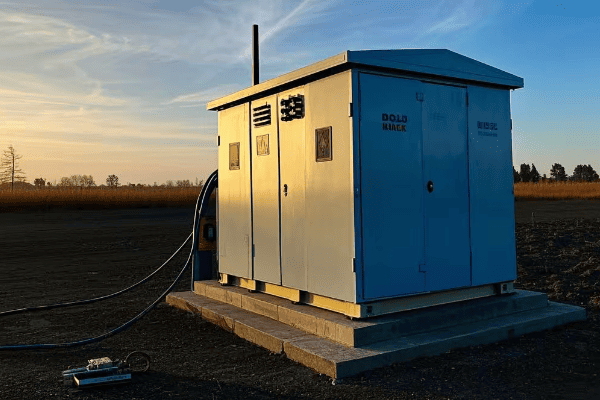

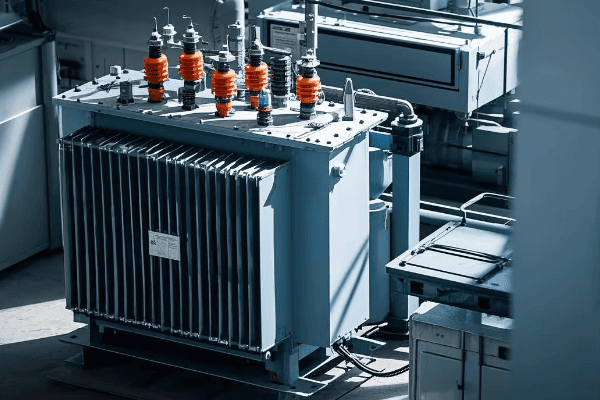

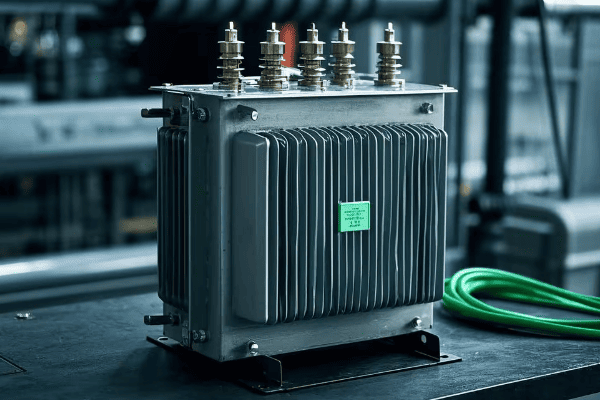

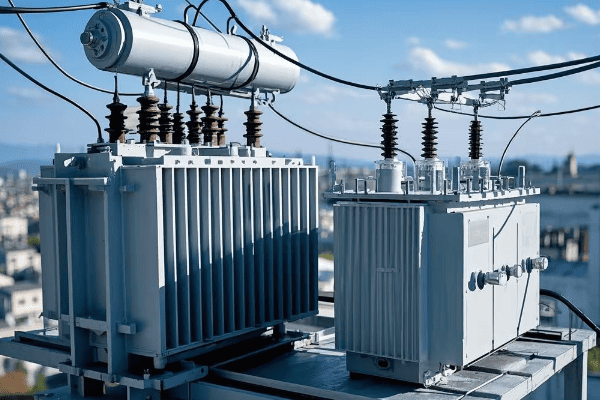

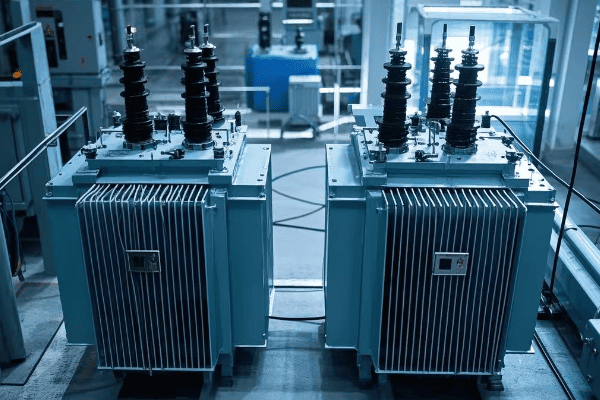

Are you wondering why some industrial sites have those large, mysterious metal boxes? You might be looking at a tank transformer, the unsung hero of power distribution.

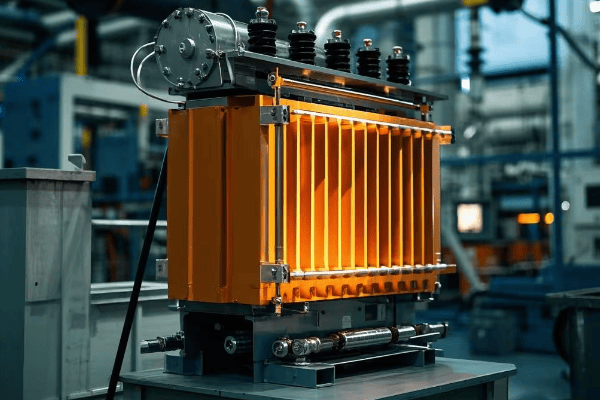

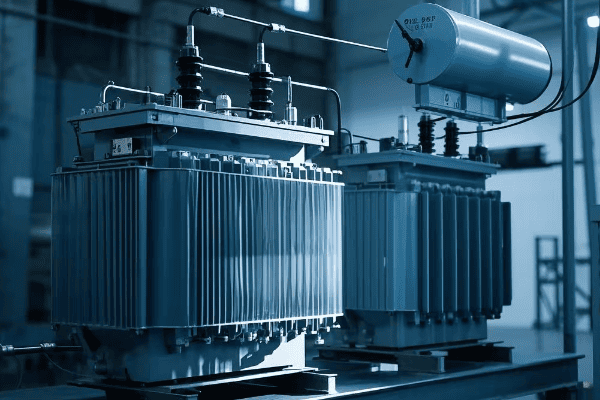

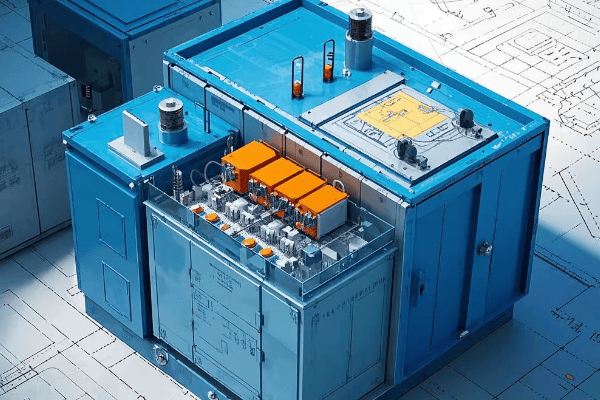

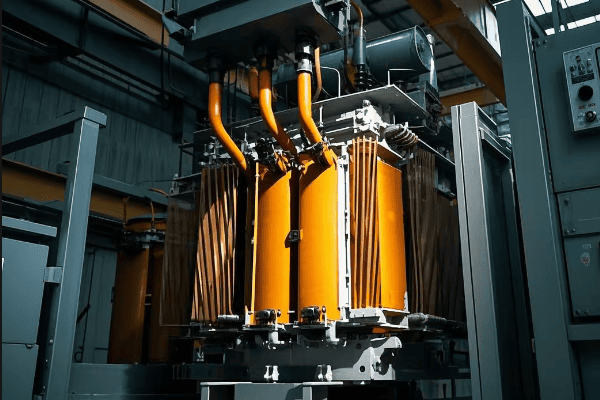

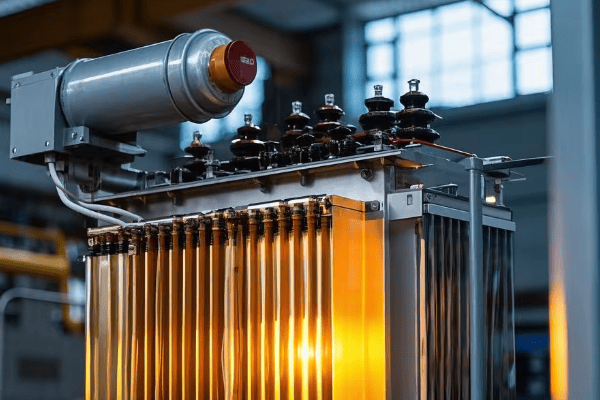

A tank transformer is a type of electrical transformer filled with oil for insulation and cooling. It’s crucial for industrial power systems, stepping voltage up or down to meet specific needs. These transformers are the backbone of electrical distribution in factories, refineries, and large commercial buildings.

I’ve worked with tank transformers for over two decades, and I’m always amazed by their impact on industrial operations. In this article, I’ll break down everything you need to know about these powerhouses. Whether you’re an engineer, a plant manager, or just curious about industrial electricity, you’ll find valuable insights here.

How Does a Tank Transformer Work: The Basic Principles Explained?

Have you ever wondered what’s happening inside those massive metal tanks? The inner workings of a tank transformer might surprise you with their elegant simplicity.

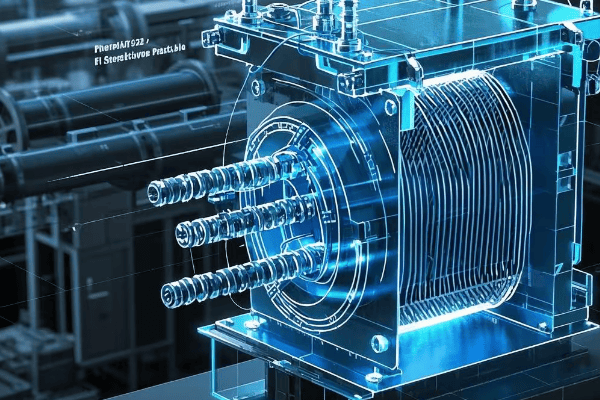

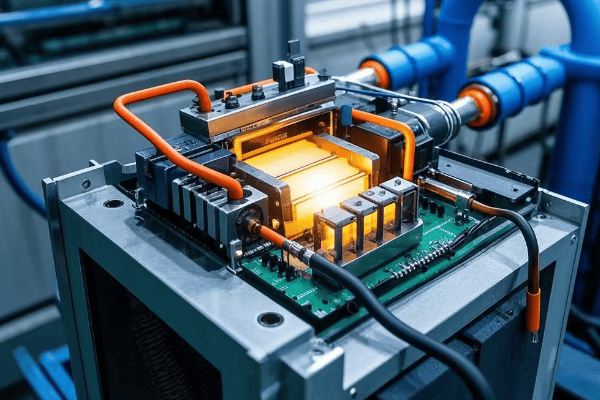

Tank transformers work on the principle of electromagnetic induction. They use two or more coils of wire wrapped around an iron core. When alternating current flows through one coil (the primary), it creates a changing magnetic field. This field induces a voltage in the other coil (the secondary), effectively transferring electrical energy.

I remember the first time I opened up a tank transformer during maintenance. The sheer size of the coils and the precision of their arrangement left me in awe. Let me break down how these giants of industry actually work.

The Core: The Heart of the Transformer

The core of a tank transformer is crucial to its operation:

-

Material:

- Usually made of thin laminations of silicon steel

- Designed to minimize energy losses due to eddy currents

-

Shape:

- Can be "core-type" (rectangular) or "shell-type" (surrounded by windings)

- Shape affects efficiency and cooling capabilities

-

Function:

- Provides a path for the magnetic flux

- Concentrates the magnetic field, improving transformer efficiency

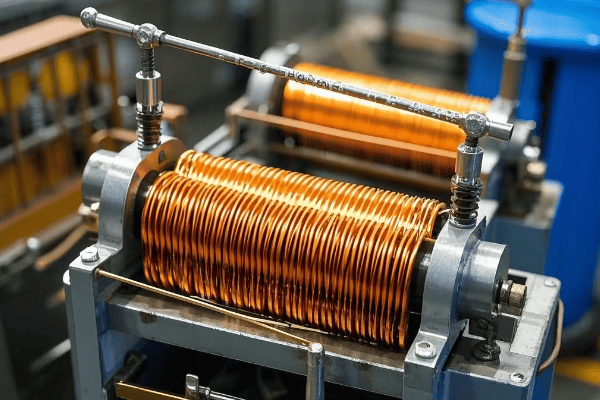

The Windings: Where the Magic Happens

The windings are where electrical energy is transformed:

-

Primary Winding:

- Receives the input voltage

- Creates the changing magnetic field

-

Secondary Winding:

- Induced voltage creates the output

- Number of turns determines the voltage change

-

Winding Ratio:

- Determines the voltage transformation ratio

- More turns on secondary = step-up transformer

- Fewer turns on secondary = step-down transformer

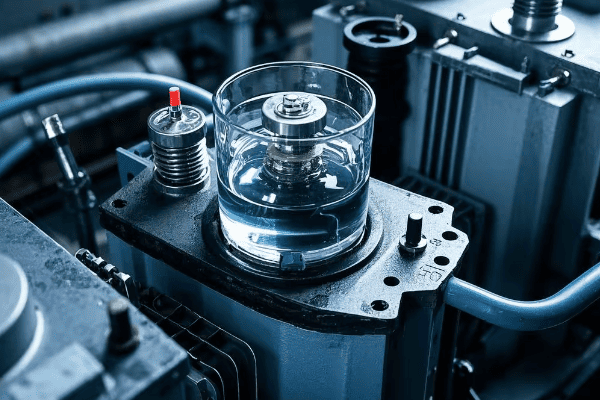

The Oil: More Than Just Cooling

The oil in a tank transformer serves multiple purposes:

-

Insulation:

- Provides electrical insulation between components

- Allows for closer spacing of parts, reducing transformer size

-

Cooling:

- Absorbs heat from the core and windings

- Circulates naturally or through forced circulation systems

-

Protection:

- Prevents oxidation of the internal components

- Can be analyzed to detect potential issues early

| Component | Function | Importance |

|---|---|---|

| Core | Magnetic flux path | High – affects efficiency |

| Primary Winding | Input voltage | Critical – creates magnetic field |

| Secondary Winding | Output voltage | Critical – produces desired voltage |

| Oil | Insulation & Cooling | Essential – enables compact design and longevity |

In my years working with tank transformers, I’ve seen firsthand how these principles play out in real-world applications. One memorable project involved upgrading a factory’s power system. We replaced an old, inefficient transformer with a modern tank transformer. The improvement in power quality and energy efficiency was remarkable. The factory owner was amazed at how much smoother their equipment ran and how much they saved on energy costs.

However, it’s important to note that while the basic principles of tank transformers are straightforward, their design and construction require precise engineering. Factors like core material quality, winding arrangement, and oil composition all play crucial roles in a transformer’s performance and lifespan.

Understanding these basics is just the start. As we delve deeper into the world of tank transformers, you’ll see how these principles are applied in various types of transformers, how they compare to other designs, and how they’re evolving to meet the changing needs of industry and energy distribution.

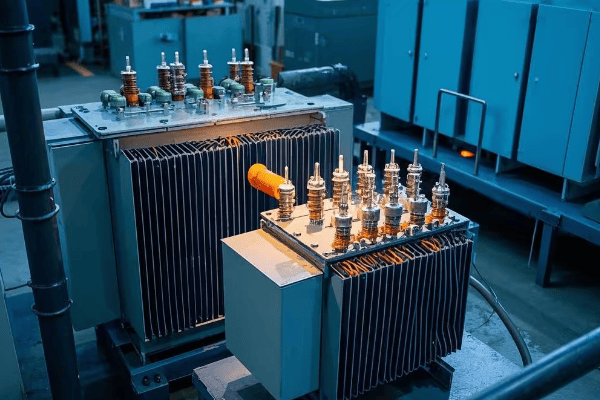

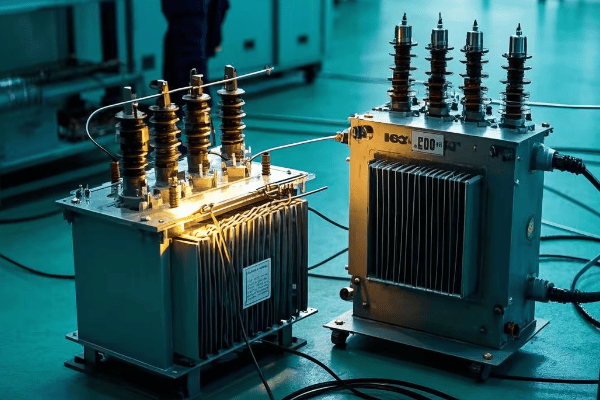

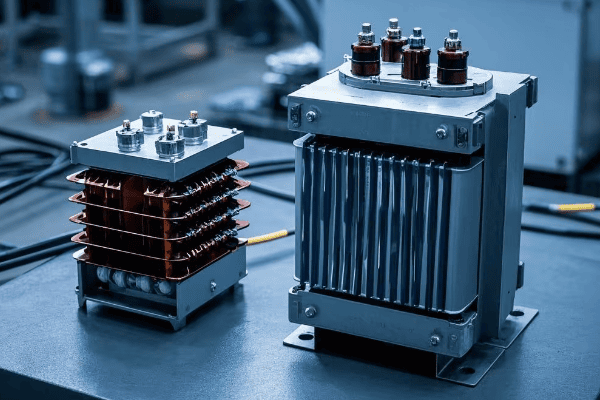

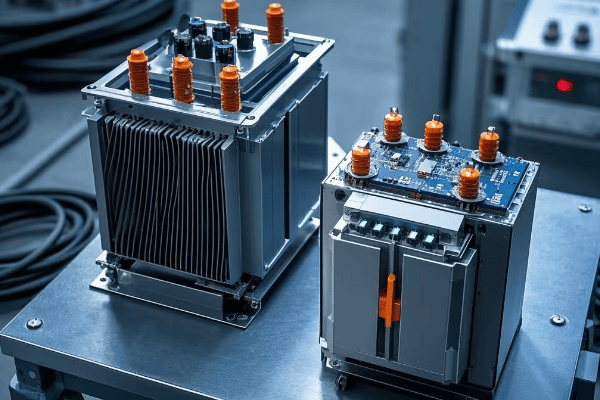

Key Components of a Tank Transformer: From Core to Cooling System?

Ever wondered what’s inside that massive metal tank? The components of a tank transformer are like a well-orchestrated team, each playing a crucial role in powering our industries.

A tank transformer consists of several key components: the core, windings, insulation system, tank, cooling system, and various accessories. Each part is essential for the transformer’s operation, from converting voltage to ensuring safety and efficiency.

I’ve spent countless hours working on these transformers, and I’m always impressed by how each component contributes to the overall function. Let’s dive into the details of these crucial parts.

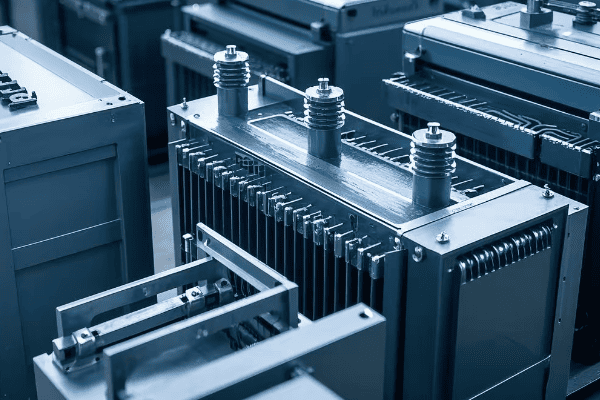

The Core: The Magnetic Powerhouse

The core is the heart of the transformer:

-

Material:

- Usually made of high-grade silicon steel

- Laminated to reduce eddy current losses

-

Design:

- Can be core-type or shell-type

- Affects the transformer’s efficiency and size

-

Function:

- Provides a low-reluctance path for magnetic flux

- Critical for the transformer’s overall efficiency

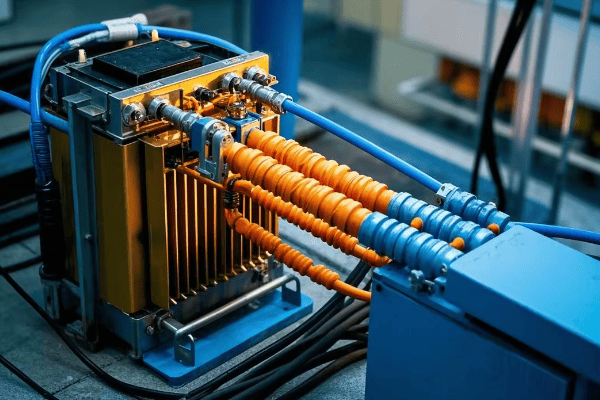

Windings: Where Voltage Transformation Happens

Windings are the key to voltage transformation:

-

Primary Winding:

- Receives input voltage

- Creates the magnetic field

-

Secondary Winding:

- Induced voltage creates output

- Number of turns determines voltage ratio

-

Material:

- Usually copper or aluminum

- Choice affects cost and efficiency

Insulation System: Keeping Everything Safe

The insulation system is crucial for safety and longevity:

-

Oil:

- Provides insulation and cooling

- Can be mineral oil or synthetic alternatives

-

Paper:

- Wraps around windings

- Impregnated with oil for better insulation

-

Barriers:

- Separate different voltage components

- Enhance overall insulation strength

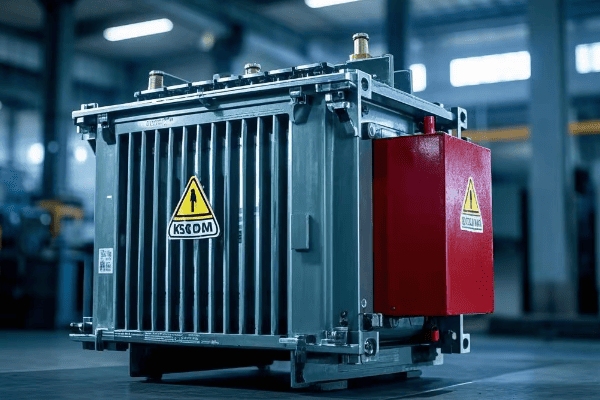

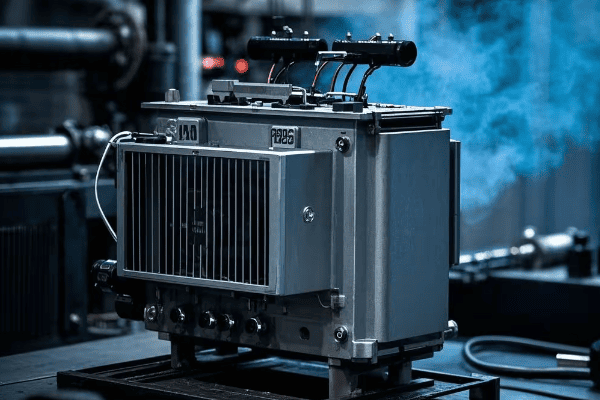

Tank and Conservator: Housing and Protection

The tank and conservator protect and contain:

-

Tank:

- Houses all internal components

- Designed to withstand internal pressure

-

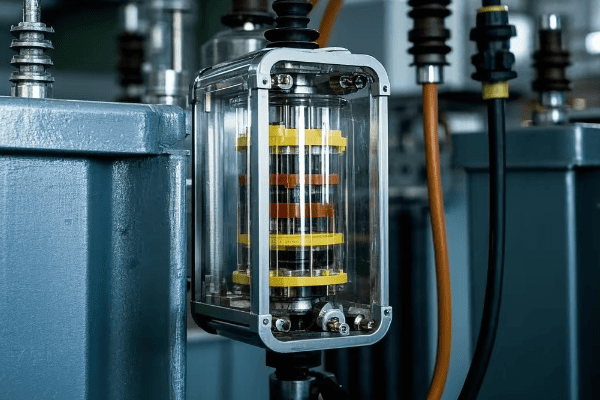

Conservator:

- Allows for oil expansion

- Maintains oil level and purity

Cooling System: Keeping Things Cool

The cooling system is vital for efficiency and longevity:

-

Radiators:

- Increase surface area for heat dissipation

- Can be detachable for maintenance

-

Fans:

- Used in forced-air cooling systems

- Enhance cooling capacity

-

Oil Pumps:

- Used in forced-oil cooling systems

- Circulate oil for more efficient cooling

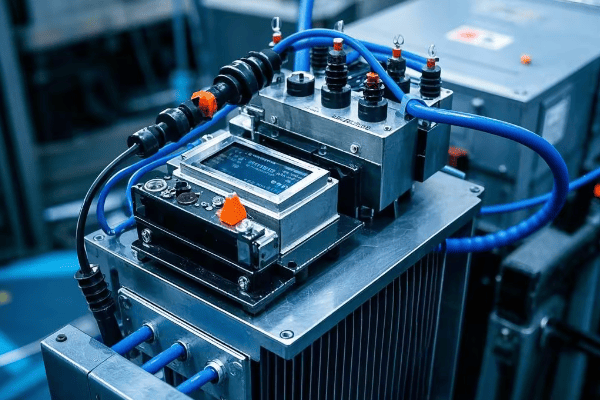

Accessories: Monitoring and Control

Various accessories ensure safe and efficient operation:

-

Bushings:

- Insulate and support external connections

- Critical for safety and performance

-

Tap Changer:

- Allows for voltage adjustment

- Can be on-load or off-load type

-

Monitoring Devices:

- Temperature gauges

- Pressure relief devices

- Oil level indicators

| Component | Function | Maintenance Needs |

|---|---|---|

| Core | Magnetic flux path | Low – Check for vibrations |

| Windings | Voltage transformation | Medium – Insulation tests |

| Insulation | Safety and efficiency | High – Regular oil tests |

| Tank | Protection and containment | Low – Inspect for leaks |

| Cooling System | Temperature control | Medium – Clean and check fans/pumps |

| Accessories | Monitoring and control | High – Regular calibration and checks |

In my experience, understanding these components is crucial for anyone working with tank transformers. I remember a project where we were troubleshooting a transformer that kept overheating. By systematically checking each component, we discovered that the cooling fans weren’t activating properly. A simple fix to the control system solved the problem, saving the client from a potential catastrophic failure.

It’s important to note that while each component has its specific role, they all work together as an integrated system. The quality and condition of each part affect the overall performance and lifespan of the transformer. Regular maintenance and monitoring of all components are essential for ensuring reliable operation.

As technology advances, we’re seeing innovations in each of these areas. For example, new core materials are being developed to reduce losses, and advanced monitoring systems are making it easier to predict and prevent failures. Staying updated on these developments is crucial for anyone involved in transformer design, operation, or maintenance.

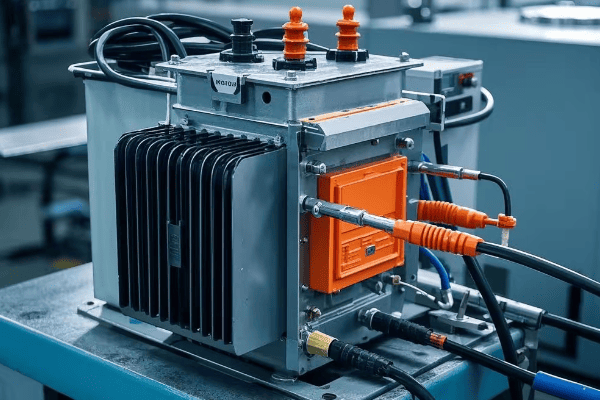

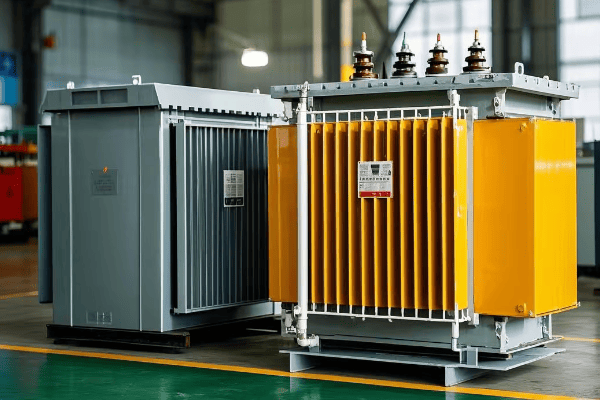

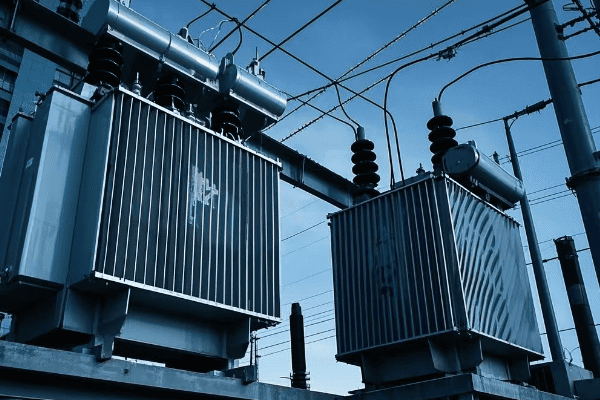

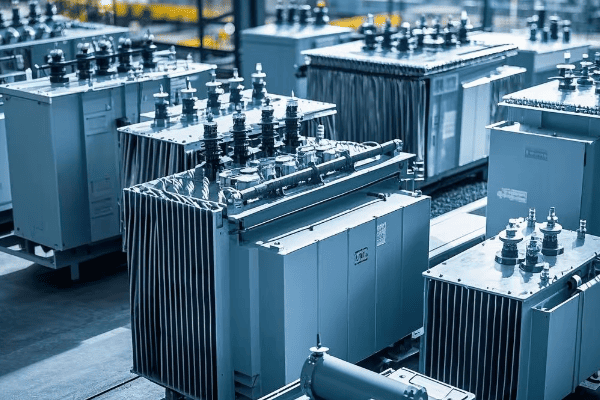

Types of Tank Transformers: Choosing the Right One for Your Needs?

Are you confused by the variety of tank transformers available? You’re not alone. Selecting the right type can make or break your power distribution system.

Tank transformers come in various types, including step-up, step-down, distribution, and power transformers. Each type is designed for specific voltage levels and applications, from powering neighborhoods to supporting large industrial complexes. The choice depends on your specific power requirements and system design.

I’ve helped many clients choose the right transformer for their needs. It’s not always straightforward, but understanding the types can make a huge difference. Let me break it down for you.

Step-Up Transformers: Powering the Grid

Step-up transformers are crucial for power transmission:

-

Function:

- Increase voltage for long-distance transmission

- Typically used at power generation plants

-

Characteristics:

- Very high voltage output (up to 765kV)

- Large size and capacity

-

Applications:

- Connecting power plants to the grid

- Reducing transmission losses over long distances

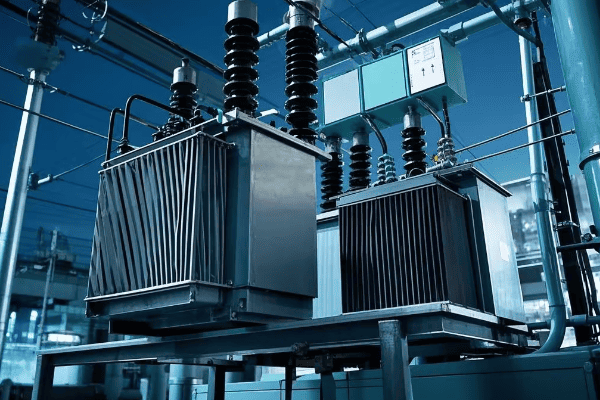

Step-Down Transformers: Bringing Power to Users

Step-down transformers make electricity usable for end consumers:

-

Function:

- Reduce high transmission voltages to usable levels

- Found at substations and distribution points

-

Characteristics:

- Wide range of output voltages

- Various sizes depending on application

-

Applications:

- Substations in residential areas

- Industrial facilities requiring specific voltages

Distribution Transformers: The Last Mile

Distribution transformers are the workhorses of the power grid:

-

Function:

- Further step down voltage for final consumer use

- Typically reduce voltage to 120/240V for homes

-

Characteristics:

- Smaller size compared to other types

- Often seen on utility poles or in ground-level boxes

-

Applications:

- Residential neighborhoods

- Small commercial buildings

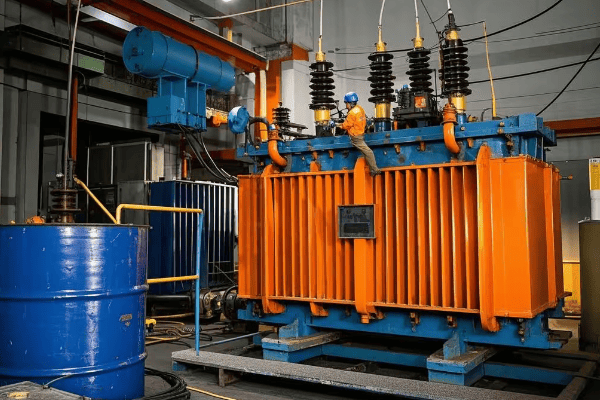

Power Transformers: Industrial Strength

Power transformers handle the heavy lifting in large-scale operations:

-

Function:

- Transform voltage for large power systems

- Can step up or step down voltage as needed

-

Characteristics:

- High capacity (typically above 500 kVA)

- Often custom-designed for specific applications

-

Applications:

- Large industrial complexes

- Data centers

- Renewable energy installations

Specialty Transformers: Tailored Solutions

Some applications require specialized transformer types:

-

Autotransformers:

- Single winding serves as both primary and secondary

- More compact and efficient for certain applications

-

Three-Phase Transformers:

- Handle three-phase power systems

- Common in industrial and utility applications

-

Isolation Transformers:

- Provide electrical isolation between circuits

- Used in sensitive equipment protection

| Type | Typical Voltage Range | Common Applications | Key Advantages |

|---|---|---|---|

| Step-Up | Up to 765kV | Power plants | Efficient long-distance transmission |

| Step-Down | 765kV to 120/240V | Substations, Industries | Voltage reduction for end-use |

| Distribution | 4kV to 34.5kV primary | Residential areas | Last-mile power delivery |

| Power | Varies (often >69kV) | Large industries, Data centers | High capacity, custom solutions |

| Autotransformer | Varies | Voltage regulation | Compact, efficient for small adjustments |

| Three-Phase | Varies | Industrial power systems | Efficient for three-phase loads |

| Isolation | Varies | Sensitive equipment | Noise reduction, safety improvement |

In my career, I’ve encountered numerous situations where choosing the right transformer type was critical. One memorable project involved a new data center. The client initially thought they needed a standard power transformer, but after analyzing their power requirements and future expansion plans, we recommended a custom-designed three-phase transformer with additional capacity. This foresight saved them from costly upgrades down the line.

It’s important to note that selecting the right transformer isn’t just about matching voltage and capacity. Factors like efficiency, cooling requirements, maintenance needs, and even physical size constraints all play a role. I always advise clients to consider their long-term needs and potential future expansions when making a choice.

The field of transformer design is constantly evolving. We’re seeing innovations like more efficient core materials, better cooling systems, and smart monitoring capabilities across all types of transformers. Staying informed about these advancements can help you make better decisions for your power systems.

Remember, the right transformer can significantly impact your system’s efficiency, reliability, and overall cost of operation. Don’t hesitate to consult with experts when making your choice – it’s an investment that will affect your operations for decades to come.

Tank Transformer vs. Dry-Type Transformer: A Comprehensive Comparison?

Stuck between choosing a tank transformer or a dry-type transformer? This decision can significantly impact your power system’s performance, cost, and maintenance needs.

Tank transformers use oil for insulation and cooling, while dry-type transformers use air and solid insulation. Tank transformers are typically more efficient and suitable for higher voltages, while dry-type transformers are safer in fire-sensitive areas and require less maintenance. The choice depends on your specific application, environment, and budget.

I’ve worked with both types of transformers throughout my career, and I’ve seen firsthand how this choice can make or break a project. Let’s dive into the key differences and help you make an informed decision.

Insulation and Cooling: Oil vs. Air

The primary difference lies in the insulation and cooling method:

-

Tank Transformers:

- Use mineral oil or synthetic fluids for insulation and cooling

- Excellent heat dissipation properties

- Require regular oil maintenance

-

Dry-Type Transformers:

- Use air and solid materials (like epoxy resin) for insulation

- Less efficient cooling, but no risk of oil leaks

- Minimal maintenance required for insulation

Voltage and Capacity Range

Each type has its sweet spot in terms of voltage and capacity:

-

Tank Transformers:

- Suitable for a wide range of voltages, from distribution to transmission levels

- Can handle very high capacities (up to hundreds of MVA)

- Ideal for outdoor substations and large industrial applications

-

Dry-Type Transformers:

- Typically used for voltages up to 35kV

- Capacities usually up to 10 MVA

- Perfect for indoor applications in commercial buildings and small to medium industries

Environmental Considerations

Environmental factors play a crucial role in the choice:

-

Tank Transformers:

- Risk of oil spills and environmental contamination

- Better suited for outdoor installations

- Can operate in a wide range of temperatures

-

Dry-Type Transformers:

- No risk of oil leaks or spills

- Ideal for environmentally sensitive areas

- May require climate-controlled environments for optimal performance

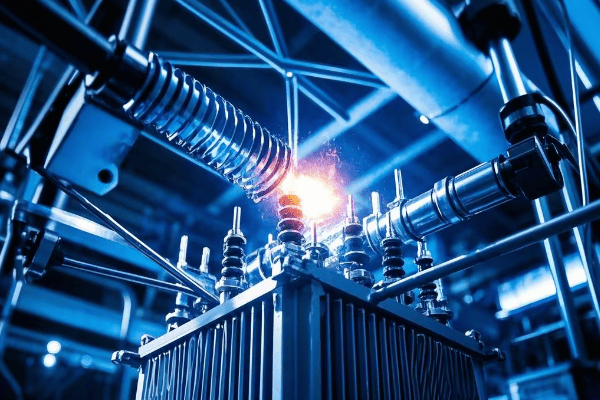

Fire Safety

Fire safety is a critical consideration, especially in certain environments:

-

Tank Transformers:

- Higher fire risk due to flammable oil

- Require fire suppression systems in many installations

- Not suitable for areas with strict fire safety regulations

-

Dry-Type Transformers:

- Lower fire risk due to absence of flammable liquids

- Preferred in buildings, hospitals, and other fire-sensitive areas

- Often don’t require additional fire suppression systems

Maintenance and Lifespan

Maintenance needs and expected lifespan differ significantly:

-

Tank Transformers:

- Require regular oil testing and maintenance

- Can have a longer lifespan (30-40 years) with proper maintenance

- Oil acts as a preservative for internal components

-

Dry-Type Transformers:

- Minimal maintenance required

- Typical lifespan of 20-30 years

- More susceptible to environmental factors like humidity and dust

Cost Considerations

Initial and long-term costs vary between the two types:1. Tank Transformers:

- Higher initial cost due to complex design and oil system

- Lower operating costs due to better efficiency

- Additional costs for oil maintenance and potential environmental compliance

- Dry-Type Transformers:

- Lower initial cost for smaller capacities

- Higher operating costs due to lower efficiency

- Minimal ongoing maintenance costs

Efficiency and Losses

Efficiency is a crucial factor in transformer selection:

-

Tank Transformers:

- Generally more efficient, especially at higher capacities

- Lower core and winding losses due to better cooling

- Efficiency can degrade if oil quality is not maintained

-

Dry-Type Transformers:

- Slightly less efficient, especially in larger sizes

- Higher losses due to air cooling

- Consistent efficiency over time with minimal maintenance

| Factor | Tank Transformer | Dry-Type Transformer |

|---|---|---|

| Insulation | Oil | Air and solid materials |

| Voltage Range | Wide (up to 765kV+) | Limited (typically up to 35kV) |

| Capacity | Up to hundreds of MVA | Usually up to 10 MVA |

| Environmental Risk | Higher (oil spills) | Lower |

| Fire Safety | Lower | Higher |

| Maintenance | Higher | Lower |

| Lifespan | 30-40 years | 20-30 years |

| Initial Cost | Higher | Lower for small capacities |

| Efficiency | Higher | Lower |

In my experience, the choice between tank and dry-type transformers often comes down to the specific application and environment. I remember a project for a new hospital where we initially considered tank transformers for their efficiency. However, due to strict fire safety regulations and the indoor installation requirement, we opted for dry-type transformers. The peace of mind in terms of safety and reduced maintenance needs outweighed the slight efficiency loss.

On the other hand, for a large outdoor substation project, tank transformers were the clear choice. The high voltage requirements and the need for maximum efficiency over a long lifespan made them ideal, despite the higher initial cost and maintenance needs.

It’s crucial to consider future needs as well. In one industrial project, we chose a tank transformer with slightly higher capacity than immediately needed, anticipating future expansion. This foresight saved the client from a costly upgrade just a few years later.

Remember, there’s no one-size-fits-all solution. The right choice depends on a careful analysis of your specific needs, including voltage requirements, capacity needs, installation environment, safety considerations, maintenance capabilities, and long-term cost projections. Always consult with experienced professionals to make the best decision for your unique situation.

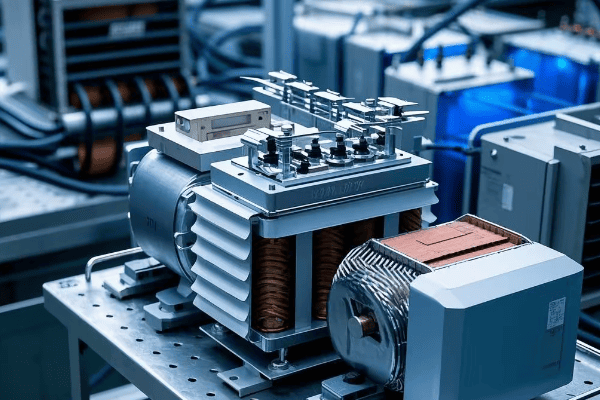

The Role of Tank Transformers in Industrial Power Distribution?

Ever wondered how massive factories and industrial complexes manage their enormous power needs? Tank transformers play a crucial role in this complex power dance.

Tank transformers are the backbone of industrial power distribution. They handle the high voltages and large capacities required by industrial processes, stepping down transmission voltages to usable levels. These transformers ensure reliable, efficient power supply for everything from heavy machinery to sensitive control systems.

I’ve been involved in numerous industrial power projects, and I’m always amazed at how central tank transformers are to these operations. Let me share some insights on their critical role.

Voltage Transformation: Powering the Industrial Heartbeat

Tank transformers are vital for voltage management in industries:

-

Primary Function:

- Step down high transmission voltages to usable levels

- Typically transform voltages from 69kV or 138kV to 4.16kV, 13.8kV, or other medium voltages

-

Load Management:

- Handle large, fluctuating loads common in industrial settings

- Provide stable voltage despite varying demand

-

Power Quality:

- Help maintain consistent power quality for sensitive equipment

- Mitigate voltage sags and surges

Capacity and Reliability: Meeting Demanding Industrial Needs

Industrial operations require high capacity and unwavering reliability:

-

High Capacity:

- Tank transformers can handle capacities from a few MVA to over 100 MVA

- Suitable for energy-intensive industries like steel mills or chemical plants

-

Reliability:

- Designed for continuous operation under harsh conditions

- Robust construction to withstand industrial environments

-

Redundancy:

- Often installed in parallel for critical operations

- Allow for maintenance without shutting down production

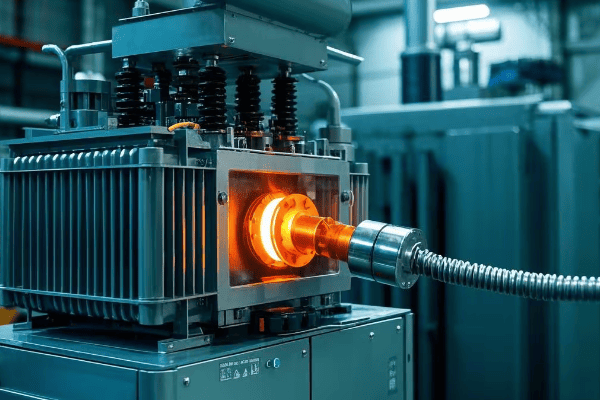

Energy Efficiency: Optimizing Industrial Power Use

Efficiency is crucial in industrial settings where energy costs are a significant factor:

-

Low Losses:

- High-efficiency designs minimize energy losses

- Can significantly reduce operating costs over time

-

Load Tap Changers:

- Allow for voltage adjustment under load

- Optimize efficiency across varying load conditions

-

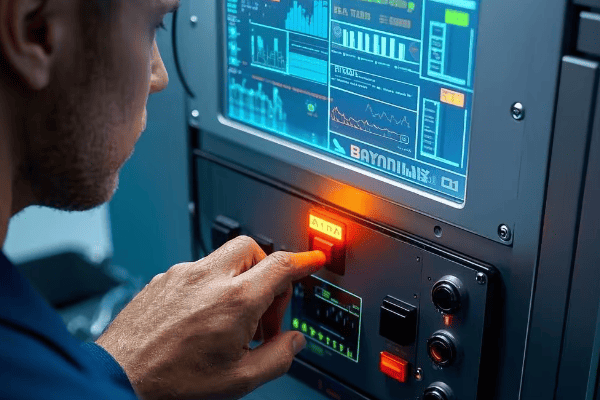

Monitoring and Control:

- Modern tank transformers often include advanced monitoring systems

- Enable real-time efficiency optimization

Safety and Environmental Considerations

Tank transformers must meet strict safety and environmental standards:

-

Containment Systems:

- Designed to prevent oil leaks and spills

- Often include secondary containment measures

-

Fire Safety:

- Equipped with fire suppression systems

- Located in dedicated areas away from main production

-

Environmental Compliance:

- Use of biodegradable oils in some modern designs

- Regular monitoring for environmental impact

Integration with Industrial Power Systems

Tank transformers are key components in complex industrial power systems:

-

Substation Integration:

- Often part of on-site substations in large industrial complexes

- Interface between utility supply and plant distribution

-

Power Factor Correction:

- Work in conjunction with power factor correction equipment

- Help maintain optimal power factor for the facility

-

Renewable Energy Integration:

- Increasingly used to integrate on-site renewable generation

- Handle bidirectional power flow in modern industrial microgrids

| Aspect | Role in Industrial Power Distribution |

|---|---|

| Voltage Transformation | Step down high voltages to usable levels |

| Capacity | Handle large loads (up to 100+ MVA) |

| Reliability | Ensure continuous power for critical processes |

| Efficiency | Minimize energy losses in power distribution |

| Safety | Comply with industrial safety standards |

| Environmental | Manage environmental risks of oil-filled equipment |

| System Integration | Key component in complex power systems |

In my career, I’ve seen firsthand how crucial tank transformers are in industrial settings. One particularly memorable project involved a large automotive manufacturing plant. The facility needed to upgrade its power distribution system to accommodate new high-power robotic welding lines. We installed a new 40 MVA tank transformer as part of the upgrade. The transformer not only handled the increased power demand but also improved overall energy efficiency. The plant manager was amazed at how this single piece of equipment could have such a significant impact on their operations.

Another interesting case was a chemical plant that needed extremely reliable power for its sensitive processes. We implemented a system with redundant tank transformers and advanced monitoring. This setup allowed for continuous operation even during maintenance periods and provided early warning of any potential issues.

It’s important to note that while tank transformers are powerful and efficient, they require careful planning and maintenance. In industrial settings, even a short power interruption can result in significant production losses. That’s why I always emphasize the importance of regular maintenance, monitoring, and having a solid contingency plan.

As industries evolve, so do the demands on power distribution systems. We’re seeing trends towards more energy-efficient processes, increased automation, and integration of renewable energy sources. Tank transformers are adapting to these changes with more efficient designs, smart monitoring capabilities, and the ability to handle bidirectional power flow. Staying informed about these advancements is crucial for anyone involved in industrial power systems.

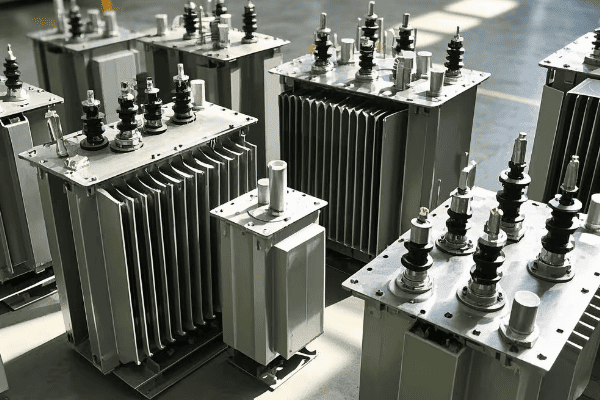

Advantages and Disadvantages of Tank Transformers: What You Need to Know?

Considering a tank transformer for your project? It’s crucial to weigh both the pros and cons before making this significant investment.

Tank transformers offer high efficiency, large capacity, and excellent cooling capabilities. They’re ideal for high-voltage applications and outdoor installations. However, they come with higher maintenance needs, environmental risks due to oil, and greater fire hazards. Understanding these trade-offs is key to making the right choice for your power needs.

I’ve worked with tank transformers for years, and I’ve seen their strengths and weaknesses in action. Let me break down what you really need to know.

Advantages: The Power of Tank Transformers

Tank transformers have several significant benefits:

-

High Efficiency:

- Lower energy losses due to superior cooling

- Can maintain efficiency even at high loads

-

Large Capacity:

- Capable of handling very high voltages and power loads

- Ideal for industrial and utility-scale applications

-

Excellent Cooling:

- Oil provides superior heat dissipation

- Allows for more compact design relative to capacity

-

Longevity:

- Can last 30-40 years with proper maintenance

- Oil acts as a preservative for internal components

-

Outdoor Suitability:

- Designed to withstand various weather conditions

- Ideal for substations and outdoor installations

-

Overload Capability:

- Can handle short-term overloads better than dry-type transformers

- Provides operational flexibility

Disadvantages: Challenges to Consider

However, tank transformers also come with some drawbacks:

-

Maintenance Requirements:

- Regular oil testing and maintenance needed

- Potential for oil leaks and contamination

-

Environmental Concerns:

- Risk of oil spills and environmental damage

- Disposal of old oil can be challenging and costly

-

Fire Hazard:

- Oil is flammable, increasing fire risk

- May require additional fire suppression systems

-

Initial Cost:

- Generally more expensive upfront than dry-type transformers

- Installation costs can be higher due to size and weight

-

Size and Weight:

- Larger and heavier than equivalent dry-type transformers

- May require special transportation and installation equipment

-

Noise:

- Can be noisier than dry-type transformers

- May require additional noise mitigation in some settings

Real-World Implications

These advantages and disadvantages play out in various ways:

-

Industrial Applications:

- Pros: High efficiency and capacity are crucial for large industrial operations

- Cons: Environmental risks may require additional safeguards

-

Urban Installations:

- Pros: Ability to handle high loads in compact spaces

- Cons: Fire risk and noise may be problematic in densely populated areas

-

Utility Substations:

- Pros: Ideal for outdoor settings and high-voltage applications

- Cons: Regular maintenance needs can increase operational costs

-

Renewable Energy Projects:

- Pros: Can handle large capacities needed for wind or solar farms

- Cons: Environmental concerns may conflict with green energy goals

| Aspect | Advantage | Disadvantage |

|---|---|---|

| Efficiency | High, especially at large capacities | – |

| Capacity | Can handle very high voltages and loads | – |

| Cooling | Excellent heat dissipation | Requires oil maintenance |

| Lifespan | 30-40 years with proper care | – |

| Environmental Impact | – | Risk of oil spills |

| Fire Safety | – | Higher fire risk |

| Maintenance | – | Regular oil testing required |

| Initial Cost | – | Generally higher than dry-type |

| Size and Weight | – | Larger and heavier |

| Noise | – | Can be noisier |

In my experience, the decision to use a tank transformer often comes down to specific project requirements and constraints. I remember a project for a large data center where we initially considered tank transformers for their efficiency and capacity. However, the client’s strict fire safety requirements and desire to minimize maintenance led us to choose dry-type transformers instead, despite the slight efficiency loss.

On the other hand, for a recent substation upgrade project, tank transformers were the clear choice. The outdoor location, high voltage requirements, and need for maximum efficiency over a long lifespan outweighed the maintenance considerations and environmental precautions we had to implement.

It’s crucial to consider long-term factors as well. In one industrial project, we chose a slightly oversized tank transformer, anticipating future expansion. This foresight saved the client from a costly upgrade just a few years later, demonstrating how the advantages of tank transformers can pay off over time.

When considering tank transformers, it’s essential to conduct a thorough cost-benefit analysis. Factor in not just the initial purchase and installation costs, but also long-term operational expenses, maintenance requirements, and potential risks. In some cases, the efficiency gains of a tank transformer can offset higher upfront costs over its lifespan.

Remember, there’s no one-size-fits-all solution. The right choice depends on a careful analysis of your specific needs, including voltage requirements, capacity needs, installation environment, safety considerations, maintenance capabilities, and long-term cost projections. Always consult with experienced professionals to make the best decision for your unique situation.

Conclusion

Tank transformers are powerful, efficient, and crucial for high-capacity power distribution. They offer significant advantages in efficiency and capacity but come with maintenance and environmental considerations. Careful analysis of your specific needs is essential for making the right choice in transformer selection.

Is your transformer at risk of a catastrophic failure? You might be overlooking a critical component that could save your entire power system.

An oil surge relay, also known as a Buchholz relay, is a vital safety device for oil-immersed transformers. It detects faults by monitoring gas accumulation and oil flow changes, providing early warning and protection against potentially disastrous transformer failures.

I’ve seen firsthand how these small devices can prevent major disasters. In this article, I’ll share my insights on oil surge relays, from basic principles to cutting-edge digital versions. Whether you’re a seasoned engineer or new to the field, you’ll discover why these devices are crucial for transformer health.

How Does an Oil Surge Relay Work: The Guardian of Your Transformer?

Have you ever wondered what happens inside a transformer when something goes wrong? The oil surge relay is your first line of defense, but how does it actually work?

Oil surge relays operate on a simple yet effective principle. They detect gas buildup or sudden oil movements caused by internal faults. When triggered, they can activate alarms or even shut down the transformer, preventing further damage.

I remember the first time I saw an oil surge relay in action. It was during a routine maintenance check, and the relay had just prevented a major breakdown. Let me break down how these devices work and why they’re so important.

The Anatomy of an Oil Surge Relay

To understand how oil surge relays work, we need to look at their key components:

-

Float Chamber:

- Contains two floats: upper and lower

- Filled with transformer oil during normal operation

- Sensitive to oil level changes and gas accumulation

-

Mercury Switches:

- Connected to the floats

- Activate when floats move due to oil level changes or gas buildup

-

Alarm and Trip Contacts:

- Linked to the mercury switches

- Trigger alarms or transformer shutdown when activated

Operating Principles

The oil surge relay works in two main stages:

-

Slow Accumulation of Gas:

- Gas bubbles rise and collect in the relay’s chamber

- The upper float drops as oil is displaced by gas

- This triggers the alarm contact

-

Sudden Oil Surge:

- Rapid oil movement pushes the lower float upwards

- This activates the trip contact

- The transformer is immediately shut down to prevent damage

Types of Faults Detected

Oil surge relays can identify various transformer issues:

-

Partial Discharges:

- Small electrical discharges in insulation

- Produce hydrogen gas, detected by the relay

-

Overheating:

- Causes oil and paper insulation to break down

- Generates gases like methane and ethylene

-

Arcing:

- Produces large amounts of hydrogen and acetylene

- Triggers rapid relay response

-

Oil Leaks:

- Detected by sudden changes in oil level

| Fault Type | Gas Produced | Relay Response |

|---|---|---|

| Partial Discharge | Hydrogen | Slow alarm |

| Overheating | Methane, Ethylene | Slow alarm |

| Arcing | Hydrogen, Acetylene | Rapid trip |

| Oil Leak | N/A | Rapid trip |

In my years of working with transformers, I’ve seen oil surge relays prevent countless potential disasters. One particularly memorable incident involved a large power transformer at a substation. The oil surge relay detected a small gas buildup, which turned out to be the early stages of a winding insulation failure. By catching this early, we avoided a catastrophic failure that could have cost millions and left thousands without power.

However, it’s important to note that while oil surge relays are incredibly useful, they’re not infallible. Regular maintenance and testing are crucial to ensure they function correctly when needed. I always advise my clients to include oil surge relay checks in their routine transformer maintenance schedules.

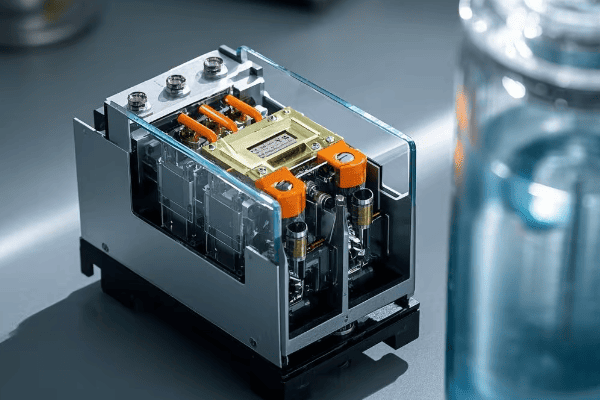

What Are the Latest Developments in Oil Surge Relay Technology: The Digital Revolution?

Are you still relying on old-school mechanical relays? The world of oil surge relays is undergoing a digital transformation that you can’t afford to ignore.

Modern oil surge relays are embracing digital technology. These new devices offer enhanced precision, real-time monitoring, and integration with smart grid systems. They’re revolutionizing how we protect and manage transformers.

I recently upgraded a substation with the latest digital oil surge relays, and the improvement in monitoring and response time was remarkable. Let me share what I’ve learned about these cutting-edge devices and how they’re changing the game.

Features of Digital Oil Surge Relays

Digital oil surge relays bring several advancements to the table:

-

Precision Sensing:

- Advanced sensors for accurate gas and oil flow detection

- Ability to differentiate between different types of gases

-

Real-time Monitoring:

- Continuous data streaming on transformer health

- Remote access for engineers to diagnose issues

-

Data Analytics:

- AI-powered analysis of transformer performance trends

- Predictive maintenance capabilities

Components of a Digital Oil Surge Relay System

A typical digital system includes:

-

Oil Flow Transmitter:

- Installed in the oil pipeline

- Uses advanced flow detection mechanisms

-

Sensor Array:

- Multiple sensors for gas, temperature, and pressure

- Provides comprehensive transformer health data

-

Digital Controller:

- Processes sensor data

- Runs diagnostic algorithms

- Manages communication with control systems

Advantages Over Traditional Relays

Digital relays offer significant benefits:

-

Increased Sensitivity:

- Can detect smaller changes in gas levels and oil flow

- Allows for earlier fault detection

-

Reduced False Alarms:

- Intelligent algorithms filter out normal fluctuations

- Improves reliability and reduces unnecessary shutdowns

-

Integration with Smart Grids:

- Seamless communication with broader power management systems

- Enables coordinated responses to grid-wide issues

-

Enhanced Diagnostics:

- Detailed fault analysis and reporting

- Aids in root cause identification and preventive maintenance

| Feature | Traditional Relay | Digital Relay |

|---|---|---|

| Sensitivity | Moderate | High |

| False Alarm Rate | Higher | Lower |

| Data Analysis | Limited | Advanced |

| Remote Monitoring | Not Available | Available |

| Smart Grid Integration | Not Possible | Fully Integrated |

The shift to digital oil surge relays is more than just a technological upgrade; it’s a fundamental change in how we approach transformer protection. In my experience, facilities that have adopted these systems have seen a significant reduction in unplanned outages and maintenance costs.

One project I worked on involved retrofitting a large industrial complex with digital oil surge relays. Within the first year, the system detected early signs of insulation breakdown in two transformers. This early warning allowed for planned maintenance during off-peak hours, avoiding costly emergency repairs and production downtime.

However, it’s important to note that implementing digital systems requires careful planning. Cybersecurity becomes a critical concern when your transformer protection is connected to networks. I always emphasize the need for robust security measures and regular software updates when installing these systems.

As we move towards smarter, more interconnected power grids, I believe digital oil surge relays will become standard equipment. Their ability to provide real-time, detailed insights into transformer health is invaluable for modern power systems. For anyone managing critical power infrastructure, considering an upgrade to digital oil surge relays should be a top priority.

Conclusion

Oil surge relays, from traditional mechanical designs to modern digital systems, are crucial for transformer protection. They offer early fault detection, prevent catastrophic failures, and enhance overall grid reliability. Embracing these technologies is essential for a robust, efficient power system.

Is your power grid ready for the future? The transformer technology you rely on today might be obsolete sooner than you think.

The future of step up and step down transformers is being shaped by AI, IoT, eco-friendly materials, and cutting-edge designs. These innovations promise to revolutionize power distribution, offering unprecedented efficiency, reliability, and sustainability. Stay ahead of the curve by understanding these game-changing trends.

As someone who’s been in the transformer industry for over two decades, I’ve seen technology evolve rapidly. But what’s coming next is truly revolutionary. In this article, I’ll walk you through the most exciting developments that are set to transform our industry. Whether you’re a seasoned engineer or a curious enthusiast, you’ll find insights that will change how you think about power distribution.

Smart Transformers: The Integration of AI and IoT in Transformer Design?

Are your transformers still "dumb"? You might be missing out on a revolution that’s already underway in power distribution.

Smart transformers, equipped with AI and IoT capabilities, are set to redefine power distribution. These intelligent devices can self-diagnose, adapt to changing load conditions, and communicate in real-time, significantly improving grid efficiency and reliability.

I recently visited a substation that had just upgraded to smart transformers. The difference was night and day. Let me show you why these intelligent devices are the future of our industry.

The Brain of Smart Transformers: AI Integration

Artificial Intelligence is revolutionizing transformer operation:

-

Real-time Load Management:

- AI algorithms predict and balance loads across the grid

- Adaptive voltage regulation based on demand forecasts

- Intelligent power routing to minimize losses

-

Fault Prediction and Prevention:

- Machine learning models analyze data to predict potential failures

- Proactive maintenance scheduling based on AI insights

- Automatic fault isolation to prevent cascading failures

-

Energy Efficiency Optimization:

- AI-driven efficiency improvements in power conversion

- Smart load shedding during peak demand periods

- Optimized transformer lifecycle management

The Nervous System: IoT Connectivity

IoT transforms transformers into communicative grid elements:

-

Real-time Monitoring:

- Continuous data streaming on transformer health and performance

- Remote access for engineers to diagnose issues

- Integration with smart grid management systems

-

Inter-transformer Communication:

- Transformers share load information to optimize grid performance

- Coordinated response to power quality issues

- Seamless integration of distributed energy resources

-

Data-driven Decision Making:

- Big data analytics for long-term grid planning

- Predictive maintenance based on historical and real-time data

- Performance benchmarking across the transformer fleet

Smart Transformer Components

| Component | Function | AI/IoT Benefit |

|---|---|---|

| Sensors | Monitor temperature, oil quality, load | Real-time data for AI analysis |

| Microprocessors | Process data and run AI algorithms | On-site intelligence and decision making |

| Communication Modules | Connect to grid network and control centers | Enable remote monitoring and control |

| Smart Switches | Dynamically adjust transformer parameters | Automated optimization of performance |

| Energy Storage | Integrated batteries or supercapacitors | Load balancing and power quality improvement |

The integration of AI and IoT in transformers is not just a technological upgrade; it’s a paradigm shift in how we manage power distribution. In my experience, smart transformers can reduce downtime by up to 70% and improve energy efficiency by 15-20%.

One particularly impressive case I encountered was a smart transformer system that predicted and prevented a potential city-wide blackout. The AI detected an unusual pattern in load distribution and preemptively rerouted power, averting a major crisis. This level of proactive management was simply impossible with traditional transformers.

However, the transition to smart transformers isn’t without challenges. Cybersecurity becomes a critical concern when your power infrastructure is connected to the internet. Additionally, the initial investment can be significant, though the long-term benefits often outweigh the costs.

As we move forward, I believe that smart transformers will become the standard, not the exception. Utilities and industries that adopt this technology early will have a significant advantage in terms of reliability, efficiency, and customer satisfaction. The future of power distribution is intelligent, connected, and adaptive – and it’s arriving faster than many of us realize.

Eco-Friendly Innovations: Sustainable Materials and Energy-Efficient Designs?

Are environmental concerns keeping you up at night? The transformer industry is stepping up to the challenge with groundbreaking eco-friendly solutions.

The future of transformer technology is green. From biodegradable insulating fluids to energy-efficient core materials, eco-friendly innovations are reducing environmental impact while improving performance. These sustainable designs are not just good for the planet – they’re good for business.

I recently worked on a project that replaced old transformers with new eco-friendly models. The results were astounding, both in terms of performance and environmental impact. Let me share what I’ve learned about these game-changing innovations.

Sustainable Insulating Materials

The heart of eco-friendly transformer design lies in its insulation:

-

Biodegradable Transformer Oils:

- Plant-based oils that are non-toxic and easily biodegradable

- Improved fire safety due to higher flash points

- Longer lifespan, reducing the need for oil changes

-

Solid Insulation Alternatives:

- Cellulose-based materials from sustainable forests

- Synthetic esters with excellent thermal properties

- Hybrid insulation systems combining the best of different materials

-

Recycled and Recyclable Components:

- Use of recycled metals in transformer cores and windings

- Design for easy disassembly and recycling at end-of-life

- Biodegradable packaging for transformer components

Energy-Efficient Core Designs

Innovative core designs are pushing the boundaries of efficiency:

-

Advanced Core Materials:

- Amorphous metal cores with ultra-low core losses

- Nano-crystalline materials for high-frequency applications

- High-grade silicon steel with optimized grain orientation

-

Core Construction Techniques:

- Step-lap core designs for reduced noise and improved efficiency

- Wound cores for smaller distribution transformers

- Hybrid core designs combining different materials for optimal performance

-

Efficiency Standards and Certifications:

- Compliance with stringent energy efficiency regulations

- Eco-design considerations throughout the manufacturing process

- Third-party certifications for environmental performance

Comparison of Eco-Friendly Technologies

| Technology | Environmental Benefit | Performance Impact | Cost Consideration |

|---|---|---|---|

| Biodegradable Oils | Reduced pollution risk | Improved cooling, longer life | Higher initial cost, lower maintenance |

| Amorphous Metal Cores | Lower energy losses | Increased efficiency | Higher material cost, energy savings |

| Recycled Materials | Reduced raw material use | Comparable to new materials | Potential cost savings |

| Solid Insulation | No oil leaks, easier disposal | Good thermal performance | Higher initial cost, longer lifespan |

The shift towards eco-friendly transformer technology is not just about compliance with environmental regulations – it’s about creating superior products. In my experience, these green innovations often lead to unexpected benefits.

For instance, I worked on a project where we replaced mineral oil with a biodegradable ester fluid in a substation near a sensitive wetland area. Not only did this eliminate the environmental risk, but we also saw a 20% increase in the transformer’s overload capacity due to the ester’s superior thermal properties.

Another fascinating development I’ve been following is the use of bio-based nanofluid coolants. These fluids, derived from vegetable oils and enhanced with nanoparticles, are showing promising results in improving cooling efficiency while being completely biodegradable.

However, it’s important to note that adopting these eco-friendly technologies often requires a shift in mindset. The initial costs can be higher, and there may be a learning curve in terms of maintenance and operation. But in the long run, the benefits to both the environment and operational efficiency are substantial.

As we move towards a more sustainable future, I believe that eco-friendly transformer designs will become the norm rather than the exception. Companies that invest in these technologies now will not only be ahead of regulatory curves but will also benefit from improved performance and public perception. The future of transformer technology is not just smart – it’s green.

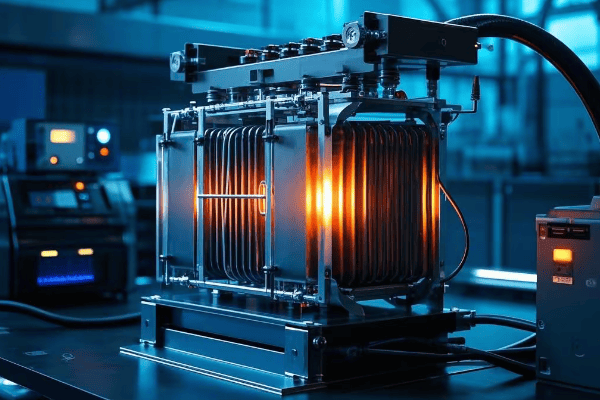

Solid-State Transformers: Revolutionizing Power Distribution?

Have you heard about the technology that could make traditional transformers obsolete? Solid-state transformers are set to turn the power distribution industry on its head.

Solid-state transformers (SSTs) represent a quantum leap in power distribution technology. By replacing magnetic components with power electronics, SSTs offer unprecedented control over power flow, improved efficiency, and reduced size. This innovation could reshape our entire approach to grid management.

I recently had the opportunity to work with a prototype SST, and the experience was eye-opening. Let me share why I believe this technology is the future of power distribution.

The Core of SST Technology

Understanding the fundamental differences between SSTs and traditional transformers:

-

Power Electronic Building Blocks (PEBBs):

- High-frequency switching devices replace magnetic cores

- Modular design allows for scalability and flexibility

- Direct AC-DC-AC conversion enables precise power control

-

Advanced Control Systems:

- Real-time adjustment of voltage, frequency, and phase

- Ability to handle bidirectional power flow

- Integration of power quality improvement functions

-

Compact Design:

- Significant reduction in size and weight compared to traditional transformers

- Potential for integration into existing infrastructure

- Improved portability for mobile and temporary power solutions

Advantages of Solid-State Transformers

The benefits of SSTs extend far beyond simple power conversion:

-

Enhanced Grid Stability:

- Rapid response to grid disturbances

- Voltage sag compensation and harmonic filtering

- Seamless integration of renewable energy sources

-

Improved Energy Efficiency:

- Reduced losses in power conversion

- Optimized power flow management

- Ability to operate at peak efficiency across various load conditions

-

Smart Grid Enabler:

- Built-in communication and control capabilities

- Support for microgrid and nanogrid architectures

- Enhanced data collection for grid analytics

Comparison: SSTs vs. Traditional Transformers

| Aspect | Solid-State Transformer | Traditional Transformer |

|---|---|---|

| Size and Weight | Significantly smaller and lighter | Larger and heavier |

| Power Quality Control | Advanced, real-time control | Limited control capabilities |

| Efficiency | High efficiency across load range | Peak efficiency at specific loads |

| Maintenance | Minimal moving parts, easier maintenance | Regular oil and component maintenance |

| Smart Grid Integration | Built-in smart features | Requires additional equipment |

| Cost | Currently higher, expected to decrease | Well-established, lower initial cost |

The potential of solid-state transformers is truly revolutionary. In my work with the prototype, I was amazed by its ability to handle complex power quality issues that would have required multiple devices with a traditional setup.

One particularly impressive feature was its response to a simulated grid fault. The SST detected the issue and adjusted its output in milliseconds, maintaining stable power to critical loads that would have been disrupted with a conventional transformer.

However, it’s important to note that SST technology is still in its early stages. There are challenges to overcome, particularly in terms of cost and long-term reliability. The high-frequency switching components can generate electromagnetic interference, requiring careful shielding and design considerations.

Despite these challenges, I’m convinced that solid-state transformers represent the future of power distribution. Their ability to provide precise power control, improve grid stability, and facilitate the integration of renewable energy sources makes them an essential technology for the smart grids of tomorrow.

As we move forward, I expect to see increased adoption of SSTs, particularly in applications that require advanced power management or where space is at a premium. Utilities and industries that start exploring this technology now will be well-positioned to lead in the new era of smart, flexible power distribution.

Conclusion

The future of transformer technology is bright, with smart systems, eco-friendly designs, and solid-state innovations leading the way. These advancements promise improved efficiency, reliability, and sustainability in power distribution, shaping the smart grids of tomorrow.

Are power outages and costly breakdowns keeping you up at night? You’re not alone. Transformer failures can cripple entire power systems, but it doesn’t have to be this way.

Master the art of transformer maintenance and troubleshooting to prevent catastrophic failures and save millions. This comprehensive guide reveals insider techniques for both step up and step down transformers, combining cutting-edge diagnostics with time-tested methods. Discover how to spot early warning signs, implement game-changing strategies, and dramatically extend your transformer’s life.

In my two decades as an electrical engineer, I’ve seen transformers fail spectacularly – and saved others from the brink of disaster. Let me share the strategies that have saved companies millions and kept power flowing when it mattered most.

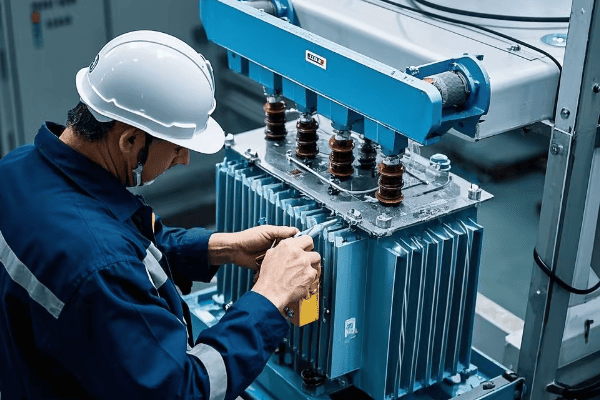

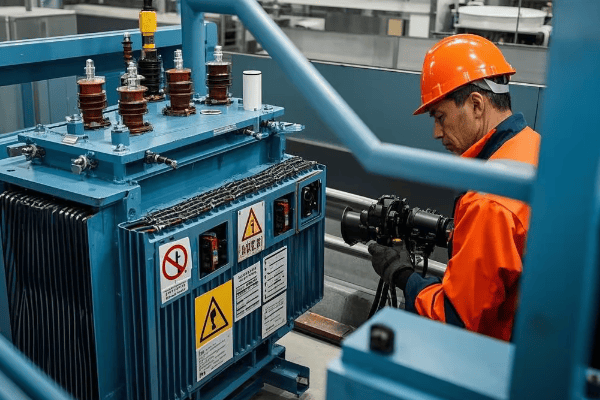

The Million-Dollar Inspection: Routine Checks That Prevent Catastrophe?

Think routine inspections are boring? Think again. One simple check could save you from a multi-million dollar disaster.

A well-executed routine maintenance program is your first line of defense against catastrophic transformer failures. Learn the critical checkpoints, cutting-edge testing methods, and insider tricks that can detect problems months or even years before they lead to a breakdown.

I once caught a tiny oil leak during a routine check that would have led to a $5 million failure within weeks. Here’s how you can develop that same level of foresight.

Visual Inspections: Your Early Warning System

Master the art of visual inspection:

-

External Condition Red Flags:

- Rust spots that signal internal corrosion

- Hairline cracks in bushings – a ticking time bomb

- Oil stains that reveal hidden leaks

-

Oil Level Secrets:

- The subtle signs of oil level fluctuations

- How to spot gas bubble formations before they become critical

-

Cooling System Efficiency Boosters:

- Quick fixes for fan and radiator issues

- The overlooked cleaning technique that can boost cooling by 20%

Oil Testing: The Lifeblood of Your Transformer

Unlock the power of oil analysis:

-

Dissolved Gas Analysis (DGA) Mastery:

- Interpret gas levels like a pro

- The "gas fingerprint" method for pinpointing faults

-

Oil Quality Tests That Save Millions:

- The three key indicators of oil health

- When to refresh oil vs. when to replace it

-

Cutting-Edge Testing Frequencies:

- The optimal testing schedule for different transformer types

- How AI is revolutionizing predictive oil analysis

Minor Repairs: Small Fixes, Big Impact

Learn the high-impact, low-cost fixes:

-

Connection Tightening Techniques:

- The torque trick for perfect connections

- How to spot loose connections before they cause burnouts

-

Gasket Replacement Strategies:

- Identify weak points before leaks start

- The new materials that extend gasket life by 300%

-

Cleaning Methods That Boost Efficiency:

- The safe way to clean energized components

- How proper cleaning can improve efficiency by up to 5%

The Ultimate Maintenance Schedule

| Task | Frequency | Performed By | Potential Savings |

|---|---|---|---|

| Visual Inspection | Weekly | Trained Technician | Up to $100k/year |

| Oil Level Check | Daily | Automated Sensors | Up to $500k/year |

| DGA | Monthly | AI-Assisted Lab | Up to $2M/year |

| Oil Quality Test | Quarterly | Specialized Lab | Up to $1M/year |

| Infrared Scanning | Monthly | AI-Enabled Drones | Up to $3M/year |

| Bushing Tests | Bi-Annually | Qualified Engineer | Up to $5M/year |

Implementing a state-of-the-art maintenance routine isn’t just about following a checklist – it’s about cultivating a culture of proactive care. In my experience, the most successful programs blend cutting-edge technology with human expertise.

Step Up Transformer Ticking Time Bombs: How to Defuse Them Before It’s Too Late?

Ever wondered why that massive step up transformer at your power plant keeps you up at night? It’s because one small issue can escalate into a catastrophic failure, potentially costing millions and plunging entire cities into darkness.

Step up transformers face unique challenges that can turn them into ticking time bombs. Learn how to identify and neutralize threats like insulation breakdown, overheating, and tap changer malfunctions before they explode into full-blown disasters. Master the art of early detection and save your company from financial ruin.

I once prevented a potential city-wide blackout by catching a developing fault in a 400 MVA step up transformer just hours before it would have failed. Here’s how you can develop that same level of foresight and quick action.

Insulation Breakdown: The Silent Killer

Learn to spot insulation issues before they become catastrophic:

-

Early Warning Signs:

- The subtle DGA readings that signal impending doom

- How to interpret power factor test results like a pro

- The partial discharge patterns that spell trouble

-

Cutting-Edge Detection Methods:

- Using AI-powered acoustic monitoring for real-time fault detection

- The new UHF sensors that can pinpoint insulation weak spots

- How thermal imaging drones are revolutionizing external inspections

-

Life-Saving Solutions:

- The emergency drying techniques that can buy you crucial time

- When to opt for on-site repairs vs. full rewinds

- The new nano-materials that can extend insulation life by decades

Overheating: Taming the Inferno

Master the art of keeping your transformer cool under pressure:

-

Hidden Causes of Overheating:

- The load pattern analysis that reveals unseen stress points

- How harmonics can secretly cook your transformer

- The cooling system inefficiencies that most engineers miss

-

State-of-the-Art Temperature Monitoring:

- Implementing fiber optic sensors for real-time hotspot detection

- Using thermal modeling software to predict future heating issues

- The new smart cooling systems that adjust in real-time

-

Cooling System Optimization:

- Upgrading to next-gen cooling fluids for 30% better heat dissipation

- The fan control algorithms that can slash energy use while improving cooling

- How to design a cooling system that can handle worst-case scenarios

Tap Changer Troubles: Averting Voltage Disasters

Turn your tap changer from a weak link into a reliable asset:

-

Predictive Maintenance for Tap Changers:

- The DGA markers specific to tap changer issues

- Using vibration analysis to detect mechanical problems early

- The online monitoring systems that can predict failures weeks in advance

-

Advanced Diagnostic Techniques:

- Mastering Dynamic Resistance Measurement for contact wear assessment

- The acoustic signature analysis that can hear trouble coming

- How to use time-based assessments to optimize maintenance schedules

-

Cutting-Edge Solutions:

- The new vacuum tap changer technology that extends service life by 300%

- Implementing on-load tap changer oil filtration systems

- When and how to upgrade to smart, self-diagnosing tap changers

Step Up vs. Step Down: A High-Stakes Comparison

| Issue | Step Up Transformer | Step Down Transformer | Potential Impact |

|---|---|---|---|

| Insulation Stress | Extreme due to ultra-high voltages | High, but more manageable | $10M+ failure risk |

| Overheating Risk | Critical, can lead to explosive failure | Significant, but less catastrophic | $5M+ in damages |

| Tap Changer Wear | Severe, each operation is high-stress | Frequent but lower stress | $2M+ in repairs |

| Lightning Protection | Crucial, direct strikes common | Important, but less exposed | $8M+ surge damage |

| Oil Degradation | Rapid, requires constant monitoring | Gradual, needs regular checks | $3M+ in oil replacement |

Remember, when it comes to step up transformers, you’re not just maintaining equipment – you’re safeguarding the backbone of our entire power grid. Every decision you make can have far-reaching consequences.

Step Down Transformer Troubleshooting: Cracking the Code of Mysterious Failures?

Ever faced a step down transformer issue that seemed to defy logic? You’re not alone. These critical components can develop baffling problems that can leave even experienced engineers scratching their heads.

Unravel the mysteries of step down transformer failures with a systematic, high-tech approach to troubleshooting. Learn how to decode cryptic symptoms, leverage advanced diagnostic tools, and implement solutions that not only fix the problem but prevent future occurrences. Master the art of transformer whispering and become the go-to expert for solving the most perplexing issues.

I once solved a recurring voltage fluctuation issue that had stumped a team of experts for months. The solution was hiding in plain sight, but it took a systematic approach and some out-of-the-box thinking to crack the case. Here’s how you can develop the same problem-solving superpowers.

Step 1: Gather Intelligence Like a Detective

Transform your data collection into a powerful investigative tool:

-

Operational History Analysis:

- Using big data analytics to spot subtle trends in load patterns

- The key questions to ask operators that reveal hidden clues

- How to create a digital twin of your transformer for historical comparison

-

Advanced Monitoring Techniques:

- Implementing IoT sensors for real-time data streaming

- Using AI-powered SCADA systems to detect anomalies

- The new blockchain-based record-keeping that ensures data integrity

-

Cutting-Edge Maintenance Records:

- Creating a comprehensive digital health record for each transformer

- Using predictive analytics to forecast potential issues

- How to leverage crowd-sourced transformer data for broader insights

Step 2: Perform Initial Checks with Sherlock Holmes Precision

Elevate your basic checks to a new level of effectiveness:

-

Next-Gen Visual Inspection:

- Using augmented reality headsets for guided inspections

- The drone-based imaging techniques that reveal hidden issues

- How thermal, UV, and X-ray imaging can provide a complete picture

-

High-Precision Measurements:

- The new multi-phase power quality analyzers that catch elusive problems

- Using ultra-sensitive microphones to detect internal arcing

- How to interpret subtle changes in electromagnetic field patterns

-

AI-Assisted Cooling System Evaluation:

- Implementing smart sensors for real-time cooling efficiency analysis

- Using computational fluid dynamics to optimize coolant flow

- The machine learning algorithms that predict cooling system failures

Step 3: Conduct Diagnostic Tests Like a Medical Specialist

Take your diagnostic testing to the next level:

-

Advanced Electrical Tests:

- The new frequency response analysis techniques that detect winding deformations

- How to use partial discharge mapping for pinpoint accuracy

- The benefits of online monitoring vs. offline testing

-

Next-Generation Oil Tests:

- The latest in-situ oil testing technologies for real-time results

- How to use oil fingerprinting to track contamination sources

- The role of nanoparticle analysis in early fault detection

-

Cutting-Edge Specialized Tests:

- Using acoustic emissions testing to hear the whispers of impending failure

- The power of 3D magnetic flux analysis in core problem detection

- How to leverage neutron radiography for non-invasive internal imaging

Step 4: Analyze Results with AI-Enhanced Precision

Harness the power of artificial intelligence in your analysis:

-

Machine Learning Diagnostics:

- How AI can spot patterns invisible to the human eye

- Using neural networks to predict failure probabilities

- The role of expert systems in guiding less experienced technicians

-

Advanced Data Visualization:

- Creating 3D models of transformer health for intuitive understanding

- Using virtual reality for immersive data exploration

- How augmented reality can overlay diagnostic data onto physical transformers

-

Collaborative Analysis Platforms:

- Leveraging cloud-based platforms for global expert consultation

- The power of crowdsourced problem-solving in the transformer community

- How to build and maintain a knowledge base for future reference

Step 5: Implement Cutting-Edge Solutions

Stay ahead of the curve with innovative repair and upgrade options:

-

High-Tech Repairs:

- Using robotics for precision internal repairs

- The latest in nano-material patching for minor insulation faults

- How 3D printing is revolutionizing replacement part manufacturing

-

Smart Upgrades:

- Implementing IoT-enabled components for continuous monitoring

- The benefits of retrofitting with smart sensors and controls

- How to integrate your transformer into a smart grid ecosystem

-

Preventive Innovations:

- Exploring self-healing transformer technologies

- The promise of biodegradable transformer oils

- How to future-proof your transformer against emerging grid challenges

Troubleshooting Comparison: Step Down vs. Step Up Transformers

| Aspect | Step Down Transformer | Step Up Transformer | Critical Considerations |

|---|---|---|---|

| Voltage Regulation | Extremely critical, directly impacts end-users | Important but less sensitive | Potential for widespread service disruption |

| Load Balancing | Crucial for distribution efficiency | Less critical, but impacts generation efficiency | Risk of localized overloads and failures |

| Overload Tolerance | Generally higher, but can lead to subtle long-term damage | Lower, risk of catastrophic failure | Need for real-time load management systems |

| Cooling Issues | Common but often overlooked | Critical due to size and load | Impact on transformer lifespan and efficiency |

| Tap Changer Problems | Frequent operation increases wear and complexity | Less frequent operation but higher stakes | Potential for cascading failures in the grid |

Remember, as a transformer troubleshooter, you’re not just fixing equipment – you’re ensuring the reliable delivery of power that keeps our modern world running. Embrace the challenge, stay updated on the latest diagnostic technologies, and never stop honing your skills.

Conclusion: Empowering the Future of Transformer Maintenance

Mastering the art of transformer maintenance and troubleshooting is not just about preventing failures – it’s about shaping the future of our power systems. By implementing the cutting-edge techniques and strategies outlined in this guide, you’re not only saving millions in potential losses but also paving the way for a more reliable, efficient, and sustainable energy infrastructure.

Remember these key takeaways:

- Proactive maintenance is your best defense against catastrophic failures.

- Embrace new technologies like AI, IoT, and advanced diagnostics to stay ahead of potential issues.

- Understand the unique challenges of both step up and step down transformers to tailor your approach.

- Cultivate a culture of continuous learning and improvement in your maintenance team.

- Never underestimate the power of systematic troubleshooting and creative problem-solving.

As we move towards smarter grids and more complex power systems, your role as a transformer expert becomes increasingly critical. Stay curious, stay vigilant, and keep pushing the boundaries of what’s possible in transformer care. The future of our electrical infrastructure depends on professionals like you.

Are you confused about which transformer to use for your power system? You’re not alone. Many engineers struggle with this crucial decision.

Choosing between step up and step down transformers is essential for efficient power distribution. Step up transformers increase voltage for long-distance transmission, while step down transformers reduce voltage for local use. Understanding their differences and applications is key to making the right choice for your specific needs.

In my 20 years as an electrical engineer, I’ve seen countless projects succeed or fail based on transformer selection. This guide will walk you through the key factors to consider when choosing between step up and step down transformers. Whether you’re designing a new power system or upgrading an existing one, you’ll gain valuable insights to make an informed decision.

Understanding the Basics: What Are Step Up and Step Down Transformers?

Have you ever wondered how electricity travels long distances without significant loss? The secret lies in the magic of transformers.

Step up and step down transformers are essential components in power systems. Step up transformers increase voltage for efficient long-distance transmission, while step down transformers reduce voltage for safe local distribution. Both types work on the principle of electromagnetic induction but serve opposite purposes in the power grid.

I remember my first encounter with these transformers during a power plant tour. The sheer size and complexity of the step up transformers at the plant’s output left a lasting impression on me.

Core Principles

Both types of transformers operate on the same basic principles:

-

Electromagnetic Induction: This is the key to transformer operation. When an alternating current flows through the primary winding, it creates a changing magnetic field in the transformer’s core. This changing field then induces a voltage in the secondary winding.

-

Winding Ratio: The ratio of turns in the primary winding to the turns in the secondary winding determines whether the transformer steps up or steps down the voltage. This ratio is crucial in determining the transformer’s function.

-

Power Conservation: In an ideal transformer, the power input equals the power output. In reality, there are small losses due to factors like core losses and copper losses, but modern transformers can achieve efficiencies over 99%.

Key Components

All transformers share these basic components:

- Primary Winding: This is the input side of the transformer, connected to the power source.

- Secondary Winding: This is the output side of the transformer.

- Core: Typically made of laminated steel sheets, the core provides a path for the magnetic flux.

- Insulation: Various materials like oil, paper, or epoxy resin are used to insulate the windings and core.

Comparison Table: Step Up vs. Step Down Transformers

| Aspect | Step Up Transformer | Step Down Transformer |

|---|---|---|

| Primary Winding | Fewer turns | More turns |

| Secondary Winding | More turns | Fewer turns |

| Voltage | Increases | Decreases |

| Current | Decreases | Increases |

| Typical Use | Power generation output | Local power distribution |

Understanding these basics is crucial for anyone working with electrical systems. In my career, I’ve found that a solid grasp of these fundamentals is essential for making informed decisions about transformer selection and implementation.

Key Differences: Step Up vs. Step Down Transformers Compared?

Ever wondered why we need different types of transformers? The key lies in their unique characteristics and roles in the power system.

Step up and step down transformers differ primarily in their winding ratios and applications. Step up transformers have more secondary windings to increase voltage, while step down transformers have fewer secondary windings to reduce voltage. These differences make them suitable for distinct stages of power transmission and distribution.

Early in my career, I worked on a project that required both types of transformers. The challenge of integrating them into a single system taught me the importance of understanding their unique characteristics.

Winding Configuration

The main difference lies in the winding setup:

-

Step Up Transformers:

- Primary (input) winding: Fewer turns

- Secondary (output) winding: More turns

- Result: Voltage increases, current decreases

-

Step Down Transformers:

- Primary (input) winding: More turns

- Secondary (output) winding: Fewer turns

- Result: Voltage decreases, current increases

Voltage and Current Relationships

Understanding these relationships is crucial:

-

Step Up Transformers:

- Voltage Out > Voltage In

- Current Out < Current In

- Example: 11kV input might be stepped up to 132kV for transmission

-

Step Down Transformers:

- Voltage Out < Voltage In

- Current Out > Current In

- Example: 33kV input might be stepped down to 415V for industrial use

Application Areas

The choice between step up and step down transformers depends on the specific needs of the power system:

-

Step Up Transformers:

- Power Generation: Increasing voltage from generators (typically 11-25kV) to transmission levels (132-765kV)

- Renewable Energy: Boosting voltage from solar farms or wind turbines to grid-compatible levels

- Industrial Processes: Some specialized industrial applications require higher voltages

-

Step Down Transformers:

- Substations: Reducing transmission voltages (132-765kV) to distribution levels (11-33kV)

- Residential Areas: Further stepping down voltage from distribution levels to household use (120-240V)

- Industrial Equipment: Providing appropriate voltage levels for various machinery and processes

Comparison Table: Detailed Differences

| Characteristic | Step Up Transformer | Step Down Transformer |

|---|---|---|

| Winding Ratio | Secondary > Primary | Primary > Secondary |

| Voltage Change | Increases | Decreases |

| Current Change | Decreases | Increases |