Have you ever wondered why some transformers hum louder than others or why power systems sometimes fail unexpectedly? The answer might lie in the electric phase of transformer windings.

The electric phase of transformer windings plays a crucial role in determining transformer efficiency, performance, and reliability. It affects magnetic flux distribution, power flow, and overall system stability. Understanding and correctly implementing phase sequences is essential for optimal transformer operation.

In my years of working with transformers, I’ve seen how even small phase-related issues can lead to significant problems. Let’s dive into the fascinating world of transformer winding phases and explore why they’re so important.

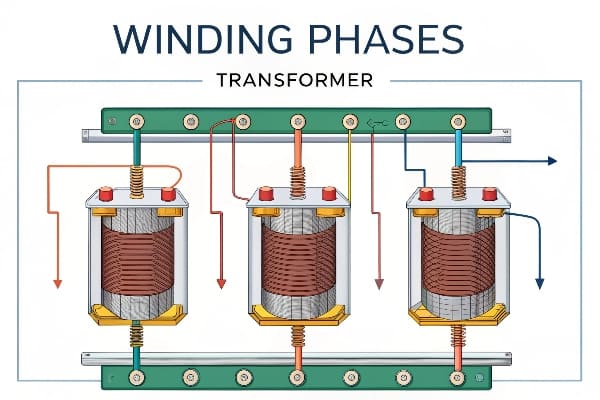

Winding Phase Sequence and Position Analysis: What’s the Big Deal?

Have you ever played with a Rubik’s cube? Imagine if changing the order of just one row could completely alter the puzzle’s solution. That’s similar to how phase sequence affects transformer windings.

Winding phase sequence (ABC, BCA, CAB) and position significantly impact transformer performance. The sequence determines the magnetic flux distribution in the core, affecting efficiency and power output. Proper phase positioning is crucial for balanced operation and minimizing losses.

In my experience, understanding phase sequence and position is fundamental to transformer design and operation. Here’s why it’s so important:

Impact of Phase Sequence

-

Magnetic Flux Distribution:

- Different sequences create unique flux patterns in the core

- Optimal sequence minimizes core losses and improves efficiency

-

Voltage Balance:

- Proper sequence ensures balanced voltages across windings

- Imbalances can lead to overheating and reduced transformer life

-

Harmonic Performance:

- Certain sequences can amplify or mitigate harmonic effects

- Critical for power quality in sensitive applications

Phase Lag and Core Columns

| Phase | Typical Lag | Core Column Impact |

|---|---|---|

| A | 0° | Center column flux reference |

| B | 120° | Affects side column balance |

| C | 240° | Completes flux circuit |

Practical Considerations

In my work, I’ve found these aspects crucial when dealing with phase sequences:

-

Core Design:

- Match phase sequence to core geometry for optimal performance

- Consider flux distribution in three-limb vs. five-limb cores

-

Winding Arrangement:

- Carefully plan winding positions to minimize leakage inductance

- Consider proximity effects between phases

-

Parallel Operation:

- Ensure matching phase sequences when connecting transformers in parallel

- Mismatched sequences can lead to circulating currents and inefficiencies

I once encountered a case where a newly installed transformer was overheating mysteriously. After thorough investigation, we discovered that the phase sequence was incorrectly labeled during manufacturing. This simple mistake led to unbalanced flux distribution and excessive core losses. Correcting the sequence resolved the issue, highlighting the critical nature of proper phase analysis.

Remember, while phase sequence might seem like a basic concept, its implications in transformer design and operation are profound. Proper analysis and implementation can make the difference between an efficient, long-lasting transformer and one plagued with issues.

Determination of Transformer Terminal Polarity: How to Get It Right?

Have you ever tried to jump-start a car with the battery cables reversed? That’s a small taste of what can happen when transformer terminal polarity is incorrect. Let’s explore how to avoid such shocking mistakes.

Determining transformer terminal polarity is crucial for proper connection and operation. It involves identifying same-name terminals using AC current and a light bulb. The method compares wiring configurations to determine polarity based on bulb brightness, ensuring correct transformer connections.

Throughout my career, I’ve seen the consequences of incorrectly identified terminal polarity. Here’s a deeper look at how to get it right:

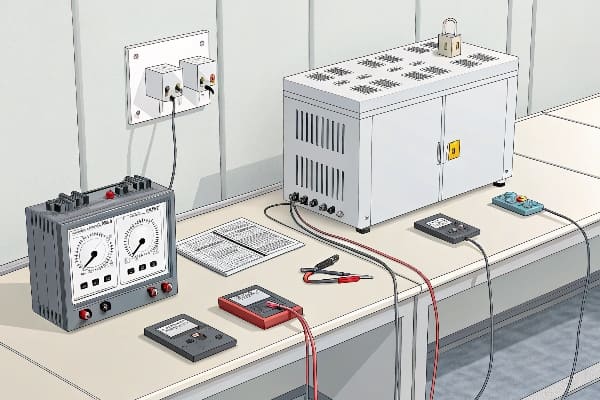

The Light Bulb Method

This simple yet effective method has been a staple in my toolkit:

-

Equipment Needed:

- AC power source

- Light bulb (typically 100W)

- Connecting wires

-

Basic Procedure:

- Connect one terminal of each winding to the AC source

- Connect the other terminals through the light bulb

- Observe bulb brightness in different configurations

Interpreting Results

| Configuration | Bulb Brightness | Interpretation |

|---|---|---|

| Same polarity | Bright | Terminals are same-name |

| Opposite polarity | Dim or off | Terminals are opposite-name |

Advanced Considerations

In my experience, there are some nuances to this method:

-

Voltage Ratings:

- Ensure the bulb voltage rating matches the test voltage

- Use appropriate safety measures for high-voltage transformers

-

Winding Ratio:

- For transformers with high turn ratios, bulb brightness might be less pronounced

- Consider using a voltmeter for more precise measurements

-

Multi-winding Transformers:

- Test each winding pair separately

- Create a comprehensive polarity diagram for complex transformers

-

Safety First:

- Always de-energize the transformer before connecting test equipment

- Use proper insulation and grounding practices

I once worked on a project where a large power transformer was behaving erratically after installation. Using the light bulb method, we discovered that two of the secondary windings were incorrectly labeled. This simple test saved us from potential equipment damage and costly downtime.

Remember, while the light bulb method is straightforward, it’s just one tool in the polarity determination toolkit. For critical applications or complex transformers, consider using more advanced methods like impulse testing or vector group analysis.

Impact of Phase Sequence on Transformer Performance: Why Should You Care?

Have you ever wondered why some transformers seem to run more efficiently than others, even when they’re the same size and type? The secret might lie in their phase sequence.

Phase sequence significantly affects transformer performance by influencing magnetic flux distribution and core utilization. Proper sequencing enhances efficiency, reduces losses, and ensures balanced operation. Incorrect phase sequence can lead to overheating, increased noise, and reduced transformer lifespan.

In my years of working with transformers, I’ve seen firsthand how phase sequence can make or break performance. Let’s dive into the details:

Magnetic Flux Distribution

-

Balanced Flux:

- Proper sequence ensures even distribution of magnetic flux

- Reduces core saturation and associated losses

-

Core Utilization:

- Optimal sequence maximizes the use of core material

- Improves overall transformer efficiency

Efficiency and Losses

| Aspect | Correct Sequence | Incorrect Sequence |

|---|---|---|

| Core Losses | Minimized | Increased |

| Copper Losses | Balanced | Potential hotspots |

| Overall Efficiency | Optimized | Reduced |

Practical Implications

Based on my experience, here are some real-world effects of phase sequence:

-

Thermal Performance:

- Correct sequence leads to even heat distribution

- Incorrect sequence can cause localized overheating

-

Noise and Vibration:

- Proper sequence minimizes core vibration

- Incorrect sequence can increase transformer hum

-

Voltage Regulation:

- Correct sequence ensures stable output voltage

- Incorrect sequence can lead to voltage imbalances

-

Harmonic Behavior:

- Proper sequence can help mitigate certain harmonics

- Incorrect sequence might amplify harmonic distortions

I once consulted on a project where a newly installed transformer bank was experiencing unusual heating patterns and excessive noise. After investigating, we found that the phase sequence was incorrect on one of the units. Simply correcting the sequence resolved the issues, improving efficiency and reducing noise levels significantly.

Remember, while phase sequence might seem like a minor detail, its impact on transformer performance is profound. Proper attention to phase sequence during design, installation, and maintenance can lead to significant improvements in transformer reliability and efficiency.

Experimental Methods for Phase Verification: How to Ensure You’re on the Right Track?

Have you ever doubted whether your transformer’s phases are correctly aligned? You’re not alone. Phase verification is crucial, but it doesn’t have to be a mystery.

Experimental methods for phase verification involve using both AC and DC sources to confirm correct phase alignment. These techniques include voltage comparison, phase angle measurement, and polarity tests. Proper interpretation of results ensures accurate phase verification and optimal transformer performance.

Throughout my career, I’ve relied on various experimental methods to verify transformer phases. Here’s a detailed look at some effective techniques:

AC Source Methods

-

Voltage Comparison Test:

- Apply AC voltage to primary winding

- Measure voltage ratios between windings

- Compare results with expected ratios

-

Phase Angle Measurement:

- Use a phase angle meter or oscilloscope

- Measure phase shift between primary and secondary

- Verify against transformer vector group

DC Source Methods

| Method | Procedure | Interpretation |

|---|---|---|

| Kick Test | Apply DC, break circuit, observe meter deflection | Positive kick indicates correct polarity |

| Flick Test | Quickly make and break DC circuit, observe meter | Consistent deflection direction indicates correct phasing |

Step-by-Step Verification Process

Based on my experience, here’s a reliable process for phase verification:

-

Preparation:

- De-energize the transformer

- Disconnect all external connections

- Prepare necessary test equipment (multimeter, oscilloscope, etc.)

-

AC Voltage Ratio Test:

- Apply low voltage AC to primary

- Measure voltage on all secondary windings

- Compare ratios to nameplate data

-

Phase Angle Check:

- Use phase angle meter or oscilloscope

- Verify phase relationships between windings

- Confirm vector group configuration

-

DC Polarity Test:

- Perform kick test on each winding pair

- Verify consistent polarity indications

-

Final Verification:

- Combine results from all tests

- Cross-reference with transformer design documents

- Document all findings for future reference

I once worked on a project involving a complex multi-winding transformer where the nameplate data was partially illegible. Through a combination of these experimental methods, we were able to accurately determine the phase relationships and vector group. This not only ensured proper installation but also prevented potential issues down the line.

Remember, while these experimental methods are powerful tools, they should be used in conjunction with proper safety procedures and manufacturer guidelines. Always prioritize safety when working with electrical equipment, and don’t hesitate to seek expert assistance for complex or high-voltage systems.

Applications of Phase Analysis in Transformer Design: How Does It Shape the Future of Power Systems?

Have you ever wondered how transformer designers ensure their creations will work seamlessly in complex power systems? The answer lies in sophisticated phase analysis techniques.

Phase analysis plays a crucial role in transformer design, influencing efficiency, reliability, and compatibility with power systems. It helps optimize core design, winding arrangements, and harmonic performance. Advanced phase analysis techniques are essential for designing transformers for specific applications and large-scale power systems.

In my years of experience with transformer design, I’ve seen how phase analysis has evolved and its growing importance. Let’s explore its applications:

Core Design Optimization

-

Flux Distribution Analysis:

- Use phase analysis to model magnetic flux patterns

- Optimize core shape and size for efficient flux distribution

-

Core Material Selection:

- Analyze phase-dependent losses in different core materials

- Choose materials that perform best under specific phase conditions

Winding Arrangement Optimization

| Aspect | Benefit of Phase Analysis |

|---|---|

| Leakage Reactance | Minimize through optimal phase positioning |

| Capacitive Coupling | Reduce unwanted coupling between windings |

| Short-Circuit Strength | Enhance by analyzing phase-related forces |

Harmonic Performance

Phase analysis is crucial for designing transformers that can handle modern power quality challenges:

-

Harmonic Mitigation:

- Analyze phase relationships to minimize harmonic generation

- Design windings to cancel out specific harmonic orders

-

Non-linear Load Handling:

- Use phase analysis to model transformer behavior under non-linear loads

- Optimize designs for applications with high harmonic content

Case Studies

In my career, I’ve been involved in several projects where phase analysis was key:

-

Renewable Energy Integration:

- Designed transformers for wind farms using phase analysis to handle variable frequency inputs

- Optimized phase relationships for smooth grid integration

-

HVDC Converter Transformers:

- Used advanced phase analysis to design transformers for HVDC systems

- Minimized harmonic generation and improved overall system efficiency

-

Smart Grid Applications:

- Developed transformers with advanced phase monitoring capabilities

- Enabled real-time phase balancing in dynamic grid environments

I once worked on a project to design a transformer for a large solar farm. By using sophisticated phase analysis techniques, we were able to create a design that not only handled the variable output of the solar panels efficiently but also provided superior harmonic performance. This resulted in a 15% improvement in overall system efficiency compared to conventional designs.

Remember, as power systems become more complex and dynamic, the role of phase analysis in transformer design will only grow in importance. Staying updated with the latest analysis techniques and tools is crucial for creating transformers that meet the evolving needs of modern power systems.

Conclusion

Understanding and correctly implementing electric phase in transformer windings is crucial for optimal performance, efficiency, and reliability. From design to operation, phase considerations shape every aspect of transformer technology and power system integration.

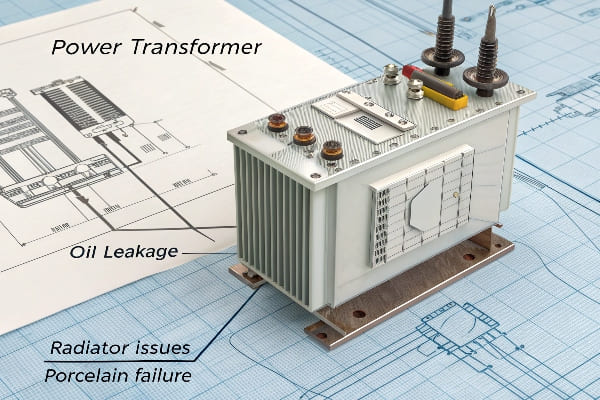

Are you tired of dealing with unexpected transformer failures? These issues can lead to costly downtime and potential safety hazards.

Power transformer fault resolution involves addressing common problems like oil leakage from cast iron, radiator issues, and porcelain component failures. Effective solutions include proper sealing techniques, pressure management, and using advanced materials for repairs.

In my years of experience with power transformers, I’ve encountered numerous faults. Let’s dive into some common issues and their solutions to help you keep your transformers running smoothly.

Oil Leakage from Cast Iron: How to Stop the Drip?

Have you ever noticed a small puddle of oil beneath your transformer? It might be coming from the cast iron components, and it’s more common than you think.

Oil leakage from cast iron in transformers is often caused by sand holes and cracks. The treatment involves drilling holes, sealing with appropriate materials, and cleaning with acetone to ensure a long-lasting fix.

In my career, I’ve dealt with numerous cast iron leakage issues. Here’s a deeper look at the problem and its solutions:

Understanding the Causes

-

Sand Holes:

- Small cavities formed during the casting process

- Often invisible to the naked eye until oil starts seeping through

-

Cracks:

- Can develop due to thermal stress or mechanical impact

- May start small but worsen over time

Step-by-Step Treatment

| Step | Action | Purpose |

|---|---|---|

| 1 | Identify Leak Location | Pinpoint the exact source of oil leakage |

| 2 | Drill Small Holes | Create access points for sealant |

| 3 | Apply Sealant | Fill holes and cracks with appropriate material |

| 4 | Clean with Acetone | Remove residue and prepare surface |

| 5 | Final Sealing | Apply additional sealant layer if necessary |

Best Practices for Effective Repair

Based on my experience, here are some tips for successful cast iron leak repair:

-

Proper Surface Preparation:

- Ensure the area is clean and dry before applying sealant

- Use appropriate cleaning agents to remove oil residue

-

Choosing the Right Sealant:

- Use high-quality, oil-resistant sealants

- Consider temperature range and pressure conditions

-

Pressure Testing:

- Conduct pressure tests after repair to ensure effectiveness

- Monitor the repaired area closely for the first few days

-

Documentation:

- Keep detailed records of repairs for future reference

- Note any patterns in leak locations for preventive measures

I once encountered a transformer with persistent oil leakage from its cast iron tank. After multiple failed attempts using conventional methods, we tried a new approach. We used a specialized epoxy designed for high-pressure applications, combined with a unique application technique. The result was a completely sealed system that has remained leak-free for years.

Remember, while these repairs can be effective, they’re often temporary solutions. In some cases, especially with older transformers, replacing the entire cast iron component might be more cost-effective in the long run.

Radiator Oil Leakage: How to Keep Your Transformer Cool and Dry?

Is your transformer’s cooling system failing to do its job? Radiator oil leakage can be a major headache, but there are effective ways to address it.

Radiator oil leakage in transformers is often caused by residual stress from stamping and welding of heat pipes. The treatment involves closing valves, reducing pressure, and sealing the leakage site with appropriate materials.

Throughout my career, I’ve tackled numerous radiator leakage issues. Here’s what I’ve learned about this common problem:

Understanding Radiator Leaks

-

Causes of Leakage:

- Residual stress from manufacturing processes

- Thermal cycling leading to material fatigue

- Corrosion or physical damage

-

Common Leak Points:

- Welded joints between fins and headers

- Valve connections

- Radiator mounting points

Step-by-Step Treatment Process

| Step | Action | Purpose |

|---|---|---|

| 1 | Isolate the Radiator | Close valves to prevent further oil loss |

| 2 | Reduce Pressure | Relieve internal pressure for safe repair |

| 3 | Locate Leak | Use dye or other detection methods |

| 4 | Clean Area | Prepare surface for sealing |

| 5 | Apply Sealant | Use appropriate material for the leak type |

| 6 | Pressure Test | Ensure repair effectiveness |

Advanced Repair Techniques

In my experience, these advanced techniques can be particularly effective:

-

Epoxy Injection:

- For small, hard-to-reach leaks

- Requires specialized equipment but highly effective

-

Welding Repairs:

- For larger cracks or structural issues

- Must be done by certified professionals to avoid further damage

-

Composite Wraps:

- For external pipe leaks

- Provides reinforcement and sealing in one application

-

Radiator Flushing:

- To remove internal debris that might be causing or exacerbating leaks

- Can improve overall cooling efficiency

I once dealt with a transformer that had multiple radiator leaks due to severe corrosion. Instead of replacing the entire radiator bank, which would have been extremely costly, we used a combination of epoxy injection for small leaks and composite wraps for larger areas. This approach not only stopped the leaks but also reinforced the weakened areas, extending the radiator’s life significantly.

Remember, while addressing radiator leaks, it’s crucial to consider the overall condition of the cooling system. Sometimes, what appears as a simple leak can be a symptom of more systemic issues that need attention.

Leakage from Porcelain Vases and Glass Oil Labels: How to Seal the Deal?

Have you ever noticed oil seeping from what should be the most secure parts of your transformer? Leaks from porcelain vases and glass oil labels can be tricky, but they’re not impossible to fix.

Leakage from porcelain vases and glass oil labels in transformers is often due to improper installation or seal failure. The treatment involves using polymer composite materials for bonding and sealing to ensure a long-lasting, leak-free connection.

In my years of working with transformers, I’ve encountered numerous issues with these delicate components. Here’s what I’ve learned about addressing these leaks effectively:

Understanding the Vulnerabilities

-

Causes of Leakage:

- Thermal cycling causing expansion and contraction

- Vibration leading to seal degradation

- Improper initial installation

- Age-related deterioration of sealing materials

-

Critical Areas:

- Junction between porcelain and metal flanges

- Seals around glass oil level indicators

- Gaskets and O-rings in bushings

Effective Treatment Strategies

| Strategy | Application | Benefits |

|---|---|---|

| Polymer Composites | Sealing and bonding | Flexible, durable, oil-resistant |

| Epoxy Resins | Filling gaps and cracks | Strong bond, resistant to chemicals |

| Silicone Sealants | Flexible joints | Good for areas with movement |

| PTFE Tapes | Thread sealing | Excellent for threaded connections |

Best Practices for Repair

Based on my experience, here are some key points to consider:

-

Surface Preparation:

- Thoroughly clean and degrease all surfaces

- Use appropriate primers for better adhesion

-

Material Selection:

- Choose sealants compatible with transformer oil

- Consider temperature range and UV exposure

-

Application Technique:

- Apply sealants in a controlled environment if possible

- Use proper tools for even application

-

Curing and Testing:

- Allow sufficient curing time as per manufacturer’s instructions

- Conduct pressure tests before refilling with oil

I once encountered a transformer with persistent leaks around its bushings. The traditional gasket replacement wasn’t effective due to slight irregularities in the porcelain surface. We solved this by using a two-part epoxy system: a flexible epoxy for initial sealing, followed by a rigid epoxy for structural strength. This combination provided both the flexibility to conform to surface irregularities and the strength to withstand operational stresses.

Remember, while these repairs can be highly effective, they require precision and patience. In some cases, especially with older or severely damaged components, replacement might be the more cost-effective long-term solution.

Prevention of Oil Leakage in Transformer Components: How to Stay Ahead of the Game?

Are you tired of constantly reacting to oil leaks in your transformers? Prevention is always better than cure, especially when it comes to maintaining these critical pieces of equipment.

Preventing oil leakage in transformer components involves regular inspections, proper maintenance schedules, and using high-quality materials. Key areas to focus on include cast iron sections, radiators, and porcelain components.

Throughout my career, I’ve learned that a proactive approach to transformer maintenance can save significant time and resources. Here’s how you can prevent oil leakage effectively:

Key Areas for Preventive Measures

-

Cast Iron Components:

- Regular inspection for early signs of corrosion or cracking

- Application of protective coatings

-

Radiators:

- Proper installation to minimize stress on joints

- Regular cleaning to prevent debris accumulation

-

Porcelain and Glass Components:

- Careful handling during installation and maintenance

- Use of appropriate gaskets and sealing materials

Preventive Maintenance Strategies

| Strategy | Purpose | Frequency |

|---|---|---|

| Visual Inspections | Identify early signs of wear or damage | Monthly |

| Thermal Imaging | Detect hot spots indicating potential issues | Quarterly |

| Oil Analysis | Monitor oil quality and detect internal problems | Annually |

| Pressure Tests | Ensure system integrity | Bi-annually |

Best Practices for Leak Prevention

Based on my experience, here are some effective preventive measures:

-

Quality Materials:

- Use high-grade gaskets and seals designed for transformer applications

- Invest in corrosion-resistant materials for vulnerable components

-

Proper Installation:

- Ensure correct torque specifications for all bolted connections

- Use appropriate techniques for welding and sealing joints

-

Environmental Controls:

- Maintain proper operating temperatures

- Control humidity levels in transformer enclosures

-

Vibration Management:

- Install vibration dampeners where necessary

- Regularly check and tighten mounting bolts

-

Training and Documentation:

- Provide thorough training for maintenance personnel

- Maintain detailed records of all maintenance activities

I once worked with a utility company that implemented a comprehensive preventive maintenance program for their transformer fleet. By focusing on regular inspections, timely replacements of wear items, and using advanced monitoring techniques, they reduced their oil leak incidents by over 70% in just two years. This not only saved them money on repairs but also significantly improved their system reliability.

Remember, prevention is an ongoing process. It requires commitment and consistency, but the long-term benefits in terms of reduced downtime, lower maintenance costs, and improved safety are well worth the effort.

Monitoring and Maintenance of Transformer Seals: How to Ensure Long-Term Reliability?

Are you wondering how to keep your transformer seals in top condition? Regular monitoring and maintenance are key to preventing leaks and ensuring long-term reliability.

Effective monitoring and maintenance of transformer seals involve regular inspections, timely replacements, and the use of advanced diagnostic tools. This proactive approach helps prevent oil leaks and extends the life of transformer components.

In my years of working with transformers, I’ve found that a systematic approach to seal maintenance can make a world of difference. Here’s what I’ve learned:

Critical Seal Locations

-

Bushing Seals:

- Interface between bushings and transformer tank

- Crucial for preventing oil leaks and moisture ingress

-

Manhole Covers:

- Access points for internal inspection and maintenance

- Must maintain a perfect seal to prevent contamination

-

Valve Seals:

- Found on drain valves, sampling ports, and radiator connections

- Critical for system integrity during operation and maintenance

Monitoring and Maintenance Strategies

| Strategy | Purpose | Frequency |

|---|---|---|

| Visual Inspections | Check for visible signs of wear or leakage | Monthly |

| Infrared Scanning | Detect temperature anomalies indicating seal failure | Quarterly |

| Ultrasonic Testing | Identify small leaks not visible to the naked eye | Annually |

| Pressure Tests | Verify overall seal integrity | Bi-annually |

Best Practices for Seal Maintenance

Based on my experience, here are some effective approaches:

-

Regular Cleaning:

- Remove oil and debris accumulation around seals

- Use appropriate cleaning agents that won’t degrade seal materials

-

Proper Torque Management:

- Regularly check and adjust torque on bolted connections

- Use calibrated tools to ensure correct tightening

-

Material Compatibility:

- Ensure all replacement seals are compatible with transformer oil

- Consider temperature ranges and chemical exposure in material selection

-

Preventive Replacements:

- Replace seals proactively based on age and condition

- Keep a stock of commonly used seals for quick replacements

-

Environmental Protection:

- Use weather shields or covers to protect exposed seals

- Control humidity and temperature in transformer enclosures

I once worked on a project where we implemented an advanced seal monitoring system using IoT sensors. These sensors continuously monitored pressure differentials and moisture levels around critical seals. The system could detect even minute changes, allowing for incredibly early intervention. Within the first year, we prevented three major leaks that would have resulted in significant downtime and repair costs.

Remember, effective seal maintenance is about more than just preventing leaks. It’s about ensuring the overall health and longevity of your transformer. By keeping moisture and contaminants out, you’re protecting the internal components and preserving the insulating properties of the transformer oil.

Repairing and Replacing Faulty Transformer Parts: When to Fix and When to Switch?

Have you ever faced the dilemma of whether to repair or replace a faulty transformer component? Making the right decision can save you time, money, and future headaches.

Deciding between repairing and replacing faulty transformer parts depends on factors like the extent of damage, age of the component, cost-effectiveness, and impact on overall performance. Critical components like cast iron sections, radiators, and seals often require careful evaluation.

Throughout my career, I’ve had to make many tough calls on whether to repair or replace transformer parts. Here’s what I’ve learned about making this crucial decision:

Factors to Consider

-

Age of the Component:

- Older parts may be more prone to recurring issues

- Availability of replacement parts for older models

-

Extent of Damage:

- Minor issues might be repairable

- Severe damage often warrants replacement

-

Cost Analysis:

- Compare repair costs with replacement costs

- Consider long-term reliability and efficiency

-

Impact on Performance:

- How the faulty part affects overall transformer efficiency

- Potential for improved performance with newer components

Decision-Making Framework

| Component | When to Repair | When to Replace |

|---|---|---|

| Cast Iron Sections | Minor cracks or leaks | Extensive corrosion or large cracks |

| Radiators | Small leaks or fin damage | Multiple leaks or severe corrosion |

| Bushings | Minor oil leaks | Cracks in porcelain or severe oil leakage |

| Windings | Not typically repairable | Any significant damage |

| Tap Changers | Wear on contacts | Severe arcing damage or mechanical failure |

Best Practices for Repair and Replacement

Based on my experience, here are some guidelines to follow:

-

Thorough Diagnostics:

- Use advanced testing methods to accurately assess damage

- Consider hidden issues that might not be immediately apparent

-

Risk Assessment:

- Evaluate the risk of failure if a part is repaired rather than replaced

- Consider the criticality of the transformer in the power system

-

Future-Proofing:

- When replacing, consider upgrading to newer, more efficient technologies

- Ensure compatibility with existing systems

-

Manufacturer Consultation:

- Seek advice from the

- Seek advice from the original manufacturer when possible

- Consider authorized third-party experts for older or discontinued models

-

Regulatory Compliance:

- Ensure all repairs or replacements meet current industry standards

- Consider environmental regulations, especially for oil-filled components

I once faced a situation with a 30-year-old transformer that had developed multiple small leaks in its radiator bank. The initial impulse was to replace the entire radiator system, but after careful analysis, we found that a combination of targeted repairs and partial replacement was more cost-effective. We repaired the minor leaks and replaced only the most severely damaged radiator sections. This approach saved nearly 40% of the replacement cost while still ensuring reliable performance.

Remember, the decision to repair or replace isn’t always straightforward. It requires a balance of technical knowledge, economic considerations, and strategic thinking. Sometimes, what seems like a more expensive option upfront (like replacement) can be more cost-effective in the long run due to improved efficiency and reliability.

Conclusion

Effective power transformer fault resolution requires a comprehensive approach to oil leakage prevention, seal maintenance, and component repair or replacement. Regular monitoring, timely interventions, and informed decision-making are key to ensuring transformer reliability and longevity.

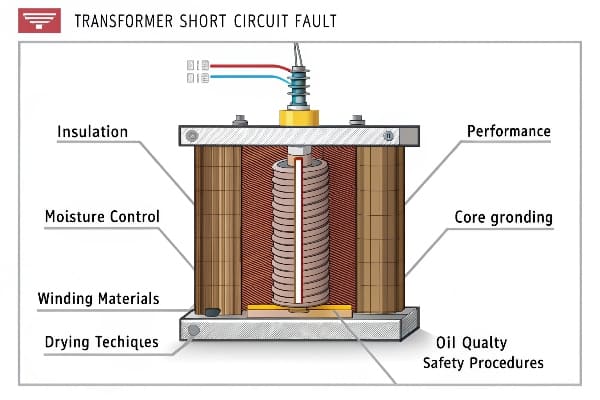

Are you worried about the reliability of your power system? Transformer short circuit faults can be a major headache for any electrical engineer or facility manager.

Treating transformer short circuit faults requires careful attention to insulation performance, moisture control, core grounding, winding materials, drying techniques, oil quality, and safety procedures. Proper handling of these aspects is crucial for maintaining transformer reliability and longevity.

In my years of experience dealing with transformer issues, I’ve learned that addressing short circuit faults is a complex process. Let’s dive into the key areas that demand our attention when tackling these problems.

Insulation Component Performance Testing and Confirmation: How Critical Is It?

Have you ever wondered why some transformers fail unexpectedly while others keep running smoothly for years? The secret often lies in the quality of insulation.

Insulation component performance testing is crucial in transformer maintenance. It helps identify potential weak points before they lead to failures. Regular testing and confirmation of insulation integrity can significantly reduce the risk of short circuit faults.

In my experience, neglecting insulation testing is like driving a car without ever checking the brakes. Here’s why it’s so important:

Types of Insulation Tests

-

Insulation Resistance Test:

- Measures the resistance between windings and ground

- Helps detect moisture ingress or contamination

-

Power Factor Test:

- Assesses the overall condition of the insulation system

- Can indicate aging or deterioration of insulation

-

Partial Discharge Test:

- Detects small electrical discharges within the insulation

- Early warning sign of insulation breakdown

Frequency of Testing

| Transformer Type | Recommended Testing Frequency |

|---|---|

| Critical Units | Annually |

| Standard Units | Every 2-3 years |

| New Installations | Before commissioning |

Interpreting Test Results

Understanding test results is crucial. Here’s what I look for:

-

Trend Analysis:

- Compare current results with historical data

- Look for gradual deterioration over time

-

Sudden Changes:

- Any abrupt change in values warrants immediate attention

- Could indicate a developing fault

-

Industry Standards:

- Compare results against IEEE or IEC standards

- Helps in determining if the insulation is within acceptable limits

In my career, I’ve seen cases where regular insulation testing caught potential issues before they turned into major failures. For instance, a slight increase in partial discharge activity led us to discover a small manufacturing defect in a new transformer. We addressed it before it could cause a short circuit, potentially saving millions in downtime and repairs.

Remember, insulation testing is not just about passing or failing a test. It’s about understanding the health of your transformer and making informed decisions about maintenance and replacement schedules.

Impact of Moisture and Oil Immersion on Insulation Performance: What’s the Big Deal?

Ever wondered why transformer experts are always fussing about moisture levels? It’s not just about keeping things dry – it’s about preventing catastrophic failures.

Moisture and oil immersion significantly affect transformer insulation performance. Excessive moisture can degrade insulation, reduce dielectric strength, and lead to short circuits. Proper oil immersion is crucial for insulation cooling and maintaining dielectric properties.

Throughout my career, I’ve seen the devastating effects of moisture on transformer insulation. Let me break it down for you:

Effects of Moisture on Insulation

-

Reduced Dielectric Strength:

- Moisture lowers the insulation’s ability to withstand electrical stress

- Can lead to partial discharges and eventual breakdown

-

Accelerated Aging:

- Moisture catalyzes chemical reactions that degrade insulation materials

- Can significantly shorten the transformer’s lifespan

-

Increased Electrical Losses:

- Wet insulation has higher conductivity

- Results in increased power losses and reduced efficiency

Oil Immersion Benefits

| Aspect | Benefit |

|---|---|

| Cooling | Efficient heat dissipation from windings |

| Insulation | Enhances overall dielectric strength |

| Longevity | Protects solid insulation from oxidation |

Moisture Control Strategies

Based on my experience, here are some effective strategies for moisture control:

-

Regular Oil Testing:

- Perform Karl Fischer titration to measure water content

- Aim for moisture levels below 10 ppm for optimal performance

-

Online Moisture Monitoring:

- Install continuous moisture sensors

- Allows for real-time tracking and early intervention

-

Proper Sealing:

- Ensure all gaskets and seals are in good condition

- Prevents moisture ingress from the environment

-

Breathing Systems:

- Use silica gel breathers to absorb moisture from incoming air

- Regularly inspect and replace silica gel

-

Oil Regeneration:

- Periodically treat oil to remove accumulated moisture

- Can significantly extend the life of both oil and solid insulation

I once dealt with a transformer that had been flooded during a storm. The moisture content in the oil skyrocketed, and we had to act fast. We implemented an emergency drying process and oil regeneration. It was a close call, but we managed to save the transformer from a potential short circuit failure.

Remember, moisture control is an ongoing process. It’s not enough to dry out a transformer once and forget about it. Continuous monitoring and maintenance are key to ensuring long-term reliability and preventing those dreaded short circuit faults.

Prevention and Inspection of Core Grounding Issues: Why Is It Crucial?

Have you ever considered how a tiny grounding issue could lead to a major transformer failure? Core grounding problems are often overlooked but can have serious consequences.

Core grounding issues can lead to circulating currents, localized heating, and insulation breakdown. Regular inspection and proper maintenance of core grounding systems are essential to prevent short circuit faults and ensure transformer longevity.

In my years of working with transformers, I’ve learned that core grounding is not just a minor detail – it’s a critical aspect of transformer health. Here’s what you need to know:

Importance of Proper Core Grounding

-

Prevents Circulating Currents:

- Proper grounding eliminates stray magnetic flux

- Reduces eddy currents and associated losses

-

Enhances Safety:

- Ensures the core remains at ground potential

- Protects personnel during maintenance

-

Improves Transformer Efficiency:

- Reduces core losses

- Contributes to overall energy efficiency

Common Core Grounding Issues

| Issue | Potential Consequences |

|---|---|

| Loose Connections | Increased core losses, localized heating |

| Multiple Ground Points | Circulating currents, increased losses |

| Insulation Breakdown | Core-to-ground faults, short circuits |

Inspection and Maintenance Practices

Based on my experience, here are key practices for maintaining proper core grounding:

-

Regular Visual Inspections:

- Check for signs of overheating or discoloration

- Inspect grounding straps for corrosion or damage

-

Electrical Testing:

- Perform core insulation resistance tests

- Measure core ground current during operation

-

Thermographic Surveys:

- Use infrared cameras to detect hot spots

- Can reveal hidden grounding issues

-

Proper Grounding Techniques:

- Ensure single-point grounding to avoid circulating currents

- Use appropriate materials for grounding connections

-

Documentation and Trending:

- Keep detailed records of all inspections and tests

- Track changes over time to identify developing issues

I once encountered a transformer with unexplained efficiency losses. After thorough investigation, we discovered that the core grounding strap had corroded, creating a high-resistance connection. This seemingly small issue was causing significant core losses and putting the transformer at risk of a more serious failure.

Remember, core grounding issues might not cause immediate, dramatic failures, but they can lead to long-term degradation and increased risk of short circuits. Regular inspection and maintenance of core grounding systems are investments in your transformer’s health and longevity.

Optimizing Winding Materials and Transformer Structure: What’s the Secret?

Ever wondered why some transformers seem to handle stress better than others? The answer often lies in the choice of winding materials and structural design.

Optimizing winding materials and transformer structure is crucial for enhancing short circuit strength. Proper selection of conductor materials, insulation systems, and mechanical support structures can significantly improve a transformer’s ability to withstand fault conditions.

Throughout my career, I’ve seen how the right choices in materials and design can make a world of difference. Let’s dive into the key aspects:

Winding Material Selection

-

Conductor Materials:

- Copper vs. Aluminum: Trade-offs between conductivity and weight

- CTC (Continuously Transposed Conductor): Reduces eddy current losses

-

Insulation Materials:

- Paper-based: Traditional, reliable, but moisture-sensitive

- Synthetic materials: Better moisture resistance, potentially longer life

Structural Design Considerations

| Aspect | Importance |

|---|---|

| Radial Supports | Prevents winding deformation under radial forces |

| Axial Supports | Resists axial displacement during faults |

| End Insulation | Critical for withstanding voltage spikes |

Advanced Design Techniques

Based on my experience, here are some advanced techniques for optimizing transformer structure:

-

FEM (Finite Element Method) Analysis:

- Simulates electromagnetic and mechanical stresses

- Helps identify weak points in the design before manufacturing

-

Dynamic Short Circuit Modeling:

- Analyzes transformer behavior under fault conditions

- Aids in designing more robust structures

-

Innovative Winding Configurations:

- Interleaved windings: Improves voltage distribution

- Split windings: Enhances short circuit strength

-

Advanced Clamping Systems:

- Ensures windings remain tight throughout the transformer’s life

- Reduces the risk of mechanical failure during faults

-

Material Innovations:

- High-temperature insulation materials

- Composite conductors for improved strength and conductivity

I once worked on a project where we redesigned a transformer prone to frequent faults. By implementing a combination of CTC windings, advanced FEM analysis, and an innovative clamping system, we were able to significantly improve its short circuit withstand capability. The redesigned transformer has been operating flawlessly for years, even in a high-stress industrial environment.

Remember, optimizing winding materials and transformer structure is not just about using the most expensive materials. It’s about finding the right balance between performance, reliability, and cost-effectiveness. A well-designed transformer with carefully selected materials can provide superior performance and longevity, even in challenging operating conditions.

Importance of Efficient Drying Techniques in Transformer Maintenance: Why Does It Matter?

Have you ever wondered why so much emphasis is placed on drying transformers? It’s not just about removing moisture – it’s about preserving the heart of your electrical system.

Efficient drying techniques are crucial in transformer maintenance. Proper drying removes moisture from insulation, restores dielectric strength, and prevents premature aging. It’s essential for maintaining transformer reliability and extending its operational life.

In my years of experience with transformer maintenance, I’ve seen firsthand how proper drying can breathe new life into a transformer. Let’s explore why it’s so important:

Effects of Moisture on Transformers

-

Reduced Insulation Resistance:

- Moisture lowers the insulation’s ability to resist current flow

- Increases the risk of electrical breakdowns

-

Accelerated Aging:

- Moisture catalyzes chemical reactions that degrade insulation

- Can significantly shorten transformer lifespan

-

Decreased Efficiency:

- Wet insulation increases electrical losses

- Results in higher operating costs

Drying Techniques

| Method | Advantages | Considerations |

|---|---|---|

| Vacuum Drying | Highly effective, faster | Requires specialized equipment |

| Hot Oil Circulation | Can be done on-site | Time-consuming, risk of oil contamination |

| Low Frequency Heating | Uniform drying, less stress on insulation | Requires specific LF power source |

Best Practices for Efficient Drying

Based on my experience, here are some key practices for effective transformer drying:

-

Moisture Assessment:

- Perform oil and insulation moisture tests before drying

- Helps determine the extent of drying required

-

Temperature Control:

- Maintain optimal temperature throughout the process

- Too high temperatures can damage insulation

-

Vacuum Application:

- Use vacuum to enhance moisture removal

- Ensures thorough drying of hard-to-reach areas

-

Continuous Monitoring:

- Track moisture levels throughout the drying process

- Ensures drying is complete before recommissioning

-

Post-Drying Tests:

- Conduct insulation resistance and other tests after drying

- Confirms the effectiveness of the drying process

I once dealt with a transformer that had been out of service for years in a humid environment. The insulation was saturated with moisture, and the owner was considering scrapping it. We implemented a comprehensive drying process using a combination of vacuum and low-frequency heating. After several days of careful drying and monitoring, we were able to restore the transformer to a serviceable condition, saving the company a significant amount in replacement costs.

Remember, efficient drying is not just about removing visible moisture. It’s about extracting moisture from deep within the insulation structure. A well-executed drying process can significantly extend the life of a transformer and prevent costly failures down the line.

Transformer Oil Quality Monitoring and Fault Analysis: How to Stay Ahead of Problems?

Ever felt like you’re always reacting to transformer issues instead of preventing them? The key to staying ahead lies in effective oil quality monitoring and fault analysis.

Regular transformer oil quality monitoring and fault analysis are essential for early detection of potential issues. By analyzing oil properties and dissolved gases, you can identify developing faults before they lead to catastrophic failures.

Throughout my career, I’ve seen how proactive oil monitoring can save companies millions in prevented downtime. Here’s what you need to know:

Key Oil Quality Parameters

-

Dielectric Strength:

- Indicates oil’s ability to withstand electrical stress

- Low values suggest contamination or moisture ingress

-

Acidity:

- Measures oil degradation

- High acidity can lead to insulation breakdown

-

Moisture Content:

- Critical for maintaining insulation integrity

- High moisture content accelerates aging

Dissolved Gas Analysis (DGA)

| Gas | Potential Indication |

|---|---|

| Hydrogen (H2) | Partial discharge, arcing |

| Methane (CH4) | Low energy electrical fault |

| Acetylene (C2H2) | High energy arcing |

| Ethylene (C2H4) | Thermal fault |

Effective Monitoring Strategies

Based on my experience, here are some strategies for effective oil quality monitoring:

-

Regular Sampling:

- Establish a consistent sampling schedule

- Frequency depends on transformer criticality and operating conditions

-

Trend Analysis:

- Track oil parameters over time

- Look for gradual changes that might indicate developing issues

-

Online Monitoring:

- Install real-time monitoring systems for critical transformers

- Allows for immediate detection of sudden changes

-

Comprehensive Testing:

- Perform both routine tests and detailed analysis

- Include physical, chemical, and electrical property tests

-

Fault Gas Ratios:

- Use established methods like Duval Triangle or Rogers Ratio

- Helps in diagnosing specific types of faults

I once worked with a utility company that implemented a comprehensive oil monitoring program. Within the first year, they detected a developing partial discharge in a critical substation transformer. By catching it early, they were able to schedule a controlled outage for repairs, avoiding a potential unplanned outage that could have affected thousands of customers.

Remember, oil quality monitoring is not just about collecting data – it’s about interpreting that data effectively. A well-designed monitoring program, combined with expert analysis, can provide invaluable insights into your transformer’s health and help you make informed maintenance decisions.

Impact of Prolonged Short Circuit on Transformer and Repair Strategies: What’s at Stake?

Have you ever wondered what happens to a transformer during a prolonged short circuit? The consequences can be severe, but with the right strategies, recovery is possible.

Prolonged short circuits can cause severe damage to transformers, including winding deformation, insulation breakdown, and core damage. Effective repair strategies involve thorough assessment, careful disassembly, and meticulous reconstruction to restore the transformer’s functionality and reliability.

In my years of dealing with transformer failures, I’ve seen the devastating effects of prolonged short circuits. Let’s dive into the impacts and repair strategies:

Effects of Prolonged Short Circuit

-

Mechanical Damage:

- Winding deformation due to extreme electromagnetic forces

- Loosening of clamping structures

-

Thermal Damage:

- Insulation breakdown from excessive heat

- Oil degradation and potential carbonization

-

Electrical Stress:

- Voltage spikes leading to turn-to-turn insulation failure

- Potential core saturation and damage

Repair Strategies

| Stage | Actions |

|---|---|

| Assessment | Visual inspection, electrical tests, oil analysis |

| Disassembly | Careful removal of affected components |

| Repair/Replace | Rewinding, insulation replacement, core treatment |

| Reassembly | Precise reconstruction, ensuring proper alignment |

| Testing | Comprehensive electrical and mechanical tests |

Key Considerations in Repair Process

Based on my experience, here are crucial points to consider during transformer repair:

-

Root Cause Analysis:

- Identify the cause of the short circuit

- Implement measures to prevent recurrence

-

Extent of Damage Evaluation:

- Use advanced diagnostic tools like frequency response analysis

- Determine if repair is economically viable compared to replacement

-

Quality of Repair Materials:

- Use high-quality insulation and conductor materials

- Ensure compatibility with existing components

-

Skilled Technicians:

- Employ experienced personnel for complex repairs

- Proper training in latest repair techniques

-

Documentation and Traceability:

- Maintain detailed records of all repair procedures

- Ensure traceability of all replaced parts

I once dealt with a transformer that had suffered a prolonged short circuit due to a lightning strike. The initial assessment showed severe winding deformation. We decided to completely rewind the transformer, using the opportunity to upgrade the insulation system. The repaired transformer not only regained its original performance but also showed improved resilience to future stresses.

Remember, while repairing a transformer after a prolonged short circuit is possible, prevention is always better than cure. Regular maintenance, proper protection systems, and quick fault clearance mechanisms are your best defenses against severe short circuit damage.

Safety Considerations During Transformer Maintenance: How to Protect Your Team?

Have you ever stopped to think about the risks involved in transformer maintenance? Safety should always be your top priority when working with these high-voltage giants.

Transformer maintenance involves significant safety risks including electrical shock, arc flash, and exposure to hazardous materials. Proper safety protocols, personal protective equipment (PPE), and thorough risk assessments are essential to protect maintenance teams.

Throughout my career, I’ve emphasized the importance of safety in transformer maintenance. Here’s what you need to know to keep your team safe:

Key Safety Risks

-

Electrical Hazards:

- High voltage shock risk

- Arc flash potential

-

Chemical Hazards:

- Exposure to transformer oil

- Potential PCB contamination in older units

-

Physical Hazards:

- Heavy lifting and moving parts

- Working at heights

Essential Safety Measures

| Measure | Purpose |

|---|---|

| Lockout/Tagout | Ensure equipment is de-energized |

| PPE | Protect against electrical and chemical hazards |

| Proper Grounding | Prevent electrical shock |

| Ventilation | Reduce exposure to oil vapors |

Best Practices for Safe Maintenance

Based on my experience, here are crucial safety practices to implement:

-

Comprehensive Risk Assessment:

- Conduct thorough job safety analysis before each maintenance task

- Identify potential hazards and mitigation strategies

-

Proper Training:

- Ensure all personnel are trained in electrical safety

- Provide specific training on transformer maintenance procedures

-

Use of Appropriate PPE:

- Provide and enforce the use of proper protective equipment

- Regularly inspect and replace PPE as needed

-

Clear Communication:

- Establish clear communication protocols during maintenance

- Use a buddy system for high-risk tasks

-

Emergency Preparedness:

- Have emergency response plans in place

- Conduct regular drills and training on emergency procedures

I once witnessed a near-miss incident where a technician almost contacted a live bushing during what was supposed to be a routine inspection. This experience led us to implement a strict double-check system for our lockout/tagout procedures, significantly enhancing our safety protocols.

Remember, safety in transformer maintenance is not just about following rules – it’s about creating a culture where every team member is committed to their own safety and the safety of their colleagues. Regular safety meetings, open communication about near-misses, and continuous improvement of safety procedures are key to maintaining a safe work environment.

Conclusion

Proper attention to insulation, moisture control, core grounding, winding materials, drying techniques, oil quality, and safety is crucial in managing transformer short circuit faults. Regular maintenance and adherence to best practices ensure transformer reliability and longevity.

**

Are you struggling to choose between a dry type and an oil-filled transformer for your project? You’re not alone in this dilemma.

Dry type and oil-filled transformers are two main types of power transformers. They differ in their cooling and insulation methods, with dry types using air and solid materials, while oil-filled types use insulating oil for cooling and insulation.

I’ve worked with both types of transformers throughout my career. Let’s dive into their differences and help you make an informed decision for your specific needs.

What is the difference between dry type and oil transformers?

Have you ever wondered why some transformers are filled with oil while others aren’t? The answer lies in their fundamental design and cooling methods.

The main difference between dry type and oil transformers is their cooling and insulation system. Dry type transformers use air and solid insulating materials, while oil transformers use insulating oil for both cooling and insulation.

In my years of experience with transformer installations, I’ve noticed several key differences between these two types:

Cooling System

-

Dry Type:

- Uses air for cooling

- Often has additional fans for forced air cooling

- Heat dissipates directly into the surrounding air

-

Oil-Filled:

- Uses oil for cooling

- Oil circulates naturally or is forced through cooling radiators

- More efficient at heat dissipation

Insulation

-

Dry Type:

- Uses solid insulating materials like epoxy resin

- No liquid insulation means no risk of leaks

-

Oil-Filled:

- Uses oil as both coolant and insulator

- Oil provides excellent insulation properties

Maintenance

| Aspect | Dry Type | Oil-Filled |

|---|---|---|

| Routine Checks | Less frequent | Regular oil testing required |

| Leak Risk | None | Potential oil leaks |

| Lifespan | 20-30 years | 30-40 years with proper maintenance |

Environmental Considerations

-

Dry Type:

- No oil means no risk of environmental contamination

- Suitable for environmentally sensitive areas

-

Oil-Filled:

- Risk of oil spills

- Requires proper containment measures

Size and Weight

-

Dry Type:

- Generally smaller and lighter

- Easier to install in confined spaces

-

Oil-Filled:

- Larger and heavier due to oil content

- Requires more installation space

In my experience, understanding these differences is crucial for selecting the right transformer for your specific application. Each type has its own strengths and is better suited for certain environments and uses.

What is the advantage of a dry type transformer?

Are you looking for a transformer solution that’s safe, environmentally friendly, and low maintenance? A dry type transformer might be just what you need.

Dry type transformers offer advantages in safety, environmental protection, and maintenance. They have no risk of oil leaks, are fire-resistant, and require less maintenance compared to oil-filled transformers.

Throughout my career, I’ve seen dry type transformers become increasingly popular. Here’s why they’re often preferred:

Safety Benefits

-

Fire Resistance:

- No flammable oil means reduced fire risk

- Ideal for indoor installations and populated areas

-

No Oil Leaks:

- Eliminates the risk of oil spills

- Safer for personnel and equipment around the transformer

Environmental Advantages

-

Eco-Friendly:

- No risk of oil contamination to soil or water

- Easier to dispose of at end of life

-

Indoor Use:

- Can be installed close to the load center

- Reduces the need for long cable runs

Low Maintenance

| Aspect | Benefit |

|---|---|

| No Oil Checks | Eliminates need for regular oil testing |

| Simpler Inspections | Visual checks are straightforward |

| No Oil Handling | Reduces maintenance complexity |

Space Efficiency

-

Compact Design:

- Often smaller than equivalent oil-filled transformers

- Ideal for areas with limited space

-

Flexible Installation:

- Can be installed in various orientations

- No need for oil containment structures

Reliability in Harsh Environments

-

Moisture Resistance:

- Less affected by humid environments

- Suitable for coastal areas or high-humidity locations

-

Altitude Performance:

- Performs well at high altitudes

- No oil to thin out in low-pressure environments

In my experience, dry type transformers are particularly well-suited for:

- Commercial buildings

- Hospitals and healthcare facilities

- Data centers

- Offshore platforms

- Underground installations

Their combination of safety, environmental friendliness, and low maintenance makes them an attractive option for many modern applications. However, it’s important to note that they may have limitations in very high power ratings compared to oil-filled transformers.

What is the advantage of oil-filled transformers?

Are you dealing with high-power applications or looking for a transformer with excellent cooling efficiency? Oil-filled transformers might be your best bet.

Oil-filled transformers excel in high-power applications, offer superior cooling efficiency, and typically have a longer lifespan. They’re also more cost-effective for higher power ratings and can handle overloads better than dry type transformers.

In my years working with power systems, I’ve seen oil-filled transformers dominate in certain areas. Here’s why they’re often preferred:

Superior Cooling Efficiency

-

Oil as Coolant:

- Oil is an excellent heat conductor

- Allows for more efficient cooling of transformer components

-

Natural Circulation:

- Oil naturally circulates as it heats and cools

- Provides passive cooling without additional systems

High Power Capacity

-

Higher Voltage Ratings:

- Can handle much higher voltages than dry type transformers

- Suitable for power transmission and large industrial applications

-

Overload Capability:

- Can handle short-term overloads better

- Oil helps dissipate excess heat during peak loads

Longer Lifespan

| Aspect | Benefit |

|---|---|

| Typical Lifespan | 30-40 years with proper maintenance |

| Insulation Longevity | Oil helps preserve insulation materials |

| Overload Recovery | Better recovery from overload conditions |

Cost-Effectiveness at High Ratings

-

Lower Cost per MVA:

- More economical for high power ratings

- Cost advantage increases with transformer size

-

Established Technology:

- Well-understood manufacturing processes

- Wide availability of parts and service

Noise Reduction

- Oil Dampening:

- Oil helps reduce operational noise

- Beneficial in noise-sensitive environments

Voltage Regulation

- Better Voltage Control:

- Oil provides better insulation properties

- Allows for finer control of voltage regulation

In my experience, oil-filled transformers are particularly well-suited for:

- Power generation plants

- Electrical substations

- Large industrial facilities

- High-voltage power transmission

Their ability to handle high power ratings, coupled with their excellent cooling properties, makes them indispensable in many large-scale electrical systems. However, it’s crucial to consider the maintenance requirements and potential environmental risks associated with oil leaks.

Which is more expensive, a dry type or oil type transformer?

Are you trying to balance your budget with your transformer needs? The cost difference between dry type and oil type transformers isn’t as straightforward as you might think.

Generally, dry type transformers are more expensive upfront for lower power ratings, while oil type transformers become more cost-effective at higher ratings. However, the total cost of ownership depends on factors like maintenance, installation, and operational costs.

In my experience working with various transformer projects, I’ve found that the cost comparison isn’t just about the initial price tag. Let’s break it down:

Initial Purchase Cost

-

Dry Type Transformers:

- More expensive for lower power ratings (up to about 10 MVA)

- Cost increases sharply with power rating

-

Oil Type Transformers:

- More cost-effective for higher power ratings

- Better economies of scale for large transformers

Installation Costs

| Aspect | Dry Type | Oil Type |

|---|---|---|

| Space Requirements | Less space needed | More space for oil containment |

| Weight | Lighter, easier to transport | Heavier, may need special transport |

| Additional Equipment | Minimal | Oil processing equipment needed |

Maintenance Costs

-

Dry Type:

- Lower maintenance costs

- No oil testing or replacement needed

-

Oil Type:

- Higher maintenance costs

- Regular oil testing and potential oil replacement

Operational Costs

-

Dry Type:

- Generally higher losses, especially at lower loads

- May result in higher energy costs over time

-

Oil Type:

- Lower losses, especially at higher loads

- Can lead to energy savings in high-load applications

Lifespan and Replacement

-

Dry Type:

- Typical lifespan of 20-30 years

- May need earlier replacement in harsh environments

-

Oil Type:

- Typical lifespan of 30-40 years with proper maintenance

- Potential for longer service life

Environmental and Safety Considerations

-

Dry Type:

- No oil containment or processing costs

- Lower insurance costs due to reduced fire risk

-

Oil Type:

- Costs for oil containment and potential spill cleanup

- Higher insurance costs due to fire and environmental risks

In my experience, the true cost comparison needs to consider all these factors. For example:

- A dry type transformer might be more expensive upfront but could save money over time in a commercial building due to lower maintenance and insurance costs.

- An oil type transformer could be more cost-effective for a large industrial application where its lower losses and longer lifespan offset the higher maintenance costs.

The key is to analyze your specific needs, including power requirements, installation environment, expected lifespan, and maintenance capabilities. In some cases, I’ve seen the total cost of ownership for a dry type transformer end up lower than an oil type, despite a higher initial cost, due to savings in maintenance and operational costs.

Conclusion

Choosing between dry type and oil-filled transformers depends on your specific needs. Consider factors like power requirements, installation environment, maintenance capabilities, and long-term costs to make the best decision for your project.

Are you struggling with power distribution challenges in your industrial setup? The solution might be simpler than you think.

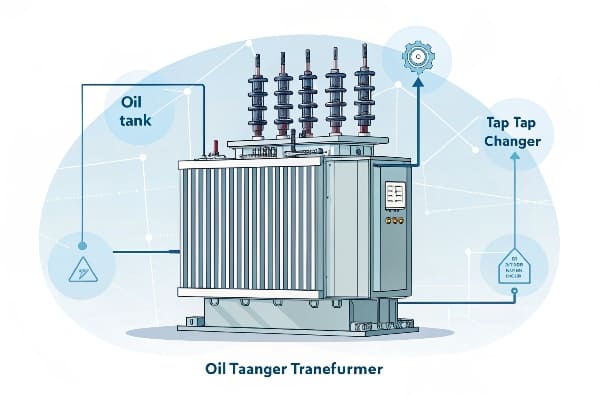

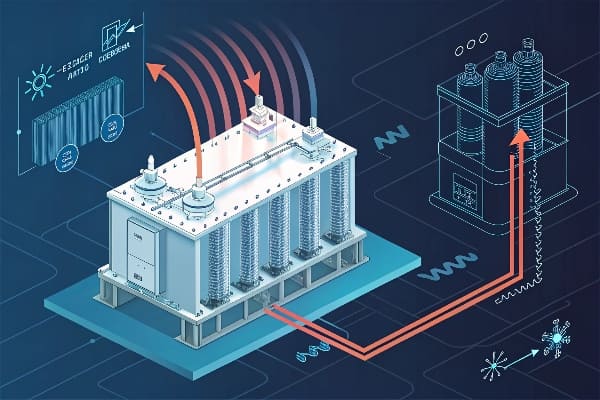

An oil-immersed transformer is a type of electrical transformer that uses oil as a coolant and insulator. It’s designed for high-voltage applications and is known for its efficiency in heat dissipation and electrical insulation.

I’ve seen many industries benefit from oil-immersed transformers. Let’s dive deeper into how these transformers work and why they might be the right choice for your power distribution needs.

Oil-immersed Transformer: Working Principle

Have you ever wondered how these massive transformers manage to handle such high voltages without breaking a sweat? The secret lies in their unique working principle.

Oil-immersed transformers work on the principle of electromagnetic induction, using oil as both a coolant and insulator. The oil surrounds the core and windings, efficiently dissipating heat and providing excellent electrical insulation.

In my years of experience with power systems, I’ve come to appreciate the elegance of oil-immersed transformers. Here’s a deeper look at how they function:

Core Components

The main parts of an oil-immersed transformer include:

- Core: Usually made of laminated silicon steel sheets

- Windings: Primary and secondary coils, typically made of copper

- Insulating Oil: Mineral oil or synthetic alternatives

- Tank: Houses all components and the insulating oil

- Bushings: For connecting external circuits

- Cooling System: Radiators or fans for larger units

Electromagnetic Induction

The basic principle is simple:

- When AC voltage is applied to the primary winding, it creates a changing magnetic field in the core.

- This changing magnetic field induces a voltage in the secondary winding.

- The ratio of primary to secondary turns determines the voltage transformation.

Role of Oil

The oil in these transformers serves multiple crucial functions:

| Function | Description |

|---|---|

| Cooling | Absorbs and dissipates heat from the core and windings |

| Insulation | Provides electrical insulation between components |

| Arc Suppression | Helps quench arcs that may form during operation |

| Moisture Protection | Prevents moisture from degrading the insulation |

Heat Dissipation

One of the most impressive aspects of oil-immersed transformers is their cooling efficiency:

- As the transformer operates, heat is generated in the core and windings.

- The oil absorbs this heat through direct contact.

- Natural convection circulates the oil, carrying heat to the tank walls.

- For larger transformers, external radiators or forced-air cooling may be used.

In my experience, this cooling system is what allows oil-immersed transformers to handle such high power ratings efficiently.

Types of Oil-Filled Transformers

Are you wondering which type of oil-filled transformer might be best for your specific needs? You’re not alone in this quest.

Oil-filled transformers come in various types, including distribution transformers, power transformers, and specialty transformers. Each type is designed for specific voltage levels, power ratings, and applications, ranging from residential power distribution to large industrial use.

Throughout my career, I’ve worked with various types of oil-filled transformers. Let me break down the main categories for you:

Distribution Transformers

These are the workhorses of the power grid:

- Voltage Range: Typically 34.5 kV and below

- Power Rating: Usually up to 2500 kVA

- Applications: Residential areas, small commercial buildings

- Features: Often pole-mounted or pad-mounted

Power Transformers

These handle the heavy lifting in power transmission:

- Voltage Range: Can go up to 765 kV or higher

- Power Rating: From a few MVA to hundreds of MVA

- Applications: Power plants, large industrial facilities, substations

- Features: Usually very large, with advanced cooling systems

Specialty Transformers

These are designed for specific applications:

| Type | Application | Special Features |

|---|---|---|

| Furnace Transformers | Electric arc furnaces | High current output, robust design |

| Rectifier Transformers | DC power supply | Special winding configurations |

| Traction Transformers | Electric railways | Compact design, vibration resistant |

Cooling Methods

The cooling method used can also categorize oil-filled transformers:

- ONAN (Oil Natural Air Natural): Relies on natural oil circulation and air cooling

- ONAF (Oil Natural Air Forced): Uses fans to enhance air cooling

- OFAF (Oil Forced Air Forced): Uses pumps for oil circulation and fans for air cooling

- ODAF (Oil Directed Air Forced): Directs oil flow through windings for more efficient cooling

In my experience, choosing the right type of transformer and cooling method is crucial for optimal performance and longevity.

Maintenance and Safety Considerations for Oil-Immersed Transformers

Are you concerned about keeping your oil-immersed transformer in top shape? You should be – proper maintenance is key to longevity and safety.

Maintaining oil-immersed transformers involves regular oil testing, monitoring for leaks, and periodic inspections. Safety considerations include fire prevention, environmental protection, and proper handling of transformer oil.

Over the years, I’ve learned that a well-maintained transformer is a reliable transformer. Here’s what you need to know about maintenance and safety:

Regular Maintenance Tasks

- Oil Testing: Check oil quality at least annually

- Visual Inspections: Look for leaks, rust, or damage monthly

- Thermal Imaging: Conduct annually to detect hot spots

- Bushing Maintenance: Clean and inspect bushings yearly

- DGA (Dissolved Gas Analysis): Perform annually or as needed

Oil Quality Management

The health of the transformer oil is crucial:

| Test | Frequency | Purpose |

|---|---|---|

| Dielectric Strength | Annually | Ensures insulating properties |

| Acidity | Annually | Checks for oil degradation |

| Moisture Content | Bi-annually | Prevents insulation breakdown |

| Interfacial Tension | Annually | Indicates oil contamination |

Safety Considerations

Safety should always be your top priority:

- Fire Prevention: Install fire suppression systems

- Spill Containment: Use proper oil containment methods

- Grounding: Ensure proper grounding of the transformer

- Personal Protective Equipment: Use when handling oil or working near transformers

- Emergency Procedures: Have clear protocols for oil leaks or electrical faults

Environmental Concerns

In today’s world, environmental responsibility is crucial:

- Use biodegradable transformer oils when possible

- Have a proper disposal plan for old transformer oil

- Implement spill prevention and response plans

- Consider retrofilling with more environmentally friendly oils

Predictive Maintenance

I’ve found that predictive maintenance can save a lot of trouble:

- Online Monitoring: Use sensors for real-time data on key parameters

- Trend Analysis: Track oil quality and electrical parameters over time

- Acoustic Monitoring: Detect partial discharges early

- Load Analysis: Ensure the transformer isn’t consistently overloaded

In my experience, a comprehensive maintenance and safety program not only extends the life of your transformer but also prevents costly downtime and potential environmental incidents.

Conclusion

Oil-immersed transformers are vital for efficient power distribution. With proper maintenance and safety measures, they offer reliable performance and longevity. Understanding their types and care needs is key to maximizing their benefits in various applications.