Are you confused about the different types of dry type transformers? You’re not alone. Many of my clients struggle to understand the options available for their power distribution needs.

Dry type transformers come in several types, including cast resin, vacuum pressure impregnated (VPI), open-wound, and encapsulated. Each type has unique features suited for different applications, from indoor installations to industrial settings. Understanding these types is crucial for choosing the right transformer for your project.

In my years of experience in the power industry, I’ve worked with all types of dry transformers. Let’s explore each type in detail to help you make an informed decision for your power distribution needs.

What are the main types of dry type transformers?

Have you ever wondered about the different types of dry transformers available? I often get this question from clients who are new to power distribution systems.

The main types of dry type transformers are cast resin, vacuum pressure impregnated (VPI), open-wound, and encapsulated. Each type has its own manufacturing process, characteristics, and ideal applications. The choice depends on factors like environment, load requirements, and budget.

Let’s dive deeper into each type of dry transformer. My experience with these different types will help you understand their unique features and applications.

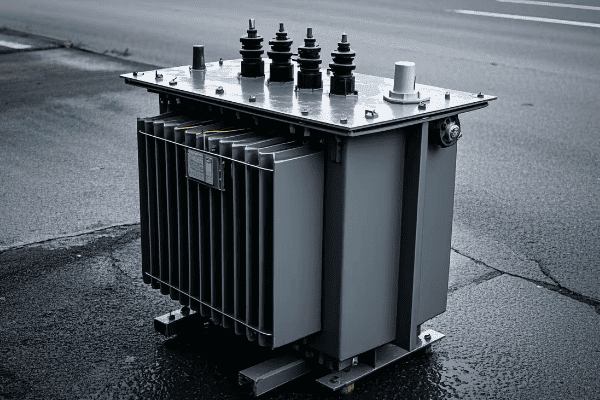

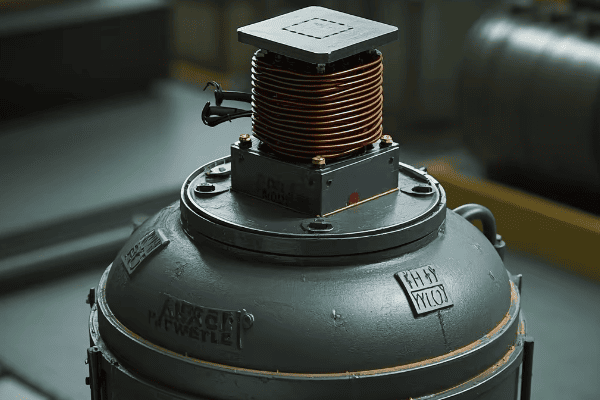

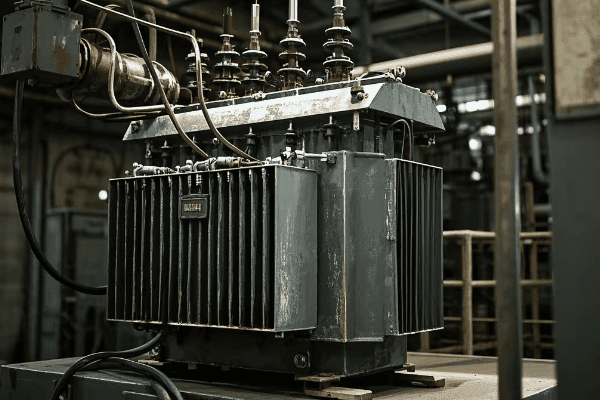

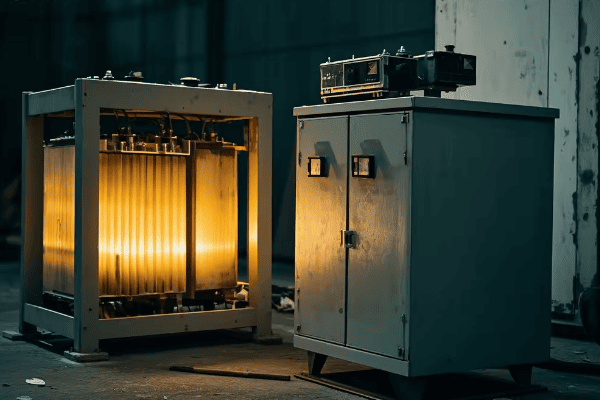

Cast Resin Transformers

Cast resin transformers are a popular choice for many of my clients. Here’s why:

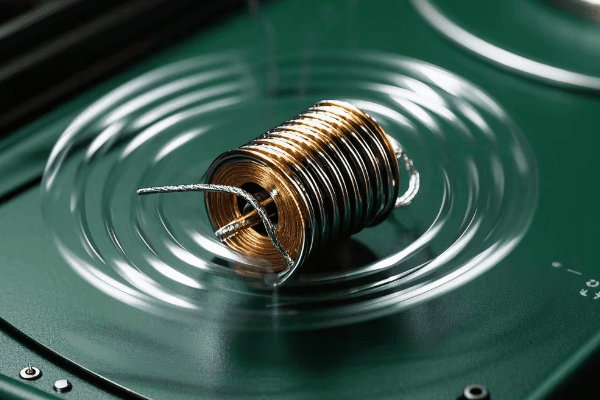

- Manufacturing Process: The windings are cast in epoxy resin under vacuum.

- Characteristics: Excellent moisture resistance, high mechanical strength.

- Applications: Ideal for harsh environments, marine applications, and areas with high humidity.

I once installed a cast resin transformer in a coastal industrial plant. Its resistance to moisture and salt air made it perfect for the challenging environment.

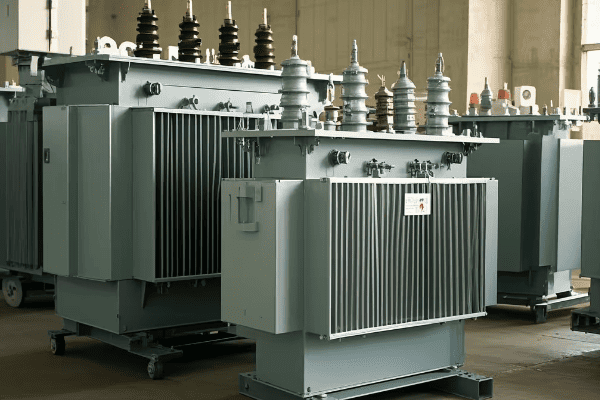

Vacuum Pressure Impregnated (VPI) Transformers

VPI transformers offer a good balance of performance and cost:

- Manufacturing Process: Windings are impregnated with varnish under vacuum and pressure.

- Characteristics: Good thermal properties, cost-effective.

- Applications: Suitable for most indoor industrial and commercial applications.

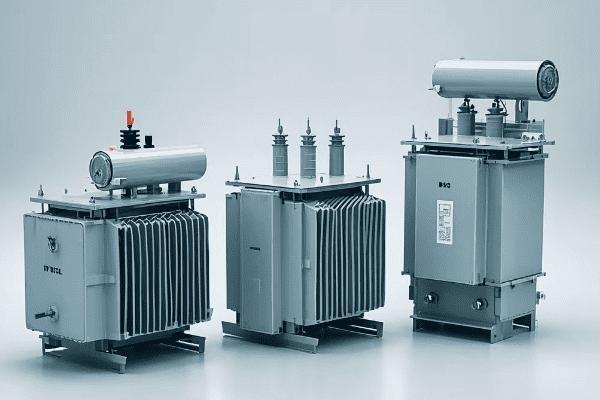

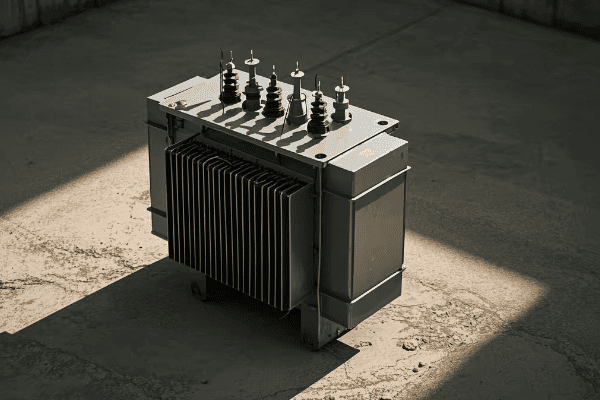

Open-Wound Transformers

These are the simplest type of dry transformers:

- Manufacturing Process: Windings are simply coated with varnish.

- Characteristics: Lightweight, good for low humidity environments.

- Applications: Used in some industrial settings where environmental protection is not a major concern.

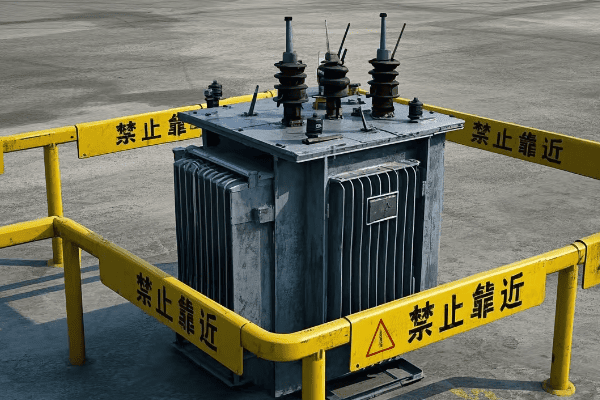

Encapsulated Transformers

Encapsulated transformers offer enhanced protection:

- Manufacturing Process: Entire core and coil assembly is encapsulated in epoxy.

- Characteristics: Excellent protection against moisture and contaminants.

- Applications: Ideal for outdoor installations or very harsh environments.

| Type | Key Feature | Best For |

|---|---|---|

| Cast Resin | Moisture resistant | Harsh environments |

| VPI | Cost-effective | General indoor use |

| Open-Wound | Lightweight | Low humidity areas |

| Encapsulated | Fully protected | Outdoor/harsh conditions |

In my experience, understanding these types is crucial for selecting the right transformer for your specific needs. Each type has its strengths, and the best choice depends on your unique situation.

How do cast resin and VPI dry type transformers differ?

Clients often ask me about the differences between cast resin and VPI transformers. It’s a common dilemma when choosing a dry type transformer for their projects.

Cast resin transformers have windings encased in epoxy, offering superior moisture and contamination resistance. VPI transformers have windings impregnated with varnish, providing good performance at a lower cost. Cast resin is better for harsh environments, while VPI is suitable for most indoor applications.

Let’s explore the key differences between these two popular types of dry transformers. My experience with both types will help you understand their unique characteristics.

Manufacturing Process

The manufacturing process is a key differentiator:

-

Cast Resin:

- Windings are placed in a mold.

- Epoxy resin is poured and cured under vacuum.

- Results in a solid, void-free insulation.

-

VPI:

- Windings are wound with insulating material.

- Entire assembly is placed in a vacuum tank and impregnated with varnish.

- Process is repeated several times for thorough impregnation.

I once visited a transformer manufacturing plant. The precision required for the cast resin process was impressive, while the VPI process was more straightforward but still effective.

Environmental Resistance

Environmental factors often guide the choice between these types:

-

Cast Resin:

- Excellent resistance to moisture and contamination.

- Can withstand harsh environments, including outdoor installations.

- Suitable for high humidity areas.

-

VPI:

- Good resistance to normal indoor environmental conditions.

- Less suitable for very humid or contaminated environments.

- Typically used in controlled indoor settings.

Thermal Performance

Heat management is crucial for transformer longevity:

-

Cast Resin:

- Excellent heat dissipation due to solid insulation.

- Can handle higher temperature rises.

- Better short-circuit strength due to epoxy encapsulation.

-

VPI:

- Good thermal performance for most applications.

- May require additional cooling in high ambient temperature conditions.

- Slightly lower short-circuit strength compared to cast resin.

Cost Considerations

Budget often plays a role in the decision:

-

Cast Resin:

- Higher initial cost due to more complex manufacturing process.

- Lower maintenance costs over time.

- Longer lifespan can offset higher initial investment.

-

VPI:

- Lower initial cost.

- May require more frequent maintenance in challenging environments.

- Good value for standard indoor applications.

| Feature | Cast Resin | VPI |

|---|---|---|

| Moisture Resistance | Excellent | Good |

| Environmental Tolerance | High | Moderate |

| Initial Cost | Higher | Lower |

| Maintenance | Low | Moderate |

| Typical Applications | Harsh environments, outdoors | General indoor use |

In my experience, the choice between cast resin and VPI often comes down to the specific environmental conditions and budget constraints of the project. For critical applications in challenging environments, I usually recommend cast resin. For standard indoor applications where cost is a significant factor, VPI transformers often provide the best value.

Which dry type transformer is best for indoor applications?

When clients ask me about indoor transformer solutions, I often recommend dry type transformers. But which type is best? It’s a question I hear frequently.

For most indoor applications, Vacuum Pressure Impregnated (VPI) dry type transformers are the best choice. They offer a good balance of performance, cost-effectiveness, and safety. VPI transformers are suitable for various indoor settings, from commercial buildings to light industrial applications.

Let’s explore why VPI transformers are often the top choice for indoor use and when other types might be more suitable. My experience with various indoor installations will provide valuable insights.

Why VPI Transformers Excel Indoors

VPI transformers have several advantages for indoor use:

-

Cost-Effectiveness:

- Lower initial cost compared to cast resin transformers.

- Good performance for the price in controlled environments.

-

Safety:

- Fire-resistant design suitable for indoor spaces.

- No oil, reducing fire risk compared to liquid-filled transformers.

-

Maintenance:

- Relatively low maintenance requirements.

- Easy to inspect and clean in indoor settings.

I once installed a VPI transformer in a large office building. Its compact size and low maintenance needs made it perfect for the limited utility space available.

When to Consider Other Types

While VPI is often the best choice, there are situations where other types might be more suitable:

-

Cast Resin:

- Best for indoor areas with high humidity or contamination risk.

- Ideal for critical applications where reliability is paramount.

-

Open-Wound:

- Suitable for very dry, clean indoor environments.

- Can be a cost-effective option for specific industrial applications.

-

Encapsulated:

- Good for indoor areas exposed to unusual environmental stresses.

- Useful in manufacturing facilities with airborne contaminants.

Factors to Consider for Indoor Applications

When choosing a dry type transformer for indoor use, consider these factors:

-

Environment:

- Humidity levels

- Presence of contaminants

- Temperature fluctuations

-

Load Profile:

- Steady loads vs. variable loads

- Peak demand requirements

-

Space Constraints:

- Available floor space

- Ventilation requirements

-

Noise Considerations:

- Proximity to work areas

- Local noise regulations

-

Future Expansion:

- Potential for increased power needs

- Flexibility for system upgrades

| Factor | VPI | Cast Resin | Open-Wound |

|---|---|---|---|

| Cost | Moderate | High | Low |

| Humidity Resistance | Good | Excellent | Poor |

| Maintenance | Low | Very Low | Moderate |

| Noise Level | Low | Low | Moderate |

| Size | Compact | Larger | Most Compact |

In my experience, while VPI transformers are often the best all-around choice for indoor applications, the final decision should always be based on a thorough assessment of the specific installation environment and requirements. I always recommend a site visit and detailed load analysis before making a final recommendation.

Are open-wound dry type transformers suitable for industrial use?

I often get asked about open-wound transformers for industrial applications. It’s a topic that causes a lot of confusion among my clients in the manufacturing sector.

Open-wound dry type transformers can be suitable for some industrial uses, particularly in clean, dry environments with low humidity. They are cost-effective and efficient for certain applications. However, their lack of environmental protection limits their use in harsh industrial settings with moisture, dust, or chemical contaminants.

Let’s delve into the suitability of open-wound transformers for industrial use. My experience with various industrial installations will help clarify when these transformers are a good choice and when they’re not.

Advantages of Open-Wound Transformers in Industry

Open-wound transformers have some benefits for industrial use:

-

Cost-Effectiveness:

- Lower initial cost compared to other dry type transformers.

- Can be a budget-friendly option for suitable environments.

-

Efficiency:

- Good efficiency due to direct air cooling of windings.

- Can handle load variations well in appropriate conditions.

-

Size and Weight:

- Generally smaller and lighter than other types.

- Easier to install in space-constrained industrial settings.

I once installed an open-wound transformer in a small, climate-controlled manufacturing facility. Its compact size and lower cost made it an ideal choice for their limited budget and space.

Limitations in Industrial Settings

However, open-wound transformers have significant limitations:

-

Environmental Sensitivity:

- Vulnerable to moisture and dust.

- Not suitable for outdoor use or humid environments.

-

Contamination Risk:

- Exposed windings can accumulate dirt and debris.

- Potential for reduced lifespan in dirty industrial environments.

-

Safety Concerns:

- Less protected against accidental contact.

- May require additional safety measures in some industrial settings.

Suitable Industrial Applications

Open-wound transformers can be appropriate for:

-

Clean Room Environments:

- Electronics manufacturing

- Pharmaceutical production

-

Climate-Controlled Facilities:

- Indoor assembly lines

- Warehouses with stable environments

-

Temporary Installations:

- Short-term industrial projects

- Portable power solutions

Unsuitable Industrial Applications

These transformers are not recommended for:

-

Chemical Plants:

- Risk of corrosive atmospheres

- Potential for chemical contamination

-

Food Processing Facilities:

- Hygiene concerns with exposed windings

- Risk of moisture exposure

-

Heavy Manufacturing:

- High levels of airborne particulates

- Potential for mechanical damage

| Factor | Suitable | Unsuitable |

|---|---|---|

| Environment | Clean, dry, controlled | Humid, dusty, corrosive |

| Application | Light manufacturing, assembly | Heavy industry, chemical processing |

| Maintenance | Regular cleaning possible | Limited access or harsh conditions |

| Safety Requirements | Standard industrial safety | Enhanced safety needs |

| Budget | Limited | Flexible |

In my experience, the decision to use open-wound transformers in industrial settings requires careful consideration of the specific environment and application. While they can be a cost-effective solution in the right conditions, their limitations often make other dry type transformers, like VPI or cast resin, more suitable for many industrial uses. Always conduct a thorough site assessment and consider long-term reliability before choosing an open-wound transformer for industrial applications.

What are the advantages of using encapsulated dry type transformers?

Clients often ask me about encapsulated transformers, especially when they need a robust solution for challenging environments. It’s a type that offers unique benefits in certain situations.

Encapsulated dry type transformers offer superior protection against environmental factors like moisture, dust, and chemicals. They are highly reliable, require minimal maintenance, and can be used in a wide range of applications, including outdoor and harsh industrial settings. Their sealed design also enhances safety and longevity.

Let’s explore the advantages of encapsulated transformers in detail. My experience with these transformers in various challenging environments will provide valuable insights.

Superior Environmental Protection

Encapsulated transformers excel in harsh conditions:

-

Moisture Resistance:

- Fully sealed against water ingress.

- Ideal for high humidity environments.

-

Dust and Contaminant Protection:

- No entry points for particulates.

- Suitable for dusty industrial settings.

-

Chemical Resistance:

- Epoxy encapsulation resists many chemicals.

- Can be used in corrosive atmospheres.

I once installed an encapsulated transformer in a coastal chemical plant. Its resistance to both salt air and chemical vapors made it the perfect choice for this challenging environment.

Enhanced Safety Features

Safety is a key advantage of encapsulated transformers:

-

Reduced Fire Risk:

- No flammable materials used.

- Excellent fire resistance.

-

Electrical Insulation:

- Complete insulation of live parts.

- Minimizes risk of electrical shock.

-

Quiet Operation:

- Encapsulation reduces operational noise.

- Suitable for noise-sensitive areas.

Minimal Maintenance Requirements

Encapsulated transformers are low-maintenance:

-

Sealed Design:

- No need for regular internal cleaning.

- Reduces risk of contamination over time.

-

Long Lifespan:

- Protected components last longer.

- Fewer replacements needed over time.

-

Simple Inspections:

- Visual checks are often sufficient.

- No need for complex maintenance procedures.

Versatility in Applications

These transformers are suitable for various uses:

-

Outdoor Installations:

- Can withstand rain, snow, and sun exposure.

- Often used in solar and wind energy systems.

-

Marine Environments:

- Resistant to salt spray and high humidity.

- Used in shipboard and offshore applications.

-

Food and Beverage Industry:

- Easy to clean exterior.

- Meets hygiene standards for food processing areas.

-

Mining and Heavy Industry:

- Withstands vibration and mechanical stress.

- Resistant to dust and mineral contaminants.

Compact Design

Encapsulated transformers often have space advantages:

-

Smaller Footprint:

- No need for additional protective enclosures.

- Can be installed in tight spaces.

-

Flexible Mounting:

- Can be mounted in various orientations.

- Suitable for wall or floor mounting.

| Advantage | Benefit |

|---|---|

| Environmental Protection | Suitable for harsh conditions |

| Safety | Reduced fire and shock risk |

| Maintenance | Minimal upkeep required |

| Versatility | Wide range of applications |

| Compact Design | Space-saving installation |

In my experience, encapsulated dry type transformers are an excellent choice for applications where reliability and environmental resistance are crucial. While they may have a higher initial cost compared to other dry type transformers, their long-term benefits in terms of reliability, safety, and reduced maintenance often make them a costoften make them a cost-effective solution in the long run. I’ve seen these transformers perform exceptionally well in some of the most challenging environments, from offshore oil rigs to food processing plants.

How do I choose the right dry type transformer for my project?

Selecting the right dry type transformer can be overwhelming. I’ve had many clients struggle with this decision, unsure of which factors to prioritize for their specific needs.

To choose the right dry type transformer, consider the installation environment, load requirements, budget, and maintenance capabilities. Evaluate factors like moisture exposure, temperature fluctuations, and contaminant presence. Match the transformer type (VPI, cast resin, open-wound, or encapsulated) to your specific needs for optimal performance and longevity.

Let’s break down the selection process step by step. My experience in helping clients choose the right transformer will guide you through this important decision.

Step 1: Assess Your Environment

The installation environment is crucial:

-

Indoor vs. Outdoor:

- Indoor: VPI or cast resin are often suitable.

- Outdoor: Consider encapsulated or specially designed cast resin.

-

Humidity Levels:

- High Humidity: Cast resin or encapsulated are best.

- Low Humidity: VPI or even open-wound might suffice.

-

Contaminants:

- Dusty: Avoid open-wound, prefer encapsulated or cast resin.

- Chemical Exposure: Encapsulated or specially treated cast resin.

I once helped a client choose a transformer for a paper mill. The high humidity and paper dust in the air led us to select an encapsulated transformer, which has performed flawlessly for years.

Step 2: Determine Load Requirements

Understanding your power needs is essential:

-

Capacity:

- Calculate your current and future power needs.

- Allow for potential expansion.

-

Load Profile:

- Steady Loads: Any dry type can handle this well.

- Variable Loads: Cast resin or VPI with good overload capacity.

-

Voltage Requirements:

- Ensure the transformer can handle your input and output voltages.

Step 3: Consider Space and Weight Constraints

Physical limitations can narrow your options:

-

Available Space:

- Limited Space: VPI or open-wound are typically more compact.

- Ample Space: Cast resin or encapsulated can be considered.

-

Weight Restrictions:

- Floor Loading Limits: Open-wound or VPI are generally lighter.

- No Restrictions: Any type can be considered.

Step 4: Evaluate Maintenance Capabilities

Consider your ability to maintain the transformer:

-

High Maintenance Capability:

- Regular inspections possible: Any type can be managed.

- Skilled personnel available: Open-wound can be considered.

-

Low Maintenance Capability:

- Limited access: Encapsulated or cast resin are best.

- Minimal oversight: Avoid open-wound types.

Step 5: Assess Budget Constraints

Balance initial costs with long-term value:

-

Limited Budget:

- Short-term: Open-wound or VPI might be suitable.

- Long-term: Consider lifetime costs, not just initial investment.

-

Flexible Budget:

- Invest in cast resin or encapsulated for challenging environments.

- Consider long-term savings from reduced maintenance and longer lifespan.

Step 6: Consider Special Requirements

Some projects have unique needs:

-

Noise Restrictions:

- Low Noise: Encapsulated or specially designed VPI.

- Standard: Any type is generally acceptable.

-

Fire Safety:

- Critical: Cast resin or encapsulated offer the best fire resistance.

- Standard: All dry types offer good fire safety compared to oil-filled.

-

Seismic Requirements:

- High Risk Areas: Specially designed cast resin or encapsulated.

- Low Risk: Standard designs are usually sufficient.

| Factor | VPI | Cast Resin | Open-Wound | Encapsulated |

|---|---|---|---|---|

| Environment | Indoor | Versatile | Clean, Dry | Harsh |

| Maintenance | Moderate | Low | High | Very Low |

| Initial Cost | Moderate | High | Low | Highest |

| Size | Compact | Larger | Most Compact | Compact |

| Best For | General Use | Critical Apps | Cost-Sensitive | Extreme Conditions |

In my experience, choosing the right dry type transformer often involves balancing these factors. I always recommend taking the time to thoroughly assess your needs and consult with experts. The right choice can lead to significant long-term benefits in reliability, efficiency, and cost-effectiveness.

Can dry type transformers handle high voltage applications?

I often get this question from clients working on large-scale projects. There’s a common misconception that dry type transformers are limited to low voltage applications.

Dry type transformers can indeed handle high voltage applications, typically up to 35kV. Advanced designs, particularly in cast resin and some VPI models, can manage even higher voltages. These transformers offer safety and environmental benefits in high voltage scenarios, making them suitable for many industrial and utility applications.

Let’s explore the capabilities of dry type transformers in high voltage applications. My experience with various high voltage installations will provide insights into their performance and limitations.

Voltage Capabilities of Dry Type Transformers

Dry type transformers have come a long way:

-

Standard Voltage Ranges:

- Low Voltage: Up to 1000V

- Medium Voltage: 1kV to 35kV

- High Voltage: Some designs can handle up to 72.5kV

-

Types Suitable for High Voltage:

- Cast Resin: Excellent for high voltage applications

- VPI: Some advanced designs can handle high voltages

- Encapsulated: Specially designed units for high voltage use

I once worked on a project where we installed a 33kV cast resin transformer in a wind farm substation. Its performance was on par with traditional oil-filled units, but with added safety benefits.

Advantages in High Voltage Applications

Dry type transformers offer unique benefits:

-

Safety:

- Reduced fire risk compared to oil-filled transformers

- No risk of oil spills or environmental contamination

-

Maintenance:

- Lower maintenance requirements

- No oil testing or replacement needed

-

Environmental Friendliness:

- No oil disposal concerns

- Suitable for environmentally sensitive areas

-

Indoor Installation:

- Can be installed closer to the load

- Reduces the need for separate transformer rooms

Limitations and Considerations

There are some factors to consider:

-

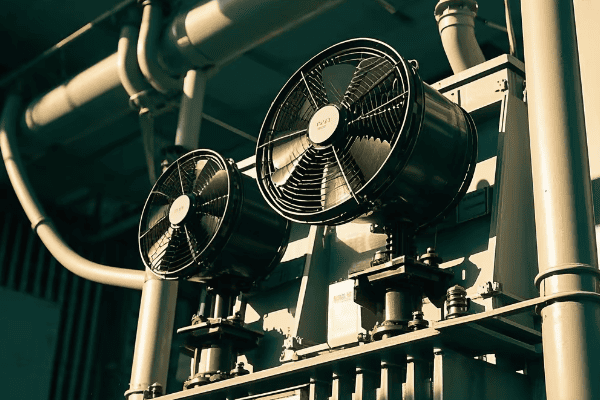

Cooling:

- High voltage units may require forced air cooling

- Temperature monitoring is crucial

-

Size and Weight:

- May be larger than equivalent oil-filled transformers

- Installation space needs careful planning

-

Cost:

- Initially more expensive than oil-filled types

- Long-term savings in maintenance and safety features

-

Environmental Protection:

- Need proper enclosures for outdoor high voltage applications

- Moisture and contamination protection is crucial

Applications of High Voltage Dry Type Transformers

These transformers are used in various high voltage scenarios:

-

Renewable Energy:

- Wind farms

- Solar power plants

-

Industrial Facilities:

- Steel mills

- Chemical plants

-

Urban Substations:

- Where space and safety are primary concerns

-

Data Centers:

- High power requirements with emphasis on safety

-

Marine and Offshore:

- Oil rigs

- Large ships

| Aspect | Dry Type (High Voltage) | Oil-Filled (High Voltage) |

|---|---|---|

| Voltage Range | Up to 72.5kV | Up to 1200kV |

| Fire Safety | High | Lower |

| Maintenance | Low | Higher |

| Environmental Risk | Minimal | Potential oil leaks |

| Size | Larger | More compact |

| Initial Cost | Higher | Lower |

| Best Use Case | Indoor, sensitive environments | Very high voltage, outdoor |

In my experience, while dry type transformers can effectively handle many high voltage applications, the choice between dry type and oil-filled still depends on specific project requirements. For voltages up to 35kV, and in some cases even higher, dry type transformers often provide an excellent balance of performance, safety, and environmental benefits. However, for very high voltage applications (above 100kV), oil-filled transformers still dominate due to their superior insulation properties at extreme voltages.

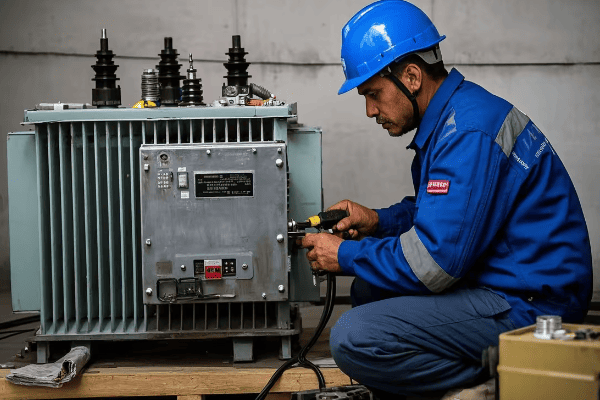

What maintenance is required for different types of dry type transformers?

Maintenance is a crucial aspect of transformer ownership that many of my clients overlook initially. Each type of dry transformer has its own maintenance needs, which can significantly impact long-term costs and reliability.

Maintenance requirements vary among dry type transformers. VPI types need regular cleaning and insulation checks. Cast resin transformers require minimal maintenance, mainly visual inspections. Open-wound types need frequent cleaning and insulation testing. Encapsulated transformers have the lowest maintenance needs, typically just external inspections.

Let’s break down the maintenance requirements for each type of dry transformer. My experience in maintaining various transformer types will help you understand what to expect.

VPI (Vacuum Pressure Impregnated) Transformers

VPI transformers require moderate maintenance:

-

Regular Cleaning:

- Remove dust and debris from windings and core

- Frequency: Annually or semi-annually, depending on environment

-

Insulation Resistance Tests:

- Check for any degradation in insulation

- Frequency: Annually

-

Visual Inspections:

- Look for signs of overheating or physical damage

- Frequency: Quarterly

-

Tightness Checks:

- Ensure all connections are secure

- Frequency: Annually

I once worked with a client who neglected cleaning their VPI transformer. We found a significant buildup of dust, which was affecting cooling efficiency. After a thorough cleaning, the transformer’s performance noticeably improved.

Cast Resin Transformers

Cast resin transformers are known for low maintenance:

-

Visual Inspections:

- Check for cracks or signs of deterioration in resin

- Frequency: Annually

-

Cleaning:

- Light dusting of accessible parts

- Frequency: Annually or as needed

-

Insulation Resistance Tests:

- Less frequent than VPI types

- Frequency: Every 2-3 years

-

Thermal Imaging:

- Check for hot spots

- Frequency: Annually

Open-Wound Transformers

Open-wound types require the most frequent maintenance:

-

Regular Cleaning:

- Crucial to prevent dust accumulation on windings

- Frequency: Quarterly or more in dusty environments

-

Insulation Tests:

- Check for any degradation due to environmental factors

- Frequency: Semi-annually

-

Visual Inspections:

- Look for signs of overheating, discoloration, or damage

- Frequency: Monthly

-

Varnish Touch-ups:

- Reapply varnish if worn off

- Frequency: As needed, typically every few years

Encapsulated Transformers

Encapsulated transformers need minimal maintenance:

-

External Inspections:

- Check for any damage to the encapsulation

- Frequency: Annually

-

Cleaning:

- Wipe down external surfaces

- Frequency: As needed, typically annually

-

Connection Checks:

- Ensure all external connections are secure

- Frequency: Annually

-

Thermal Imaging:

- Optional, to check for any internal issues

- Frequency: Every 2-3 years

| Maintenance Task | VPI | Cast Resin | Open-Wound | Encapsulated |

|---|---|---|---|---|

| Cleaning | Semi-annual | Annual | Quarterly | As needed |

| Insulation Tests | Annual | 2-3 Years | Semi-annual | Not required |

| Visual Inspections | Quarterly | Annual | Monthly | Annual |

| Specialized Tasks | None | Thermal imaging | Varnish touch-up | External checks |

In my experience, proper maintenance is key to the longevity and reliability of any transformer. While some types like encapsulated and cast resin require less frequent attention, regular inspections are still crucial. I always advise my clients to set up a maintenance schedule based on the transformer type and operating environment. This proactive approach can prevent unexpected failures and extend the transformer’s lifespan significantly.

Conclusion

Dry type transformers offer diverse solutions for modern power distribution needs. From VPI to encapsulated types, each has unique advantages. Proper selection and maintenance are key to ensuring reliability, efficiency, and longevity in your power systems. Choose wisely based on your specific requirements.

I’ve seen many changes in the power industry over the years. But nothing has impressed me more than the rise of dry type transformers. They’re changing how we think about indoor power distribution.

Dry type transformers are becoming the go-to choice for indoor power distribution. They offer improved safety, lower maintenance, and better environmental performance compared to traditional oil-filled transformers. These benefits make them ideal for use in buildings, hospitals, and data centers.

I remember when I first learned about dry type transformers. I was amazed by their potential. Let’s explore why these transformers are shaping the future of indoor power distribution.

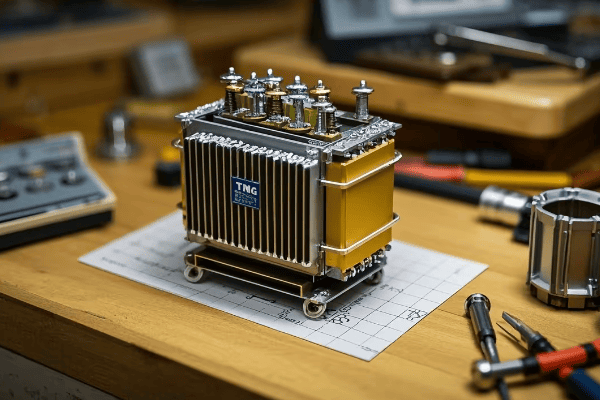

What is a Dry Type Distribution Transformer and How Does it Work?

Have you ever wondered how power safely reaches different parts of a building? The answer often lies in a dry type distribution transformer. It’s a key player in modern power systems.

A dry type distribution transformer is an electrical device that changes voltage levels without using oil for insulation or cooling. It uses air and solid materials instead. This transformer works by electromagnetic induction, transferring electrical energy between two or more circuits through a shared magnetic field.

Let’s dive deeper into how these transformers work and why they’re so important for indoor power distribution.

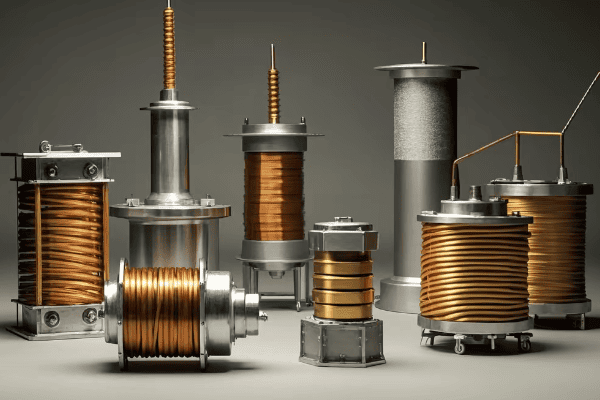

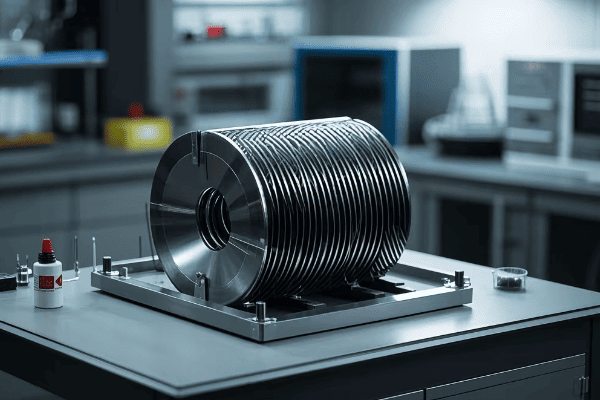

The Basic Structure

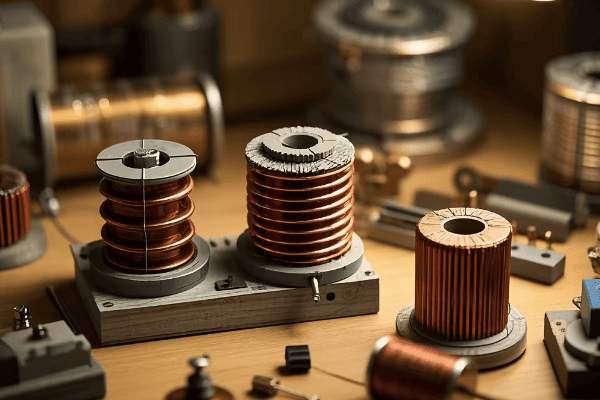

Dry type transformers have a simple yet effective structure:

- Core: This is usually made of silicon steel laminations. It provides a path for the magnetic flux.

- Windings: These are typically made of copper or aluminum. They’re wrapped around the core.

- Insulation: Instead of oil, dry type transformers use solid insulation materials like epoxy resin.

How It Works

The working principle of a dry type transformer is fascinating:

- Primary Winding: When AC power enters the primary winding, it creates a changing magnetic field in the core.

- Magnetic Field: This field extends to the secondary winding.

- Secondary Winding: The changing magnetic field induces a voltage in the secondary winding.

- Voltage Change: The voltage change depends on the number of turns in each winding.

I once had to explain this to a client who was skeptical about switching to dry type transformers. I used a simple analogy: "Imagine the transformer as a gear system. The primary winding is like the input gear, the core is the connecting shaft, and the secondary winding is the output gear. The number of teeth on each gear determines the speed (or in our case, voltage) change."

Types of Dry Type Transformers

There are several types of dry type transformers:

- Cast Resin Transformers: These use epoxy resin for insulation.

- VPI (Vacuum Pressure Impregnated) Transformers: These are impregnated with varnish under vacuum.

- Open Wound Transformers: These have exposed windings and are used in specific industrial applications.

| Type | Insulation | Typical Use | Advantages |

|---|---|---|---|

| Cast Resin | Epoxy resin | Indoor, high moisture areas | Excellent moisture resistance |

| VPI | Varnish | General indoor use | Cost-effective, good performance |

| Open Wound | Air | Industrial, low humidity | Simple design, easy maintenance |

Understanding these types helps in choosing the right transformer for specific needs. In my experience, cast resin transformers are often the best choice for critical indoor applications due to their superior moisture resistance and fire safety.

Why Are Dry Type Transformers Gaining Popularity in Modern Buildings?

I’ve noticed a growing trend in modern building design. More and more architects and engineers are choosing dry type transformers. There’s a good reason for this shift.

Dry type transformers are gaining popularity in modern buildings due to their enhanced safety features, lower maintenance requirements, and eco-friendly design. They eliminate fire risks associated with oil-filled transformers, require less space, and align with green building standards.

Let’s explore the reasons behind this growing popularity and why it matters for modern building design.

Safety First

Safety is always my top priority when designing power systems. Dry type transformers excel in this area:

- Fire Safety: They don’t use flammable oil, greatly reducing fire risk.

- No Oil Leaks: This eliminates the risk of oil spills and associated hazards.

- Indoor Friendly: They can be safely installed close to the point of use.

I once worked on a project for a high-rise office building. The client was concerned about fire safety. When I explained how dry type transformers eliminate the risk of oil fires, they were immediately sold on the idea.

Space Efficiency

In modern buildings, space is often at a premium. Dry type transformers offer significant advantages:

- Compact Design: They’re generally smaller than oil-filled transformers.

- No Oil Containment: This saves even more space in the installation area.

- Flexible Installation: They can be installed in various orientations.

Low Maintenance

Building managers appreciate the low maintenance requirements of dry type transformers:

- No Oil Checks: There’s no need for regular oil testing or replacement.

- Simple Inspections: Visual checks are often sufficient.

- Longer Life: With proper care, they can last for decades.

Eco-Friendly Design

Modern buildings often aim for green certifications. Dry type transformers can help:

- No Oil Disposal: This eliminates a potential environmental hazard.

- Energy Efficient: Many models offer high efficiency ratings.

- Recyclable Materials: Many components can be recycled at end-of-life.

| Feature | Benefit for Modern Buildings |

|---|---|

| Fire Safety | Reduces insurance costs, meets strict safety codes |

| Space Efficiency | Allows for more rentable space in the building |

| Low Maintenance | Reduces operational costs over time |

| Eco-Friendly | Helps achieve green building certifications |

In my experience, the combination of these factors makes dry type transformers an attractive choice for modern building designers. They align well with the goals of safety, efficiency, and sustainability that are so important in contemporary architecture.

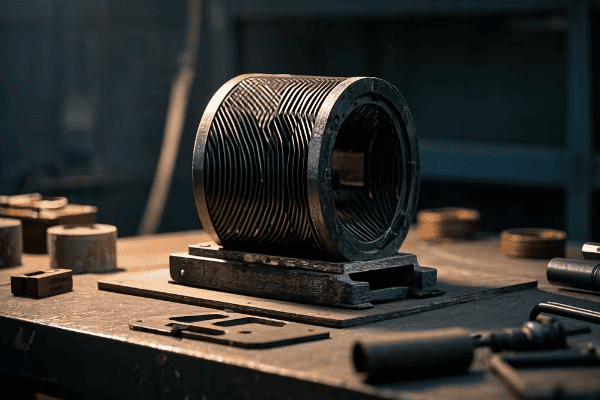

The Core of Dry Type Transformers: Understanding Its Critical Role?

The core of a dry type transformer might not be visible, but it’s the heart of the device. I’ve found that many people overlook its importance. Let’s change that.

The core of a dry type transformer plays a critical role in its operation. It provides a path for the magnetic flux, enabling the transfer of energy between the primary and secondary windings. The core’s design and material significantly impact the transformer’s efficiency, size, and performance.

Let’s dive deeper into the world of transformer cores and why they’re so crucial for the performance of dry type transformers.

Core Materials

The choice of core material is crucial:

- Silicon Steel: This is the most common material. It offers a good balance of performance and cost.

- Amorphous Metal: This newer material can reduce energy losses by up to 70% compared to silicon steel.

- Nanocrystalline Materials: These offer even better performance but are currently very expensive.

I once worked on a project where we used amorphous metal cores. The energy savings were impressive, and the client was thrilled with the reduced operating costs.

Core Designs

There are several core designs, each with its own advantages:

- Core Type: The windings surround the core limbs.

- Shell Type: The core surrounds the windings.

- Toroidal: A ring-shaped core with windings wrapped around it.

The Role of the Core

The core serves several critical functions:

- Magnetic Flux Path: It provides a low-reluctance path for the magnetic flux.

- Energy Transfer: It enables the transfer of energy between the primary and secondary windings.

- Efficiency: A well-designed core minimizes energy losses.

Core Losses

Understanding core losses is crucial for optimizing transformer performance:

- Hysteresis Loss: This occurs due to the changing magnetic field.

- Eddy Current Loss: This is caused by currents induced in the core material.

To minimize these losses, cores are often made of thin laminations stacked together.

| Core Type | Advantages | Best For |

|---|---|---|

| Core Type | Good cooling, easy maintenance | General purpose |

| Shell Type | Better short-circuit strength | High current applications |

| Toroidal | Very low stray magnetic field | Sensitive electronic equipment |

In my experience, the choice of core design and material can make a significant difference in transformer performance. I always pay close attention to these factors when designing or specifying transformers for a project.

Dry vs. Oil Type Transformers: A Comprehensive Comparison?

I’ve worked with both dry and oil type transformers throughout my career. Each has its strengths and weaknesses. Let’s compare them to see which might be best for your needs.

Dry type transformers offer better fire safety and environmental protection, while oil type transformers generally have better cooling and overload capacity. Dry types are preferred for indoor and environmentally sensitive locations, while oil types are often used for outdoor and high-capacity applications.

Let’s dive deeper into the key differences between these two transformer types.

Safety Considerations

Safety is always my top priority:

-

Fire Risk:

- Dry Type: Low fire risk due to absence of flammable oil.

- Oil Type: Higher fire risk due to presence of flammable oil.

-

Environmental Risk:

- Dry Type: No risk of oil leaks or spills.

- Oil Type: Potential for oil leaks, requiring containment measures.

I once worked on a project for a hospital where we chose dry type transformers specifically for their superior fire safety.

Performance and Efficiency

Performance can vary depending on the application:

-

Cooling Efficiency:

- Dry Type: Air-cooled, less efficient for heat dissipation.

- Oil Type: Oil provides excellent cooling, allowing for better overload capacity.

-

Noise Levels:

- Dry Type: Generally quieter operation.

- Oil Type: Can be noisier, especially with cooling fans.

-

Efficiency:

- Dry Type: Slightly less efficient, especially at partial loads.

- Oil Type: Often more efficient, particularly in larger sizes.

Maintenance and Lifespan

Maintenance needs can significantly impact long-term costs:

-

Routine Maintenance:

- Dry Type: Lower maintenance requirements, no oil testing needed.

- Oil Type: Regular oil testing and potential oil replacement required.

-

Lifespan:

- Dry Type: Typical lifespan of 20-30 years.

- Oil Type: Can last 30-40 years or more with proper maintenance.

Installation and Space Requirements

Space considerations are often crucial:

-

Space Needs:

- Dry Type: Generally more compact, no need for oil containment.

- Oil Type: Requires more space, including area for oil containment.

-

Weight:

- Dry Type: Typically lighter.

- Oil Type: Heavier, may require additional structural support.

| Feature | Dry Type | Oil Type |

|---|---|---|

| Fire Safety | High | Lower |

| Environmental Risk | Low | Higher |

| Cooling Efficiency | Lower | High |

| Maintenance | Low | Higher |

| Lifespan | 20-30 years | 30-40+ years |

| Space Requirements | Lower | Higher |

| Best For | Indoor, sensitive environments | Outdoor, high capacity |

In my experience, the choice between dry and oil type transformers often comes down to the specific needs of the project. For indoor applications, especially in sensitive environments, I usually recommend dry type transformers. For outdoor substations or very high capacity needs, oil type transformers might be the better choice.

Key Advantages of Dry Type Transformers for Indoor Applications?

When it comes to indoor power distribution, dry type transformers have some clear advantages. I’ve seen these benefits firsthand in many projects.

Dry type transformers excel in indoor applications due to their enhanced safety, reduced maintenance needs, and environmental friendliness. They eliminate fire and environmental risks associated with oil, require less space, and align well with green building standards. These factors make them ideal for use in commercial buildings, hospitals, and data centers.

Let’s explore these advantages in more detail and see why they matter for indoor applications.

Enhanced Safety

Safety is paramount in indoor environments:

- Fire Resistance: The absence of oil significantly reduces fire risk.

- No Oil Leaks: Eliminates the risk of oil spills and associated hazards.

- Reduced Explosion Risk: Lower risk of explosive failure compared to oil-filled transformers.

I once worked on a project for a large library. The client was particularly concerned about fire safety. The choice of dry type transformers gave them peace of mind.

Space Efficiency

In indoor settings, space is often at a premium:

- Compact Design: Generally smaller than equivalent oil-filled units.

- No Oil Containment Needed: Saves additional space.

- Flexible Installation: Can be installed closer to the load, saving on cable costs.

Low Maintenance Requirements

Building managers appreciate the ease of maintenance:

- No Oil Testing: Eliminates the need for regular oil testing and replacement.

- Simpler Inspections: Visual inspections are often sufficient.

- Longer Intervals Between Services: Reduces downtime and maintenance costs.

Environmental Benefits

Dry type transformers align well with green building initiatives:

- No Oil Disposal: Eliminates the need for hazardous waste disposal.

- Recyclable Materials: Many components can be recycled at end-of-life.

- Energy Efficiency: Many models offer high efficiency ratings.

Noise Reduction

Quiet operation is crucial in many indoor settings:

- Lower Noise Levels: Generally quieter than oil-filled transformers.

- No Cooling Fans: Many designs don’t require noisy cooling fans.

| Advantage | Benefit for Indoor Applications |

|---|---|

| Fire Safety | Crucial for occupied buildings |

| Space Efficiency | Maximizes usable floor space |

| Low Maintenance | Reduces operational costs |

| Environmental Benefits | Helps achieve green certifications |

| Noise Reduction | Improves occupant comfort |

In my experience, these advantages make dry type transformers the preferred choice for most indoor applications. They offer a combination of safety, efficiency, and environmental benefits that are hard to match with other transformer types.

Common Misconceptions About Dry Type Transformers: Debunking the Myths?

Throughout my career, I’ve encountered many misconceptions about dry type transformers. These myths can lead to poor decisions in power system design. Let’s clear up some of these misunderstandings.

Common misconceptions about dry type transformers include beliefs that they are less efficient, more expensive, and less durable than oil-filled types. In reality, modern dry type transformers are highly efficient, often more cost-effective in the long run, and can last for decades with proper care.

Let’s examine some of these myths in detail and see why they don’t hold up to scrutiny.

Myth 1: Dry Type Transformers Are Less Efficient

This is a common misconception I often hear:

Reality: While it’s true that some older dry type models were less efficient, modern designs have significantly improved. Many dry type transformers now offer efficiency levels comparable to or even exceeding oil-filled types.

Key Points:

- Advanced Materials: Use of materials like amorphous metal cores has greatly reduced losses.

- Design Improvements: Better winding techniques and insulation have improved efficiency.

- Regulation Compliance: Many dry type transformers meet or exceed efficiency standards.

I once worked on a project where we replaced old oil-filled transformers with modern dry types. The energy savings were substantial, surprising even the skeptical facility manager.

Myth 2: Dry Type Transformers Are Always More Expensive

Initial cost is often a concern:

Reality: While the upfront cost of dry type transformers can be higher, they often prove more cost-effective over their lifetime.

Key Points:

- Lower Maintenance Costs: No oil testing or replacement needed.

- Reduced Installation Costs: No need for oil containment systems.

- Longer Lifespan: Many dry type transformers last for decades with proper care.

- Lower Insurance Costs: Reduced fire risk can lead to lower insurance premiums.

Myth 3: Dry Type Transformers Can’t Handle Overloads

This misconception canThis misconception can lead to overdesign:

Reality: While it’s true that dry type transformers generally have lower overload capacity than oil-filled types, they can still handle short-term overloads when properly designed.

Key Points:

- Design Flexibility: Dry type transformers can be designed for specific overload requirements.

- Temperature Monitoring: Advanced monitoring systems can safely manage overload conditions.

- Cooling Options: Some designs incorporate forced air cooling for better overload handling.

In a data center project I worked on, we successfully used dry type transformers with forced air cooling to handle the variable loads typical in such environments.

Myth 4: Dry Type Transformers Are Not Suitable for Harsh Environments

This myth often limits their use:

Reality: While it’s true that standard dry type transformers are designed for indoor use, there are specially designed models for harsh environments.

Key Points:

- Enclosures: Dry type transformers can be housed in protective enclosures for outdoor use.

- Special Designs: Some models are specifically designed for high humidity or corrosive environments.

- Temperature Range: Many dry type transformers can operate in a wide temperature range.

I once specified a specially designed dry type transformer for a coastal industrial plant. It performed excellently despite the salty, humid environment.

| Myth | Reality |

|---|---|

| Less Efficient | Modern designs are highly efficient |

| More Expensive | Often more cost-effective over lifetime |

| Can’t Handle Overloads | Can be designed for overload capacity |

| Not for Harsh Environments | Special designs available for challenging conditions |

Debunking these myths is crucial for making informed decisions about transformer selection. In my experience, understanding the true capabilities of dry type transformers often leads to better, more efficient power system designs.

The Environmental Impact: How Dry Type Transformers Contribute to Sustainability?

As an engineer, I’ve always been interested in the environmental impact of the systems I design. Dry type transformers have a lot to offer in this regard. Let’s explore how they contribute to sustainability.

Dry type transformers contribute to sustainability through their eco-friendly design, energy efficiency, and long lifespan. They eliminate the risk of oil leaks, reduce the need for hazardous waste disposal, and often use recyclable materials. Their efficiency and durability also contribute to reduced energy consumption over time.

Let’s dive deeper into the environmental benefits of dry type transformers and why they matter in our increasingly eco-conscious world.

Elimination of Oil-Related Environmental Risks

This is perhaps the most obvious environmental benefit:

- No Oil Leaks: Eliminates the risk of soil and water contamination.

- No Oil Disposal: Removes the need for hazardous waste management.

- Reduced Fire Risk: Lowers the chance of environmentally damaging fires.

I once worked on a project near a protected wetland. The choice of dry type transformers was crucial in getting environmental approval for the development.

Energy Efficiency

Efficiency is key to reducing environmental impact:

- Low Losses: Modern dry type transformers have very low core and winding losses.

- Consistent Performance: Efficiency remains high even at partial loads.

- Cool Operation: Less energy wasted as heat compared to some oil-filled types.

Long Lifespan and Recyclability

Sustainability is about more than just operation:

- Durability: Many dry type transformers last 20-30 years or more.

- Recyclable Materials: Core and windings are often made of recyclable metals.

- Less Frequent Replacement: Longer lifespan means less frequent manufacturing and disposal.

Reduced Carbon Footprint

The overall impact on carbon emissions is significant:

- Manufacturing: Often requires less energy-intensive processes than oil-filled types.

- Transportation: Lighter weight can mean lower transport-related emissions.

- Operation: High efficiency leads to lower energy consumption over time.

Alignment with Green Building Standards

Dry type transformers can help achieve green certifications:

- LEED Points: Can contribute to LEED certification for buildings.

- Energy Star: Many models meet Energy Star efficiency requirements.

- Green Grid Initiatives: Align well with efforts to create more sustainable power grids.

| Environmental Aspect | Benefit of Dry Type Transformers |

|---|---|

| Oil-Related Risks | Eliminated |

| Energy Efficiency | High, reducing overall energy consumption |

| Lifespan | Long, reducing manufacturing and disposal impacts |

| Recyclability | High, especially for core and windings |

| Green Building Compliance | Often contributes to certifications |

In my experience, the environmental benefits of dry type transformers are becoming increasingly important. As sustainability becomes a key focus in many industries, the choice of transformer type can play a significant role in reducing a project’s overall environmental impact.

Conclusion

Dry type transformers are revolutionizing indoor power distribution. They offer enhanced safety, efficiency, and environmental benefits. As we move towards more sustainable and smart buildings, dry type transformers will play a crucial role in shaping our power systems.

Have you ever wondered how electricity from a power plant safely reaches your home appliances? The secret lies in the magical world of transformers, specifically step-up and step-down transformers.

Step-up transformers increase voltage while decreasing current, typically used in power plants to boost voltage for long-distance transmission. Step-down transformers do the opposite, reducing voltage and increasing current, commonly found in local substations and residential areas. The key difference lies in their winding ratios: step-up transformers have more secondary windings than primary, while step-down transformers have fewer.

As an electrical engineer with over 15 years of experience in power systems, I’ve worked extensively with both types of transformers. Let’s dive into the fascinating world of these voltage-changing marvels and uncover what makes each type unique and indispensable in our modern electrical grid.

How Do Step-Up Transformers Work?

Have you ever seen those massive transformers at power plants? Those are likely step-up transformers in action.

Step-up transformers increase voltage by having more turns in the secondary coil than in the primary coil. This results in a higher induced electromotive force (EMF) in the secondary coil compared to the primary voltage. The relationship is defined by the equation: Vs/Vp = Ns/Np, where V is voltage and N is the number of turns in each coil.

Key characteristics of step-up transformers:

- Secondary coil turns (N2) > Primary coil turns (N1)

- Secondary voltage (U2) > Primary voltage (U1)

- Secondary current (I2) < Primary current (I1)

- Power remains constant (P = VI) on both sides (ignoring small losses)

I remember working on a project at a wind farm where we used massive step-up transformers to increase the voltage from 690V (generated by the turbines) to 400kV for long-distance transmission. The sheer size of these transformers – some as big as a small house – was a testament to their crucial role in power distribution.

Key Takeaway: Step-up transformers are essential for efficient long-distance power transmission, allowing electricity to travel hundreds of miles with minimal losses.

What Makes Step-Down Transformers Different?

Ever noticed those barrel-shaped devices on utility poles in your neighborhood? Those are likely step-down transformers, bringing high-voltage power down to a level safe for your home.

Step-down transformers decrease voltage by having fewer turns in the secondary coil compared to the primary coil. This results in a lower induced EMF in the secondary coil. The same principle applies: Vs/Vp = Ns/Np, but in this case, Ns is smaller than Np.

Key characteristics of step-down transformers:

- Secondary coil turns (N2) < Primary coil turns (N1)

- Secondary voltage (U2) < Primary voltage (U1)

- Secondary current (I2) > Primary current (I1)

- Power remains constant (P = VI) on both sides (ignoring small losses)

In a recent urban development project, we installed numerous step-down transformers to reduce the 11kV distribution voltage to the 230V used in homes. It’s fascinating to think that these relatively small devices are the final link in a chain that starts at massive power plants.

Key Takeaway: Step-down transformers are crucial for delivering usable power to end consumers, ensuring safe voltage levels for homes and businesses.

How Do Step-Up and Step-Down Transformers Compare?

Understanding the differences between step-up and step-down transformers is crucial for anyone involved in electrical engineering or power distribution. Let’s break it down:

The main difference between step-up and step-down transformers lies in their winding ratios and their effect on voltage and current. While step-up transformers increase voltage and decrease current, step-down transformers do the opposite. Both types play crucial roles in different parts of the power distribution system.

Here’s a comparison table to highlight the key differences:

| Feature | Step-Up Transformer | Step-Down Transformer |

|---|---|---|

| Winding Ratio | N2 > N1 | N2 < N1 |

| Voltage Change | Increases (U2 > U1) | Decreases (U2 < U1) |

| Current Change | Decreases (I2 < I1) | Increases (I2 > I1) |

| Primary Use | Power generation plants | Distribution substations, residential areas |

| Typical Input Voltage | 11kV – 33kV | 33kV – 765kV |

| Typical Output Voltage | 132kV – 765kV | 11kV – 415V |

| Core Size | Larger | Smaller |

| Winding Wire Gauge | Thicker primary, thinner secondary | Thicker secondary, thinner primary |

I once worked on a project that involved tracing electricity from a power plant to a residential area. We started with a massive step-up transformer at the plant, increasing voltage from 20kV to 400kV for transmission. Then, at various substations along the way, we used step-down transformers to gradually reduce the voltage, ending with small transformers on local poles that brought the voltage down to 230V for household use.

Key Takeaway: Both step-up and step-down transformers are essential components of our power distribution system, each serving a specific purpose in ensuring efficient and safe electricity delivery.

What Are the Future Trends in Transformer Technology?

As our energy landscape evolves, so does transformer technology. But what does the future hold for these essential devices?

Future trends in transformer technology focus on increased efficiency, smart monitoring capabilities, and environmental sustainability. We’re seeing developments in high-temperature superconducting materials, solid-state transformers, and integration with smart grid technologies for both step-up and step-down transformers.

Emerging trends include:

- Use of amorphous metal cores to reduce energy losses

- Implementation of biodegradable insulating fluids

- Integration of IoT sensors for real-time monitoring and predictive maintenance

- Development of compact, modular designs for urban installations

- Enhanced resilience against cyber threats in smart grid applications

In a recent pilot project, we tested solid-state transformers that can handle AC and DC conversion, potentially revolutionizing how we integrate renewable energy sources and electric vehicle charging stations into the grid.

Key Takeaway: The future of transformer technology lies in smarter, more efficient, and more flexible designs that can adapt to the changing needs of our evolving power systems.

Conclusion

Understanding the differences between step-up and step-down transformers is crucial for grasping how our modern electrical grid functions. From the massive step-up transformers at power plants to the small step-down units in your neighborhood, these devices work in harmony to ensure safe and efficient power delivery. As we move towards a future with more distributed energy resources and smart grids, the role of transformers will continue to evolve, making this field an exciting area for innovation and development.

FAQs: Common Questions About Step-Up and Step-Down Transformers

- Can a step-up transformer be used as a step-down transformer?

Theoretically, yes. The direction of voltage change depends on which side you use as the primary. However, in practice, transformers are designed and optimized for specific step-up or step-down ratios. Using a transformer in the opposite direction can lead to inefficiencies and potential safety issues. Always use transformers as designed for optimal performance and safety.

- Do transformers consume power?

Transformers don’t consume power in the sense of converting it to another form of energy, but they do have some power losses. These losses are primarily due to core losses (hysteresis and eddy currents) and copper losses in the windings. Modern transformers are highly efficient, with large power transformers achieving efficiencies up to 99.75%. However, even small losses can be significant when dealing with large amounts of power.

- Why don’t we use higher voltages all the way to our homes?

While higher voltages are more efficient for long-distance transmission, they’re extremely dangerous and impractical for home use. The insulation required for high voltages would make home wiring prohibitively expensive and bulky. Additionally, high voltages can cause corona discharge and other safety issues. Step-down transformers allow us to balance the efficiency of high-voltage transmission with the safety and practicality of low-voltage distribution.

- How long do transformers typically last?

With proper maintenance, power transformers can last 30-40 years or even longer. I’ve worked with transformers that have been in service for over 50 years and are still functioning well. However, lifespan can vary depending on factors like load conditions, environmental factors, and maintenance practices. Regular monitoring and maintenance are key to extending a transformer’s operational life.

- Are there any alternatives to traditional transformers?

Yes, emerging technologies are challenging traditional transformer designs. Solid-state transformers, which use power electronics to convert voltage levels, are a promising alternative. They offer benefits like smaller size, lighter weight, and the ability to handle both AC and DC power. However, as of now, they’re generally more expensive and less efficient than traditional transformers for high-power applications. Research is ongoing, and we may see more widespread adoption of these alternatives in the future, especially in specific applications like renewable energy integration and electric vehicle charging.

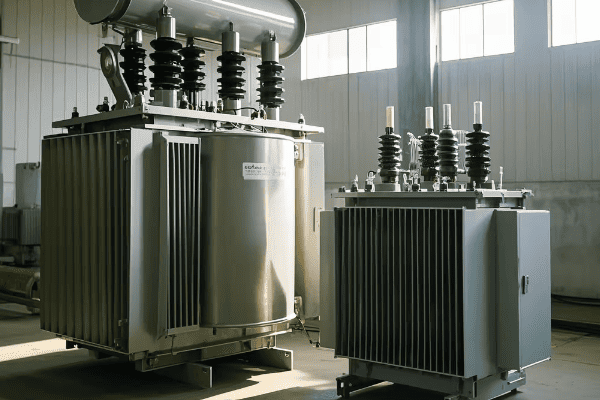

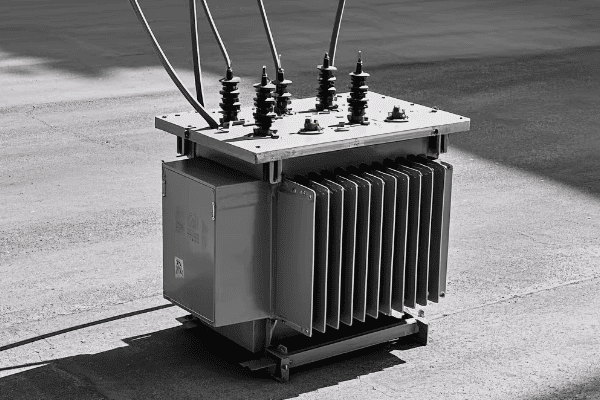

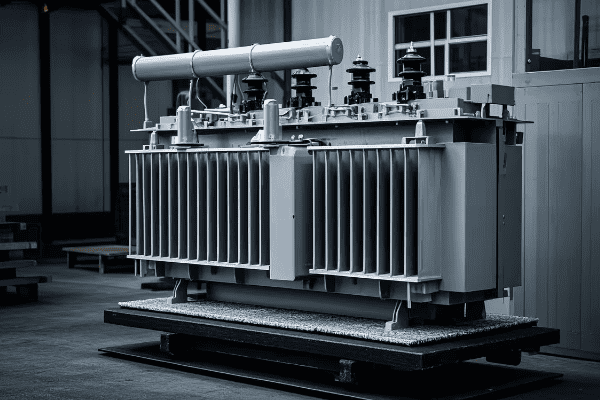

Have you ever wondered why some electrical transformers are shaped like cylinders while others look like boxes with fins? The answer lies in the specific design of OMP and TMG transformers, two crucial components in our power distribution systems.

OMP transformers are single-phase, oil-immersed units designed for voltage step-down in various applications, including electrical supply networks and railroad systems. TMG transformers, on the other hand, are three-phase, oil-immersed units in hermetic corrugated cases, primarily used for transforming electrical energy in supply networks and consumer mains. Both types play vital roles in power distribution but have distinct characteristics suited for different applications.

As an electrical engineer with over 15 years of experience in power systems, I’ve worked extensively with both OMP and TMG transformers. Let’s dive into the world of these essential devices and uncover what makes each type unique and indispensable in modern power distribution.

What Are OMP Transformers and Where Are They Used?

Have you ever seen a small cylindrical transformer mounted on a utility pole? Chances are, you’ve spotted an OMP transformer in action.

OMP transformers are single-phase, oil-immersed converter transformers designed for stepping down voltage in electrical supply networks. They’re commonly used in power circuits of alarm equipment and railroad automatic block systems. These transformers are built to withstand extreme temperatures, operating efficiently in both temperate (-45°C to +40°C) and cold (-60°C to +40°C) climates.

Key features of OMP transformers include:

- Single-phase design

- Oil-immersed for better insulation and cooling

- Compact cylindrical shape

- Wide temperature operating range

- Primarily used for voltage step-down

I recall a project where we installed OMP transformers along a new railroad line in a mountainous region. The transformers’ ability to operate in extreme cold was crucial for maintaining reliable signaling systems throughout the harsh winter months.

Key Takeaway: OMP transformers are versatile, robust units ideal for outdoor installations in challenging environments, particularly where single-phase power is needed.

What Makes TMG Transformers Unique?

Ever noticed those large, finned boxes in electrical substations? Those are likely TMG transformers, the workhorses of power distribution.

TMG transformers are three-phase, oil-immersed units housed in hermetic corrugated cases. They’re designed for transforming electrical energy in supply networks and consumer mains. A key advantage of TMG transformers is their low maintenance requirements – they need no preventive repair or inspection throughout their operational lifetime, making them cost-effective for long-term use.

Distinctive features of TMG transformers include:

- Three-phase design

- Hermetically sealed corrugated case

- Low maintenance requirements

- Suitable for both indoor and outdoor installations

- Used in larger power distribution applications

In a recent urban development project, we chose TMG transformers for the main power distribution substations. Their low maintenance needs and reliable performance were perfect for the high-demand, continuous operation required in a growing city center.

Key Takeaway: TMG transformers offer a low-maintenance, reliable solution for three-phase power transformation, ideal for both utility and industrial applications.

How Do OMP and TMG Transformers Compare?

Choosing between OMP and TMG transformers can significantly impact your power distribution system’s efficiency and reliability. But how do they stack up against each other?

OMP and TMG transformers differ in phase count, application scope, and maintenance needs. While OMP transformers excel in single-phase, outdoor applications with extreme temperature variations, TMG transformers are preferred for three-phase systems where low maintenance and hermetic sealing are priorities.

Here’s a comparison table to highlight the key differences:

| Feature | OMP Transformer | TMG Transformer |

|---|---|---|

| Phase | Single-phase | Three-phase |

| Design | Cylindrical, oil-immersed | Rectangular, hermetically sealed |

| Temperature Range | -60°C to +40°C | Standard range (typically -20°C to +40°C) |

| Main Applications | Railroad systems, alarm circuits | Supply networks, consumer mains |

| Maintenance | Regular inspection needed | Minimal maintenance required |

| Size | Generally smaller | Larger, suited for higher capacities |

| Installation | Often pole-mounted | Usually ground-mounted |

I once consulted on a project where we needed to decide between OMP and TMG transformers for a mixed-use development. We ultimately chose OMP transformers for the residential areas due to space constraints and single-phase requirements, while opting for TMG transformers in the commercial sector to handle the higher three-phase power demands.

Key Takeaway: The choice between OMP and TMG transformers depends on specific application needs, considering factors like phase requirements, installation environment, and maintenance capabilities.

What Are the Future Trends in Transformer Technology?

As our power needs evolve, so do our transformers. But what does the future hold for OMP and TMG transformers?

Future trends in transformer technology are focusing on increased efficiency, smart monitoring capabilities, and environmental sustainability. For both OMP and TMG transformers, we’re seeing developments in biodegradable insulating oils, advanced cooling systems, and integration with smart grid technologies.

Emerging trends include:

- Use of natural ester fluids as an eco-friendly alternative to mineral oil

- Integration of IoT sensors for real-time monitoring and predictive maintenance

- Development of more compact designs for urban installations

- Improved energy efficiency to reduce losses

- Enhanced resilience against cyber threats in smart grid applications

In a recent pilot project, we tested new OMP transformers with biodegradable insulating fluid and built-in smart monitoring systems. The results were promising, showing improved environmental performance and the potential for significant long-term cost savings through predictive maintenance.

Key Takeaway: The future of both OMP and TMG transformers lies in smarter, more efficient, and environmentally friendly designs that can meet the evolving demands of our power distribution systems.

Conclusion

Understanding the differences between OMP and TMG transformers is crucial for anyone involved in power distribution system design or management. While OMP transformers offer flexibility and resilience in single-phase, often challenging environments, TMG transformers provide reliable, low-maintenance solutions for three-phase power distribution. As technology advances, both types are evolving to meet the demands of smarter, more efficient power grids. Whether you’re working on a small-scale project or a large power distribution network, choosing the right transformer type can significantly impact the system’s performance, reliability, and long-term cost-effectiveness.

FAQs: Common Questions About OMP and TMG Transformers

- Are OMP transformers more efficient than TMG transformers?

Efficiency depends on the specific application. OMP transformers are generally more efficient for smaller, single-phase applications, especially in variable temperature conditions. TMG transformers, however, can be more efficient in larger, three-phase systems due to their design and lower maintenance needs. In my experience, the efficiency difference is usually minimal when each type is used in its intended application.

- Can TMG transformers be used in extremely cold climates like OMP transformers?

While TMG transformers are robust, they’re typically not designed for the extreme temperature ranges that OMP transformers can handle. For very cold climates (below -40°C), OMP transformers are usually the better choice. However, special versions of TMG transformers can be manufactured for colder climates if necessary.

- How long do OMP and TMG transformers typically last?

Both OMP and TMG transformers are built for longevity. With proper maintenance, OMP transformers can last 20-30 years, while TMG transformers, due to their hermetic design and lower maintenance needs, often last 30-40 years or more. I’ve seen TMG transformers in operation for over 50 years, still performing efficiently.

- Are there any special installation requirements for OMP and TMG transformers?

Yes, there are. OMP transformers, being often pole-mounted, require proper support structures and consideration for weight distribution. TMG transformers, typically larger and ground-mounted, need a stable foundation and adequate clearance for cooling. Both types require proper electrical protection and grounding. Always consult local electrical codes and manufacturer guidelines for specific installation requirements.

- Can OMP and TMG transformers be used with renewable energy sources?

Yes, both can be adapted for use with renewable energy sources. However, the choice depends on the specific renewable system. For example, small-scale solar installations might use OMP transformers, while large wind farms typically require TMG transformers for their three-phase output. In recent years, I’ve seen an increase in specialized transformer designs optimized for renewable energy applications, incorporating features like enhanced harmonics handling and bidirectional power flow capabilities.

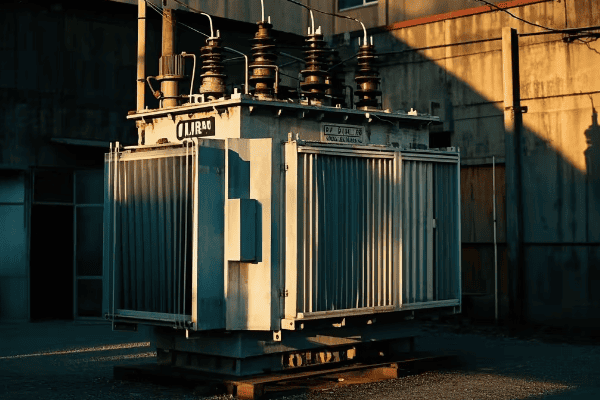

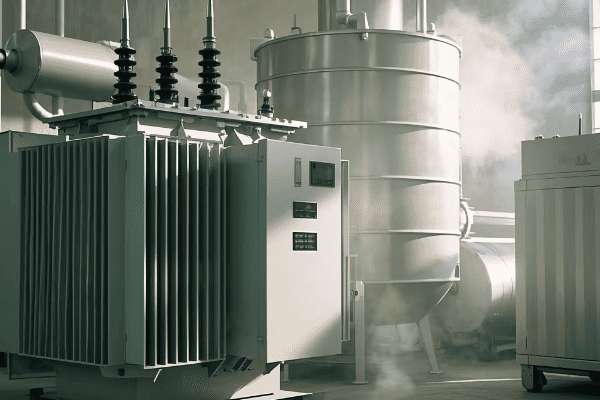

What Is a Station Transformer?

Many buyers and engineers struggle to understand what a station transformer is and why it’s essential for grid safety. Choosing the wrong transformer or ignoring its role can lead to costly outages, inefficiency, and safety risks. This guide explains station transformers, their types, prices, and technologies—helping you select the right solution for a stable and efficient power system

A station transformer is a large electrical device that converts high-voltage electricity from power plants to lower voltages suitable for distribution to homes and businesses. These transformers are essential components of power substations, capable of handling voltages up to 765,000 volts and weighing up to 400 tons. Without station transformers, our modern electrical grid simply couldn’t function.

As an electrical engineer with over 15 years of experience in power distribution, I’ve seen firsthand how crucial these transformers are to our daily lives. Let’s dive into the world of station transformers and uncover why they’re the unsung heroes of our electrical infrastructure.

How Do Station Transformers Work?

Ever wondered why we don’t just send electricity straight from power plants to our homes? The answer lies in the fascinating operation of station transformers.

Station transformers work on the principle of electromagnetic induction1. They use two sets of coils – primary and secondary – wound around an iron core. When alternating current passes through the primary coil, it creates a changing magnetic field, which induces a voltage in the secondary coil. By varying the number of turns in each coil, the transformer can step voltage up or down as needed.

station transformer working principle diagram

Here’s a breakdown of the process:

- High-voltage electricity enters the primary coil

- The alternating current creates a changing magnetic field in the iron core

- This magnetic field induces a voltage in the secondary coil

- The voltage in the secondary coil depends on the ratio of turns between primary and secondary coils

I once worked on a project to upgrade a substation where we installed a new 500 kV to 230 kV station transformer. The sheer size of the unit – about the size of a small house – was a stark reminder of the immense power these devices handle.

Key Takeaway: Station transformers are the vital link between power generation and distribution, enabling the safe and efficient transfer of electricity across vast distances.

Types of Station Transformers Explained

Did you know that not all station transformers are created equal? The type of transformer used can significantly impact the efficiency and reliability of power distribution.

Station transformers come in several types, including step-down transformers, step-up transformers, and autotransformers. The most common in distribution substations are step-down transformers, which reduce high transmission voltages to lower distribution voltages. Step-up transformers are used at power plants to increase voltage for long-distance transmission, while autotransformers are used for smaller voltage changes.

Here’s a quick comparison of the main types:

| Type | Primary Use | Typical Voltage Change |

|---|---|---|

| Step-Down | Distribution Substations | 500 kV to 69 kV |

| Step-Up | Power Plants | 20 kV to 765 kV |

| Autotransformer | Transmission Substations | 345 kV to 138 kV |

In my career, I’ve worked with all these types. I remember a particularly challenging project involving the installation of a massive step-up transformer at a new wind farm. The transformer was crucial in converting the 34.5 kV output from the wind turbines to 345 kV for long-distance transmission.

Key Takeaway: The choice of transformer type depends on its specific role in the power system, with each type optimized for certain voltage transformations.

Why Station Transformers Are Critical for Grid Stability

Have you ever experienced a widespread power outage? The stability of our electrical grid often hinges on the reliable operation of station transformers.