Are you struggling with power quality issues in your electrical system? Traditional transformers might not be enough. Electronic Power Transformers (EPTs) offer a solution, but many engineers are unsure about their benefits and applications.

Electronic Power Transformers combine power electronics with traditional transformer technology. They provide enhanced control over power flow, voltage regulation, and power quality. EPTs offer advantages in efficiency, power quality improvement, and integration with smart grids and renewable energy systems.

In this guide, I’ll break down the complexities of Electronic Power Transformers. We’ll explore their principles, advantages, components, and applications. Whether you’re designing a new system or upgrading an existing one, understanding EPTs is crucial for modern electrical engineering.

What is an Electronic Power Transformer: Definition and Basic Principles?

Have you ever wished for a transformer that could do more than just change voltage levels? That’s where Electronic Power Transformers come in. But what exactly are they, and how do they work?

An Electronic Power Transformer (EPT) is a hybrid device that combines traditional transformer technology with power electronics. It uses solid-state switches and control systems to manipulate power flow, providing enhanced control over voltage, current, and power quality.

Let’s dive deeper into the world of Electronic Power Transformers. Understanding their basic principles is crucial for grasping their potential in modern electrical systems.

Basic Structure of EPTs

-

Input Stage

- AC-DC conversion

- Often uses a rectifier

-

DC Link

- Energy storage

- Typically uses capacitors

-

Output Stage

- DC-AC conversion

- Uses inverter technology

Operating Principles

-

Power Flow Control

- Bidirectional power flow capability

- Independent control of active and reactive power

-

Voltage Regulation

- Fast and precise voltage control

- Can compensate for voltage sags and swells

-

Frequency Control

- Ability to change output frequency

- Useful for grid synchronization

| Component | Function | Advantage over Traditional Transformers |

|---|---|---|

| Input Stage | AC-DC Conversion | Allows for power flow control |

| DC Link | Energy Storage | Enables power buffering and smoothing |

| Output Stage | DC-AC Conversion | Provides flexible output control |

The concept of Electronic Power Transformers fascinated me when I first encountered it. It was during a project to integrate a large solar farm into the grid. We were facing issues with voltage fluctuations and power quality. Traditional transformers weren’t cutting it, and that’s when I delved into EPTs.

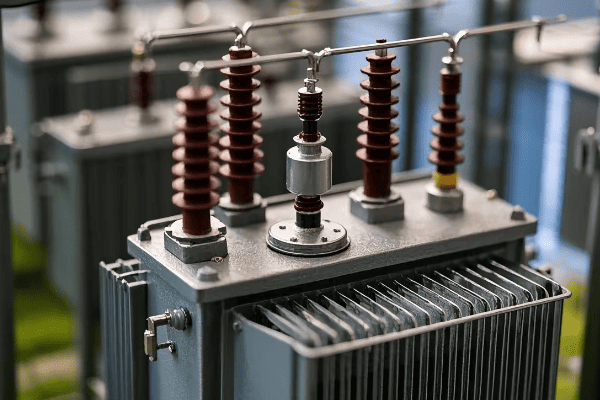

The basic structure of an EPT is quite different from a traditional transformer. It starts with an input stage that converts AC to DC. This is typically done using a rectifier. I remember being surprised at first – converting to DC in a transformer seemed counterintuitive. But this conversion is what gives EPTs their flexibility.

Next comes the DC link. This is usually a capacitor bank that serves as an energy storage buffer. It’s this component that allows EPTs to smooth out power fluctuations. In our solar farm project, this was crucial for dealing with the intermittent nature of solar power.

The output stage is where the magic really happens. It uses inverter technology to convert the DC back to AC. But here’s the key – this conversion can be precisely controlled. We can adjust the voltage, frequency, and phase angle of the output AC waveform.

This structure allows for some impressive operating principles. First, there’s power flow control. EPTs can handle bidirectional power flow, which is increasingly important in modern grids with distributed generation. They can also independently control active and reactive power. This was a game-changer in our solar farm project, allowing us to provide voltage support to the grid even when the sun wasn’t shining.

Voltage regulation is another key principle. EPTs can provide fast and precise voltage control, compensating for sags and swells in real-time. I’ve seen this capability solve power quality issues that had been plaguing industrial clients for years.

Frequency control is another fascinating aspect of EPTs. They can change the output frequency, which is particularly useful for grid synchronization. In one project, we used this feature to integrate a microgrid with the main grid, smoothly transitioning between grid-connected and islanded modes.

The advantages over traditional transformers are significant. The input stage allows for power flow control that’s simply not possible with a conventional transformer. The DC link provides a buffer that can smooth out power fluctuations. And the output stage offers a level of control over the output waveform that’s unmatched by traditional technology.

However, it’s important to note that EPTs are not a one-size-fits-all solution. They’re more complex and generally more expensive than traditional transformers. They also introduce harmonics due to the switching in the power electronic stages, which needs to be managed.

As we continue to push the boundaries of our power systems, with more renewable integration and smart grid technologies, I believe EPTs will play an increasingly important role. Their flexibility and control capabilities make them well-suited to the challenges of modern and future power systems.

Advantages of Electronic Power Transformers over Conventional Transformers?

Are you tired of the limitations of conventional transformers? Do voltage fluctuations and power quality issues keep you up at night? Electronic Power Transformers (EPTs) might be the solution you’re looking for.

Electronic Power Transformers offer several advantages over conventional transformers. These include improved voltage regulation, power factor correction, harmonic mitigation, and bidirectional power flow capability. EPTs also provide faster response to grid disturbances and better integration with smart grid systems.

Let’s explore the key advantages of Electronic Power Transformers in more detail. Understanding these benefits is crucial for engineers considering upgrades to their electrical systems.

Improved Voltage Regulation

-

Fast Response

- Can react to voltage changes in milliseconds

- Maintains stable voltage under varying load conditions

-

Wide Range

- Can handle larger voltage variations than conventional transformers

- Useful in weak grid conditions

Power Factor Correction

-

Dynamic Compensation

- Can adjust reactive power in real-time

- Improves overall system efficiency

-

Independent Control

- Can control active and reactive power separately

- Useful for grid support services

Harmonic Mitigation

-

Active Filtering

- Can cancel out harmonic currents

- Improves power quality for sensitive loads

-

Programmable Response

- Can be tuned to target specific harmonic frequencies

- Adaptable to changing load conditions

Other Advantages

-

Bidirectional Power Flow

- Supports integration of distributed generation

- Enables advanced grid functionalities

-

Size and Weight

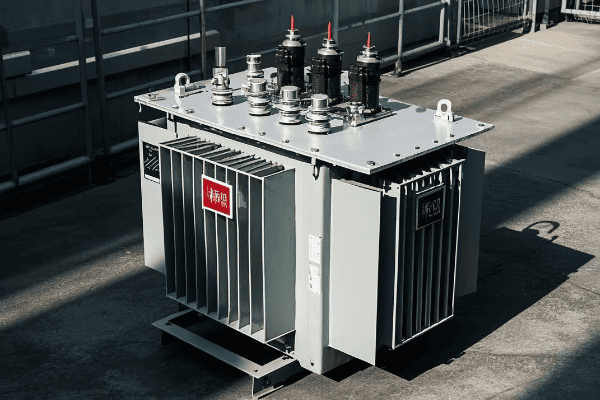

- Generally smaller and lighter than equivalent conventional transformers

- Easier installation and transportation

| Feature | Conventional Transformer | Electronic Power Transformer |

|---|---|---|

| Voltage Regulation | Passive, limited range | Active, wide range |

| Power Factor Correction | Requires separate equipment | Integrated capability |

| Harmonic Mitigation | Limited, passive | Active, programmable |

| Power Flow | Unidirectional | Bidirectional |

The advantages of Electronic Power Transformers over conventional transformers are significant and multifaceted. When I first started working with EPTs, I was amazed at their capabilities and the problems they could solve.

Let’s start with voltage regulation. Conventional transformers typically use tap changers for voltage adjustment, which are slow and have limited range. EPTs, on the other hand, can react to voltage changes in milliseconds. I remember a project at a manufacturing plant where voltage fluctuations were causing production issues. We installed an EPT, and the improvement was immediate. The voltage stayed rock-steady even under rapidly changing load conditions.

The wide range of voltage regulation is particularly useful in weak grid conditions. In one rural electrification project, we used EPTs to maintain stable voltage at the end of long distribution lines, something that would have been challenging with conventional transformers.

Power factor correction is another area where EPTs shine. Conventional systems often require separate capacitor banks for power factor correction. EPTs can dynamically adjust reactive power in real-time. This not only improves system efficiency but can also provide valuable grid support services. I’ve seen cases where utilities have incentivized the use of EPTs for this very reason.

The ability to independently control active and reactive power is a game-changer. In one project involving a large solar farm, we used this feature to provide voltage support to the grid even during nighttime when the solar panels weren’t generating power.

Harmonic mitigation is becoming increasingly important as we see more non-linear loads and power electronic devices on the grid. Conventional transformers offer limited, passive harmonic mitigation. EPTs, however, can actively cancel out harmonic currents. I’ve seen EPTs solve power quality issues in data centers and industrial facilities that had been struggling with harmonics for years.

The programmable nature of EPT harmonic mitigation is particularly useful. In one factory, we were able to tune the EPT to target specific harmonic frequencies that were causing issues with sensitive equipment. As the factory’s load profile changed over time, we could easily adjust the EPT’s response.

Bidirectional power flow capability is crucial for modern grids with high penetration of distributed generation. Conventional transformers are designed for unidirectional power flow from higher to lower voltage. EPTs can handle power flow in both directions, making them ideal for integrating rooftop solar, energy storage, and other distributed resources.

Size and weight advantages shouldn’t be overlooked. In urban substations where space is at a premium, the smaller footprint of EPTs can be a significant benefit. I’ve worked on substation upgrade projects where the compact size of EPTs allowed us to increase capacity without expanding the substation’s physical footprint.

However, it’s important to note that EPTs are not without challenges. They’re generally more expensive than conventional transformers and involve more complex control systems. They also introduce harmonics due to their switching operation, which needs to be managed.

Despite these challenges, I believe the advantages of EPTs make them a compelling choice for many modern power system applications. As we continue to push towards more flexible, resilient, and efficient grids, the role of EPTs is likely to grow.

Key Components of Electronic Power Transformers: Power Electronics and Control Systems?

Have you ever wondered what makes Electronic Power Transformers so versatile? The secret lies in their key components. But what are these components, and how do they work together to provide the advanced functionality of EPTs?

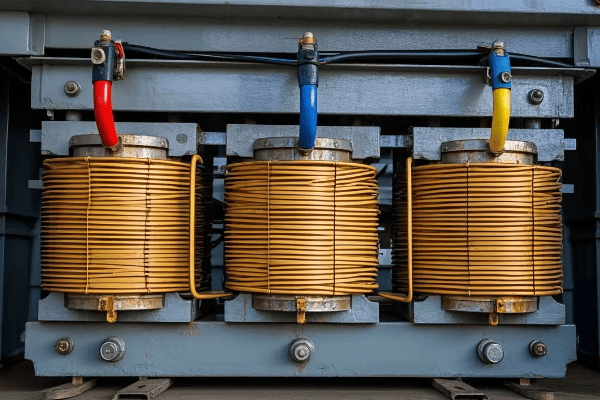

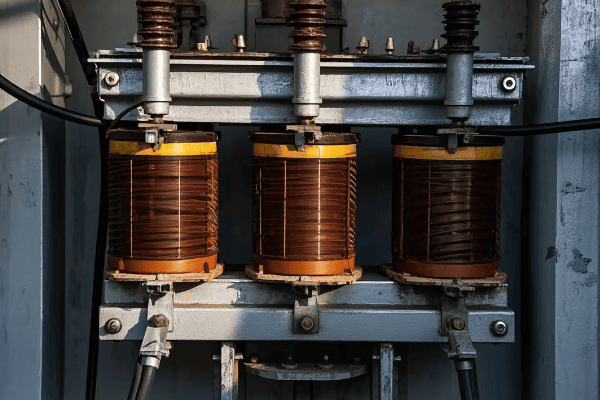

Electronic Power Transformers rely on two main component groups: power electronics and control systems. Power electronics include rectifiers, inverters, and DC link capacitors. Control systems comprise sensors, microprocessors, and software algorithms. Together, these enable the advanced features of EPTs.

Let’s delve into the key components of Electronic Power Transformers. Understanding these elements is crucial for grasping how EPTs achieve their advanced capabilities.

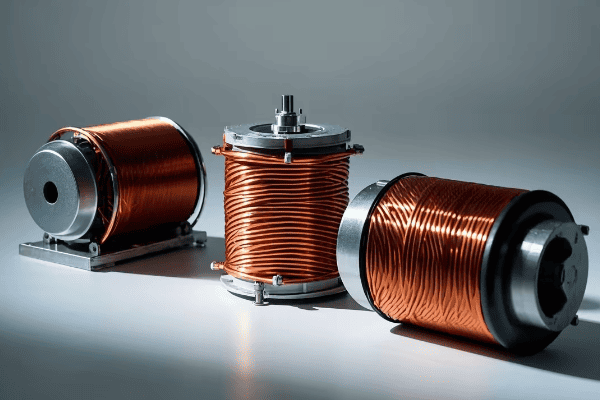

Power Electronics Components

-

Rectifier

- Converts AC to DC

- Often uses IGBTs or MOSFETs

-

DC Link

- Energy storage and smoothing

- Typically uses capacitors

-

Inverter

- Converts DC back to AC

- Allows for flexible output control

Control System Components

-

Sensors

- Voltage and current measurements

- Temperature and other operational parameters

-

Microprocessor

- Processes sensor data

- Executes control algorithms

-

Software

- Implements control strategies

- Manages protection functions

Other Key Components

-

Cooling System

- Manages temperature of power electronics

- Often uses forced air or liquid cooling

-

Protection Devices

- Overcurrent and overvoltage protection

- Fault detection and isolation

| Component | Function | Impact on EPT Performance |

|---|---|---|

| Rectifier | AC-DC Conversion | Enables power flow control |

| DC Link | Energy Storage | Smooths power fluctuations |

| Inverter | DC-AC Conversion | Provides flexible output |

| Microprocessor | Control Execution | Enables advanced features |

The key components of Electronic Power Transformers work together in a fascinating synergy to provide capabilities far beyond those of conventional transformers. When I first started working with EPTs, understanding these components and their interactions was crucial to effectively designing and troubleshooting systems.

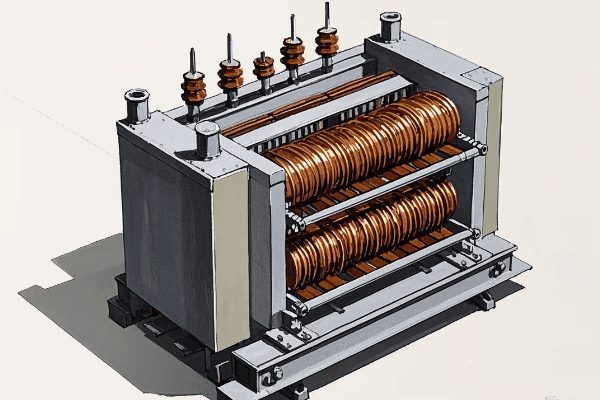

Let’s start with the power electronics components. The rectifier is the first stage, converting AC input to DC. This is typically done using high-power semiconductor switches like IGBTs (Insulated Gate Bipolar Transistors) or MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors). I remember being impressed by the efficiency of modern IGBTs when I first worked with them. Their fast switching speeds and low losses are key to the overall performance of EPTs.

The DC link, usually a bank of capacitors, serves as an energy buffer. This component is crucial for smoothing out power fluctuations and enabling the independent control of input and output. In one project involving a large industrial motor drive, the DC link allowed us to maintain a stable output voltage even when the input was fluctuating due to other loads on the system.

The inverter, which converts the DC back to AC, is where much of the magic happens. By controlling the switching of the inverter, we can precisely shape the output waveform. This allows for voltage regulation, frequency control, and even harmonic cancellation. I’ve seen inverters solve power quality issues that had been plaguing facilities for years.

Moving to the control system, sensors are the eyes and ears of the EPT. They continuously monitor voltages, currents, temperatures, and other parameters. The accuracy and speed of these sensors are crucial. In one project, we upgraded to high-speed digital sensors, which allowed for much faster response to grid disturbances.

The microprocessor is the brain of the EPT. It processes the sensor data and executes the control algorithms. The processing power of modern microprocessors allows for incredibly sophisticated control strategies. I remember being amazed at how we could implement complex adaptive control algorithms that would have been impossible just a few years earlier.

Software is where the control strategies are implemented. This includes everything from basic voltage regulation to advanced features like harmonic mitigation and grid support functions. The flexibility of software control is one of the biggest advantages of EPTs. In one project, we were able to completely change the behavior of an EPT through a software update, adapting it to new grid requirements without any hardware changes.

Cooling systems are often overlooked but are crucial for the reliable operation of EPTs. The high-frequency switching of power electronic components generates significant heat. In one data center project, we implemented a liquid cooling system for the EPTs, which allowed for higher power density and improved efficiency.

Protection devices are the last line of defense against faults. They need to be fast-acting and coordinated with the EPT’s control system. I’ve seen cases where well-designed protection systems prevented minor faults from cascading into major outages.

The interaction between these components is what gives EPTs their advanced capabilities. For example, the fast switching of the power electronics, combined with sophisticated control algorithms, allows for rapid voltage regulation. The energy storage in the DC link, coupled with bidirectional power flow capability, enables features like ride-through of short grid disturbances.

However, it’s important to note that the complexity of these components also presents challenges. Reliability can be an issue, especially in harsh environments. EMI (Electromagnetic Interference) from high-frequency switching needs to be carefully managed. And the cost of these advanced components is generally higher than for conventional transformers.

Despite these challenges, I believe the capabilities offered by these key components make EPTs a powerful tool for addressing the challenges of modern power systems. As we continue to see advancements in power electronics, control systems, and software, the potential of EPTs will only grow.

Topology and Design Considerations for Electronic Power Transformers?

Are you grappling with the complexities of designing an Electronic Power Transformer? The topology and design choices can seem overwhelming. But understanding these considerations is crucial for creating an EPT that meets your specific needs.

EPT topology and design involve choices in power electronic circuit configuration, control strategy, and physical layout. Key considerations include voltage and power ratings, efficiency, power quality requirements, and grid integration needs. The design process balances performance, cost, reliability, and specific application requirements.

Let’s explore the topology and design considerations for Electronic Power Transformers in more detail. This knowledge is essential for engineers involved in EPT development or selection.

Topology Considerations

-

Single-stage vs. Multi-stage

- Single-stage: Simpler, potentially more efficient

- Multi-stage: More flexible, better for high voltage applications

-

Modular vs. Integrated Design

- Modular: Easier maintenance, scalability

- Integrated: Potentially more compact and efficient

-

Bidirectional vs. Unidirectional

- Bidirectional: Supports reverse power flow, useful for renewable integration

- Unidirectional: Simpler, suitable for traditional load-supply scenarios

Design Considerations

-

Voltage and Power Ratings

- Determines component selection and overall size

- Influences efficiency and cost

-

Switching Frequency

- Higher frequency: Smaller passive components, potentially higher losses

- Lower frequency: Larger components, potentially lower losses

-

Control Strategy

- Determines EPT’s response to various grid conditions

- Influences power quality improvement capabilities

-

Thermal Management

- Crucial for reliability and efficiency

- Influences size and cost

Other Key Considerations

-

EMI/EMC

- Electromagnetic interference and compatibility

- Critical for grid integration and regulatory compliance

-

Protection and Fault Handling

- Determines EPT’s response to abnormal conditions

- Crucial for reliability and safety

| Consideration | Impact on Design | Trade-offs |

|---|---|---|

| Topology | Overall structure and capabilities | Complexity vs. Flexibility |

| Voltage/Power Rating | Component selection, size | Cost vs. Capacity |

| Switching Frequency | Size of passive components, losses | Efficiency vs. Size |

| Control Strategy | Performance in various scenarios | Complexity vs. Capability |

The topology and design of Electronic Power Transformers involve a complex interplay of various factors. When I first started working on EPT designs, I was struck by how each decision could have far-reaching implications for the transformer’s performance, cost, and reliability.

Let’s start with topology considerations. The choice between single-stage and multi-stage designs is often one of the first decisions to make. I remember a project where we initially went with a single-stage design for its simplicity and potentially higher efficiency. However, as the voltage requirements increased, we had to switch to a multi-stage approach to handle the higher voltages without overstressing individual components.

Modular versus integrated design is another key consideration. In one data center project, we opted for a modular design. This allowed for easier maintenance and the ability to scale up capacity as the data center grew. However, for a compact substation project, an integrated design was more suitable due to space constraints.

The choice between bidirectional and unidirectional power flow capability is becoming increasingly important with the growth of distributed energy resources. In a recent microgrid project, the bidirectional capability of our EPT design was crucial for managing power flow between the microgrid and the main grid.

Moving on to design considerations, voltage and power ratings are fundamental. These ratings drive many other design decisions, from component selection to cooling system design. I’ve seen cases where underestimating future power needs led to premature obsolescence of EPTs. It’s often worth considering future expansion plans when specifying these ratings.

Switching frequency is a critical parameter that affects many aspects of EPT performance. Higher switching frequencies allow for smaller passive components, potentially reducing the overall size of the EPT. However, they can also lead to higher switching losses and EMI issues. In one project, we had to reduce the switching frequency to meet EMC requirements, which required a redesign of the filtering components.

The control strategy is where much of the EPT’s advanced functionality is implemented. This includes voltage regulation, harmonic mitigation, and grid support functions. I’ve been amazed at how sophisticated these control strategies have become. In a recent project, we implemented an adaptive control algorithm that could optimize the EPT’s performance based on changing grid conditions.

Thermal management is often underappreciated but is crucial for the reliability and efficiency of EPTs. The high-frequency switching of power electronic components generates significant heat. In one industrial application, we had to design a liquid cooling system to handle the high power density and harsh environment.

EMI/EMC considerations are becoming increasingly important as EPTs are integrated into complex power systems. Ensuring that the EPT doesn’t interfere with other equipment and can withstand electromagnetic disturbances from the environment is crucial. I remember a case where EMI from an EPT was causing issues with nearby control systems. We had to redesign the EMI filtering and shielding to resolve the problem.

Protection and fault handling are critical for the safe and reliable operation of EPTs. This includes both internal protection of the EPT components and the EPT’s response to external grid faults. In one project, we implemented a sophisticated fault detection and isolation system that could reconfigure the EPT to maintain partial functionality even under certain fault conditions.

The interplay between these various considerations often leads to complex trade-offs. For example, increasing the switching frequency to reduce size might require more advanced (and expensive) semiconductor devices and more sophisticated thermal management. Implementing more advanced control strategies might require more powerful (and costly) processors.

One trend I’m seeing is the increasing use of wide-bandgap semiconductors like Silicon Carbide (SiC) and Gallium Nitride (GaN) in EPT designs. These devices allow for higher switching frequencies and temperatures, potentially leading to more compact and efficient designs. However, they also bring new challenges in terms of control, EMI, and thermal management.

Another interesting development is the use of artificial intelligence and machine learning in EPT control strategies. I’ve been involved in research projects exploring how these techniques can be used to optimize EPT performance in real-time, adapting to changing grid conditions and learning from past experiences.

As we continue to push the boundaries of EPT design, I believe we’ll see even more innovative topologies and design approaches. The challenge will be balancing the advanced capabilities of these designs with practical considerations of cost, reliability, and manufacturability. Whether you’re designing a new EPT or specifying one for your application, understanding these topology and design considerations is crucial for making informed decisions.

Power Quality Improvement with Electronic Power Transformers: Harmonics and Reactive Power Compensation?

Are power quality issues causing headaches in your electrical system? Harmonics and reactive power problems can lead to equipment malfunction, energy waste, and even system failures. Electronic Power Transformers offer a solution, but how exactly do they improve power quality?

Electronic Power Transformers can significantly improve power quality by actively mitigating harmonics and compensating for reactive power. They use advanced control algorithms and fast-switching power electronics to shape the current and voltage waveforms, reducing harmonic distortion and correcting power factor in real-time.

Let’s delve into how Electronic Power Transformers address power quality issues, focusing on harmonic mitigation and reactive power compensation. Understanding these capabilities is crucial for engineers dealing with power quality challenges.

Harmonic Mitigation

-

Active Harmonic Filtering

- Injects opposing harmonic currents to cancel out distortions

- Can target specific harmonic frequencies

-

Harmonic Isolation

- Prevents harmonics from propagating through the system

- Protects sensitive equipment from harmonic disturbances

-

Adaptive Control

- Adjusts filtering based on real-time harmonic content

- Effective for varying harmonic profiles

Reactive Power Compensation

-

Dynamic VAR Compensation

- Adjusts reactive power in real-time

- Improves power factor and voltage stability

-

Independent P-Q Control

- Allows separate control of active and reactive power

- Enables flexible grid support functions

-

Fast Response

- Reacts to changes in milliseconds

- Effective for rapidly changing loads

Other Power Quality Improvements

-

Voltage Regulation

- Maintains stable voltage under varying load conditions

- Mitigates voltage sags and swells

-

Flicker Reduction

- Compensates for rapid voltage fluctuations

- Improves power quality for sensitive loads

| Feature | Traditional Solution | EPT Solution |

|---|---|---|

| Harmonic Mitigation | Passive filters | Active, adaptive filtering |

| Reactive Power Compensation | Fixed capacitor banks | Dynamic, continuous adjustment |

| Response Time | Slow (cycles to seconds) | Fast (milliseconds) |

| Adaptability | Limited | Highly adaptable to changing conditions |

Power quality improvement is one of the most compelling features of Electronic Power Transformers. When I first started working with EPTs, I was amazed at their ability to address power quality issues that had been challenging to solve with traditional methods.

Let’s start with harmonic mitigation. Harmonics are a growing concern in modern power systems due to the proliferation of non-linear loads like variable frequency drives, LED lighting, and switch-mode power supplies. Traditional transformers do little to address harmonics, and passive harmonic filters have limitations in terms of their effectiveness and adaptability.

EPTs, on the other hand, can actively mitigate harmonics through a technique called active harmonic filtering. I remember a project at a large data center where harmonic distortion was causing overheating in neutral conductors and nuisance tripping of circuit breakers. We implemented an EPT with active harmonic filtering, and the improvement was dramatic. The EPT injected currents that precisely opposed the harmonic currents, effectively cancelling them out.

What’s particularly impressive about EPTs is their ability to target specific harmonic frequencies. In one industrial facility, we were able to program the EPT to focus on the 5th and 7th harmonics, which were the most problematic in that particular system. This level of precision is simply not possible with traditional harmonic mitigation techniques.

The adaptive nature of EPT harmonic control is another significant advantage. In systems where the harmonic content varies over time (for example, in a factory with different equipment running at different times), the EPT can continuously adjust its filtering to match the changing harmonic profile. I’ve seen this capability solve power quality issues that had been plaguing facilities for years.

Moving on to reactive power compensation, EPTs offer a level of control and responsiveness that’s unmatched by traditional methods. Conventional approaches often use fixed capacitor banks, which can only provide step changes in reactive power and may even exacerbate harmonic issues.

EPTs, in contrast, can provide dynamic VAR compensation, adjusting reactive power continuously and in real-time. I worked on a project involving a large induction motor that caused significant voltage dips when starting. The EPT’s ability to rapidly inject reactive power during motor start-up eliminated these voltage dips, improving the overall system stability.

The ability to independently control active and reactive power is another powerful feature of EPTs. This allows them to provide a wide range of grid support functions. In one project involving a solar farm, we used this capability to provide voltage support to the grid even when the solar panels weren’t generating power.

The speed of response of EPTs is truly impressive. They can react to changes in power quality in milliseconds, compared to the much slower response of traditional systems. This fast response is crucial for dealing with rapid load changes or transient events on the grid.

Beyond harmonics and reactive power, EPTs can address other power quality issues as well. Their voltage regulation capabilities can maintain stable voltage under varying load conditions, mitigating issues like voltage sags and swells. In one project involving a rural feeder with significant voltage drop issues, an EPT at the end of the line was able to maintain stable voltage despite large load variations.

Flicker reduction is another area where EPTs excel. By rapidly adjusting voltage in response to load changes, they can mitigate the rapid voltage fluctuations that cause visible flicker in lighting systems. I’ve seen this capability solve longstanding issues in industrial facilities with large, cyclical loads.

It’s worth noting that while EPTs are powerful tools for power quality improvement, they’re not a panacea. They introduce their own high-frequency switching noise, which needs to be managed. They also typically have higher losses than conventional transformers, although this is often offset by the energy savings from improved power quality.

As we continue to see increasing penetration of non-linear loads and distributed generation in our power systems, I believe the role of EPTs in power quality improvement will only grow. Their ability to adaptively and dynamically address a wide range of power quality issues makes them well-suited to the challenges of modern and future power systems.

Whether you’re dealing with harmonic distortion, poor power factor, voltage instability, or other power quality issues, EPTs offer a flexible and effective solution. Understanding their capabilities in this area is crucial for any engineer working on power quality challenges in modern electrical systems.

Integration of Electronic Power Transformers in Smart Grids and Renewable Energy Systems?

Are you struggling to integrate renewable energy sources into your grid? Or perhaps you’re looking to enhance the flexibility and resilience of your power system? Electronic Power Transformers (EPTs) could be the key, but how exactly do they fit into smart grids and renewable energy systems?

Electronic Power Transformers play a crucial role in smart grids and renewable energy integration. They provide bidirectional power flow control, voltage regulation, and power quality improvement. EPTs enable seamless integration of intermittent renewables, enhance grid stability, and support advanced grid functionalities like demand response and energy storage integration.

Let’s explore how Electronic Power Transformers are integrated into smart grids and renewable energy systems. Understanding this integration is crucial for engineers working on modern power system design and renewable energy projects.

Smart Grid Integration

-

Bidirectional Power Flow

- Enables integration of distributed energy resources

- Supports advanced grid functionalities like demand response

-

Real-Time Monitoring and Control

- Provides detailed data on power flow and quality

- Enables adaptive grid management

-

Grid Stability Enhancement

- Rapid response to grid disturbances

- Voltage and frequency support

Renewable Energy Integration

-

Voltage Regulation

- Manages voltage fluctuations from intermittent renewables

- Maintains grid stability with high renewable penetration

-

Harmonic Mitigation

- Addresses power quality issues from inverter-based generation

- Improves overall system efficiency

-

Fault Ride-Through

- Helps renewable sources stay connected during grid faults

- Enhances grid resilience

Other Integration Aspects

-

Energy Storage Interface

- Facilitates integration of battery systems

- Enables advanced functionalities like peak shaving

-

Microgrid Support

- Enables seamless transition between grid-connected and islanded modes

- Enhances local grid resilience

| Feature | Benefit in Smart Grids | Benefit in Renewable Integration |

|---|---|---|

| Bidirectional Power Flow | Enables prosumer participation | Facilitates feed-in from distributed generation |

| Voltage Regulation | Enhances grid stability | Manages fluctuations from intermittent sources |

| Real-Time Control | Enables adaptive grid management | Allows for optimal renewable utilization |

The integration of Electronic Power Transformers in smart grids and renewable energy systems is a fascinating area that’s rapidly evolving. When I first started working on these projects, I was amazed at how EPTs could address many of the challenges we were facing in modernizing our power systems.

Let’s start with smart grid integration. One of the key features of EPTs that makes them ideal for smart grids is their ability to handle bidirectional power flow. This is crucial in a world where consumers are increasingly becoming "prosumers" – both consuming and producing energy. I remember a project in a residential area with high rooftop solar penetration. The EPTs we installed could seamlessly manage power flow in both directions, allowing excess solar power to be fed back into the grid during the day and drawing power from the grid at night.

The real-time monitoring and control capabilities of EPTs are another major advantage in smart grid applications. EPTs can provide detailed, high-resolution data on power flow, voltage levels, power quality, and other parameters. In one project, we used this data to implement an advanced distribution management system that could dynamically optimize grid operation based on real-time conditions.

Grid stability enhancement is another crucial role of EPTs in smart grids. Their ability to respond rapidly to grid disturbances can significantly improve system stability. I’ve seen cases where EPTs were able to maintain voltage stability during large load changes that would have caused issues in a conventional system.

Moving on to renewable energy integration, voltage regulation is a key challenge that EPTs can address. The intermittent nature of many renewable sources, particularly solar and wind, can cause significant voltage fluctuations. In one large solar farm project, we used EPTs to manage these fluctuations, maintaining stable voltage even with rapidly changing solar output.

Harmonic mitigation is another important aspect of renewable integration. Inverter-based generation sources like solar PV can introduce harmonics into the grid. EPTs can actively filter these harmonics, improving overall power quality. In a project involving a mix of wind and solar generation, the EPTs’ harmonic mitigation capabilities were crucial in meeting grid code requirements.

Fault ride-through capability is becoming increasingly important as the penetration of renewables increases. Grid codes in many areas now require renewable sources to stay connected and support the grid during fault conditions. EPTs can help achieve this by providing voltage support during faults and helping manage the reconnection process after the fault clears.

The role of EPTs in interfacing with energy storage systems is an exciting area of development. In one microgrid project, we used EPTs to manage the interface between a large battery system and the grid. The EPTs’ ability to control both active and reactive power independently was crucial for implementing advanced functionalities like peak shaving and voltage support.

Speaking of microgrids, EPTs can play a vital role in enabling seamless transitions between grid-connected and islanded modes. I worked on a campus microgrid project where EPTs were key to maintaining stable operation in both modes and managing the transition between them.

It’s worth noting that while EPTs offer many advantages in these applications, they also present some challenges. Their complex control systems require careful integration with existing grid management systems. EMI issues need to be carefully managed, especially in systems with multiple EPTs. And the higher cost of EPTs compared to conventional transformers needs to be justified by the additional functionalities they provide.

One trend I’m seeing is the increasing use of artificial intelligence and machine learning in conjunction with EPTs. These technologies can help optimize the operation of EPTs in complex, dynamic grid environments. I’m currently involved in a research project exploring how AI can be used to predict grid disturbances and preemptively adjust EPT settings to enhance stability.

Another interesting development is the use of EPTs in hybrid AC/DC systems. As we see more DC loads and generation sources, EPTs’ ability to interface between AC and DC systems becomes increasingly valuable. I recently worked on a project where EPTs were used to create a hybrid AC/DC distribution system in a large industrial facility, significantly improving energy efficiency.

The role of EPTs in enabling vehicle-to-grid (V2G) technology is also worth mentioning. As electric vehicles become more prevalent, their potential to act as distributed energy storage becomes significant. EPTs can facilitate the bidirectional power flow required for V2G applications, potentially turning electric vehicle fleets into valuable grid assets.

As we continue to push towards more renewable energy integration and smarter, more flexible grids, I believe the role of EPTs will only grow. Their ability to provide precise, dynamic control over power flow and quality makes them ideally suited to the challenges of modern and future power systems.

Whether you’re working on integrating large-scale renewables, designing a microgrid, or implementing advanced smart grid functionalities, understanding the capabilities and integration considerations of EPTs is crucial. These devices are not just transformers; they’re key enablers of the clean, smart, and flexible power systems of the future.

Efficiency and Loss Reduction in Electronic Power Transformers: Advanced Techniques?

Are you concerned about the efficiency of your power system? With energy costs rising and environmental concerns growing, minimizing losses in power equipment is more important than ever. But how do Electronic Power Transformers stack up in terms of efficiency, and what advanced techniques are used to reduce losses?

Electronic Power Transformers employ several advanced techniques to improve efficiency and reduce losses. These include the use of wide-bandgap semiconductors, advanced magnetic materials, optimized switching strategies, and intelligent cooling systems. While EPTs introduce switching losses, their ability to optimize power flow can lead to overall system efficiency improvements.

Let’s explore the advanced techniques used to improve efficiency and reduce losses in Electronic Power Transformers. Understanding these methods is crucial for engineers looking to optimize their power systems.

Advanced Semiconductor Technologies

-

Wide-Bandgap Semiconductors

- Silicon Carbide (SiC) and Gallium Nitride (GaN) devices

- Higher switching frequencies with lower losses

-

Advanced Packaging

- Improved thermal management

- Reduced parasitic inductances

Magnetic Component Optimization

-

Advanced Core Materials

- Nanocrystalline and amorphous metals

- Reduced core losses at high frequencies

-

Optimized Winding Designs

- Litz wire for high-frequency applications

- Interleaved windings to reduce leakage inductance

Intelligent Control Strategies

-

Soft-Switching Techniques

- Zero Voltage Switching (ZVS) and Zero Current Switching (ZCS)

- Significantly reduces switching losses

-

Adaptive Switching Frequency

- Adjusts switching frequency based on load conditions

- Balances between switching losses and passive component size

Thermal Management

-

Advanced Cooling Systems

- Liquid cooling for high-power applications

- Phase-change materials for thermal buffering

-

Temperature-Aware Control

- Adjusts operation based on component temperatures

- Maximizes efficiency while ensuring reliability

| Technique | Primary Benefit | Potential Drawback |

|---|---|---|

| Wide-Bandgap Semiconductors | Lower switching losses | Higher cost |

| Advanced Core Materials | Reduced core losses | Material cost and availability |

| Soft-Switching | Lower switching losses | Increased control complexity |

| Liquid Cooling | Better thermal management | System complexity and maintenance |

Efficiency and loss reduction in Electronic Power Transformers is a fascinating and rapidly evolving field. When I first started working with EPTs, I was initially concerned about the additional losses introduced by the power electronic stages. However, I’ve been amazed at how advanced techniques have not only mitigated these losses but in many cases led to overall system efficiency improvements.

Let’s start with advanced semiconductor technologies. The introduction of wide-bandgap semiconductors like Silicon Carbide (SiC) and Gallium Nitride (GaN) has been a game-changer. These materials allow for higher switching frequencies with lower losses compared to traditional silicon devices. I remember a project where we upgraded an EPT from silicon IGBTs to SiC MOSFETs. The reduction in switching losses was significant, allowing us to increase the switching frequency and reduce the size of passive components without sacrificing efficiency.

Advanced packaging techniques are also playing a crucial role. By improving thermal management and reducing parasitic inductances, these techniques allow the semiconductor devices to operate more efficiently. In one high-power EPT design, we used advanced packaging with integrated cooling to significantly improve the power density and efficiency.

Moving on to magnetic components, the use of advanced core materials has been crucial in reducing losses, especially at high frequencies. Nanocrystalline and amorphous metal cores can significantly reduce core losses compared to traditional silicon steel. I worked on a project where replacing the core material in an EPT’s high-frequency transformer stage led to a notable improvement in overall efficiency.

Optimized winding designs are another area of focus. The use of Litz wire in high-frequency applications can significantly reduce skin effect losses. Interleaved windings can reduce leakage inductance, improving efficiency and reducing electromagnetic emissions. These techniques require careful design and can be more expensive, but the efficiency gains often justify the additional cost.

Intelligent control strategies are perhaps the most exciting area of development in EPT efficiency improvement. Soft-switching techniques like Zero Voltage Switching (ZVS) and Zero Current Switching (ZCS) can dramatically reduce switching losses. I remember being skeptical about the complexity of implementing these techniques in a high-power system, but the efficiency gains we achieved in one project were truly impressive.

Adaptive switching frequency is another intelligent control strategy that can optimize efficiency across different operating conditions. By adjusting the switching frequency based on load conditions, we can balance between switching losses and the size of passive components. In one project involving an EPT for a variable renewable energy source, this adaptive approach allowed us to maintain high efficiency across a wide range of operating conditions.

Thermal management is crucial for both efficiency and reliability. Advanced cooling systems, including liquid cooling for high-power applications, can significantly improve efficiency by keeping component temperatures low. In one data center project, we used a combination of liquid cooling and phase-change materials to manage thermal transients, allowing the EPT to operate more efficiently even under rapidly changing load conditions.

Temperature-aware control strategies take thermal management a step further. By adjusting the EPT’s operation based on real-time temperature measurements, we can maximize efficiency while ensuring long-term reliability. I’ve seen this approach extend the operational life of EPTs in harsh industrial environments.

It’s worth noting that while these advanced techniques can significantly improve EPT efficiency, they often come with trade-offs in terms of cost, complexity, or reliability. The choice of which techniques to employ should be based on a careful analysis of the specific application requirements and overall system considerations.

One trend I’m seeing is the increasing use of digital twin technology in EPT design and operation. By creating a detailed digital model of the EPT, we can simulate and optimize its performance under a wide range of conditions. This allows for more efficient designs and can also be used for predictive maintenance, further improving long-term efficiency.

Another exciting development is the use of AI and machine learning in EPT control. These technologies can potentially optimize EPT operation in real-time, adapting to changing grid conditions and load profiles to maximize efficiency. I’m currently involved in a research project exploring how reinforcement learning can be used to develop adaptive control strategies for EPTs.

As we continue to push the boundaries of power electronic technologies and control strategies, I believe we’ll see further improvements in EPT efficiency. The challenge will be balancing these advanced techniques with practical considerations of cost, reliability, and manufacturability.

Whether you’re designing a new EPT, upgrading an existing system, or simply trying to optimize your power system’s efficiency, understanding these advanced techniques for efficiency improvement and loss reduction is crucial. EPTs are not just about functionality; with the right design and control strategies, they can be powerful tools for improving overall system efficiency.

Applications and Future Trends of Electronic Power Transformers in Modern Electrical Systems?

Are you wondering how Electronic Power Transformers fit into the evolving landscape of electrical systems? Or perhaps you’re curious about where this technology is headed? EPTs are finding their way into a wide range of applications, and the future looks bright with emerging trends.

Electronic Power Transformers are increasingly used in renewable energy integration, smart grids, industrial power systems, and electric vehicle charging infrastructure. Future trends include advanced grid services, integration with energy storage, use in HVDC systems, and the development of solid-state transformers. EPTs are poised to play a crucial role in the transition to more flexible, efficient, and resilient power systems.

Let’s explore the current applications and future trends of Electronic Power Transformers in modern electrical systems. This knowledge is essential for engineers and decision-makers planning for the future of power systems.

Current Applications

-

Renewable Energy Integration

- Managing intermittency and power quality issues

- Facilitating grid connection of large-scale renewables

-

Smart Grid Implementation

- Enabling bidirectional power flow

- Providing real-time grid management capabilities

-

Industrial Power Systems

- Improving power quality for sensitive processes

- Enhancing energy efficiency in manufacturing

-

Electric Vehicle Charging Infrastructure

- Managing high-power, variable loads

- Enabling vehicle-to-grid (V2G) functionality

Future Trends

-

Advanced Grid Services

- Synthetic inertia provision

- Dynamic grid support functions

-

Integration with Energy Storage

- Hybrid transformer-battery systems

- Enhanced grid stability and resilience

-

HVDC and Flexible AC Transmission Systems (FACTS)

- EPTs as key components in HVDC converter stations

- Advanced power flow control in transmission systems

-

Solid-State Transformers

- Fully electronic transformers without traditional magnetic cores

- Potential for significant size and weight reduction

| Application/Trend | Key Benefit | Challenges |

|---|---|---|

| Renewable Integration | Manages intermittency | High power requirements |

| Smart Grids | Enables advanced functionalities | Complex control systems |

| Industrial Systems | Improves power quality | Cost justification |

| EV Charging | Handles variable high-power loads | Fast response requirements |

| Solid-State Transformers | Size and weight reduction | Technology maturity |

The applications and future trends of Electronic Power Transformers in modern electrical systems are truly exciting. As someone who’s been working with this technology for years, I’m continually amazed at how EPTs are evolving and finding new roles in our power systems.

Let’s start with current applications. In renewable energy integration, EPTs are proving to be invaluable. I remember a project involving a large offshore wind farm where EPTs played a crucial role in managing the variable power output and ensuring power quality standards were met. The ability of EPTs to provide voltage support and harmonic mitigation was key to successfully integrating this large renewable source into the grid.

In smart grid implementations, the bidirectional power flow capability of EPTs is a game-changer. I worked on a smart city project where EPTs were used at key points in the distribution network. They enabled seamless integration of distributed energy resources and provided real-time data for advanced grid management. The level of control and visibility we achieved was far beyond what’s possible with conventional transformers.

Industrial power systems are another area where EPTs are making a big impact. In one manufacturing facility, we used EPTs to address severe power quality issues that were affecting sensitive production equipment. The EPTs’ ability to mitigate harmonics and provide stable voltage not only improved product quality but also reduced equipment downtime, resulting in significant cost savings for the client.

The role of EPTs in electric vehicle charging infrastructure is rapidly growing. I recently worked on a project for a large EV charging station where EPTs were crucial in managing the high-power, highly variable loads. The fast response of EPTs allowed for efficient load balancing and power factor correction, ensuring stable operation even with multiple vehicles charging simultaneously.

Looking to the future, I’m particularly excited about the potential of EPTs in providing advanced grid services. The concept of synthetic inertia, where EPTs emulate the inertial response of traditional generators, could be crucial as we move towards grids with high penetration of inverter-based resources. I’m currently involved in a research project exploring how EPTs can provide fast frequency response and dynamic voltage support to enhance grid stability.

The integration of EPTs with energy storage is another trend I’m watching closely. I’ve seen concepts for hybrid transformer-battery systems that could provide enhanced grid stability and resilience. Imagine a distribution transformer that not only steps down voltage but also provides local energy storage for outage ride-through and peak shaving. The potential for improving grid reliability is enormous.

In the realm of high-voltage transmission, EPTs are set to play a significant role in HVDC and Flexible AC Transmission Systems (FACTS). I’ve been following developments where EPTs are being considered as key components in HVDC converter stations. Their ability to provide precise, rapid control over power flow could revolutionize how we manage our transmission systems.

Perhaps the most radical future trend is the development of solid-state transformers. These are fully electronic transformers without traditional magnetic cores. While still in the early stages, the potential for significant size and weight reduction is exciting. I’ve seen prototypes that are a fraction of the size of conventional transformers with equivalent ratings. However, there are still challenges to overcome in terms of efficiency and reliability before we see widespread adoption.

It’s worth noting that while these applications and trends are exciting, they also come with challenges. The high power requirements for renewable integration and EV charging push the limits of current power electronic technologies. The complex control systems required for smart grid applications can be challenging to design and maintain. And in many cases, the higher cost of EPTs compared to conventional transformers needs to be justified by the additional functionalities they provide.

One trend I’m seeing is the increasing use of modular, scalable EPT designs. This approach allows for more flexible deployment and easier maintenance. I worked on a project where we used a modular EPT system in a large industrial facility. The ability to easily add or replace modules as power requirements changed was a significant advantage.

Another interesting development is the use of EPTs in microgrid applications. As we see more interest in resilient, locally controlled power systems, EPTs’ ability to manage bidirectional power flow and provide advanced grid support functions makes them ideal for microgrid implementations.

The integration of AI and machine learning with EPTs is also an area of rapid development. I’m currently involved in a project exploring how these technologies can be used to optimize EPT operation in real-time, adapting to changing grid conditions and predicting potential issues before they occur.

As we move towards more distributed, renewable-based, and digitally controlled power systems, I believe EPTs will play an increasingly crucial role. Their flexibility, controllability, and advanced functionalities make them well-suited to the challenges of modern and future electrical systems.

Whether you’re planning a new power system, upgrading existing infrastructure, or simply trying to understand where the industry is headed, keeping an eye on the applications and trends in EPT technology is crucial. These devices are not just transformers; they’re key enablers of the flexible, efficient, and resilient power systems of the future.

Conclusion

Electronic Power Transformers represent a significant leap in transformer technology. They offer enhanced control, improved power quality, and better integration with modern grid systems. As power systems evolve, EPTs will play a crucial role in enabling smarter, more efficient, and more resilient electrical infrastructure.

Are you confused by power transformer ratings? You’re not alone. Many engineers struggle to understand these complex specifications, but they’re crucial for proper transformer selection and operation.

Power transformer ratings are essential specifications that define a transformer’s capacity, voltage levels, and operating limits. They include parameters like kVA/MVA ratings, voltage ratings, current ratings, impedance, temperature rise, and efficiency. Understanding these ratings is crucial for proper transformer selection and safe operation.

In this guide, I’ll break down the complexities of power transformer ratings. We’ll explore each key parameter, its significance, and how it impacts transformer performance and system design. Let’s dive in and demystify these critical specifications.

What is Power Transformer Rating: Key Parameters and Their Significance?

Have you ever looked at a transformer nameplate and felt overwhelmed by the numbers? You’re not alone. Transformer ratings can seem like a jumble of figures, but each one is crucial for safe and efficient operation.

Power transformer ratings are a set of key parameters that define a transformer’s operational capabilities and limits. These include power capacity (kVA/MVA), voltage ratings, current ratings, impedance, temperature rise, and efficiency. Each parameter plays a vital role in transformer selection and system design.

Let’s dive deeper into these key parameters and their significance. Understanding these ratings is essential for any electrical engineer working with power systems.

Power Capacity Rating

-

kVA/MVA Rating

- Defines the transformer’s power handling capacity

- Based on voltage and current ratings

-

Continuous vs. Short-time Ratings

- Continuous rating for normal operation

- Short-time ratings for temporary overloads

Voltage Ratings

-

Primary and Secondary Voltages

- Defines input and output voltage levels

- Critical for system compatibility

-

Tap Settings

- Allows for voltage adjustment

- Helps maintain system voltage stability

Current Ratings

-

Full Load Current

- Maximum current at rated kVA and voltage

- Used for sizing conductors and protection devices

-

Inrush Current

- Initial surge when energizing the transformer

- Important for protection system design

Other Key Ratings

-

Impedance

- Affects short-circuit current and voltage regulation

- Critical for system protection coordination

-

Temperature Rise

- Indicates thermal performance

- Linked to insulation life and loading capacity

-

Efficiency

- Measure of transformer losses

- Important for operational cost calculations

| Rating Parameter | Typical Units | Significance |

|---|---|---|

| Power Capacity | kVA or MVA | Defines overall capacity |

| Voltage | kV | Determines system compatibility |

| Current | A | Used for conductor and protection sizing |

| Impedance | % | Affects short-circuit behavior |

| Temperature Rise | °C | Indicates thermal performance |

| Efficiency | % | Reflects energy losses |

Understanding transformer ratings is crucial for proper selection, operation, and maintenance of these vital components in our power systems. Each rating parameter provides important information about the transformer’s capabilities and limitations.

The power capacity rating, typically expressed in kVA (kilovolt-amperes) or MVA (megavolt-amperes), is perhaps the most fundamental. It defines the maximum power the transformer can handle continuously under rated conditions. I remember a project where we had to upgrade a substation transformer. The existing 10 MVA unit was consistently overloaded during peak hours, leading to accelerated aging. We replaced it with a 15 MVA transformer, which not only resolved the overloading issue but also provided capacity for future load growth.

Voltage ratings are equally critical. They define the input and output voltage levels the transformer is designed to handle. Mismatched voltage ratings can lead to disastrous consequences. Early in my career, I witnessed the aftermath of a 13.8 kV transformer mistakenly connected to a 34.5 kV line. The result was a spectacular failure that I’ll never forget. It drove home the importance of always double-checking voltage ratings before energizing a transformer.

Current ratings are derived from the power and voltage ratings. The full load current rating is particularly important for sizing conductors and protection devices. Inrush current, which occurs when the transformer is first energized, can be several times the full load current. This needs to be considered in protection system design to avoid nuisance tripping during transformer energization.

Impedance rating, typically expressed as a percentage, is a key parameter that affects the transformer’s behavior under short-circuit conditions and its voltage regulation characteristics. A higher impedance limits short-circuit currents but results in poorer voltage regulation. I’ve seen cases where improper consideration of transformer impedance led to coordination issues in the protection system.

Temperature rise rating is linked to the insulation system and directly affects the transformer’s life expectancy and loading capacity. A lower temperature rise generally indicates a more conservatively designed transformer that can handle overloads better. However, it usually comes at the cost of higher initial expense and larger size.

Efficiency ratings have become increasingly important in recent years due to energy cost and environmental considerations. Even a small improvement in efficiency can lead to significant energy savings over the transformer’s lifetime. I once worked on a project where replacing old, inefficient transformers with modern, high-efficiency units resulted in annual energy savings that paid for the upgrade in just a few years.

Understanding these ratings is not just about knowing what the numbers mean. It’s about understanding how they interrelate and impact the overall system design. For instance, a transformer with a higher impedance might be chosen to limit short-circuit currents, but this decision would need to be balanced against the resulting poorer voltage regulation.

As we delve deeper into each of these parameters in the following sections, keep in mind that transformer rating is not just about individual numbers. It’s about how these parameters work together to define the transformer’s place and performance in the power system. Whether you’re selecting a new transformer, troubleshooting an existing one, or designing a power system, a thorough understanding of these ratings is essential.

Understanding kVA and MVA Ratings: Capacity and Load Considerations?

Have you ever wondered why transformers are rated in kVA or MVA instead of kilowatts or megawatts? This seemingly small detail is actually crucial for understanding transformer capacity and load considerations.

kVA (kilovolt-ampere) and MVA (megavolt-ampere) ratings define a transformer’s apparent power capacity. Unlike watt ratings, they account for both real and reactive power. This is crucial because transformers must handle the total apparent power, regardless of the power factor.

Let’s dive deeper into kVA and MVA ratings and explore how they relate to transformer capacity and load considerations. This understanding is essential for proper transformer selection and system design.

kVA and MVA Basics

-

Definition

- kVA = kilovolt-amperes (1000 VA)

- MVA = megavolt-amperes (1,000,000 VA)

-

Relationship to Watts

- kVA = kW / power factor

- Accounts for both real and reactive power

Capacity Considerations

-

Nameplate Rating

- Maximum continuous load capacity

- Based on thermal limitations

-

Overload Capacity

- Short-term ratings above nameplate

- Depends on ambient temperature and load profile

Load Considerations

-

Power Factor Impact

- Lower power factor requires larger kVA rating

- Important in industrial applications

-

Load Profile

- Continuous vs. intermittent loads

- Peak load vs. average load

| Aspect | kVA/MVA Rating | kW Rating |

|---|---|---|

| Power Type | Apparent Power | Real Power |

| Reactive Power | Included | Not Included |

| Transformer Sizing | Directly Applicable | Needs Power Factor Adjustment |

| Load Calculation | Suitable for All Loads | Only for Resistive Loads |

Understanding kVA and MVA ratings is fundamental to working with transformers and power systems. These ratings represent the transformer’s apparent power capacity, which is a crucial concept in AC power systems.

Let’s start with the basics. kVA stands for kilovolt-amperes, which is 1000 volt-amperes. MVA is megavolt-amperes, or 1,000,000 volt-amperes. These units measure apparent power, which is the total power in an AC circuit, including both real power (measured in watts) and reactive power (measured in vars).

I remember a situation early in my career where this distinction became very clear. We were working on a project to power a large industrial facility with numerous induction motors. The client had initially specified the transformer based on the total kilowatt rating of their equipment. However, because many of their loads had a low power factor, the actual kVA requirement was much higher. We had to explain that the transformer needed to be sized based on the kVA demand, not just the kW, to avoid overloading.

The relationship between kVA and kW is straightforward: kVA = kW / power factor. This means that for a given kW load, a lower power factor results in a higher kVA requirement. This is why transformers are rated in kVA or MVA – they must be capable of handling the total apparent power, regardless of the power factor of the load.

When it comes to capacity considerations, the nameplate kVA or MVA rating represents the maximum continuous load the transformer can handle under rated conditions. This rating is primarily based on the transformer’s thermal limitations – the maximum temperature rise that the insulation system can handle continuously.

However, transformers often have some overload capacity for short periods. This is where things get interesting. The actual overload capacity depends on factors like ambient temperature, load profile, and the transformer’s thermal time constants. I once worked on a project where we needed to temporarily overload a transformer during a substation upgrade. We had to carefully calculate the allowable overload based on the transformer’s characteristics and the expected load profile to ensure we didn’t compromise its long-term reliability.

Load considerations are crucial when working with kVA and MVA ratings. Power factor is a key aspect. Loads with low power factors, like induction motors or lightly loaded power electronic equipment, require larger kVA ratings for a given kW output. This is particularly important in industrial applications where large motor loads are common.

The load profile is another critical consideration. A transformer’s rating is based on continuous load, but many applications have varying load profiles. I remember a project involving a transformer for a welding shop. The load was highly intermittent, with short periods of very high demand followed by longer periods of low demand. We had to carefully analyze the load profile to select a transformer that could handle the peak loads without being oversized for the average demand.

It’s also worth noting that while transformers are rated in kVA or MVA, efficiency and loss calculations are typically done in kW. This means we often need to convert between the two, taking into account the expected power factor of the load.

Understanding kVA and MVA ratings is not just about selecting the right size transformer. It’s about understanding how the transformer will interact with the entire power system. For example, a transformer with a higher kVA rating than necessary might lead to higher inrush currents during energization, potentially causing issues with protection systems.

As we move towards more complex power systems with increasing amounts of non-linear loads and distributed generation, understanding these ratings becomes even more critical. The ability to properly interpret and apply kVA and MVA ratings is a key skill for any electrical engineer working with power systems.

Voltage Ratings in Power Transformers: Primary, Secondary, and Tap Settings?

Have you ever wondered why transformers have multiple voltage ratings? Or why some transformers have taps while others don’t? Understanding voltage ratings and tap settings is crucial for proper transformer operation and system voltage control.

Voltage ratings in power transformers define the primary and secondary voltage levels. Primary voltage is the input, while secondary is the output. Tap settings allow for voltage adjustment, typically ±5% in 2.5% steps. These ratings and settings are crucial for system compatibility and voltage regulation.

Let’s explore the intricacies of voltage ratings and tap settings in power transformers. This knowledge is essential for system design, transformer selection, and voltage regulation strategies.

Primary and Secondary Voltage Ratings

-

Primary Voltage

- Input voltage from the source

- Typically higher in step-down transformers

-

Secondary Voltage

- Output voltage to the load

- Typically lower in step-down transformers

-

Voltage Ratio

- Relationship between primary and secondary voltages

- Determines the transformer’s turns ratio

Tap Settings

-

Purpose

- Allow for voltage adjustment

- Compensate for system voltage variations

-

Types of Taps

- No-load taps (de-energized changes)

- On-load tap changers (OLTC)

-

Typical Range

- Often ±5% in 2.5% steps

- Can vary based on specific requirements

Voltage Regulation

-

Definition

- Change in secondary voltage from no-load to full-load

- Expressed as a percentage of rated voltage

-

Factors Affecting Regulation

- Transformer impedance

- Load power factor

| Aspect | Primary Voltage | Secondary Voltage | Tap Settings |

|---|---|---|---|

| Typical Location | Source Side | Load Side | Primary or Secondary |

| Purpose | System Input | Load Supply | Voltage Adjustment |

| Variation | Fixed | Fixed | Adjustable |

| Impact on Ratio | Reference | Determined by Turns Ratio | Modifies Effective Ratio |

Voltage ratings and tap settings are fundamental aspects of transformer design and operation. They play a crucial role in ensuring system compatibility, maintaining voltage levels, and adapting to changing network conditions.

Let’s start with primary and secondary voltage ratings. The primary voltage rating corresponds to the input voltage from the source, while the secondary voltage rating is the output voltage delivered to the load. In a step-down transformer, which is common in distribution systems, the primary voltage is higher than the secondary. The reverse is true for step-up transformers, typically used in power generation plants.

I remember a project early in my career where we were replacing an old 34.5 kV / 4.16 kV transformer in an industrial facility. The new transformer had to match these voltage ratings exactly to ensure compatibility with the existing system. Any mismatch could have led to equipment damage or system instability.

The relationship between the primary and secondary voltages defines the transformer’s voltage ratio, which in turn determines its turns ratio. This ratio is crucial for the transformer’s basic operation. For example, a transformer with a 10:1 voltage ratio will have approximately 10 times as many turns in its primary winding as in its secondary winding.

Now, let’s talk about tap settings. Taps are connections on transformer windings that allow for voltage adjustment. They’re incredibly useful for compensating for voltage variations in the power system. I’ve seen many cases where tap settings made the difference between acceptable and unacceptable voltage levels at the load.

There are two main types of taps: no-load taps and on-load tap changers (OLTC). No-load taps can only be changed when the transformer is de-energized. They’re simpler and less expensive, but less flexible. OLTCs, on the other hand, allow for voltage adjustment while the transformer is energized and under load. They’re more complex and expensive, but provide dynamic voltage control.

The typical tap range is often ±5% in 2.5% steps, although this can vary based on specific requirements. This means the voltage can be adjusted up or down by up to 5% of the rated voltage, in 2.5% increments. I once worked on a project where we needed a wider tap range due to significant voltage variations in the local grid. We ended up specifying a transformer with a ±10% tap range, which was crucial for maintaining stable voltage at the load.

Voltage regulation is another important concept related to transformer voltage ratings. It refers to the change in secondary voltage from no-load to full-load conditions, expressed as a percentage of rated voltage. A lower percentage indicates better voltage regulation.

Factors affecting voltage regulation include the transformer’s impedance and the load power factor. Higher impedance and lower power factor both lead to poorer voltage regulation. I remember a case where a factory was experiencing voltage dips during motor starting. By analyzing the transformer’s voltage regulation characteristics and the load profile, we were able to recommend changes that significantly improved the situation.

Understanding voltage ratings and tap settings is crucial for system design and operation. For example, when integrating a new transformer into an existing system, you need to ensure not only that the voltage ratings are compatible, but also that the tap range is sufficient to handle expected voltage variations.

In recent years, with the increasing integration of renewable energy sources and the development of smart grids, voltage control has become more complex. Transformers with OLTCs are playing a larger role in dynamic voltage regulation. I’ve been involved in projects where we’ve used transformers with advanced OLTCs and control systems to help manage voltage in distribution networks with high penetration of solar PV.

As we continue to push the boundaries of our power systems, understanding and properly applying transformer voltage ratings and tap settings becomes ever more crucial. Whether you’re designing a new system, troubleshooting voltage issues, or planning for future grid enhancementsWhether you’re designing a new system, troubleshooting voltage issues, or planning for future grid enhancements, a solid grasp of these concepts is essential for any electrical engineer working with power systems.

Current Ratings and Their Importance in Transformer Design and Operation?

Have you ever wondered why transformers have specific current ratings? Or how these ratings impact the overall power system? Understanding current ratings is crucial for safe and efficient transformer operation.

Current ratings in transformers define the maximum current that can flow through the windings without causing damage. They’re directly related to the kVA rating and voltage. These ratings are crucial for sizing conductors, designing protection systems, and ensuring the transformer can handle both normal loads and fault conditions.

Let’s delve into the world of transformer current ratings and explore their significance in transformer design and operation. This knowledge is essential for system planning, protection coordination, and transformer maintenance.

Basic Current Ratings

-

Full Load Current

- Maximum continuous current at rated kVA and voltage

- Used for sizing conductors and protection devices

-

Primary vs. Secondary Current

- Inversely proportional to voltage ratings

- Higher current on the low voltage side

Special Current Considerations

-

Inrush Current

- Initial surge when energizing the transformer