Are you confused about which single phase power transformer to choose? You’re not alone. Many people find this decision challenging. But don’t worry, I’m here to help you make the right choice.

Choosing the right single phase power transformer involves considering several key factors. These include power capacity, voltage ratings, efficiency, size, cooling method, and installation location. The right transformer should meet your specific power needs while being efficient, reliable, and suitable for your environment.

As someone who has worked with power transformers for years, I’ve seen how crucial this choice can be. The right transformer can save you money and headaches in the long run. Let’s dive into the key factors you need to consider when choosing your single phase power transformer.

Single Phase Superstar: What Makes This Transformer Special in the Electrical World?

Have you ever wondered why single phase transformers are so common? They’re like the unsung heroes of our electrical world. But what makes them so special?

Single phase transformers are special because they’re simple, efficient, and perfect for most residential and light commercial applications. They convert high voltage electricity to a lower, safer voltage for everyday use. Their design makes them ideal for powering homes, small businesses, and many appliances.

I remember the first time I installed a single phase transformer in a small business. The owner was amazed at how this relatively small device could power their entire operation. Let’s explore what makes these transformers so unique.

The Basics of Single Phase Power

To understand why single phase transformers are special, we need to grasp the concept of single phase power:

- What is Single Phase Power?: It’s a two-wire AC power circuit.

- Voltage: It usually comes in at 120V or 240V in the US.

- Usage: It’s the standard for homes and small businesses.

Advantages of Single Phase Transformers

Single phase transformers have several advantages:

- Simplicity: They have a simpler design than three-phase transformers.

- Cost-effective: They’re usually cheaper to produce and install.

- Versatility: They can be used for a wide range of applications.

- Efficiency: They’re highly efficient for their intended uses.

Here’s a quick comparison:

| Feature | Single Phase | Three Phase |

|---|---|---|

| Wires | 2 | 3 or 4 |

| Typical Use | Residential, Small Commercial | Large Commercial, Industrial |

| Cost | Lower | Higher |

| Power Capacity | Lower | Higher |

Applications of Single Phase Transformers

These transformers are used in many places:

- Homes: Powering all your household appliances.

- Small Businesses: From coffee shops to small offices.

- Lighting Systems: Both indoor and outdoor.

- HVAC Systems: For heating and cooling in smaller buildings.

I once worked on a project to electrify a remote village. We used single phase transformers because they were perfect for the small loads and were easy to install and maintain.

The Inner Workings

The magic of a single phase transformer lies in its simplicity:

- Primary Winding: This is where the high voltage enters.

- Core: Usually made of laminated steel sheets.

- Secondary Winding: This is where the lower voltage exits.

The transformer works by electromagnetic induction. The changing magnetic field in the primary winding induces a voltage in the secondary winding.

Challenges and Solutions

While single phase transformers are great, they do have some limitations:

- Power Capacity: They can’t handle as much power as three-phase transformers.

- Voltage Fluctuations: They can be more prone to voltage drops under heavy loads.

To address these issues, manufacturers have developed:

- Tap Changers: To adjust voltage under different load conditions.

- Advanced Materials: To improve efficiency and reduce losses.

- Smart Monitoring Systems: To track performance and predict maintenance needs.

Single phase transformers might not be as flashy as their three-phase cousins, but they’re the backbone of our everyday electrical world. They’re the reason you can plug in your coffee maker or charge your phone without a second thought. Next time you flip a light switch, remember the humble single phase transformer that made it possible.

Size Matters: How to Pick the Perfect Power Punch for Your Single Phase Transformer?

Have you ever tried to fill a swimming pool with a garden hose? Or water a single plant with a fire hose? Choosing the wrong size transformer is kind of like that. Too small, and you’ll be left in the dark. Too big, and you’re wasting money and energy.

Choosing the right size single phase transformer involves matching the transformer’s kVA rating to your power needs. You need to consider the total load of all connected devices, potential future expansion, and peak demand. A properly sized transformer ensures efficient operation and prevents overloading or underutilization.

I once helped a small business owner who had constant power issues. It turned out their transformer was too small for their needs. After we installed the right size, their problems disappeared. Let’s dive into how you can avoid this mistake and pick the perfect power punch for your needs.

Understanding kVA Ratings

The size of a transformer is typically expressed in kVA (kilovolt-amperes). Here’s what you need to know:

- What is kVA?: It’s a measure of apparent power.

- Relation to Watts: For most applications, kVA is roughly equal to kilowatts (kW).

- Common Sizes: Single phase transformers typically range from 0.25 kVA to 167 kVA.

Calculating Your Power Needs

To choose the right size, you need to know your power requirements:

- List All Loads: Write down all devices that will be powered.

- Find Wattage: Note the wattage of each device.

- Calculate Total: Add up all the wattages.

- Convert to kVA: Divide the total watts by 1000 for kVA.

Here’s a simple example:

| Device | Wattage |

|---|---|

| Lights | 500W |

| Computer | 200W |

| Air Conditioner | 1500W |

| Total | 2200W |

In this case, you’d need at least a 2.2 kVA transformer.

Factors to Consider

Choosing the right size isn’t just about current needs. Consider these factors:

- Future Expansion: Plan for potential growth.

- Peak Demand: Account for times when all devices might be on.

- Startup Loads: Some devices need more power to start than to run.

- Efficiency: Transformers are most efficient when loaded to 50-70% of their capacity.

I once worked with a small factory that was planning to expand. We chose a transformer with extra capacity, which saved them from having to upgrade again in just a few years.

The Dangers of Incorrect Sizing

Choosing the wrong size transformer can lead to problems:

- Undersized: Can lead to overheating, reduced lifespan, and power outages.

- Oversized: Results in higher initial costs and lower efficiency.

Sizing Guidelines

Here’s a general guide to help you choose:

| Load (kVA) | Recommended Transformer Size (kVA) |

|---|---|

| 0-2 | 3 |

| 2-4 | 5 |

| 4-6 | 7.5 |

| 6-8 | 10 |

| 8-12 | 15 |

Remember, it’s usually better to go slightly larger than your calculated need to allow for future growth and peak demands.

When to Seek Professional Help

While these guidelines can help, some situations call for professional assistance:

- Complex Loads: If you have a mix of motors, electronics, and other diverse loads.

- Critical Applications: Where power interruption could be dangerous or costly.

- Large Systems: For loads above 50 kVA, it’s best to consult an expert.

I once helped a hospital choose transformers for their new wing. The mix of sensitive medical equipment and critical power needs required careful calculation and selection.

Choosing the right size transformer is crucial for efficient and reliable power. It’s not just about meeting your current needs, but also planning for the future. By considering all factors and using these guidelines, you can ensure you get the perfect power punch for your single phase transformer needs.

Efficiency Detective: Unmasking the Energy-Saving Secrets of Single Phase Transformers

Are you tired of high energy bills? The culprit might be hiding in plain sight. An inefficient transformer can be like a hole in your pocket, silently draining your money. But fear not! I’m here to unmask the energy-saving secrets of single phase transformers.

Efficient single phase transformers can significantly reduce energy losses and operating costs. Key factors affecting efficiency include core material, winding design, cooling systems, and load management. Modern high-efficiency transformers use advanced materials and designs to minimize both no-load and load losses.

I once helped a small business reduce their energy bills by 15% just by upgrading to a more efficient transformer. The savings paid for the new transformer in less than two years. Let’s dive into the secrets of transformer efficiency.

Understanding Transformer Losses

To improve efficiency, we first need to understand where energy is lost:

- No-Load Losses: These occur even when the transformer is energized but not supplying load.

- Load Losses: These increase as the transformer supplies more power.

Core Materials: The Heart of Efficiency

The core material is crucial for efficiency:

- Silicon Steel: The traditional choice, but not the most efficient.

- Amorphous Metal: Can reduce no-load losses by up to 70%.

- Grain-Oriented Steel: A good balance of performance and cost.

Here’s a comparison:

| Core Material | No-Load Loss Reduction |

|---|---|

| Silicon Steel | Baseline |

| Grain-Oriented Steel | Up to 30% |

| Amorphous Metal | Up to 70% |

I once worked on a project replacing old transformers with amorphous core units. The energy savings were impressive, and the utility company even offered rebates for the upgrade.

Winding Design: The Efficiency Multiplier

The design of the windings can also impact efficiency:

- Copper vs. Aluminum: Copper has lower resistance but is more expensive.

- Foil Windings: Can reduce eddy current losses.

- Optimal Turns Ratio: Balances voltage regulation and efficiency.

Cooling Systems: Keeping It Cool

Efficient cooling helps reduce load losses:

- Oil-Filled: Provides excellent cooling and insulation.

- Dry-Type: Uses air for cooling, good for indoor applications.

- Sealed Tank: Protects the oil from contamination, extending life and maintaining efficiency.

Load Management: The Efficiency Sweet Spot

Transformers are most efficient when operated in their optimal load range:

- Typical Efficiency Range: 50-70% of rated capacity.

- Oversizing Issues: Operating below 40% load can lead to poor efficiency.

- Undersizing Risks: Operating above 80% load can increase losses and reduce lifespan.

I once helped a factory optimize their transformer loading. By redistributing loads among multiple transformers, we improved overall efficiency and reduced wear on overloaded units.

Energy Efficiency Standards

Governments worldwide have implemented efficiency standards:

- DOE Standards: In the US, the Department of Energy sets minimum efficiency levels.

- EU Ecodesign Directive: Sets standards for transformers in Europe.

- Energy Star: Recognizes high-efficiency transformers.

Smart Transformers: The Future of Efficiency

New smart transformer technologies are pushing efficiency even further:

- Real-Time Monitoring: Allows for optimal load management.

- Automatic Voltage Regulation: Maintains efficiency under varying loads.

- Predictive Maintenance: Prevents efficiency drops due to developing issues.

Calculating Efficiency and Savings

To understand the impact of efficiency, consider this example:

- Old Transformer: 97% efficient, 100 kVA

- New High-Efficiency Transformer: 98.5% efficient, 100 kVA

- Annual Energy Savings: About 13,140 kWh

- Cost Savings: At $0.10/kWh, that’s $1,314 per year

These savings can quickly offset the higher initial cost of a high-efficiency transformer.

Improving transformer efficiency is like finding hidden treasure in your electrical system. By choosing the right core materials, optimizing winding design, managing loads effectively, and embracing new technologies, you can unmask significant energy savings. Remember, an efficient transformer isn’t just good for your wallet – it’s good for the planet too.

Location, Location, Location: Finding the Perfect Spot for Your Single Phase Transformer

Have you ever tried to squeeze into a seat that’s too small on an airplane? Or felt lost in a massive auditorium? The same principle applies to transformers. Finding the right location is crucial for their performance and longevity. But where should you put your single phase transformer?

The ideal location for a single phase transformer balances accessibility, safety, and environmental factors. It should be close to the load center to minimize voltage drop, protected from the elements, well-ventilated, and easily accessible for maintenance. The location must also comply with local electrical codes and safety standards.

I once helped a small business owner who had installed their transformer in a damp basement. The transformer failed prematurely due to moisture damage. After relocating it to a better spot, their new transformer has been running smoothly for years. Let’s explore how to find the perfect home for your transformer.

Indoor vs. Outdoor: The Great Debate

The first decision is whether to install your transformer indoors or outdoors:

-

Indoor Installation:

- Pros: Protected from weather, easier to maintain

- Cons: Requires dedicated space, may need additional ventilation

-

Outdoor Installation:

- Pros: Saves indoor space, natural cooling

- Cons: Exposed to elements, may need weatherproofing

Here’s a quick comparison:

| Factor | Indoor | Outdoor |

|---|---|---|

| Weather Protection | High | Low |

| Space Requirements | High | Low |

| Cooling Needs | May need ventilation | Natural air cooling |

| Accessibility | Can be limited | Usually good |

| Noise Concerns | May be an issue | Less problematic |

Key Factors for Transformer Location

When choosing a location, consider these factors:

- Proximity to Load: Closer is usually better to minimize voltage drop.

- Accessibility: Ensure easy access for maintenance and repairs.

- Ventilation: Adequate airflow is crucial for cooling.

- Safety: Keep it away from flammable materials and high-traffic areas.

- Environmental Protection: Shield from moisture, dust, and extreme temperatures.

I once worked on a project where we had to relocate a transformer because it was too close to a water pipe. The risk of water damage was just too high.

Specific Location Guidelines

Here are some specific guidelines for different installation types:

-

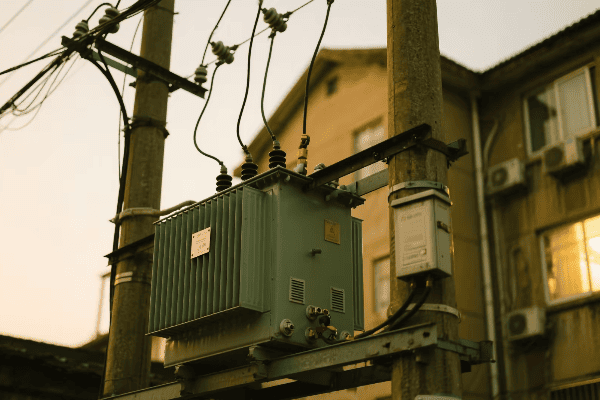

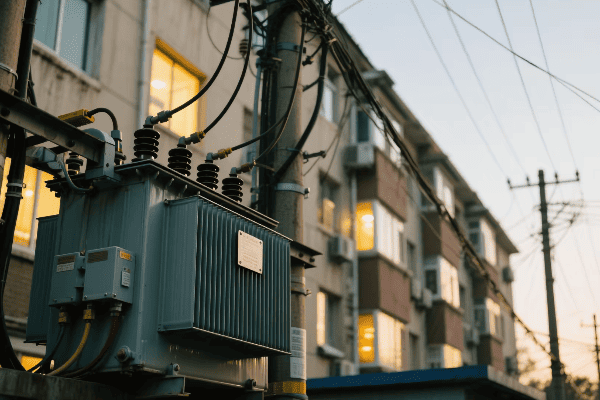

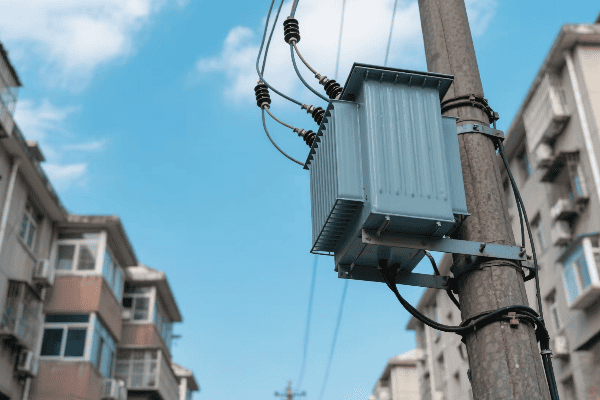

Pole-Mounted:

- Install at a height that’s safe from flooding and vandalism

- Ensure the pole can support the transformer’s weight

- Consider wildlife protection (e.g., squirrel guards)

-

Pad-Mounted:

- Place on a sturdy concrete pad

- Ensure proper drainage to prevent water accumulation

- Install protective barriers if in areas with vehicle traffic

-

Indoor Wall-Mounted:

- Ensure the wall can support the weight

- Allow for proper clearance around the transformer

- Consider noise levels if near occupied areas

-

Indoor Floor-Mounted:

- Place on a level, sturdy surface

- Allow for proper clearance for ventilation and maintenance

- Consider vibration dampening if needed

Compliance and Regulations

Always check local codes and regulations:

- Clearance Requirements: Most codes specify minimum distances from walls, ceilings, and other equipment.

- Fire Safety: Some locations may require fire-resistant construction or sprinkler systems.

- Environmental Regulations: Especially important for oil-filled transformers.

I once had to redesign an entire electrical room because the original plan didn’t meet the local fire code requirements for transformer installation.

Special Considerations

Some situations require extra thought:

- Flood-Prone Areas: Install above the flood line or use waterproof enclosures.

- Seismic Zones: Use special mounting and anchoring techniques.

- Coastal Areas: Consider corrosion-resistant materials and extra weatherproofing.

- High Altitude: May require derating due to reduced air cooling efficiency.

I once worked on a project in a coastal area where we had to use special corrosion-resistant enclosures for the transformers. The salt air was incredibly corrosive, but these measures helped ensure a long service life.

Noise Considerations

Transformer hum can be an issue, especially in residential or office settings:

- Sound Barriers: Consider installing sound-absorbing materials around the transformer.

- Vibration Isolation: Use vibration-dampening mounts to reduce noise transmission.

- Location Planning: Place transformers away from quiet areas if possible.

Future Expansion

Always plan for the future:

- Access for Replacement: Ensure there’s a clear path to remove and replace the transformer if needed.

- Space for Upgrades: Leave room for a larger transformer if load growth is expected.

- Additional Equipment: Plan space for potential additions like surge protectors or monitoring equipment.

Finding the perfect spot for your single phase transformer is a balancing act. You need to consider safety, efficiency, accessibility, and future needs. By carefully evaluating these factors and following local regulations, you can ensure your transformer has a happy, efficient, and long-lasting home.

Transformer TLC: Keeping Your Single Phase Power Buddy Happy and Healthy

Have you ever had a car break down because you forgot to change the oil? Well, transformers are a bit like cars. They need regular TLC to keep running smoothly. But how do you take care of something that doesn’t have moving parts?

Proper maintenance of single phase transformers involves regular inspections, cleaning, oil testing (for oil-filled units), and monitoring of electrical parameters. This includes checking for physical damage, ensuring proper cooling, testing insulation, and monitoring load levels. Regular maintenance extends the transformer’s life, improves efficiency, and prevents unexpected failures.

I once saw a transformer fail spectacularly because of neglected maintenance. The resulting power outage cost the company thousands. Let’s dive into how you can keep your transformer happy and healthy, and avoid such costly disasters.

The Basics of Transformer Maintenance

Regular maintenance is crucial. Here’s a basic checklist:

- Visual Inspection: Look for physical damage, leaks, or rust.

- Cleaning: Remove dust and debris that can impair cooling.

- Tightening Connections: Loose connections can cause overheating.

- Insulation Testing: Check the integrity of the insulation.

- Oil Testing: For oil-filled transformers, check oil quality regularly.

Maintenance Schedule

Different tasks need different frequencies:

| Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Cleaning | Quarterly |

| Connection Check | Annually |

| Insulation Test | Annually |

| Oil Test | Annually or as needed |

Oil-Filled Transformer Care

Oil-filled transformers need special attention:

- Oil Sampling: Regular testing can reveal potential issues early.

- Moisture Content: Keep moisture levels low to prevent insulation breakdown.

- Acidity: High acidity can indicate oil degradation.

- Dissolved Gas Analysis: Can reveal internal faults before they become serious.

I once detected a developing fault in a transformer through oil analysis. We were able to schedule a repair during a planned shutdown, avoiding a costly emergency outage.

Dry-Type Transformer Maintenance

Dry-type transformers have their own needs:

- Dust Removal: Regular cleaning is crucial for proper cooling.

- Ventilation Check: Ensure cooling vents are unobstructed.

- Insulation Resistance: Test regularly to detect deterioration.

- Thermal Imaging: Can reveal hot spots indicating potential problems.

Load Management

Proper loading is key to transformer health:

- Avoid Overloading: Consistently high loads can shorten transformer life.

- Balance Loads: Unbalanced loads can cause overheating.

- Monitor Peak Loads: Brief overloads are usually okay, but frequent peaks can cause damage.

I once helped a client implement a load management system that balanced loads across multiple transformers. This not only improved efficiency but also extended the life of their transformers.

Environmental Factors

The environment can greatly affect transformer health:

- Temperature: Extreme heat or cold can impact performance and lifespan.

- Humidity: High humidity can degrade insulation.

- Pollution: In industrial areas, contaminants can accumulate on transformer surfaces.

Smart Monitoring

New technologies are making maintenance easier:

- Online Monitoring: Real-time data on transformer health.

- Predictive Maintenance: AI algorithms can predict potential failures.

- Remote Diagnostics: Allows experts to analyze transformer health from afar.

Safety First

Always prioritize safety in maintenance:

- De-energize: Always disconnect power before performing maintenance.

- Personal Protective Equipment: Use appropriate PPE for the task.

- Follow Procedures: Stick to established safety protocols.

When to Call the Pros

While some maintenance can be done in-house, some tasks require professionals:

- Major Repairs: Anything involving internal components.

- Oil Replacement: For oil-filled transformers.

- Specialized Testing: Like sweep frequency response analysis.

I once saw a maintenance team attempt a complex repair without proper expertise. The result was a damaged transformer and a hefty repair bill. Sometimes, calling in the experts is the most cost-effective choice.

Documentation

Keep detailed records of all maintenance activities:

- Maintenance Logs: Record all inspections and actions taken.

- Test Results: Keep a history of all test results for trend analysis.

- Repair History: Document any repairs or part replacements.

Good documentation can help identify recurring issues and inform future maintenance strategies.

Proper maintenance is the key to a long and healthy life for your single phase transformer. By following these guidelines, you can ensure your transformer keeps humming along efficiently for years to come. Remember, a little TLC goes a long way in preventing costly breakdowns and ensuring reliable power supply.

Conclusion

Choosing and maintaining the right single phase transformer is crucial for efficient and reliable power distribution. Consider factors like size, efficiency, location, and maintenance needs. With proper selection and care, your transformer will provide years of dependable service, ensuring your power needs are met effectively and economically.

Have you ever wondered how the massive power from electrical plants safely reaches your home? It’s not magic, but it’s close. The unsung heroes of this process are step-down power transformers.

Step-down power transformers play a crucial role in electrical distribution systems by reducing high voltage electricity to lower, safer levels for use in homes and businesses. They act as a bridge between power plants and end-users, ensuring efficient power transmission and safe consumption.

As someone who has worked in the power industry for years, I’ve seen firsthand how these devices keep our lights on and our appliances running. They’re the silent guardians of our electrical world. Let’s dive into the fascinating world of step-down transformers and discover why they’re so important.

Voltage Tamer: How Step-Down Transformers Make High-Voltage Electricity Safe for Your Home?

Imagine trying to fill a small glass with water from a fire hose. That’s what using electricity straight from a power plant would be like. It’s just too powerful. This is where step-down transformers come in.

Step-down transformers reduce high voltage electricity to safer levels for home use. They use electromagnetic induction to transfer energy between two or more coils of wire, lowering the voltage while maintaining the overall power. This process makes the electricity from power plants safe for your household appliances.

I remember the first time I saw a step-down transformer in action. It was during my early days in the industry, and I was amazed by how this device could take in thousands of volts and output a safe 120 volts for home use. Let’s break down how these voltage tamers work.

The Basics of Step-Down Transformer Operation

Step-down transformers work on a simple yet ingenious principle:

- They have two sets of wire coils: a primary (input) and a secondary (output).

- The primary coil has more turns of wire than the secondary coil.

- This difference in turns reduces the voltage proportionally.

Here’s a simple example:

| Coil | Number of Turns | Voltage |

|---|---|---|

| Primary | 1000 | 10,000V |

| Secondary | 100 | 1,000V |

In this case, the secondary coil has 1/10th the turns of the primary coil, so the output voltage is 1/10th of the input voltage.

The Transformation Process

Let’s walk through the process step by step:

- High-voltage electricity enters the primary coil.

- This creates a changing magnetic field in the transformer’s core.

- The changing magnetic field induces a current in the secondary coil.

- The induced current has a lower voltage due to fewer turns in the secondary coil.

Safety Features

Step-down transformers don’t just reduce voltage. They also provide important safety features:

- Electrical Isolation: The primary and secondary coils are not directly connected. This helps prevent high voltage from reaching your home circuits.

- Grounding: Transformers are usually grounded, which helps protect against electrical faults.

- Overload Protection: Many transformers have built-in circuit breakers or fuses.

I once worked on a project to upgrade a neighborhood’s transformers. The old ones were showing signs of wear, and we replaced them with newer models that had better safety features. The peace of mind this gave to the residents was palpable.

Efficiency Considerations

While step-down transformers are incredibly useful, they’re not 100% efficient. Some energy is lost as heat during the transformation process. However, modern transformers are highly efficient, often above 98%.

To maximize efficiency, transformer designers focus on:

- Using high-quality core materials to reduce magnetic losses.

- Optimizing coil design to minimize resistance losses.

- Implementing effective cooling systems to manage heat.

I’ve seen the evolution of transformer efficiency over my career. The improvements in materials and design have been remarkable. Today’s transformers are marvels of engineering, quietly and efficiently doing their job day in and day out.

Step-down transformers are the unsung heroes of our electrical world. They take the raw power from electrical plants and tame it into a form that’s safe and useful for our homes. Next time you plug in an appliance, spare a thought for the transformer that made it possible.

The Gentle Giants: Why Do We Need Step-Down Transformers to Keep Our Lights On?

Have you ever driven past those big substations with their massive equipment and wondered what it all does? Those "gentle giants" you see are often step-down transformers, and they’re crucial for keeping your lights on.

Step-down transformers are essential in electrical distribution systems because they allow for efficient long-distance power transmission and safe local power use. They reduce high transmission voltages to lower distribution voltages, making electricity suitable for homes and businesses while minimizing power losses over distances.

In my years working in the power industry, I’ve come to see these transformers as the unsung heroes of our electrical grid. Let me share why these gentle giants are so important.

The Power Transmission Dilemma

To understand why we need step-down transformers, we first need to grasp the challenge of power transmission. Here’s the dilemma:

- Long Distances: Power plants are often far from where electricity is used.

- Power Losses: Electricity loses power as it travels through wires due to resistance.

- Safety: The high voltages good for transmission are dangerous for home use.

Step-down transformers help solve all these problems. Here’s how:

| Problem | Solution |

|---|---|

| Long Distances | Allow high-voltage transmission |

| Power Losses | High voltage means lower current, reducing losses |

| Safety | Step down voltage for safe local use |

The Journey of Electricity

Let’s follow the journey of electricity from a power plant to your home:

- Generation: Electricity is generated at 10,000 to 25,000 volts.

- Step-Up: Voltage is increased to 100,000 to 750,000 volts for transmission.

- Transmission: Electricity travels long distances on high-voltage lines.

- Step-Down: At substations, voltage is reduced to 4,000 to 35,000 volts for distribution.

- Distribution: Electricity travels to neighborhoods.

- Final Step-Down: Transformers on poles or in green boxes reduce voltage to 120/240 volts for home use.

I once had the opportunity to tour a large substation. Seeing those massive transformers in action, quietly humming as they handled enormous amounts of power, was awe-inspiring.

Balancing Act: Efficiency and Safety

Step-down transformers perform a delicate balancing act:

- Efficiency: They allow for efficient high-voltage transmission.

- Safety: They provide safe low-voltage electricity for local use.

- Reliability: They help isolate faults and manage power flow.

Beyond Voltage Reduction

Step-down transformers do more than just reduce voltage:

- Load Management: They help balance the load across the grid.

- Power Quality: They can help smooth out voltage fluctuations.

- Fault Isolation: They can help prevent problems from spreading across the grid.

I once worked on a project to upgrade a city’s transformer network. We installed new smart transformers that could communicate with the grid control center. This allowed for much better load management and faster response to problems.

The Future of Step-Down Transformers

As our power needs evolve, so do our transformers:

- Smart Transformers: These can adjust their output based on demand.

- Green Transformers: New designs are more energy-efficient and use eco-friendly materials.

- Compact Designs: Some new transformers are smaller, perfect for urban areas.

Step-down transformers are the gentle giants that make our modern electrical world possible. They ensure that the massive power generated at plants can safely and efficiently reach our homes. Next time you see a substation, remember the crucial role these devices play in keeping your lights on.

From Danger to Domestic: How Step-Down Transformers Act as Safety Guards in Our Electrical World?

Have you ever touched a 9-volt battery to your tongue and felt that tiny zap? Now imagine that feeling multiplied by thousands. That’s the kind of power flowing through transmission lines. Scary, right? This is where step-down transformers become our electrical safety superheroes.

Step-down transformers act as crucial safety guards in our electrical systems by reducing dangerously high voltages to levels safe for domestic use. They provide electrical isolation between transmission and distribution systems, protect against voltage spikes, and help prevent electrical fires and equipment damage in homes and businesses.

In my years working with power systems, I’ve seen firsthand how these devices keep us safe from the immense power flowing through our electrical grid. Let’s explore how these transformers guard our homes and businesses.

The Safety Challenges of Electricity

Before we dive into how step-down transformers protect us, let’s consider the dangers they’re guarding against:

- High Voltage: Transmission lines carry voltages that can be instantly fatal.

- High Current: Even lower voltages can be dangerous if there’s high current.

- Electrical Fires: Overloaded circuits can cause fires.

- Equipment Damage: Voltage spikes can destroy electronic devices.

Step-down transformers address all these issues. Here’s how:

| Danger | How Transformers Help |

|---|---|

| High Voltage | Reduce voltage to safe levels |

| High Current | Limit current flow in low-voltage circuits |

| Electrical Fires | Prevent overloading of domestic wiring |

| Equipment Damage | Absorb voltage spikes and provide stable output |

Electrical Isolation: Creating a Safety Barrier

One of the key safety features of step-down transformers is electrical isolation. Here’s what this means:

- No Direct Connection: There’s no direct wire connection between the high-voltage and low-voltage sides.

- Magnetic Coupling: Energy is transferred via a magnetic field, not a physical connection.

- Fault Protection: If something goes wrong on one side, it’s less likely to affect the other side.

I once investigated a case where a lightning strike hit a transmission line. The step-down transformer prevented the surge from reaching homes in the area, likely saving lives and preventing massive damage.

Voltage Regulation: Keeping Power Steady

Step-down transformers don’t just reduce voltage; they help keep it steady:

- Tap Changers: Many transformers can adjust their output voltage.

- Load Regulation: They help maintain steady voltage despite changing loads.

- Surge Absorption: They can absorb small voltage spikes.

This steady voltage is crucial for the safety and longevity of your appliances and electronics.

Overload Protection: Preventing Burnout

Step-down transformers also help protect against overloads:

- Current Limiting: They naturally limit the current in the secondary circuit.

- Thermal Protection: Many have sensors to detect dangerous heating.

- Circuit Breakers: Some are equipped with built-in circuit breakers.

I once worked on upgrading a factory’s power system. The new transformers we installed had advanced overload protection. Months later, the factory manager told me how these features had prevented a potential fire when a piece of equipment malfunctioned.

Grounding: An Extra Layer of Safety

Proper grounding is crucial for electrical safety, and step-down transformers play a role here too:

- System Grounding: They often provide a ground point for the electrical system.

- Fault Current Path: This grounding helps direct fault currents safely away.

- Static Charge Dissipation: Grounding helps prevent static buildup.

The Future of Transformer Safety

As technology advances, so does transformer safety:

- Smart Monitoring: New transformers can detect potential issues before they become dangerous.

- Rapid Disconnection: Some can disconnect faster than ever if they detect a problem.

- Fire-Resistant Materials: New designs use materials that resist catching fire.

Step-down transformers are the unsung heroes of our electrical safety. They stand guard 24/7, protecting us from the dangers of high-voltage electricity. Next time you plug in an appliance, remember the complex safety system, centered on these transformers, that’s keeping you safe.

The Journey of a Spark: Where Do Step-Down Transformers Come into Play as Electricity Travels to Your Outlet?

Have you ever wondered about the incredible journey electricity takes from a power plant to the outlet in your wall? It’s a trek full of transformations, and step-down transformers play a starring role in this electrifying adventure.

Step-down transformers are crucial waypoints in electricity’s journey from power plants to homes. They appear at key stages to reduce voltage, making power transmission efficient over long distances and then safe for local distribution. These transformers ensure electricity completes its journey safely and efficiently.

As someone who’s worked in the power industry for years, I’ve always been fascinated by this journey. Let’s trace the path of a spark from its birth to your home, and see where step-down transformers come into play.

The Birth of a Spark: Generation

Our journey begins at the power plant. Here’s where electricity is born:

- Generators produce electricity, typically at 10,000 to 25,000 volts.

- This voltage is too low for efficient long-distance transmission.

At this stage, we actually use step-up transformers to increase the voltage for transmission. But don’t worry, our step-down transformers will come into play soon!

The Long-Distance Sprint: Transmission

Now, our electricity is ready for its cross-country journey:

- Electricity travels on high-voltage transmission lines, often at 100,000 to 750,000 volts.

- These high voltages reduce power losses over long distances.

I once visited a major transmission substation. The buzz of electricity in the air was palpable. It’s amazing to think of the sheer power flowing through those lines.

First Pit Stop: Primary Step-Down Substation

Here’s where our step-down transformers first enter the scene:

- Massive transformers reduce the voltage from transmission levels to distribution levels.

- Typically, they bring the voltage down to between 4,000 and 35,000 volts.

These transformers are the giants of the transformer world. I remember the first time I saw one up close. It was the size of a small house!

The Local Journey: Distribution

Now at a more manageable voltage, electricity continues its journey:

- It travels on smaller power lines to local areas.

- These are the lines you often see on street poles.

Second Pit Stop: Distribution Transformer

As electricity nears its final destination, it encounters another step-down transformer:

- These are the barrel-shaped devices you see on power poles or in green boxes on the ground.

- They reduce the voltage further, typically to 120/240 volts for residential use.

I once helped install a new distribution transformer in a growing neighborhood. It was satisfying to know we were literally bringing power to people’s homes.

The Final Stretch: Service Drop

Finally, electricity makes its way to your home:

- It travels from the distribution transformer to your house’s service head.

- From there, it enters your home’s electrical panel.

Journey’s End: Your Outlet

At last, the electricity reaches your wall outlet, ready to power your devices.

Here’s a summary of the voltage changes throughout this journey:

| Stage | Voltage Range | Transformer Type |

|---|---|---|

| Generation | 10,000 – 25,000 V | Step-Up |

| Transmission | 100,000 – 750,000 V | – |

| Primary Distribution | 4,000 – 35,000 V | Step-Down |

| Secondary Distribution | 120/240 V | Step-Down |

The Crucial Role of Step-Down Transformers

Throughout this journey, step-down transformers play several key roles:

- Efficiency: They allow for efficient high-voltage transmission over long distances.

- Safety: They bring voltages down to safe levels for local use.

- Flexibility: They provide different voltage levels for different needs (industrial, commercial, residential).

- Reliability: They help isolate faults and manage power flow.

I once worked on a project to map out the transformer network for a small city. It was fascinating to see how these devices formed a crucial part of the electrical ecosystem, each playing its part in bringing power to the people.

The journey of electricity from power plant to your home is a marvel of modern engineering. Step-down transformers are the unsung heroes of this journey, ensuring that the massive power generated at plants can safely and efficiently reach your devices. Next time you plug something in, take a moment to appreciate the incredible voyagethat electricity has taken, and the crucial role step-down transformers have played in making it possible.

Power Perfectors: How Step-Down Transformers Help Squeeze the Most Out of Our Electrical Grid?

Have you ever wondered how our electrical grid manages to keep up with our ever-growing power demands? It’s not just about generating more electricity. It’s also about using what we have more efficiently. This is where step-down transformers shine as true power perfectors.

Step-down transformers play a crucial role in optimizing our electrical grid. They reduce power losses during transmission, enable voltage optimization for efficiency, and facilitate the integration of renewable energy sources. These transformers help utilities manage load more effectively and improve overall grid reliability.

In my years working with power systems, I’ve seen how step-down transformers have evolved from simple voltage reducers to sophisticated tools for grid optimization. Let’s explore how these devices help us squeeze the most out of our electrical grid.

Efficiency Through Voltage Optimization

One of the key ways step-down transformers help optimize the grid is through voltage optimization. Here’s how it works:

- Voltage Range: Appliances are designed to work within a range of voltages.

- Optimal Voltage: There’s often an optimal voltage within this range for energy efficiency.

- Adjustable Output: Modern step-down transformers can fine-tune their output voltage.

By maintaining voltage at the optimal level, we can reduce energy consumption without affecting performance. I once worked on a project where we implemented voltage optimization in a small town. The energy savings were impressive – about 5% reduction in overall consumption!

Load Management and Demand Response

Step-down transformers also play a crucial role in load management:

- Load Monitoring: Smart transformers can monitor the load in real-time.

- Demand Response: They can adjust their output based on demand.

- Peak Shaving: This helps reduce strain on the grid during peak times.

Here’s a simple table showing how transformer load might be managed throughout the day:

| Time | Load | Transformer Action |

|---|---|---|

| Night | Low | Slight voltage reduction |

| Morning | Rising | Voltage increase |

| Afternoon | High | Maintain optimal voltage |

| Evening Peak | Very High | Possible slight overload, closely monitored |

I remember implementing a smart transformer system that could communicate with the utility’s control center. During a heatwave, it helped prevent blackouts by managing load more effectively.

Facilitating Renewable Energy Integration

As we move towards more renewable energy, step-down transformers are adapting to new challenges:

- Bidirectional Power Flow: They handle power flowing both to and from the grid (for solar panels, for example).

- Voltage Fluctuation Management: They help manage the voltage fluctuations common with renewable sources.

- Harmonic Mitigation: They can help reduce the harmonics introduced by some renewable energy systems.

I recently worked on a project integrating a large solar farm into the local grid. The advanced step-down transformers we used were crucial in managing the variable output of the solar panels.

Improving Power Quality

Step-down transformers also play a role in maintaining power quality:

- Harmonic Filtering: Some advanced transformers can filter out harmful harmonics.

- Voltage Stabilization: They help maintain stable voltage despite fluctuations in supply or demand.

- Power Factor Correction: Some can help improve the power factor, increasing efficiency.

Predictive Maintenance and Grid Reliability

Modern step-down transformers are getting smarter, contributing to grid reliability:

- Condition Monitoring: They can monitor their own health.

- Predictive Maintenance: This allows for maintenance before failures occur.

- Fault Localization: They can help pinpoint issues in the grid.

I was once involved in a pilot project for predictive maintenance of transformers. The system alerted us to a developing fault in one transformer, allowing us to fix it before any outage occurred. It was a great example of how these smart systems can improve reliability.

The Future of Grid Optimization

As we look to the future, step-down transformers are set to play an even bigger role in grid optimization:

- AI Integration: Artificial intelligence could allow for even more sophisticated load management.

- Edge Computing: Transformers might become nodes in a distributed computing network for grid management.

- Energy Storage Integration: Some transformers might integrate with battery systems for even better load balancing.

Step-down transformers have come a long way from being simple voltage reducers. They’re now sophisticated tools for squeezing the most out of our electrical grid. As we face the challenges of increasing energy demand and the integration of renewable sources, these power perfectors will continue to play a crucial role in keeping our lights on and our grid efficient.

Conclusion

Step-down transformers are the unsung heroes of our electrical distribution systems. They ensure safe, efficient power delivery from plants to homes, optimize grid performance, and facilitate the integration of renewable energy. As our energy needs evolve, these versatile devices will continue to play a crucial role in shaping a more efficient and sustainable electrical future.

Have you ever wondered how electricity travels from power plants to your home? It’s not as simple as you might think. There’s a crucial player in this journey that often goes unnoticed: the power transformer.

A power transformer is a vital device in energy distribution that changes voltage levels between electrical circuits. It allows electricity to be transmitted efficiently over long distances and then safely used in homes and businesses. Power transformers are essential for maintaining a reliable and stable electrical grid.

As someone who has worked in the power industry for years, I’ve seen firsthand how important these devices are. They’re like the unsung heroes of our electrical world. Let’s dive deeper into what power transformers do and why they’re so crucial for keeping our lights on.

The Magic Box: How Does a Power Transformer Turn High Voltage into Home-Friendly Electricity?

Imagine trying to fill a small glass with water from a fire hose. That’s kind of what it would be like to use electricity straight from a power plant. It’s just too powerful. This is where transformers come in.

Power transformers use electromagnetic induction to change voltage levels. They step down high voltage from power plants to lower, safer levels for home use. This process involves two or more coils of wire wrapped around an iron core, which transfers energy between circuits without a direct electrical connection.

I remember the first time I saw the inside of a transformer. It was during my early days in the industry, and I was amazed by how such a seemingly simple device could perform such a crucial function. Let me break down how this "magic box" works.

The Basics of Transformer Operation

At its core, a transformer’s operation is based on two principles:

- Changing magnetic fields can induce an electric current in a wire.

- Electric current flowing through a wire creates a magnetic field around it.

Here’s how these principles come together in a transformer:

- Primary Coil: This is where the high-voltage electricity enters the transformer.

- Iron Core: This amplifies the magnetic field created by the primary coil.

- Secondary Coil: This is where the transformed electricity exits.

The Transformation Process

Let’s walk through the process step by step:

- High-voltage electricity enters the primary coil.

- This creates a changing magnetic field in the iron core.

- The changing magnetic field induces a current in the secondary coil.

- The voltage of this induced current depends on the number of turns in the secondary coil compared to the primary coil.

Here’s a simple table to illustrate:

| Coil | Number of Turns | Voltage |

|---|---|---|

| Primary | 1000 | 10,000V |

| Secondary | 100 | 1,000V |

In this example, the secondary coil has 1/10th the turns of the primary coil, so the output voltage is 1/10th of the input voltage.

Efficiency and Heat Management

One of the amazing things about transformers is their efficiency. A well-designed transformer can be over 99% efficient. However, even that small loss can generate a lot of heat when dealing with large amounts of power.

This is why you’ll often see transformers with:

- Cooling fins

- Oil baths

- Fans or pumps

I once worked on a project to upgrade a substation’s cooling system. It was fascinating to see how much engineering goes into just keeping these devices at the right temperature.

Transformers might seem like simple devices, but they’re the result of over a century of engineering refinement. They’re a perfect example of how sometimes, the most important technologies are the ones we rarely think about.

From Power Plant to Plug: Why Are Transformers the Superheroes of Our Electrical World?

Have you ever thought about the journey electricity takes from a power plant to your phone charger? It’s an epic adventure, and transformers are the superheroes that make it possible. Without them, our electrical grid simply wouldn’t work.

Transformers are crucial in electrical distribution because they allow electricity to be transmitted efficiently over long distances and then used safely in homes and businesses. They step up voltage for transmission, reducing power losses, and then step it down for local distribution and consumption.

I’ve spent years working with power systems, and I’m still amazed by how transformers enable our modern electrical grid. Let’s explore why these devices are so important.

The Journey of Electricity

To understand why transformers are so crucial, we need to follow the journey of electricity:

- Generation: At the power plant

- Transmission: Over long distances

- Distribution: To local areas

- Consumption: In homes and businesses

Transformers play a key role at each stage. Here’s how:

| Stage | Transformer Type | Function |

|---|---|---|

| Generation | Step-up | Increases voltage for efficient transmission |

| Transmission | – | (No transformation during transmission) |

| Distribution | Step-down | Decreases voltage for local distribution |

| Consumption | Step-down | Further reduces voltage for safe use in buildings |

Why High Voltage for Transmission?

You might wonder why we need to increase voltage for transmission. The answer lies in power loss. When electricity flows through a wire, some energy is lost as heat. This loss is proportional to the current flowing through the wire.

Here’s the key: for the same amount of power, higher voltage means lower current. Lower current means less power loss. This is why we use extremely high voltages for long-distance transmission.

I once visited a high-voltage transmission line. The buzz of electricity was almost palpable. It’s incredible to think that transformers make it possible to safely step this power down to the 120V we use in our homes.

Transformers in Action

Let’s look at a simplified example of how transformers work in the grid:

- A power plant generates electricity at 20,000V

- A step-up transformer increases this to 765,000V for transmission

- At a substation, a step-down transformer reduces it to 10,000V for local distribution

- Another transformer on your street reduces it further to 240V

- A final transformer (often in your home’s circuit box) brings it down to 120V for your outlets

Each of these transformations is crucial for balancing efficiency and safety.

Beyond Voltage Change

Transformers do more than just change voltage levels. They also:

- Isolate Circuits: This provides protection against faults and surges

- Balance Loads: Some transformers help distribute power evenly across three-phase systems

- Regulate Voltage: Some transformers can adjust their output to maintain steady voltage despite fluctuations in supply or demand

I once worked on a project to install a new substation in a rapidly growing area. It was fascinating to see how the right combination of transformers could take a massive influx of power and distribute it safely and efficiently to thousands of new homes and businesses.

Transformers truly are the unsung heroes of our electrical world. They work tirelessly, often for decades, to ensure that we have safe, reliable power at our fingertips. Next time you plug in your phone or turn on a light, spare a thought for the transformers that made it possible.

Transformer Types: Big Ones, Small Ones, and Everything in Between

When you hear "transformer," you might think of those big grey boxes in your neighborhood. But did you know there’s a whole world of transformers out there, from tiny ones in your phone charger to massive ones in power stations?

Transformers come in various types and sizes, each designed for specific applications. These include power transformers for electricity transmission, distribution transformers for local power supply, and smaller transformers for electronic devices. Their design varies based on factors like power capacity, voltage levels, and cooling methods.

In my years in the power industry, I’ve worked with all sorts of transformers. Each type has its own quirks and challenges. Let’s explore the different types of transformers and what makes each one special.

Power Transformers: The Heavy Lifters

Power transformers are the giants of the transformer world. They’re used in power stations and substations to step voltage up for transmission or down for distribution.

Key features:

- High power capacity (up to hundreds of MVA)

- High voltage (up to 765 kV or more)

- Often oil-cooled for better insulation and heat dissipation

I once visited a substation with a massive 500 MVA transformer. It was the size of a small house and required a special transport system just to move it!

Distribution Transformers: Bringing Power to Your Neighborhood

These are the transformers you’re most likely to see in your daily life. They’re the ones mounted on poles or in those green boxes in your neighborhood.

Key features:

- Medium power capacity (up to about 5 MVA)

- Medium voltage (typically 4-35 kV primary, 120/240V secondary)

- Can be oil-filled or dry-type

Instrument Transformers: The Precision Tools

These smaller transformers are used for measuring voltage (potential transformers) or current (current transformers) in power systems.

Key features:

- High accuracy

- Used with meters and protective relays

- Provide electrical isolation for safety

Special Application Transformers

There are also many specialized transformers for specific uses:

| Type | Application | Special Features |

|---|---|---|

| Autotransformers | Voltage adjustment | Single winding, more compact |

| Isolation Transformers | Electrical safety | Provides galvanic isolation |

| Rectifier Transformers | DC power supplies | Designed for high harmonic currents |

| Traction Transformers | Electric trains | Compact, lightweight design |

Cooling Methods: Keeping It Cool

One of the biggest challenges in transformer design is managing heat. Different types of transformers use different cooling methods:

- Oil-Immersed: The core and windings are immersed in insulating oil. This is common for large power transformers.

- Dry-Type: These use air for cooling and insulation. They’re often used indoors where oil-filled transformers would be a fire hazard.

- Gas-Insulated: Some modern transformers use sulfur hexafluoride (SF6) gas for insulation.

I once worked on a project to replace an old oil-filled transformer with a modern dry-type unit in a hospital. The improved safety and reduced maintenance were significant benefits.

Smart Transformers: The Future is Here

As our power grids become smarter, so do our transformers. Modern "smart" transformers can:

- Monitor their own health

- Adjust voltage levels automatically

- Communicate with grid control systems

These features help improve grid stability and efficiency. I’m excited to see how these technologies develop in the coming years.

From the tiny transformer in your phone charger to the massive units in power stations, each type of transformer plays a crucial role in our electrical systems. Understanding these different types helps us appreciate the complex network that keeps our lights on and our devices charged.

Keeping the Lights On: How Transformers Make Sure Your Fridge Stays Cold and Your Phone Stays Charged

Have you ever experienced a power outage? It’s frustrating, right? Suddenly, your fridge stops humming, your lights go out, and your phone battery becomes a precious resource. But have you ever wondered what keeps these annoyances from happening more often? The answer, in large part, is transformers.

Transformers play a crucial role in maintaining a stable and reliable power supply. They help regulate voltage, manage power distribution, and isolate different parts of the grid. This ensures that your home appliances receive a consistent power supply, protecting them from damage and keeping them running smoothly.

As someone who’s spent years working on power systems, I’ve seen firsthand how transformers keep our modern lives running smoothly. Let’s dive into how these devices work tirelessly to keep your lights on and your devices charged.

Voltage Regulation: Keeping the Power Just Right

One of the key functions of transformers in power distribution is voltage regulation. Here’s why it’s important:

- Consistent Power Supply: Your appliances are designed to work at a specific voltage (usually 120V in the US). Too much or too little voltage can damage them.

- Efficiency: The right voltage ensures that appliances operate efficiently.

- Safety: Proper voltage regulation helps prevent electrical fires and other hazards.

Many distribution transformers come with tap changers that can adjust the output voltage. I once worked on a project to upgrade these tap changers to automatic systems. It was amazing to see how they could respond in real-time to changes in load, keeping the voltage steady despite fluctuations in demand.

Load Management: Balancing the Power

Transformers also play a crucial role in managing the load on the power system. Here’s how:

- Load Sharing: Multiple transformers can share the load in a neighborhood, preventing any one transformer from being overloaded.

- Peak Load Handling: Transformers are designed to handle short-term overloads during peak usage times.

- Fault Isolation: If there’s a problem in one area, transformers can help isolate it, preventing widespread outages.

| Time of Day | Typical Load | Transformer Action |

|---|---|---|

| Night | Low | May reduce output slightly |

| Morning | Rising | Increases output to meet demand |

| Afternoon | High | Maintains high output, may engage cooling systems |

| Evening | Peak | Operates at maximum capacity, may allow short-term overload |

I remember working on a system during a heatwave. The transformers were running at their limits, but thanks to good design and maintenance, they kept the power flowing despite the unprecedented demand from air conditioners.

Protection and Isolation: Keeping Problems Contained

Transformers also serve as a form of protection for the grid and your home appliances:

- Electrical Isolation: Transformers create a barrier between different parts of the grid. This can prevent problems from spreading.

- Surge Protection: Some transformers can help absorb voltage spikes, protecting your appliances.

- Fault Current Limitation: Transformers can limit the amount of current that flows during a fault, reducing damage.

I once investigated a case where a lightning strike hit a power line. The local distribution transformer prevented the surge from reaching homes in the area, likely saving thousands of dollars in damaged appliances.

Efficiency and Longevity: Keeping Costs Down

Modern transformers are designed to be highly efficient and long-lasting:

- Low Losses: High-efficiency transformers minimize energy waste, keeping your electricity bills lower.

- Long Lifespan: A well-maintained transformer can last 30 years or more.

- Smart Features: Newer transformers can report their status, allowing for predictive maintenance.

These features not only keep your power reliable but also help keep costs down in the long run. It’s a win-win for both consumers and power companies.

From regulating voltage to managing loads and protecting against faults, transformers work tirelessly to keep your power flowing smoothly. They’re the unsung heroes that ensure your fridge stays cold, your lights stay on, and your phone stays charged. Next time you plug in a device, spare a thought for the transformers that make it all possible.

Green Energy’s Best Friend: How Transformers Help Solar and Wind Power Reach Your Home

Have you ever wondered how the energy from those distant wind farms or solar fields makes it to your home? It’s not as simple as connecting a really long wire. The key to making renewable energy work on our grid lies in a technology that’s been around for over a century: transformers.

Transformers play a crucial role in integrating renewable energy sources into the power grid. They help manage the variable output of solar and wind power, step up voltage for long-distance transmission, and then step it down for local use. Without transformers, large-scale renewable energy projects would not be feasible.

As someone who’s worked on renewable energy projects, I’ve seen firsthand how transformers make green energy possible on a large scale. Let’s explore how these devices are helping to power a cleaner future.

Managing Variable Output: Taming the Sun and Wind

One of the biggest challenges with renewable energy is its variability. The sun doesn’t always shine, and the wind doesn’t always blow. This is where specialized transformers come in:

- Voltage Regulation: They help smooth out the voltage fluctuations from variable sources.

- Frequency Control: Some advanced transformers can help maintain grid frequency despite variations in renewable output.

- Power Factor Correction: They can adjust for the power factor issues often associated with renewable sources.

I once worked on a solar farm project where we used special transformers with on-load tap changers. These could adjust their output in real-time based on the solar panels’ output, helping to maintain a steady supply to the grid.

Stepping Up for Long-Distance Transmission

Many renewable energy sources are located far from where the power is needed. This is where step-up transformers### Stepping Up for Long-Distance Transmission

Many renewable energy sources are located far from where the power is needed. This is where step-up transformers become crucial:

- Voltage Increase: They boost the voltage from the generation site (often 600V-35kV) to transmission levels (100kV-800kV).

- Loss Reduction: Higher voltage means lower current for the same power, which reduces transmission losses.

- Enabling Remote Locations: This allows wind farms in rural areas or offshore to connect to urban centers.

I remember visiting an offshore wind farm and being amazed by the massive transformer platform. It was like a small oil rig, but instead of extracting energy, it was preparing renewable energy for its journey to shore.

Transformers in Solar Farms

Solar farms have their own unique transformer needs:

| Location | Transformer Type | Function |

|---|---|---|

| At each inverter | Small step-up | Boosts voltage from panel level to collection level |

| Collection points | Medium step-up | Combines output from multiple inverters |

| Substation | Large step-up | Prepares power for grid transmission |

Smart Transformers for a Smart Grid

As renewable energy becomes more prevalent, we’re seeing the rise of smart transformers:

- Bidirectional Power Flow: They can handle power flowing both to and from the grid, essential for systems with home solar panels.

- Real-time Monitoring: They provide data on power quality and transformer health.

- Adaptive Response: They can adjust their operation based on grid conditions.

I recently worked on a project integrating smart transformers into a neighborhood with high solar panel adoption. The ability to manage bidirectional power flow made a huge difference in grid stability.

Overcoming Challenges

Integrating renewables isn’t without its challenges:

- Harmonics: Inverters used in solar and wind can introduce harmonics. Special transformers with higher K-factors are used to handle this.

- Intermittency: Transformers need to handle rapid changes in load as clouds pass over solar panels or wind speeds change.

- Remote Locations: Transformers for renewables often need to be more rugged to handle harsh environments.

The Future of Transformers in Renewable Energy

As we move towards a greener future, transformers are evolving:

- Higher Efficiency: New materials and designs are pushing efficiency even higher.

- Smaller Footprint: More compact designs are being developed for offshore wind and urban solar installations.

- Integration with Storage: Some transformers are being designed to work seamlessly with large-scale battery storage systems.

I’m excited about a new project I’m involved in, where we’re testing transformers integrated with large-scale batteries. This could be a game-changer for managing the variability of renewable energy.

Transformers might not be the first thing you think of when it comes to green energy, but they’re absolutely essential. They’re the unsung heroes making it possible for the clean energy from wind turbines and solar panels to power our homes and businesses. As we continue to shift towards renewable energy, the role of transformers will only become more important. They’re not just part of our energy past; they’re a crucial part of our energy future.

Conclusion

Power transformers are the unsung heroes of our electrical grid. They enable efficient power transmission, ensure safe voltage levels for home use, and play a crucial role in integrating renewable energy. As we move towards a greener future, transformers will continue to evolve, becoming smarter and more efficient to meet our changing energy needs.

Are you worried about climate change? You’re not alone. As our planet faces environmental challenges, the energy sector is under pressure to find sustainable solutions. But there’s hope on the horizon.

Power transformer manufacturers are playing a crucial role in sustainable energy solutions. They are developing innovative technologies to support renewable energy integration, improve energy efficiency, and create smart grid systems. These efforts are helping to reduce carbon emissions and promote a cleaner energy future.

As someone who has been in the power equipment industry for years, I’ve seen firsthand how transformer manufacturers are stepping up to the plate. Their contributions are not just impressive; they’re essential for our sustainable future. Let’s dive into how these companies are making a difference.

Green Giants: How Are Transformer Makers Powering the Renewable Energy Revolution?

Picture this: vast fields of solar panels and towering wind turbines dotting the landscape. It’s an inspiring sight, but have you ever wondered how all that green energy gets to your home?

Transformer manufacturers are creating specialized transformers designed to handle the unique challenges of renewable energy sources. These transformers can manage the variable output of solar and wind power, ensuring a stable and reliable supply of clean energy to the grid.

I remember visiting a wind farm a few years ago. The sight of those massive turbines was impressive, but what really caught my eye were the transformers at the base of each tower. These aren’t your average transformers. They’re specially designed to handle the unique challenges of wind power.

Adapting to Renewable Quirks

Renewable energy sources like wind and solar are fantastic for the environment, but they come with their own set of challenges. Here’s how transformer manufacturers are tackling these issues:

- Variable Output Handling: Wind doesn’t always blow, and the sun doesn’t always shine. Transformers for renewables need to handle this variability.

- Bidirectional Power Flow: With more people generating their own solar power, transformers now need to manage power flowing both ways.

- Harsh Environment Resistance: Offshore wind farms need transformers that can withstand salt spray and constant vibration.

Innovations in Transformer Design

To meet these challenges, manufacturers have come up with some clever solutions:

| Innovation | Purpose | Benefit |

|---|---|---|

| Tap Changers | Adjust voltage levels | Maintain stable output despite variable input |

| Corrosion-Resistant Materials | Protect against harsh environments | Longer lifespan for offshore transformers |

| Smart Monitoring Systems | Real-time performance tracking | Quick response to changes in renewable output |

These innovations aren’t just cool tech; they’re essential for making renewable energy a reliable part of our power grid. Without them, integrating large amounts of wind and solar power would be much more difficult.

The Impact on Renewable Adoption

The work of transformer manufacturers has had a real impact on renewable energy adoption. By creating transformers that can handle the quirks of renewable sources, they’ve made it easier and more cost-effective to add green energy to the grid.

I’ve seen small towns go from relying entirely on fossil fuels to getting a significant portion of their power from local wind farms. This wouldn’t be possible without the right transformer technology.

As we push for more renewable energy, the role of transformer manufacturers will only become more important. They’re not just keeping up with the green energy revolution; they’re helping to drive it forward.

Efficiency Wizards: What Tricks Are Transformer Companies Using to Save Energy?

Have you ever wondered how much energy is lost in the process of getting electricity from a power plant to your home? The answer might surprise you. But here’s the good news: transformer companies are working hard to minimize these losses.

Transformer manufacturers are employing advanced materials, innovative designs, and smart technologies to create more efficient transformers. These improvements reduce energy losses during transmission and distribution, leading to significant energy savings and reduced carbon emissions.

I remember when I first learned about transformer efficiency. It was eye-opening to realize how much energy could be saved with even small improvements. Now, let’s look at some of the "magic tricks" these efficiency wizards are using.

The Quest for Efficiency

Improving transformer efficiency is a bit like trying to plug all the tiny leaks in a water pipe. It requires attention to detail and innovative thinking. Here are some areas where manufacturers are focusing their efforts:

- Core Materials: The heart of a transformer

- Winding Design: How the copper coils are arranged

- Cooling Systems: Keeping transformers from overheating

- Smart Technologies: Using data to optimize performance

Innovative Materials and Designs

Let’s dive deeper into some of the specific innovations:

| Innovation | Description | Efficiency Gain |

|---|---|---|

| Amorphous Metal Cores | Uses a special alloy that reduces core losses | Up to 70% reduction in core losses |

| Copper Foil Windings | Replaces traditional wire with thin copper foil | Reduces winding losses by up to 15% |

| Vegetable Oil Insulation | Uses biodegradable oils instead of mineral oil | Improves cooling efficiency and is eco-friendly |

| Digital Monitoring Systems | Tracks performance in real-time | Allows for optimal load management |

These might sound like small changes, but they add up to big savings. I’ve seen transformers with amorphous metal cores that are so efficient, they’re almost cool to the touch even under full load.

The Impact of Efficiency Gains

The impact of these efficiency improvements goes beyond just saving energy. They also:

- Reduce operating costs for utilities

- Decrease the need for new power plants

- Lower carbon emissions

- Extend the lifespan of transformers

I once worked with a utility company that replaced all their old transformers with new, high-efficiency models. The energy savings were so significant that they were able to postpone building a new power plant. That’s the power of efficiency!

As transformer companies continue to push the boundaries of efficiency, we’re moving closer to a future where energy waste is minimized. It’s not just good for the environment; it’s good for our wallets too.

Earth-Friendly Transformers: Are These Big Machines Going Green?

When you think of "green" technology, power transformers probably aren’t the first things that come to mind. But you might be surprised to learn how these big machines are becoming more environmentally friendly.

Transformer manufacturers are adopting eco-friendly practices in their production processes and designing transformers with reduced environmental impact. This includes using biodegradable insulating fluids, recyclable materials, and designs that minimize the risk of soil and water contamination.

I remember a time when environmental concerns were an afterthought in the transformer industry. But things have changed dramatically. Let’s explore how these massive machines are going green.

The Green Transformation

Transformers are getting an eco-friendly makeover in several ways:

- Materials: Using more sustainable and recyclable components

- Insulation: Switching to biodegradable fluids

- Design: Creating leak-proof and low-noise models

- Lifecycle: Focusing on longevity and end-of-life recycling

Eco-Friendly Innovations

Here’s a closer look at some of the green innovations in transformer manufacturing:

| Innovation | Environmental Benefit | Additional Advantages |

|---|---|---|

| Vegetable-based Insulating Oil | Biodegradable, non-toxic | Higher flash point, safer operation |

| Dry-type Transformers | No oil leaks, reduced fire risk | Lower maintenance, suitable for indoor use |

| Recycled Core Steel | Reduces raw material consumption | Maintains high performance standards |

| Low-noise Designs | Reduces noise pollution | Improves quality of life in urban areas |

I once visited a transformer factory that had switched to using vegetable-based oils. The difference was remarkable – no more strong chemical smells, and the workers seemed much happier.

The Impact on the Environment

These green initiatives are having a real impact:

- Reduced Risk of Soil and Water Contamination: Biodegradable fluids and leak-proof designs minimize environmental damage in case of accidents.

- Lower Carbon Footprint: More efficient manufacturing processes and the use of recycled materials reduce overall emissions.

- Extended Lifespan: Eco-friendly designs often lead to longer-lasting transformers, reducing waste.

- Easier Recycling: The use of more recyclable materials makes end-of-life disposal less problematic.

I once worked on a project to replace old transformers in a nature reserve. We used the latest eco-friendly models, and it was gratifying to know that we were protecting the local ecosystem while still providing necessary power.

As transformer manufacturers continue to innovate, we’re seeing a shift towards truly sustainable practices. It’s not just about meeting regulations; it’s about taking responsibility for our impact on the planet.

Smart Power: How Are Transformers Getting Brainer in Our Modern Grids?