers to be smaller, lighter, and more efficient, marking a new era in power conversion technology.

Let’s dive deeper into the key differences:

1. Operating Principle

Traditional Transformers:

- Use electromagnetic induction

- Operate at low frequencies (50-60 Hz)

Electronic Transformers:

- Use power electronics (switches, capacitors, inductors)

- Operate at high frequencies (20 kHz to 1 MHz)

2. Size and Weight

The high-frequency operation of electronic transformers allows for significant size reduction:

- Traditional transformers often weigh several kilograms

- Electronic transformers can weigh just a few grams

3. Efficiency

Electronic transformers generally offer higher efficiency:

- Traditional transformers: 85-95% efficient

- Electronic transformers: Up to 98% efficient

4. Voltage Regulation

Electronic transformers provide better voltage regulation:

- They can quickly adjust to load changes

- They offer more precise output control

Here’s a comparison table:

| Feature | Traditional Transformer | Electronic Transformer |

|---|---|---|

| Size | Large | Compact |

| Weight | Heavy | Light |

| Efficiency | 85-95% | Up to 98% |

| Frequency | 50-60 Hz | 20 kHz – 1 MHz |

| Voltage Regulation | Limited | Precise |

| Cost | Lower | Higher (but decreasing) |

I remember working on a project to redesign a power supply for a medical device. By switching from a traditional to an electronic transformer, we reduced the device’s weight by 40% and improved its efficiency by 5%. The medical staff were thrilled with the more portable and reliable equipment.

The shift from traditional to electronic transformers represents a significant leap in power conversion technology. While traditional transformers still have their place in high-power applications, electronic transformers are becoming the go-to solution for modern, portable electronic devices. They’re not just a component; they’re enabling a new generation of sleeker, more efficient, and more capable electronic devices.

Powering the Future: The Advantages of Electronic Transformers in Modern Devices?

Have you ever marveled at how your latest gadget seems to do more while using less power? The secret often lies in the electronic transformer tucked away inside.

Electronic transformers offer numerous advantages in modern devices. They provide higher efficiency, better power quality, and enable advanced features like programmable output and power factor correction. These benefits result in devices that are more energy-efficient, reliable, and capable.

Let’s explore the key advantages of electronic transformers:

1. Enhanced Efficiency

Electronic transformers significantly reduce power losses:

- They minimize standby power consumption

- Their high-frequency operation reduces core losses

- Advanced control algorithms optimize power conversion

2. Improved Power Quality

Electronic transformers deliver cleaner power:

- They can filter out electrical noise and harmonics

- They provide stable output voltage even with input fluctuations

- Some can even correct power factor issues

3. Programmable Output

Unlike traditional transformers, electronic transformers offer flexible output:

- They can provide multiple voltage outputs from a single input

- Output can be adjusted through software controls

- This enables adaptive charging for different devices

4. Compact Size

The small size of electronic transformers enables sleeker device designs:

- They allow for thinner laptops and smartphones

- They free up space for other components or larger batteries

- This contributes to the overall portability of modern devices

5. Advanced Protection Features

Electronic transformers can incorporate sophisticated protection mechanisms:

- Overcurrent protection

- Overvoltage protection

- Thermal shutdown capabilities

Here’s a table summarizing these advantages:

| Advantage | Impact on Devices |

|---|---|

| Enhanced Efficiency | Longer battery life, lower energy bills |

| Improved Power Quality | More reliable operation, less interference |

| Programmable Output | Versatile charging, adaptive power supplies |

| Compact Size | Sleeker device designs, improved portability |

| Advanced Protection | Enhanced device safety and longevity |

I once worked on developing a universal power adapter for a major tech company. By using an electronic transformer with programmable output, we created a single adapter that could charge laptops, tablets, and phones. It automatically detected the connected device and provided the optimal voltage and current. The product was a hit, reducing electronic waste and simplifying users’ lives.

The advantages of electronic transformers are driving innovation across the electronics industry. From smartphones that charge faster to laptops that run cooler, these components are enabling the features we’ve come to expect in modern devices. As technology continues to advance, electronic transformers will play an increasingly crucial role in powering the devices of the future.

Energy Efficiency Unleashed: How Electronic Transformers are Greening Our Gadgets?

Did you know that the small transformer in your phone charger could be a key player in fighting climate change? It’s true – electronic transformers are making our devices significantly more energy-efficient.

Electronic transformers are greening our gadgets by dramatically improving energy efficiency. They reduce power losses, enable better power management, and support energy-saving features in devices. This results in lower energy consumption, reduced carbon footprints, and longer battery life for our electronic devices.

Let’s delve into how electronic transformers are making our devices more environmentally friendly:

1. Reduced Power Losses

Electronic transformers minimize energy waste:

- High-frequency operation reduces core losses

- Advanced materials and designs minimize copper losses

- Efficient power conversion even at low loads

2. Intelligent Power Management

These transformers enable smart power usage:

- They can rapidly adjust to changing power demands

- They support sleep and standby modes with ultra-low power consumption

- Some can learn usage patterns to optimize power delivery

3. Support for Energy-Saving Features

Electronic transformers facilitate advanced energy-saving capabilities:

- They enable fast charging, reducing overall charging time and energy use

- They support dynamic voltage scaling in processors for power-efficient computing

- They allow for precise control in LED lighting, maximizing luminous efficacy

4. Improved Battery Life

By providing efficient power conversion, electronic transformers extend battery life:

- Less energy is wasted as heat during charging

- More efficient power delivery means devices can do more with less battery capacity

- This reduces the frequency of charges, extending overall battery lifespan

Here’s a comparison of energy efficiency features:

| Feature | Traditional Power Supply | Electronic Transformer-based Supply |

|---|---|---|

| Standby Power | 0.5 – 2 W | < 0.1 W |

| Full Load Efficiency | 75 – 85% | 90 – 98% |

| Low Load Efficiency | Poor | Maintains high efficiency |

| Power Factor | Often poor | Can include power factor correction |

| Adaptability | Fixed operation | Adjusts to load demands |

I once worked on a project to redesign the power system for a data center. By replacing traditional power supplies with those using electronic transformers, we achieved a 12% reduction in overall energy consumption. This not only saved the company millions in electricity costs but also significantly reduced their carbon footprint. It was a powerful demonstration of how these small components can have a big impact on sustainability.

The energy efficiency improvements brought by electronic transformers extend beyond individual devices. As these components become more widespread, they contribute to reduced energy demand on a global scale. This means fewer power plants needed, less strain on electrical grids, and a significant step towards a more sustainable future. From our smartphones to our smart homes, electronic transformers are silently working to make our digital lives greener.

Small but Mighty: Electronic Transformers and the Miniaturization Revolution?

Have you ever wondered how your smartwatch can pack so much power into such a tiny package? The answer lies in the miniaturization revolution, and electronic transformers are at its heart.

Electronic transformers are driving the miniaturization revolution in modern devices. Their compact size and high efficiency allow for smaller, lighter, and more powerful gadgets. This enables the development of wearable tech, ultra-thin laptops, and other innovative form factors in electronics.

Let’s explore how these small but mighty components are reshaping our devices:

1. Enabling Smaller Devices

Electronic transformers take up less space than traditional ones:

- They can be a fraction of the size of conventional transformers

- This allows for slimmer profiles in laptops, phones, and tablets

- It enables the creation of tiny devices like smart earbuds and fitness trackers

2. Weight Reduction

The lightweight nature of electronic transformers contributes to portability:

- They can weigh just a few grams compared to hundreds of grams for traditional transformers

- This is crucial for wearable technology and mobile devices

- It allows for larger batteries or additional features within the same device weight

3. Heat Management

Electronic transformers generate less heat:

- This reduces the need for bulky cooling systems

- It allows for more compact device designs

- It contributes to longer lifespan of electronic components

4. Integration and Customization

Electronic transformers can be more easily integrated into circuit boards:

- They can be designed in various shapes to fit specific device layouts

- Some can be integrated directly into semiconductor packages

- This flexibility allows for more efficient use of space within devices

Here’s a comparison of size and weight in different applications:

| Application | Traditional Transformer | Electronic Transformer |

|---|---|---|

| Laptop Charger | 200-300 cm³, 200-400g | 50-100 cm³, 50-100g |

| Smartphone | Not feasible | 0.5-1 cm³, 1-2g |

| LED Driver | 20-30 cm³, 30-50g | 5-10 cm³, 5-10g |

| Wearable Device | Not feasible | 0.1-0.5 cm³, 0.2-1g |

I once worked on developing a new smartwatch for a major tech company. The challenge was to include cellular connectivity without significantly increasing the device’s size. By using a highly miniaturized electronic transformer for the power management system, we were able to squeeze in the necessary components while keeping the watch slim and lightweight. The result was a fully-featured smartwatch that was indistinguishable in size from its non-cellular predecessors.

The miniaturization enabled by electronic transformers is not just about making things smaller. It’s about reimagining what’s possible in electronic devices. It’s allowing us to put technology in places we never could before – from smart rings to medical implants. As electronic transformers continue to shrink while improving in performance, we can expect to see even more innovative and compact devices in the future. The era of bulky electronics is ending, and a new world of sleek, powerful, and ubiquitous technology is emerging.

Smart Power for Smart Devices: Electronic Transformers in the IoT Age?

Ever wondered how your smart home devices can be so small yet so powerful? The secret lies in their smart power management, made possible by electronic transformers.

Electronic transformers are enabling the proliferation of IoT devices by providing smart power solutions. They offer programmable outputs, efficient power conversion, and advanced communication capabilities. This allows IoT devices to be smaller, more energy-efficient, and capable of intelligent power management.

Let’s dive into how electronic transformers are powering the IoT revolution:

1. Programmable Power Delivery

Electronic transformers offer flexible power options:

- They can adjust voltage and current based on device needs

- This enables a single power supply to serve multiple IoT devices

- It allows for adaptive charging and power management

2. Energy Harvesting Support

Many IoT devices operate on harvested energy:

- Electronic transformers can efficiently convert small amounts of harvested energy

- They support intermittent power sources like solar or kinetic energy

- This enables self-powered IoT devices in remote locations

3. Communication Capabilities

Modern electronic transformers can communicate with devices:

- They can receive commands to adjust power output

- Some can report power usage data for analytics

- This enables smarter grid management and device coordination

4. Ultra-Low Standby Power

IoT devices often spend most time in standby mode:

- Electronic transformers can provide extremely low standby power

- This extends battery life in portable IoT devices

- It reduces overall energy consumption in always-connected devices

Here’s a table comparing power features for IoT applications:

| Feature | Traditional Power Supply | Electronic Transformer-based Supply |

|---|---|---|

| Standby Power | 0.3 – 1 W | < 0.1 W |

| Programmable Output | No | Yes |

| Energy Harvesting Support | Limited | Efficient |

| Communication Capability | No | Yes |

| Size | Larger | Compact |

I recently worked on a project developing smart sensors for agricultural use. The challenge was to create devices that could operate for months on a single battery charge. By using electronic transformers with ultra-low standby power and efficient energy harvesting support, we created sensors that could run indefinitely using small solar panels. This allowed farmers to deploy these sensors across large fields without worrying about frequent battery changes or running power lines.

Electronic transformers are not just components in IoT devices; they’re enablers of the entire IoT ecosystem. Their ability to provide smart, efficient power is allowing us to place intelligence and connectivity in places we never thought possible before. From smart cities to industrial IoT, these tiny power converters are helping to weave the fabric of our connected future. As IoT continues to grow, the role of electronic transformers in shaping this technology will only become more crucial.

Conclusion

Electronic transformers are revolutionizing power conversion in modern devices. They enable smaller, more efficient, and smarter electronics. From smartphones to IoT devices, these components are driving innovation, enhancing energy efficiency, and shaping the future of technology.

Have you ever wondered how electricity travels safely from power plants to your home? The answer lies in a device you rarely see but heavily rely on: the electrical transformer.

Electrical transformers work by using electromagnetic induction to change voltage levels. They transfer electrical energy between two or more circuits, enabling efficient power transmission over long distances and safe distribution to homes and businesses. This process is fundamental to our modern power grid.

As an electrical engineer with years of experience in the power industry, I’ve seen firsthand how crucial these devices are. Let’s dive into the fascinating world of electrical transformers and uncover the principles that keep our lights on.

The Anatomy of an Electrical Transformer: Understanding Its Key Components?

Imagine trying to understand how a car works without knowing its parts. The same goes for transformers. Knowing their components is key to grasping their function.

An electrical transformer consists of several key components: the core, primary and secondary windings, insulation, and cooling system. Each part plays a crucial role in the transformer’s operation, working together to efficiently change voltage levels and transfer power.

Let’s break down the anatomy of a transformer:

1. The Core

The core is the heart of the transformer:

- It’s usually made of thin layers of silicon steel.

- These layers, called laminations, reduce energy losses.

- The core provides a path for the magnetic field.

2. Windings

Transformers have two sets of windings:

- Primary Winding: Connects to the input power source.

- Secondary Winding: Delivers the output power.

- The ratio of turns in these windings determines the voltage change.

3. Insulation

Insulation is crucial for safety and efficiency:

- It prevents short circuits between windings and the core.

- Common insulation materials include paper, oil, and resin.

4. Cooling System

Transformers generate heat, so cooling is essential:

- Small transformers often use air cooling.

- Larger ones use oil for both cooling and insulation.

5. Tap Changer

Some transformers have tap changers:

- These adjust the turn ratio slightly.

- They help maintain consistent output voltage.

Here’s a table summarizing the key components:

| Component | Function | Material |

|---|---|---|

| Core | Provides magnetic path | Silicon steel laminations |

| Primary Winding | Receives input power | Copper or aluminum wire |

| Secondary Winding | Delivers output power | Copper or aluminum wire |

| Insulation | Prevents short circuits | Paper, oil, resin |

| Cooling System | Manages heat | Air or oil |

| Tap Changer | Adjusts voltage ratio | Mechanical or electronic switch |

I remember the first time I opened up a large power transformer. The complexity inside was astounding. The carefully wound coils, the massive core, and the intricate cooling systems all worked together in a delicate balance. It gave me a new appreciation for these devices that we often take for granted.

Understanding the anatomy of a transformer is just the first step. Each component plays a crucial role in the transformer’s operation, and they all work together to perform the seemingly magical task of changing voltage levels. This knowledge forms the foundation for understanding how transformers function in our power distribution systems.

Electromagnetic Induction: The Fundamental Principle Behind Transformer Operation?

Have you ever been amazed by a magician pulling a rabbit out of a hat? Well, transformers perform a similar magic with electricity, and the secret behind their trick is electromagnetic induction.

Electromagnetic induction is the core principle behind transformer operation. When an alternating current flows through the primary winding, it creates a changing magnetic field in the core. This field then induces a voltage in the secondary winding, allowing power transfer between circuits.

Let’s dive deeper into this fascinating principle:

The Basics of Electromagnetic Induction

Electromagnetic induction was discovered by Michael Faraday in 1831. Here’s how it works:

- A changing magnetic field creates an electric field.

- This electric field can induce a voltage in a nearby conductor.

- If the conductor is part of a closed circuit, a current will flow.

How Transformers Use This Principle

Transformers cleverly apply electromagnetic induction:

- The primary winding receives AC power, creating a changing magnetic field.

- The core channels this magnetic field to the secondary winding.

- The changing field induces a voltage in the secondary winding.

- The induced voltage depends on the turns ratio between primary and secondary windings.

The Role of Alternating Current

Transformers only work with AC power. Here’s why:

- AC constantly changes direction, creating a changing magnetic field.

- This changing field is crucial for continuous induction.

- DC would only create a momentary induction when turned on or off.

The Importance of the Core

The transformer’s core enhances the induction process:

- It provides a low-reluctance path for the magnetic field.

- This concentrates the field, making the transformer more efficient.

- The laminated design minimizes energy losses due to eddy currents.

Here’s a simplified comparison of induction with and without a core:

| Aspect | Air Core | Iron Core |

|---|---|---|

| Magnetic Field Strength | Weaker | Stronger |

| Efficiency | Lower | Higher |

| Size for Same Power | Larger | Smaller |

| Typical Use | High-frequency applications | Power distribution |

I once had the opportunity to demonstrate electromagnetic induction to a group of students. We used a simple hand-crank generator connected to a small transformer. As I turned the crank, the students could see the output voltage change on a meter. Their eyes lit up when they realized they were witnessing the same principle that powers our entire electrical grid. It was a powerful reminder of how fundamental this concept is to our modern world.

Understanding electromagnetic induction is key to grasping how transformers work. It’s the invisible force that allows these devices to change voltage levels and transfer power between circuits. This principle, discovered nearly two centuries ago, continues to be the backbone of our power distribution systems, enabling the electrical conveniences we enjoy every day.

Transformer Types Demystified: From Step-Up to Step-Down and Beyond?

Have you ever wondered why we need different types of transformers? It’s like having different tools in a toolbox – each has its specific purpose in our power distribution system.

Transformers come in various types, each designed for specific roles in power distribution. The main categories include step-up transformers for increasing voltage, step-down transformers for decreasing voltage, and isolation transformers for safety. Each type plays a crucial role in ensuring efficient and safe power delivery.

Let’s explore the main types of transformers and their unique roles:

1. Step-Up Transformers

These are the powerhouses of our transmission system:

- They increase voltage for long-distance transmission.

- Typically found at power plants.

- They reduce current, minimizing power losses over long distances.

2. Step-Down Transformers

These bring power closer to our homes:

- They decrease voltage for local distribution.

- Found at substations and on utility poles.

- They make electricity safe for residential and commercial use.

3. Isolation Transformers

These are the safety guards of our electrical systems:

- They transfer power between circuits without a direct electrical connection.

- Useful in sensitive electronic equipment.

- They help prevent electric shock and reduce noise in circuits.

4. Autotransformers

These are the space-savers:

- They use a single winding for both primary and secondary.

- More efficient for small voltage changes.

- Often used in voltage regulators.

5. Instrument Transformers

These are the measuring tools:

- They include current transformers (CTs) and potential transformers (PTs).

- Used for measuring high currents and voltages safely.

- Essential for metering and protection systems.

Here’s a comparison table of these transformer types:

| Type | Primary Use | Voltage Change | Typical Location |

|---|---|---|---|

| Step-Up | Increase voltage | Low to High | Power plants |

| Step-Down | Decrease voltage | High to Low | Substations, neighborhoods |

| Isolation | Safety, noise reduction | No change | Sensitive equipment, medical facilities |

| Autotransformer | Small voltage adjustments | Slight increase or decrease | Voltage regulators, railway systems |

| Instrument | Measurement | High to Low | Throughout power system |

I once worked on a project to upgrade a small town’s electrical infrastructure. We needed to use almost every type of transformer mentioned above. The step-up transformer at the local hydroelectric plant, the step-down transformers at the substation, isolation transformers for the hospital’s sensitive equipment, and instrument transformers for the new smart metering system. It was like conducting an orchestra, with each transformer playing its unique part in the symphony of power distribution.

Understanding these different types of transformers is crucial for anyone involved in electrical systems. Each type has its strengths and ideal applications. By using the right transformer for each job, we ensure that our power grid remains efficient, safe, and reliable. From the massive transformers at power plants to the small ones powering your electronic devices, each plays a vital role in bringing electricity to our fingertips.

Voltage Manipulation: How Transformers Adapt Power for Distribution Needs?

Have you ever tried to fit a square peg in a round hole? That’s what using electricity would be like without transformers adapting voltage for our various needs.

Transformers adapt power for distribution needs by manipulating voltage levels. They use the principle of electromagnetic induction and the turns ratio between their primary and secondary windings to increase or decrease voltage. This ability is crucial for efficient power transmission and safe consumption.

Let’s dive into how transformers perform this crucial voltage manipulation:

The Turns Ratio Principle

The key to voltage manipulation lies in the turns ratio:

- It’s the ratio of turns in the primary winding to turns in the secondary winding.

- This ratio determines the voltage change.

- The formula is: Voltage Primary / Voltage Secondary = Turns Primary / Turns Secondary

Step-Up Transformation

Used at power plants to prepare electricity for long-distance transmission:

- The secondary winding has more turns than the primary.

- This increases the voltage and decreases the current.

- Lower current means less power loss in transmission lines.

Step-Down Transformation

Used to bring high transmission voltages down for local distribution:

- The secondary winding has fewer turns than the primary.

- This decreases the voltage to safer levels for local use.

- It happens in stages, from substations to local transformers.

Fine-Tuning with Tap Changers

Some transformers can adjust their voltage ratio slightly:

- They use devices called tap changers.

- These can adjust the number of active turns in a winding.

- Useful for maintaining steady voltage despite fluctuations in supply or demand.

Here’s a table showing typical voltage changes in the power distribution system:

| Stage | Input Voltage | Output Voltage | Transformer Type |

|---|---|---|---|

| Generation | 20 kV | 345 kV | Step-Up |

| Transmission | 345 kV | 345 kV | None (transmission lines) |

| Sub-transmission | 345 kV | 69 kV | Step-Down |

| Distribution | 69 kV | 12 kV | Step-Down |

| Residential | 12 kV | 120/240 V | Step-Down |

I remember working on a project to integrate a new solar farm into the local grid. The challenge was that the solar panels produced DC at low voltage, but we needed AC at much higher voltage for the grid. We used a series of transformers: first, an inverter to convert DC to AC, then a step-up transformer to increase the voltage for transmission. At each substation, step-down transformers brought the voltage down in stages. It was a perfect example of how transformers adapt power at every stage of the journey from generation to consumption.

Voltage manipulation by transformers is what makes our modern power distribution system possible. Without it, we couldn’t transmit power efficiently over long distances or use it safely in our homes. Every time you plug in a device, you’re benefiting from this invisible but crucial process of voltage adaptation. Transformers truly are the unsung heroes of our electrical world, working tirelessly to ensure we have the right power for every need.

Efficiency and Safety: The Critical Role of Transformers in Power Transmission?

Imagine trying to carry water in a leaky bucket. That’s what power transmission would be like without efficient transformers. And using that power? It would be as dangerous as juggling live wires.

Transformers play a critical role in ensuring both efficiency and safety in power transmission. They minimize energy losses during long-distance transmission by enabling high-voltage, low-current power flow. At the distribution end, they step down voltage to safe levels for consumer use, protecting both people and equipment.

Let’s explore how transformers contribute to efficiency and safety in our power systems:

Efficiency in Power Transmission

Transformers are key to efficient power transmission:

-

Enabling High-Voltage Transmission:

- Step-up transformers increase voltage at power plants.

- Higher voltage means lower current for the same power.

- Lower current results in reduced I²R losses in transmission lines.

-

Minimizing Core Losses:

- Modern transformers use advanced core materials like grain-oriented silicon steel.

- These materials reduce hysteresis and eddy current losses.

-

Cooling Systems:

- Efficient cooling helps reduce resistance and improve overall efficiency.

- Large transformers often use oil cooling for better heat dissipation.

Safety in Power Distribution

Transformers are crucial for electrical safety:

-

Voltage Step-Down:

- They reduce high transmission voltages to levels safe for local distribution and home use.

- This protects consumers from dangerous high voltages.

-

Electrical Isolation:

- Transformers provide galvanic isolation between primary and secondary circuits.

- This helps prevent ground faults from propagating through the system.

-

Fault Current Limitation:

- The impedance of transformers helps limit fault currents.

- This can prevent more severe damage during short circuits.

Here’s a comparison of efficiency and safety aspects in power systems with and without transformers:

| Aspect | Without Transformers | With Transformers |

|---|---|---|

| Transmission Efficiency | Low (high losses) | High (minimal losses) |

| Transmission Distance | Limited | Long distances possible |

| Consumer Voltage | Potentially dangerous | Safe, standardized levels |

| Fault Isolation | Poor | Good |

| System Flexibility | Limited | High (easy voltage conversion) |

I once worked on a project to upgrade an old industrial power system. The facility was experiencing frequent equipment failures and high energy costs. By installing modern, high-efficiency transformers at key points in their power distribution system, we were able to reduce energy losses by 15% and virtually eliminate equipment failures due to power quality issues. The plant manager was amazed at how these seemingly simple devices could have such a profound impact on both their energy efficiency and operational safety.

Transformers are truly the unsung heroes of our power systems. They work silently and continuously to ensure that electricity is transmitted efficiently over long distances and distributed safely to end-users. Without them, our modern electrical grid simply wouldn’t be possible. From the massive transformers at power plants to the small ones on utility poles in your neighborhood, each plays a vital role in delivering power efficiently and safely to our homes and businesses.

Conclusion

Electrical transformers are fundamental to modern power distribution. They use electromagnetic induction to change voltage levels, enabling efficient transmission and safe usage. From power plants to our homes, transformers ensure electricity is delivered reliably and safely, powering our world.

Have you ever wondered how electricity reaches your home safely and efficiently? The answer lies in a device that’s transforming our power systems: the electrical transformer.

Transformers are revolutionizing power distribution and enabling smart grid technologies. They change voltage levels for efficient transmission, integrate renewable energy sources, and provide the foundation for intelligent power management. These devices are key to modernizing our electrical infrastructure.

As an electrical engineer with years of experience in the power industry, I’ve seen firsthand how transformers are evolving. Let’s explore how these devices are shaping the future of our power systems.

The Core Purpose of Transformers: Reshaping Modern Power Distribution Networks?

Imagine trying to pour water from a fire hose into a drinking glass. That’s similar to the challenge of getting electricity from power plants to your home. Transformers are the solution to this problem.

The core purpose of transformers is to change voltage levels in power distribution networks. They step up voltage for efficient long-distance transmission and step it down for safe local use. This ability is reshaping how we distribute power in modern networks.

Let’s dive deeper into how transformers are reshaping our power distribution networks:

1. Efficient Power Transmission

Transformers enable efficient long-distance power transmission:

- They step up voltage at power plants (often to 400,000 volts or more).

- Higher voltage means lower current for the same power.

- Lower current results in reduced power losses during transmission.

2. Safe Power Distribution

Transformers make electricity safe for end-users:

- They step down voltage at substations and in neighborhoods.

- This reduces voltage to levels safe for homes and businesses (typically 120/240 volts in the U.S.).

- It allows us to use standard electrical appliances safely.

3. Power Flow Control

Modern transformers help control power flow in the grid:

- Some transformers can adjust their voltage ratio while operating (on-load tap changers).

- This helps maintain stable voltage levels despite fluctuations in supply or demand.

- It’s crucial for integrating variable renewable energy sources.

4. Fault Isolation

Transformers play a key role in grid reliability:

- They provide electrical isolation between different parts of the grid.

- This helps prevent faults from spreading throughout the system.

- It makes maintenance and repairs safer and easier.

Here’s a table summarizing the core functions of transformers in power distribution:

| Function | Description | Impact on Power Distribution |

|---|---|---|

| Voltage Step-Up | Increase voltage for transmission | Enables efficient long-distance power transfer |

| Voltage Step-Down | Reduce voltage for end-use | Makes electricity safe for consumers |

| Power Flow Control | Adjust voltage ratios | Helps maintain grid stability |

| Fault Isolation | Separate grid sections electrically | Improves system reliability and safety |

I remember working on a project to upgrade a city’s power infrastructure. We replaced old transformers with modern ones that had on-load tap changers. The improvement in voltage stability was remarkable. Residents experienced fewer voltage fluctuations, and their appliances lasted longer. It was a clear demonstration of how transformers are reshaping our power networks.

Transformers are more than just voltage converters. They’re the backbone of our power distribution systems. Their ability to efficiently and safely move power from generation to consumption is what makes our modern electrical grid possible. As we continue to evolve our power systems, the role of transformers will only become more critical.

Transformers as Enablers: Paving the Way for Smart Grid Implementation?

Have you ever wished your power grid could think for itself? With smart grids, that’s becoming a reality, and transformers are making it possible.

Transformers are key enablers of smart grid implementation. They provide the foundation for advanced monitoring, control, and communication in power systems. Modern transformers with smart features are essential for realizing the vision of a more efficient, reliable, and flexible electrical grid.

Let’s explore how transformers are paving the way for smart grids:

1. Advanced Monitoring and Diagnostics

Smart transformers incorporate sensors and monitoring systems:

- They can track their own health and performance in real-time.

- This includes monitoring oil temperature, load current, and even gas levels in the oil.

- Early detection of potential issues helps prevent outages and extend transformer life.

2. Real-Time Data Communication

Modern transformers are becoming part of the Internet of Things (IoT):

- They can send data to control centers and receive commands remotely.

- This enables better grid management and faster response to issues.

- It’s a key component of the two-way communication essential for smart grids.

3. Power Quality Management

Smart transformers help maintain power quality:

- They can detect and sometimes correct issues like voltage sags or harmonics.

- This is crucial for sensitive electronic equipment and industrial processes.

- It helps integrate renewable energy sources, which can introduce power quality challenges.

4. Adaptive Power Flow Control

Advanced transformers can adjust to changing grid conditions:

- Some use on-load tap changers to adjust voltage ratios in real-time.

- Others incorporate power electronics for more precise control.

- This flexibility is essential for managing the variable nature of renewable energy.

Here’s a comparison of traditional and smart transformers in grid implementation:

| Feature | Traditional Transformer | Smart Transformer |

|---|---|---|

| Monitoring | Basic or manual | Continuous, real-time |

| Communication | None or limited | Two-way, integrated with grid |

| Power Quality Control | Passive | Active management |

| Adaptability | Fixed design | Dynamic adjustment capability |

| Data Analytics | Not available | Predictive maintenance, performance optimization |

I once worked on a pilot project implementing smart transformers in a small town. The difference was night and day. We could detect and resolve issues before they caused outages. The utility could balance loads more effectively, reducing strain on the system. Even the integration of local solar installations became smoother. It was a glimpse into the future of power distribution.

Transformers are evolving from passive components to active, intelligent devices. They’re not just enabling smart grids; they’re becoming a central part of them. As we continue to modernize our power infrastructure, these smart transformers will play an increasingly crucial role in creating a more resilient, efficient, and responsive electrical grid.

Green Energy and Transformers: Adapting to the Renewable Revolution?

Have you ever wondered how the energy from solar panels or wind turbines makes it to your home? The answer involves a special role for our transformers.

Transformers are adapting to play a crucial role in the renewable energy revolution. They handle the variable output of renewables, enable integration with the existing grid, and support distributed generation. Modern transformers are key to making green energy a practical and reliable power source.

Let’s explore how transformers are evolving to support green energy:

1. Handling Variable Output

Renewable sources like wind and solar have variable output. Transformers help manage this:

- They use advanced voltage regulation to handle fluctuations.

- Some incorporate energy storage to smooth out supply.

- They’re designed to operate efficiently across a wide range of loads.

2. Bidirectional Power Flow

With distributed generation, power can flow both ways:

- Modern transformers can handle power flowing from homes and businesses back to the grid.

- This is crucial for systems with rooftop solar or small wind turbines.

- It enables net metering and helps balance local power generation and consumption.

3. Harmonic Mitigation

Renewable energy systems often use inverters, which can introduce harmonics:

- Advanced transformers are designed to handle these harmonics.

- Some use special winding designs or core materials to reduce harmonic effects.

- This helps maintain power quality even with high renewable penetration.

4. Long-Distance Transmission

Many renewable sources are far from population centers:

- High-voltage transformers enable efficient long-distance transmission from remote wind or solar farms.

- Some use HVDC (High Voltage Direct Current) technology for even more efficient long-distance power transfer.

Here’s a comparison of transformer applications in conventional and renewable energy systems:

| Aspect | Conventional Power | Renewable Energy |

|---|---|---|

| Power Flow | Mostly one-way | Often bidirectional |

| Output Stability | Relatively stable | Highly variable |

| Harmonics | Limited | Significant (due to inverters) |

| Location | Near population centers | Often in remote areas |

| Voltage Levels | Standardized | May vary widely |

I recently worked on a project integrating a large offshore wind farm into the grid. The challenges were significant. We needed transformers that could handle the variable output, cope with the harsh marine environment, and efficiently transmit power over long distances. The solution involved advanced transformers with dynamic voltage regulation and HVDC technology. It was a complex project, but it showed me the incredible potential of transformers in enabling our renewable energy future.

Transformers are not just adapting to the renewable revolution; they’re enabling it. They’re the bridge between green energy sources and our existing power infrastructure. As we continue to increase our reliance on renewable sources, the role of these adaptable and resilient transformers will only grow in importance. They’re helping us build a greener, more sustainable energy future.

Technological Leaps: How Advanced Transformers are Modernizing the Grid?

Remember when phones were just for calling? Now they’re smart devices that do almost everything. The same revolution is happening with transformers, and it’s changing our power grid.

Advanced transformers are modernizing the grid through technological leaps. They incorporate digital technologies, advanced materials, and innovative designs. These improvements enhance efficiency, reliability, and flexibility of power distribution, paving the way for a smarter, more responsive electrical grid.

Let’s explore the technological advancements in transformers that are modernizing our grid:

1. Digital Integration

Modern transformers are becoming smart, connected devices:

- They incorporate sensors for real-time monitoring of various parameters.

- They have communication capabilities for integration with smart grid systems.

- Some use artificial intelligence for predictive maintenance and optimization.

2. Advanced Materials

New materials are pushing the boundaries of transformer performance:

- Amorphous metal cores can reduce no-load losses by up to 70% compared to traditional silicon steel.

- High-temperature superconducting transformers are being developed for even higher efficiency.

- Nanomaterials are being explored for improved insulation and cooling.

3. Innovative Designs

Transformer designs are evolving to meet new challenges:

- Solid-state transformers use power electronics for more precise control and additional functionalities.