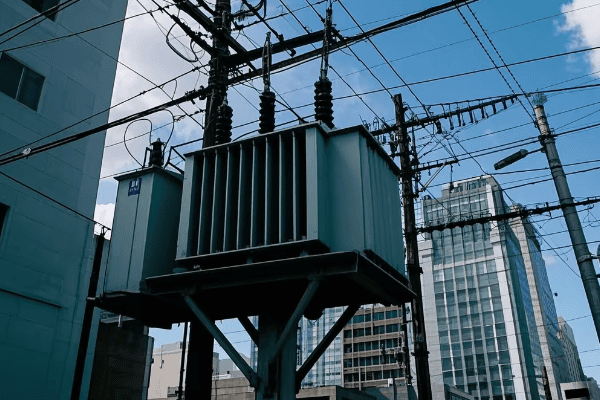

Have you ever wondered why some neighborhoods have big green boxes on the ground while others have transformers hanging on poles? The choice between these two can greatly impact urban living.

Pad mount transformers are generally more efficient for urban areas compared to pole mount transformers. They offer better space utilization, enhanced safety, improved aesthetics, and easier maintenance access. However, the choice depends on specific urban layout, cost considerations, and local regulations.

As someone who’s worked in urban power distribution for years, I’ve seen firsthand how the right transformer choice can make or break a city’s electrical infrastructure. Let’s dive into the details of pad mount and pole mount transformers to understand which one might be the best fit for your urban area.

What Are Pad Mount and Pole Mount Transformers? A Quick Overview

When I first started in this industry, I was confused by the variety of transformers out there. But understanding the basics is crucial for anyone involved in urban planning or electrical engineering.

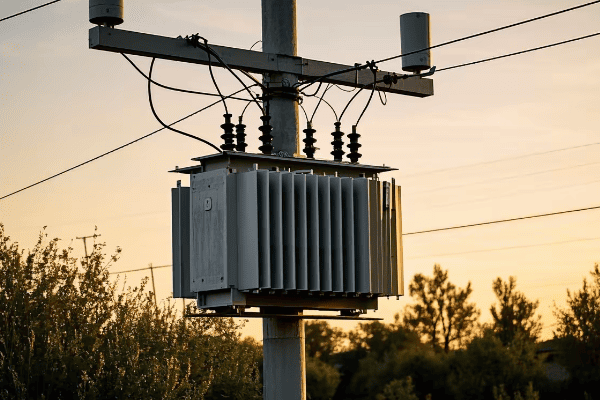

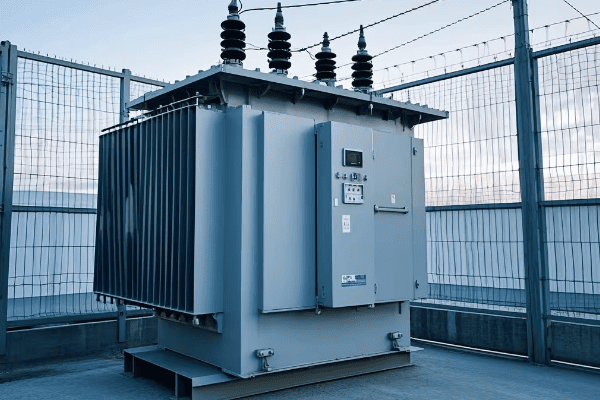

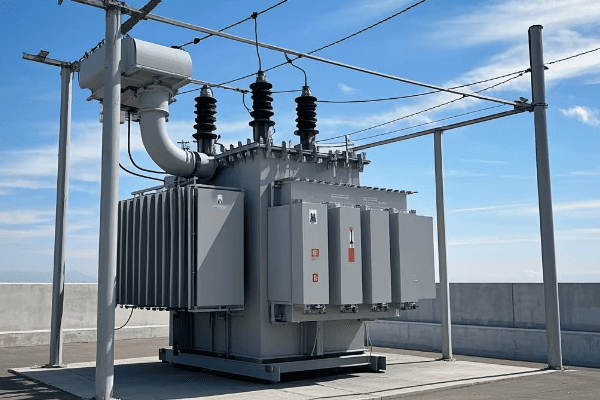

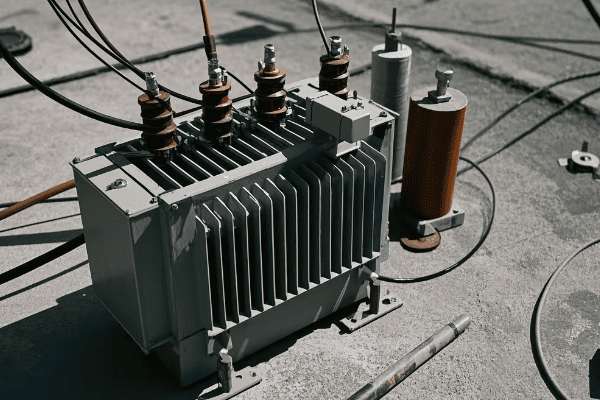

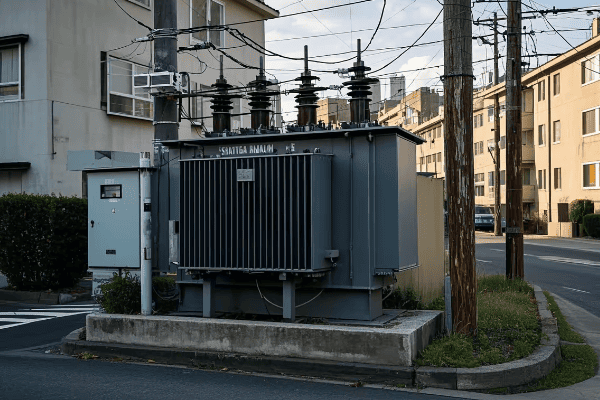

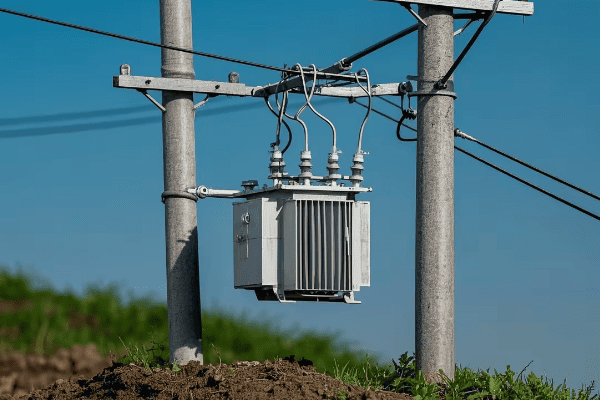

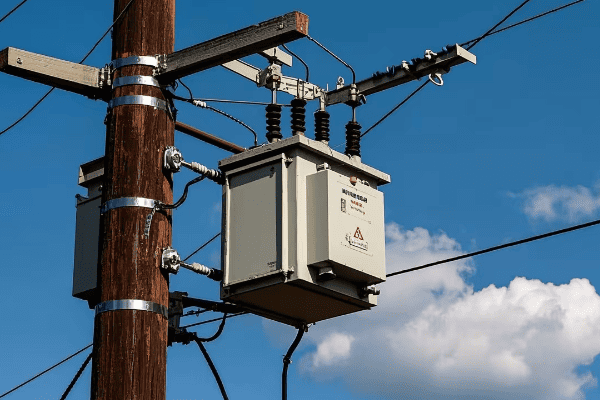

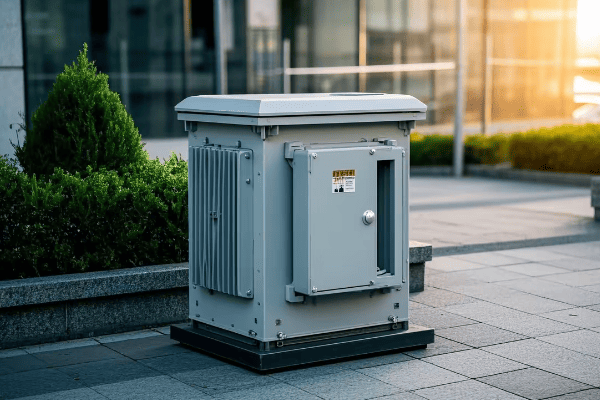

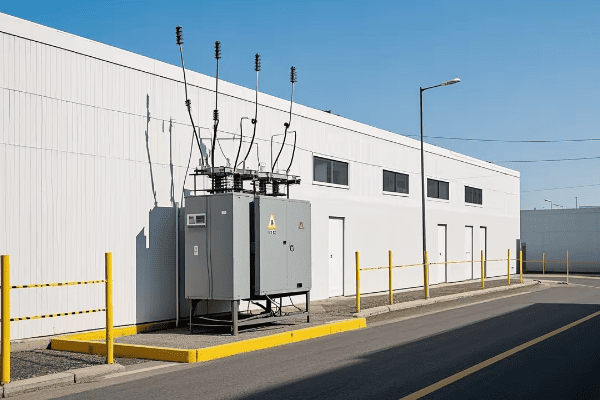

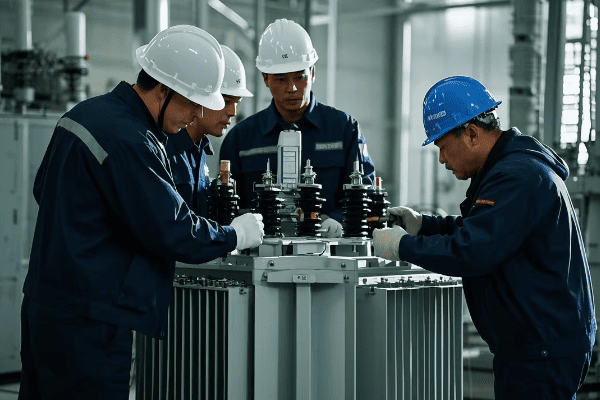

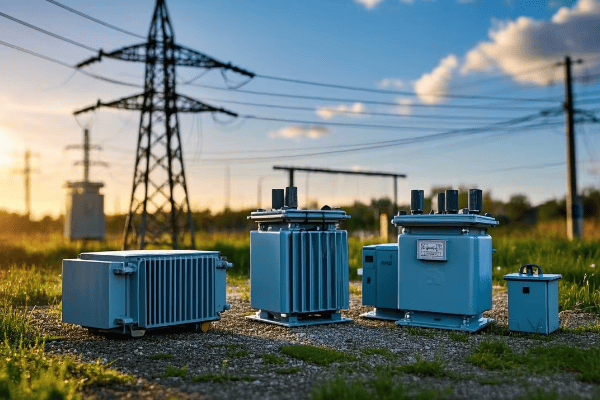

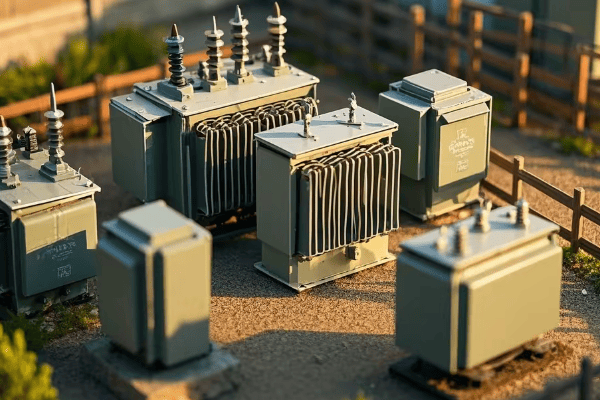

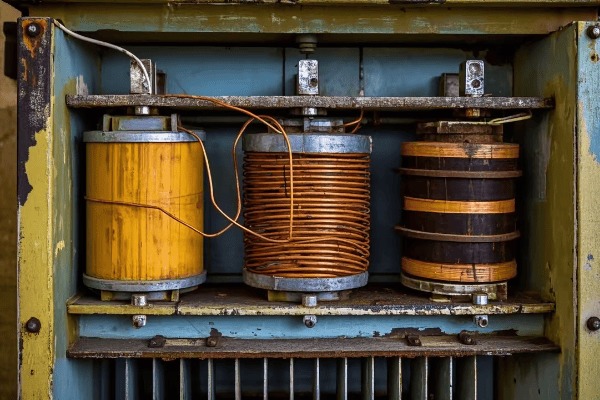

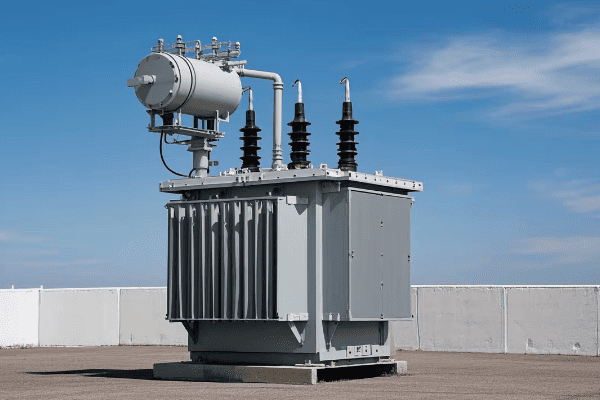

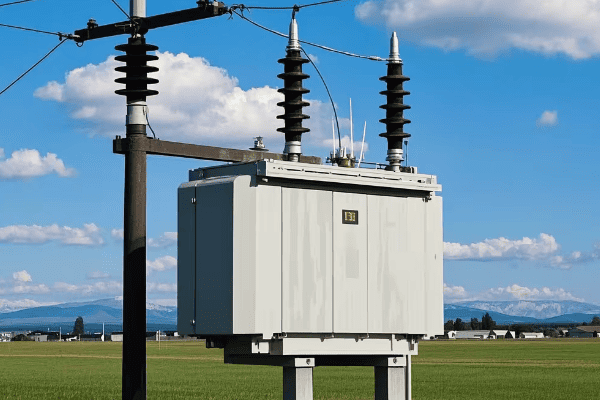

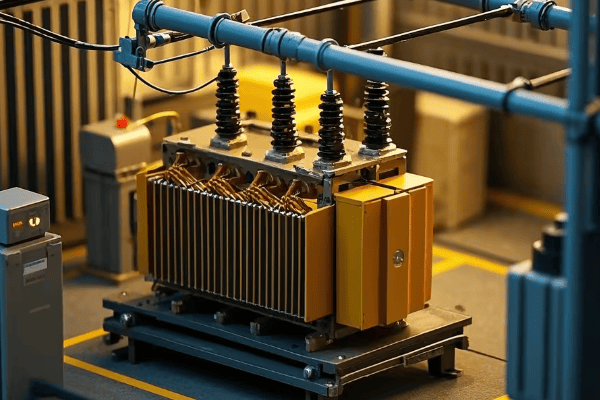

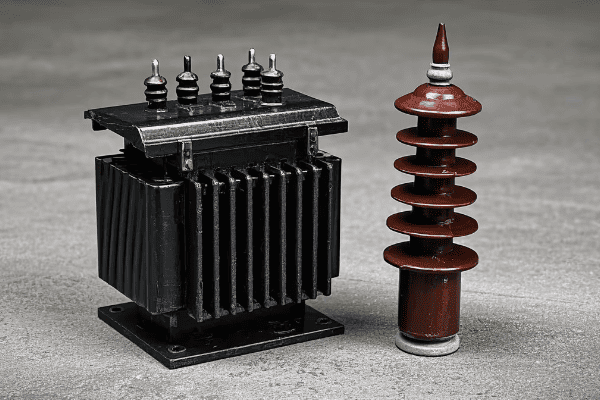

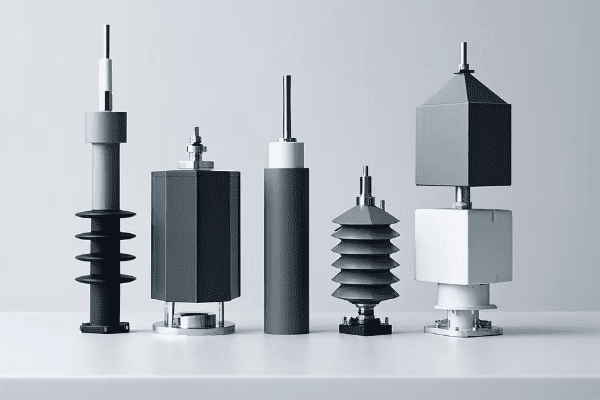

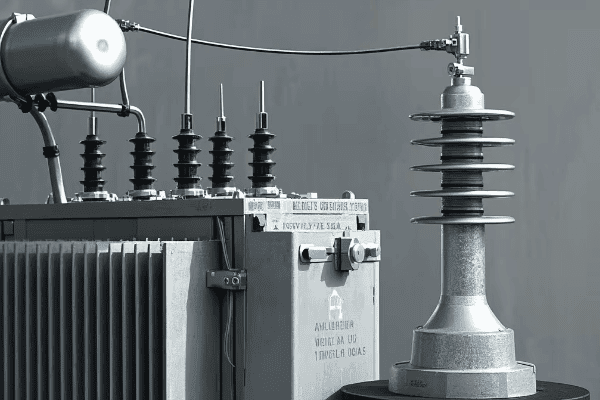

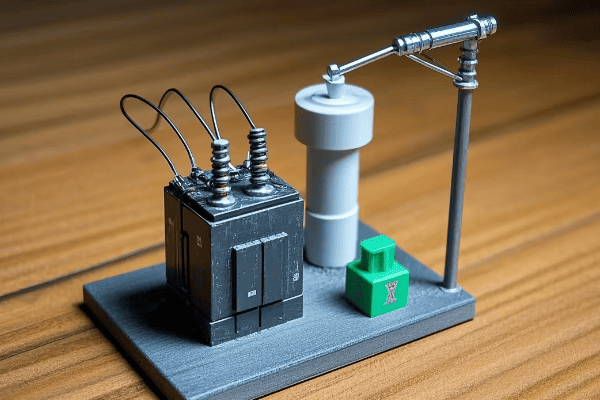

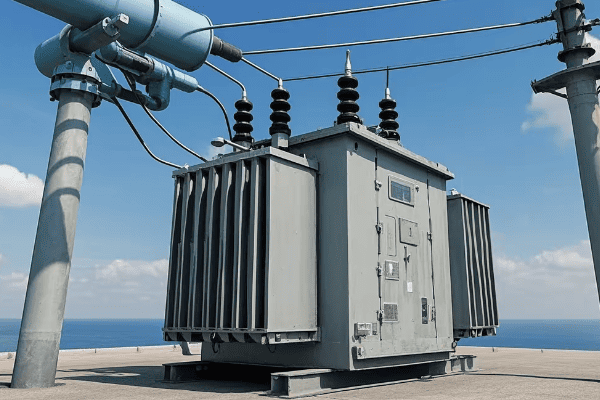

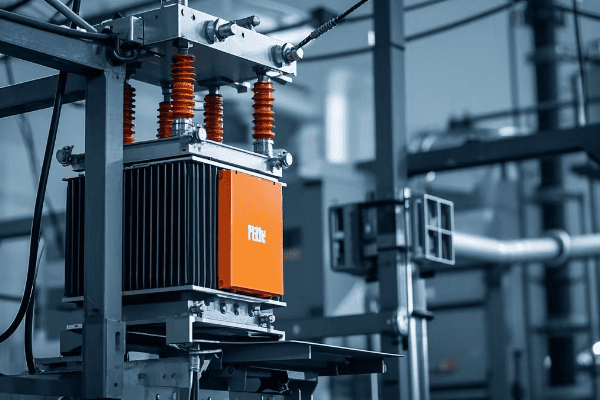

Pad mount transformers are ground-level units enclosed in metal cabinets, typically seen as green boxes in residential areas. Pole mount transformers are mounted on utility poles. Both types step down high voltage electricity to levels suitable for end-users, but their design and placement differ significantly.

Let’s break down the key characteristics of each:

Pad Mount Transformers

- Location: Ground level

- Enclosure: Metal cabinet, often green

- Size: Larger footprint, but lower profile

- Typical Use: Residential areas, commercial zones

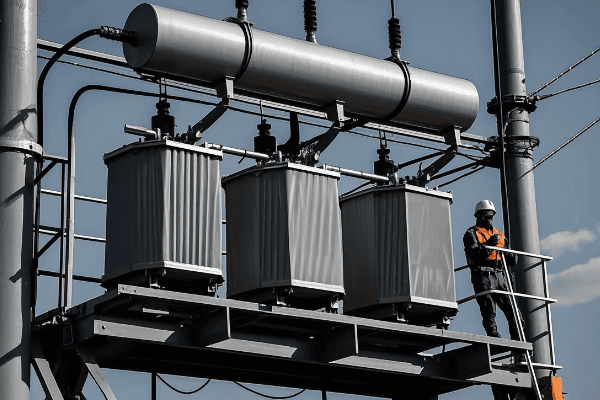

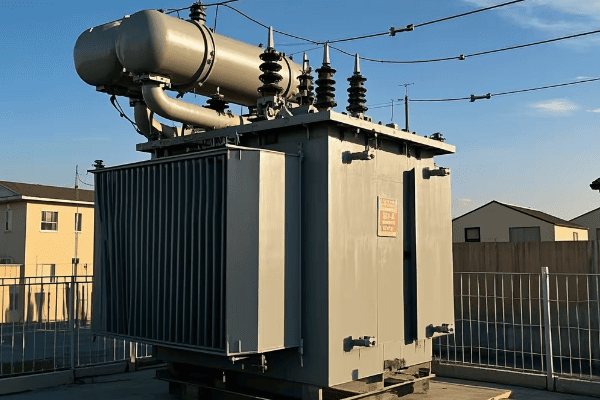

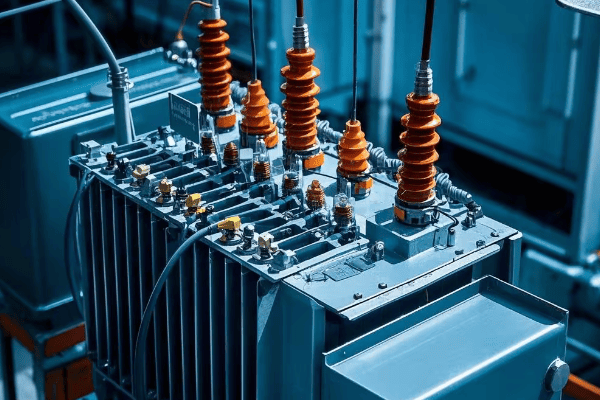

Pole Mount Transformers

- Location: Elevated on utility poles

- Enclosure: Open to air, with minimal covering

- Size: Smaller footprint, but more visible

- Typical Use: Rural areas, older urban neighborhoods

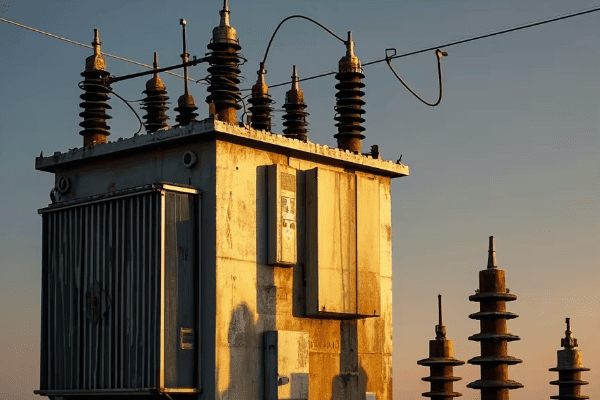

I remember a project where we were upgrading a suburban area’s electrical system. The neighborhood had a mix of old pole mount transformers and newer pad mount units. The contrast was striking – the areas with pad mounts had a cleaner, more modern look, while the pole mounts gave a more traditional, industrial feel.

Here’s a quick comparison table:

| Feature | Pad Mount | Pole Mount |

|---|---|---|

| Installation | Ground level | Elevated on poles |

| Aesthetics | Less visible | More visible |

| Space Required | More ground space | Less ground space |

| Accessibility | Easy ground access | Requires climbing |

| Safety | Enclosed, tamper-resistant | Open, potential climbing hazard |

| Typical Capacity | Higher | Lower |

The choice between pad mount and pole mount transformers often comes down to more than just technical specifications. In urban areas, factors like space availability, local regulations, and even community preferences play a big role.

Key Differences Between Pad Mount and Pole Mount Transformers

When I first started comparing these two types of transformers, I was amazed at how two devices with the same basic function could be so different in their design and application.

The key differences between pad mount and pole mount transformers lie in their installation, safety features, capacity, and visual impact. Pad mount transformers offer higher capacity and better safety features but require more ground space. Pole mount transformers are more visible but take up less ground space and are often cheaper to install.

Let’s dive deeper into these differences:

1. Installation and Space Requirements

Pad Mount:

- Requires a concrete pad at ground level

- Takes up more ground space

- Easier to install in areas with underground utilities

Pole Mount:

- Mounted on existing or new utility poles

- Minimal ground footprint

- Requires overhead power lines

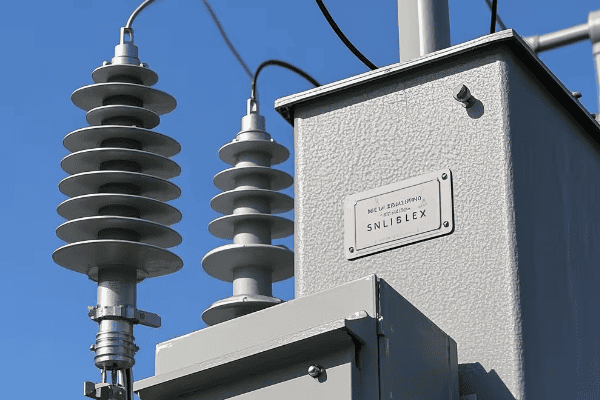

2. Safety Features

Pad Mount:

- Enclosed in tamper-resistant cabinets

- Less exposed to weather elements

- Reduced risk of public contact

Pole Mount:

- More exposed to elements

- Potential climbing hazard

- Higher risk of animal interference

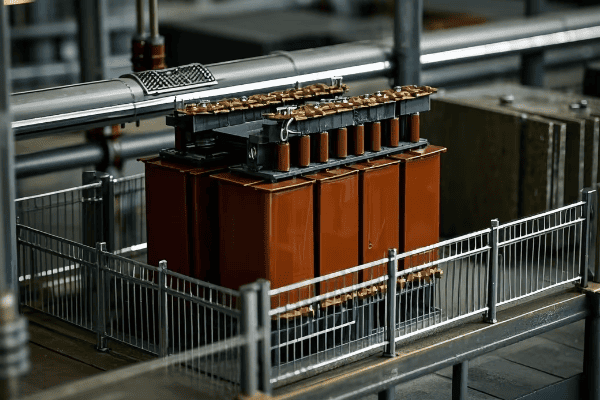

3. Capacity and Scalability

Pad Mount:

- Generally higher capacity (up to 5000 kVA)

- Easier to upgrade or replace

- Better suited for growing power demands

Pole Mount:

- Typically lower capacity (up to 167 kVA)

- More challenging to upgrade

- Limited by pole strength and space

Here’s a detailed comparison table:

| Feature | Pad Mount | Pole Mount |

|---|---|---|

| Installation Location | Ground level | Elevated on poles |

| Ground Space Required | More | Less |

| Visual Impact | Low | High |

| Typical Capacity Range | 75 kVA – 5000 kVA | 10 kVA – 167 kVA |

| Safety Enclosure | Fully enclosed | Partially open |

| Weather Protection | High | Moderate |

| Maintenance Accessibility | Easy | Challenging |

| Installation Cost | Higher | Lower |

| Scalability | Easier to upgrade | Limited by pole capacity |

| Typical Lifespan | 30-40 years | 20-30 years |

I recall a project in a rapidly growing suburban area where we initially installed pole mount transformers due to budget constraints. However, as the power demand increased, we found ourselves constantly upgrading and replacing these units. Eventually, we switched to pad mount transformers, which, despite the higher initial cost, proved more cost-effective in the long run due to their higher capacity and easier upgradability.

Space Efficiency: How Pad Mount Transformers Optimize Urban Land Use

In my years of working on urban power projects, I’ve seen how valuable every square foot of land can be. This is where pad mount transformers really shine in optimizing urban land use.

Pad mount transformers optimize urban land use by having a lower profile and integrating seamlessly with landscaping. While they require more ground space than pole mounts, their compact design allows for creative placement options. This efficiency is crucial in dense urban areas where space is at a premium.

Let’s explore how pad mount transformers contribute to space efficiency in urban settings:

1. Compact Design and Integration

Pad mount transformers are designed to blend into their surroundings:

- Low profile allows for easy concealment with shrubs or fencing

- Can be incorporated into urban design elements like planters or seating areas

- Eliminates the need for overhead lines, freeing up vertical space

2. Underground Utility Compatibility

Pad mounts work well with underground utility systems:

- Aligns with modern urban planning trends of burying power lines

- Reduces clutter in the urban skyline

- Allows for more efficient use of above-ground space

3. Flexible Placement Options

The ground-level installation offers various placement possibilities:

- Can be installed in alleys, along property lines, or in dedicated utility areas

- Multiple units can be grouped together in larger developments

- Easier to plan around in new construction projects

Here’s a comparison of space utilization:

| Aspect | Pad Mount | Pole Mount |

|---|---|---|

| Ground Footprint | Larger (typically 4-6 sq ft) | Smaller (pole base only) |

| Vertical Space Used | Minimal (3-5 ft high) | Significant (20-40 ft high) |

| Clearance Requirements | Minimal surrounding space | Large clearance around pole |

| Integration with Landscaping | Easy | Challenging |

| Impact on Usable Land | Can be incorporated into unusable spaces | Pole placement can disrupt land use |

One project that stands out in my memory involved a high-density residential development. We used pad mount transformers placed strategically around the complex. By integrating them into small garden areas, we not only provided the necessary power but also created pleasant green spaces for residents. This dual-use approach was a hit with both the developers and the city planners.

Safety Considerations: Comparing Pad Mount vs. Pole Mount in Urban Settings

Safety is always my top priority when working on any electrical project, especially in busy urban areas. The choice between pad mount and pole mount transformers can significantly impact public safety.

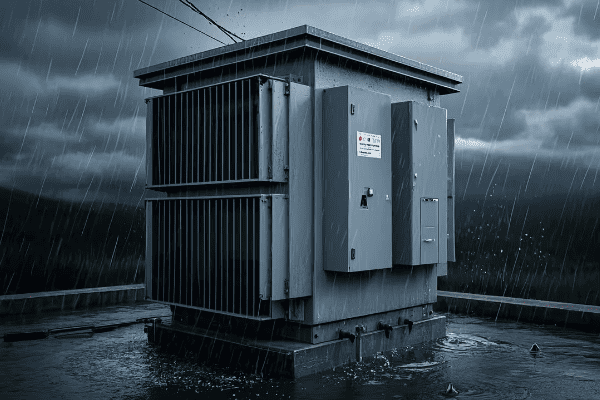

Pad mount transformers generally offer better safety features in urban settings compared to pole mount transformers. They have tamper-resistant enclosures, are less exposed to weather and accidents, and reduce the risk of electrical hazards. However, pole mount transformers have their own safety advantages, particularly in flood-prone areas.

Let’s dive into the safety aspects of both types:

Pad Mount Transformer Safety Features

-

Tamper-Resistant Enclosures

- Locked metal cabinets prevent unauthorized access

- Reduces risk of vandalism and accidental contact

-

Ground-Level Installation

- Eliminates climbing hazards associated with pole mounts

- Easier to secure and monitor

-

Weather Protection

- Enclosed design protects against rain, snow, and debris

- Less susceptible to damage from storms

Pole Mount Transformer Safety Aspects

-

Elevation Advantages

- Less vulnerable to flooding

- Reduced risk of vehicle collisions

-

Visibility

- Easier to spot issues from a distance

- Can be quickly identified in emergency situations

-

Isolation

- Physical distance from public areas

- Less likely to be tampered with by pedestrians

Here’s a safety comparison table:

| Safety Aspect | Pad Mount | Pole Mount |

|---|---|---|

| Public Access | Limited by enclosure | Limited by height |

| Weather Exposure | Low | High |

| Flood Risk | Higher | Lower |

| Vandalism Risk | Low (if properly secured) | Low (due to height) |

| Vehicle Collision Risk | Present but can be mitigated | Low |

| Electrical Shock Risk | Low (enclosed) | Higher (more exposed) |

| Fire Containment | Better | Limited |

| Emergency Access | Easy | Requires climbing equipment |

In my years of experience, I’ve encountered various safety scenarios. For instance, in a flood-prone area, we opted for pole mounts to keep the equipment above potential water levels. This decision proved wise during a severe flood season.

Aesthetic Impact: Which Transformer Type Blends Better with Urban Landscapes?

In my years of working on urban electrical projects, I’ve learned that the visual impact of infrastructure can be just as important as its technical function. The choice between pad mount and pole mount transformers can significantly affect the look and feel of an urban area.

Pad mount transformers generally blend better with urban landscapes compared to pole mount transformers. Their low profile and ability to be concealed or integrated into urban design elements make them less visually intrusive. Pole mount transformers, while more visible, can sometimes complement the aesthetic of certain urban areas, particularly in historic districts.

Let’s explore the aesthetic considerations for both types:

Pad Mount Transformers

-

Low Visual Profile

- Can be easily hidden behind landscaping

- Often painted to blend with surroundings

-

Integration with Urban Design

- Can be incorporated into street furniture or public art

- Allows for creative urban planning solutions

-

Reduction of Overhead Clutter

- Eliminates need for visible overhead lines

- Creates cleaner skylines in urban areas

Pole Mount Transformers

-

Traditional Urban Look

- Can contribute to a nostalgic or historic feel in some areas

- Part of the familiar urban infrastructure

-

Vertical Space Utilization

- Keeps ground space clear for other uses

- Can be combined with street lighting or signage

-

Visibility for Maintenance

- Easier to spot and access for repairs

- Can serve as landmarks for utility workers

Here’s an aesthetic comparison table:

| Aesthetic Aspect | Pad Mount | Pole Mount |

|---|---|---|

| Visual Impact | Low | High |

| Ability to Conceal | High | Low |

| Integration with Landscaping | Easy | Challenging |

| Skyline Impact | Minimal | Significant |

| Flexibility in Design | High | Limited |

| Historical Compatibility | Varies | Often preferred in historic areas |

I once worked on a project in a newly developed urban area where we used pad mount transformers designed to look like modern art installations. The local community loved how these functional pieces also served as interesting visual elements in their neighborhood parks.

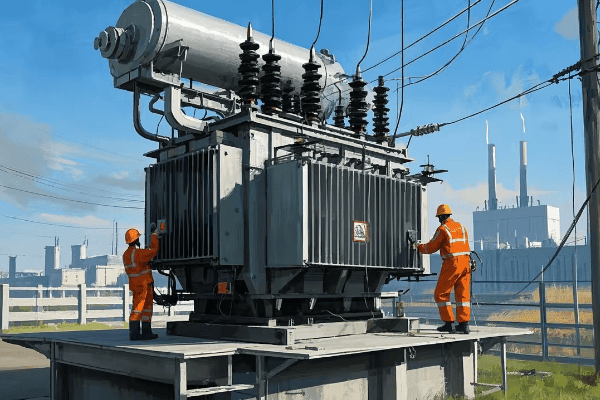

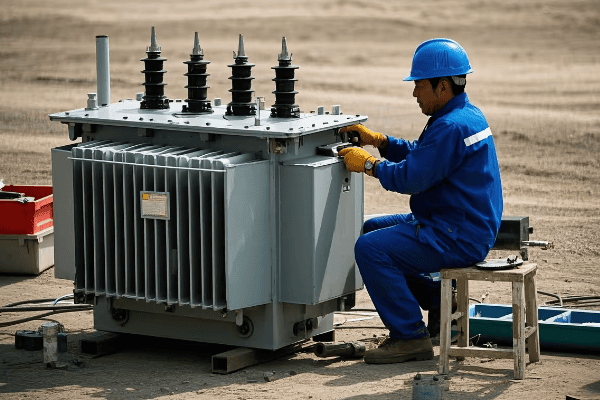

Maintenance and Accessibility: Pad Mount vs. Pole Mount in City Environments

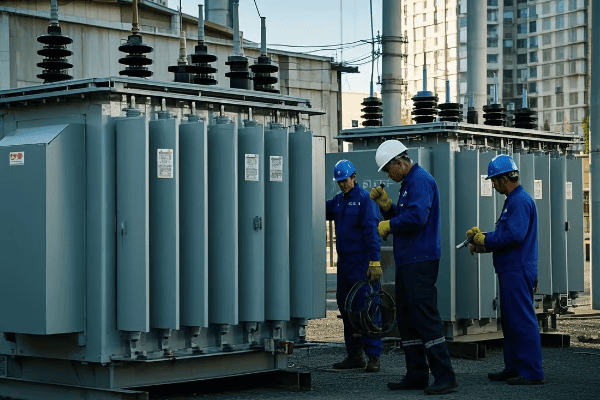

Maintaining electrical infrastructure in busy urban areas can be challenging. The choice between pad mount and pole mount transformers can significantly impact how easily and safely maintenance can be performed.

Pad mount transformers generally offer easier maintenance access in city environments compared to pole mount transformers. They can be serviced from ground level, reducing the need for specialized equipment. However, pole mount transformers have the advantage of being less susceptible to flooding and ground-level obstructions.

Let’s compare the maintenance aspects of both types:

Pad Mount Transformer Maintenance

-

Ground-Level Access

- No need for bucket trucks or climbing equipment

- Safer for maintenance workers

-

Enclosed Environment

- Components are protected from weather and debris

- Reduced frequency of cleaning and minor repairs

-

Space for Diagnostics

- Easier to set up diagnostic equipment

- More room to work on components

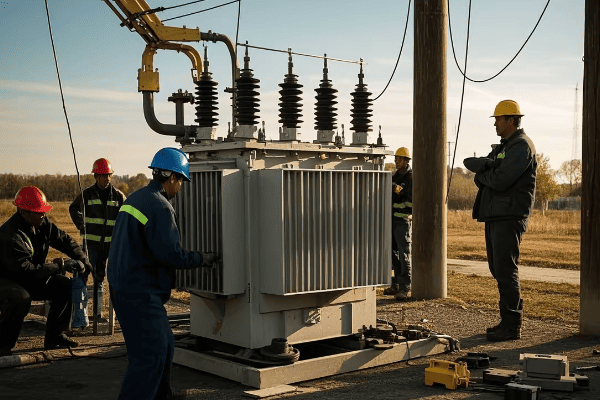

Pole Mount Transformer Maintenance

-

Elevated Position

- Requires specialized equipment for access

- Can be challenging in adverse weather conditions

-

Visibility

- Issues can often be spotted from ground level

- Easier to perform visual inspections

-

Less Susceptible to Ground-Level Issues

- Not affected by flooding or ground-level obstructions

- Less likely to be damaged by vehicles

Here’s a maintenance comparison table:

| Maintenance Aspect | Pad Mount | Pole Mount |

|---|---|---|

| Access Method | Ground level | Requires climbing or lift |

| Equipment Needed | Minimal | Bucket truck, safety harnesses |

| Weather Impact on Maintenance | Low | High |

| Ease of Component Replacement | Easier | More challenging |

| Frequency of Routine Checks | Can be higher | Generally lower |

| Space for Work Area | Ample | Limited |

| Risk to Maintenance Workers | Lower | Higher |

I recall a maintenance project in a dense urban area where we had to service both types of transformers. The pad mount units were much quicker and safer to maintain, allowing us to complete the work with minimal disruption to the busy city streets. However, during a flood event, the pole mount transformers proved more resilient and required less emergency maintenance.

Cost Analysis: Installation and Long-term Expenses of Urban Transformer Options

When it comes to choosing between pad mount and pole mount transformers for urban areas, cost is often a major factor. But it’s not just about the initial price tag – long-term expenses play a crucial role too.

Initially, pole mount transformers are often cheaper to install than pad mount transformers. However, pad mount transformers typically have lower long-term costs due to easier maintenance, longer lifespan, and better protection from environmental factors. The total cost of ownership over time often favors pad mount transformers in urban settings.

Let’s break down the cost factors for both types:

Initial Costs

-

Pad Mount Transformers

- Higher equipment cost

- Requires concrete pad and enclosure

- Often involves underground wiring installation

-

Pole Mount Transformers

- Lower equipment cost

- Uses existing or new utility poles

- Typically involves overhead wiring

Long-term Costs

-

Pad Mount Transformers

- Lower maintenance costs due to easier access

- Better protection from elements, potentially longer lifespan

- May increase property values due to improved aesthetics

-

Pole Mount Transformers

- Higher maintenance costs due to need for specialized equipment

- More exposed to weather, potentially shorter lifespan

- May require more frequent replacements or repairs

Here’s a cost comparison table:

| Cost Factor | Pad Mount | Pole Mount |

|---|---|---|

| Initial Equipment Cost | Higher | Lower |

| Installation Cost | Higher | Lower |

| Maintenance Cost (Annual) | Lower | Higher |

| Expected Lifespan | 30-40 years | 20-30 years |

| Replacement Frequency | Less frequent | More frequent |

| Property Value Impact | Potentially positive | Neutral to negative |

I remember a project where we initially chose pole mount transformers for a new urban development due to lower upfront costs. However, after five years, the maintenance and replacement costs had already surpassed what we would have spent on pad mount transformers. We ended up retrofitting the entire area with pad mounts, which proved more cost-effective in the long run.

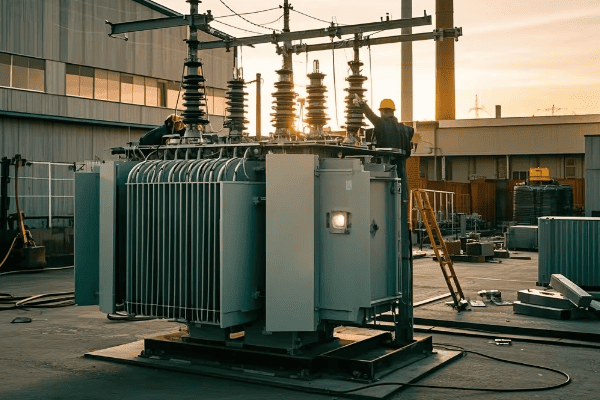

Environmental Factors: Weather Resistance of Pad Mount vs. Pole Mount Transformers

When it comes to urban power distribution, weather resistance is a crucial factor. I’ve seen firsthand how different transformer types handle various environmental challenges.

Pad mount transformers generally offer better weather resistance compared to pole mount transformers. Their enclosed design provides superior protection against rain, snow, and debris. However, pole mount transformers have an advantage in flood-prone areas due to their elevated position.

Let’s compare how these transformer types stand up to different weather conditions:

Pad Mount Transformers

-

Rain and Snow Protection

- Sealed enclosures prevent water ingress

- Less risk of internal component corrosion

-

Wind Resistance

- Lower profile reduces wind impact

- Less susceptible to damage from flying debris

-

Temperature Fluctuations

- Insulated cabinets help maintain stable internal temperatures

- Better performance in extreme heat or cold

Pole Mount Transformers

-

Flood Resistance

- Elevated position keeps components above flood waters

- Less susceptible to water damage during heavy rains

-

Lightning Protection

- Often equipped with lightning arresters

- Height can provide some natural protection

-

Ice and Snow Accumulation

- Less surface area for ice buildup

- Snow tends to slide off more easily

Here’s a weather resistance comparison table:

| Weather Condition | Pad Mount | Pole Mount |

|---|---|---|

| Rain Protection | Excellent | Good |

| Snow Accumulation | Low Impact | Moderate Impact |

| Flood Resistance | Poor | Excellent |

| Wind Resistance | Excellent | Good |

| Heat Dissipation | Good (with proper ventilation) | Excellent (natural air flow) |

| Cold Weather Performance | Good (insulated) | Fair (exposed) |

| Lightning Protection | Good (with proper grounding) | Very Good (with arresters) |

I recall a project in a coastal city prone to hurricanes. We initially installed pole mount transformers, thinking they’d be better in high winds. However, after a particularly severe storm, we found that the pad mount transformers in a neighboring district fared much better. The enclosed design protected them from wind-driven debris and salt spray, resulting in fewer outages and less damage.

Power Distribution Efficiency: Which Transformer Type Performs Better in Cities?

Efficiency in power distribution is a top priority in urban areas. As someone who’s worked on numerous city projects, I’ve seen how the choice of transformer can significantly impact overall system performance.

In urban settings, pad mount transformers often provide better power distribution efficiency compared to pole mount transformers. Their design allows for better cooling, reduced line losses, and easier integration with smart grid technologies. However, the efficiency difference can vary based on specific urban layouts and power demands.

Let’s break down the efficiency factors for both types:

Pad Mount Transformers

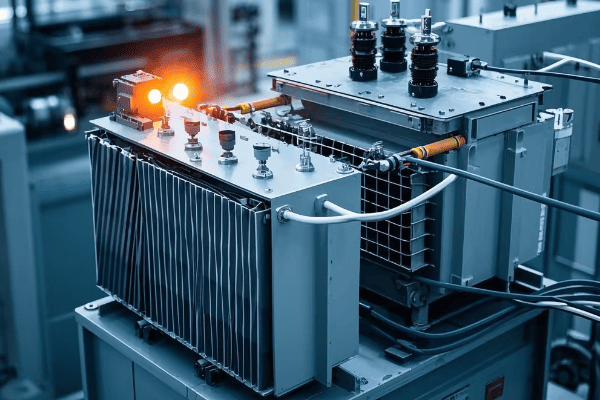

-

Cooling Efficiency

- Better heat dissipation due to larger surface area

- Often equipped with advanced cooling systems

-

Line Loss Reduction

- Shorter distance between transformer and end-user in many urban layouts

- Can be placed closer to load centers

-

Smart Grid Integration

- Easier to incorporate monitoring and control equipment

- Better suited for advanced distribution automation

Pole Mount Transformers

-

Overhead Distribution

- Can be more efficient in areas with widely spaced buildings

- Less affected by ground-level obstacles

-

Voltage Regulation

- Easier to adjust tap settings for voltage regulation

- Can be beneficial in areas with fluctuating loads

-

Heat Dissipation

- Natural air cooling can be effective in open areas

- Less affected by ground-level heat sources

Here’s an efficiency comparison table:

| Efficiency Factor | Pad Mount | Pole Mount |

|---|---|---|

| Cooling Effectiveness | High | Moderate |

| Line Losses | Lower in dense areas | Lower in spread-out areas |

| Smart Grid Compatibility | Excellent | Good |

| Voltage Regulation | Good | Very Good |

| Load Management | Excellent | Good |

| Space Efficiency | High | Moderate |

| Energy Savings Potential | Higher | Moderate |

I once worked on a project to upgrade a downtown area’s power distribution. We replaced old pole mount transformers with new pad mount units. The result was a 15% reduction in distribution losses and a significant improvement in power quality. The ability to place pad mount transformers closer to high-demand areas like office buildings and shopping centers made a noticeable difference.

Regulatory Compliance: Urban Codes and Their Impact on Transformer Choice

Navigating urban regulations can be a complex task when it comes to transformer installations. I’ve had to deal with various city codes and their impact on our transformer choices.

Urban codes often favor pad mount transformers due to their lower visual impact and better safety features. Many cities have regulations promoting underground utilities, which align well with pad mount designs. However, some historic districts may require pole mount transformers to maintain traditional aesthetics.

Let’s explore how urban regulations affect transformer choices:

Pad Mount Transformers and Regulations

-

Visual Impact Regulations

- Often preferred in areas with strict aesthetic codes

- Easier to comply with beautification ordinances

-

Safety Codes

- Enclosed design meets many urban safety requirements

- Reduced risk of public contact aligns with liability concerns

-

Noise Ordinances

- Generally quieter operation fits well with residential area regulations

Pole Mount Transformers and Regulations

-

Historic District Requirements

- May be mandated in areas preserving traditional looks

- Often grandfathered in older neighborhoods

-

Easement Regulations

- Can be easier to comply with in areas with established utility easements

- Less impact on property lines in some cases

-

Emergency Access Codes

- Elevated position can meet requirements for flood-prone areas

- May be preferred in areas with strict ground-level clearance rules

Here’s a regulatory compliance comparison table:

| Regulatory Aspect | Pad Mount | Pole Mount |

|---|---|---|

| Visual Impact Compliance | High | Low to Moderate |

| Safety Code Adherence | Excellent | Good |

| Noise Regulation Compliance | Excellent | Good |

| Historic District Suitability | Varies | Often Preferred |

| Easement Requirement Impact | Moderate | Low |

| Underground Utility Compliance | Excellent | Poor |

| ADA Compliance | Good | Excellent |

I remember a project in a rapidly developing urban area where we had to navigate a complex set of new smart city regulations. The city favored pad mount transformers because they could easily incorporate smart monitoring systems and fit with the underground utility mandate. However, we had to use pole mounts in one historic district to comply with preservation codes. It was a balancing act between modern efficiency and historical preservation.

Conclusion

In urban areas, the choice between pad mount and pole mount transformers depends on various factors including space efficiency, safety, aesthetics, maintenance, cost, environmental resistance, power distribution efficiency, and regulatory compliance. While pad mount transformers often offer advantages in dense urban settings, pole mount transformers still have their place in certain scenarios. The best choice ultimately depends on specific urban needs and constraints.

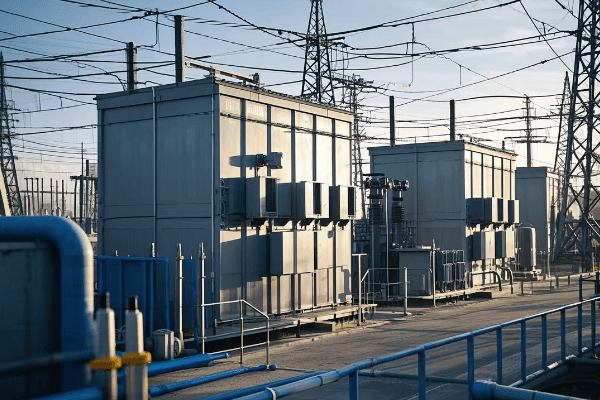

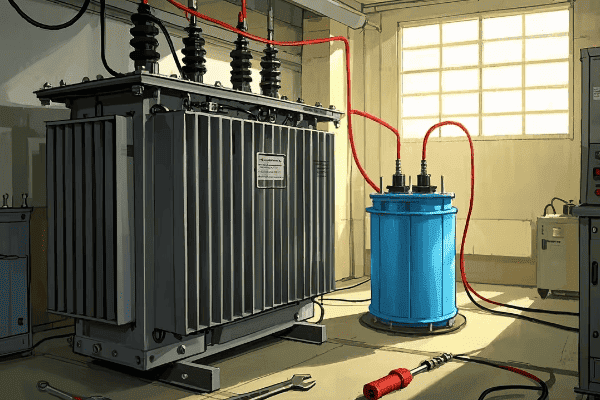

Have you ever wondered how cities manage to power skyscrapers and dense urban areas without massive electrical substations taking up valuable real estate? The answer lies in a revolutionary technology called Gas Insulated Substations (GIS).

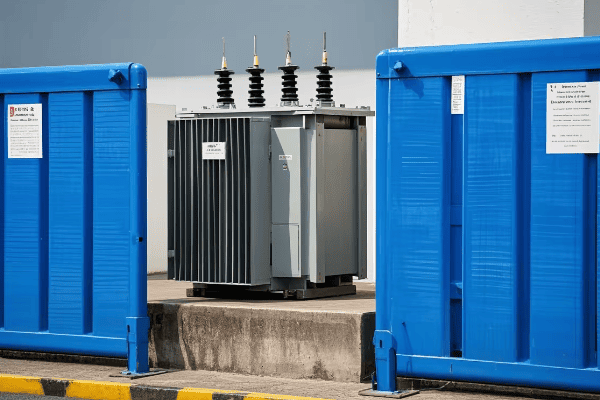

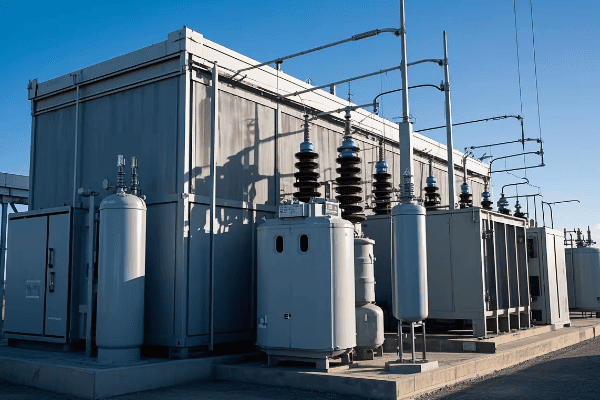

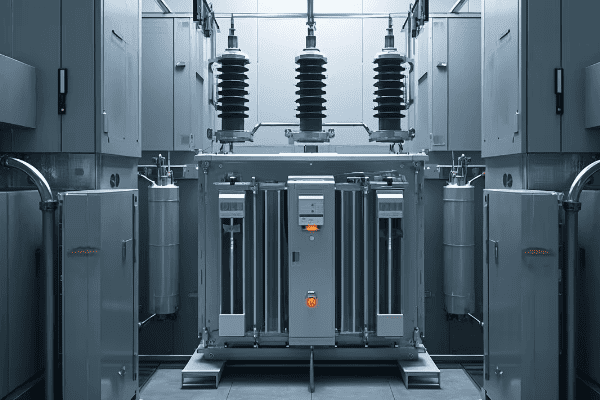

A Gas Insulated Substation (GIS) is a compact power substation that uses sulfur hexafluoride (SF6) gas as an insulating medium. It revolutionizes power distribution by dramatically reducing the substation’s size, increasing reliability, and allowing installations in space-constrained urban areas or harsh environments.

As someone who’s worked in the power industry for years, I’ve seen firsthand how GIS technology has transformed urban power distribution. Let’s dive into the details of this innovative technology and explore why it’s becoming the go-to solution for modern power systems.

How Does a Gas Insulated Substation Work? Understanding the Basics

Imagine shrinking a football field-sized substation down to the size of a small house. That’s essentially what GIS technology does, and it’s all thanks to the unique properties of SF6 gas.

A Gas Insulated Substation works by enclosing high-voltage conductors and circuit breakers in sealed metal containers filled with SF6 gas. This gas has superior insulating properties compared to air, allowing components to be placed much closer together, resulting in a compact and efficient substation design.

Let’s break down the key aspects of how a GIS operates:

The Role of SF6 Gas

SF6 gas is the hero of GIS technology. Here’s why:

- Superior Insulation: SF6 has an insulation strength 2.5 to 3 times higher than air.

- Arc Quenching: It’s excellent at extinguishing electrical arcs, enhancing safety.

- Chemical Stability: SF6 doesn’t react with other materials in the substation.

- Heat Dissipation: It efficiently conducts heat away from conductors.

Sealed Environment

The sealed metal enclosures in a GIS offer several benefits:

- Protection from Environment: Dust, moisture, and pollutants can’t affect the equipment.

- Reduced Maintenance: The clean, controlled environment means less wear and tear.

- Enhanced Safety: The risk of external interference or accidents is minimized.

Compact Design

The compact nature of GIS is its most revolutionary aspect:

- Space Saving: A GIS can be up to 90% smaller than an equivalent Air Insulated Substation (AIS).

- Flexible Installation: GIS can be installed indoors, underground, or in tight urban spaces.

- Modular Construction: Easy to expand or reconfigure as needs change.

Here’s a comparison table to illustrate the space-saving aspect:

| Voltage Level | AIS Footprint | GIS Footprint | Space Saving |

|---|---|---|---|

| 110 kV | 3000 m² | 300 m² | 90% |

| 220 kV | 8000 m² | 600 m² | 92.5% |

| 400 kV | 15000 m² | 1000 m² | 93.3% |

I remember a project where we needed to upgrade a substation in a densely populated urban area. The local authorities were concerned about the impact on the neighborhood. By choosing GIS technology, we were able to fit the entire substation in a building the size of a small warehouse. The compact design not only satisfied the authorities but also impressed the local community with its minimal visual impact.

When explaining GIS to newcomers in the industry, I often use the analogy of comparing it to the evolution of computers. Just as we’ve gone from room-sized mainframes to powerful smartphones, GIS has allowed us to shrink substations without compromising on power or functionality.

Understanding the basics of GIS operation is crucial for anyone involved in modern power distribution. As urban areas continue to grow and energy demands increase, the ability to install powerful substations in compact spaces will become even more valuable.

What Are the Key Components of a Gas Insulated Substation?

When I first encountered a Gas Insulated Substation, I was amazed by its compact design. But what’s inside this marvel of electrical engineering? Let’s unpack the key components that make GIS technology so effective.

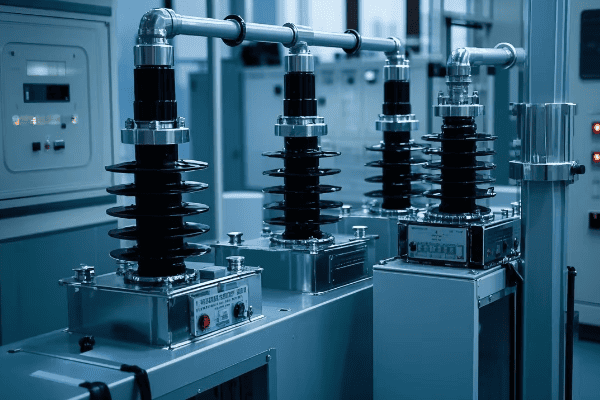

A Gas Insulated Substation consists of several key components, all enclosed in SF6-filled compartments. These include circuit breakers, disconnectors, earthing switches, current and voltage transformers, and busbars. Each component is designed to operate efficiently in the SF6 environment, contributing to the overall compact and reliable nature of the GIS.

Let’s dive deeper into each of these components:

1. Circuit Breakers

Circuit breakers are the first line of defense in a GIS. They’re designed to:

- Interrupt fault currents quickly

- Operate in the SF6 environment for enhanced arc quenching

- Require minimal maintenance due to the clean, sealed environment

2. Disconnectors and Earthing Switches

These components provide isolation and grounding:

- Disconnectors isolate sections of the substation for maintenance

- Earthing switches ensure safety during maintenance operations

- Both are designed for reliable operation in the SF6 gas

3. Current and Voltage Transformers

These are crucial for measurement and protection:

- Current transformers measure electrical current

- Voltage transformers measure voltage levels

- Both are compact and designed specifically for GIS environments

4. Busbars

Busbars are the highways of electrical distribution in a GIS:

- They connect different sections of the substation

- SF6 insulation allows for compact busbar design

- They’re typically made of aluminum or copper

5. SF6 Gas System

This system is unique to GIS and includes:

- Gas monitoring equipment

- Pressure relief devices

- Gas handling and recycling systems

Here’s a table summarizing the key components and their functions:

| Component | Function | Unique GIS Feature |

|---|---|---|

| Circuit Breakers | Interrupt fault currents | Enhanced arc quenching in SF6 |

| Disconnectors | Isolate sections | Compact design in SF6 |

| Earthing Switches | Provide grounding | Safe operation in sealed environment |

| Current/Voltage Transformers | Measurement and protection | Designed for GIS environment |

| Busbars | Connect substation sections | Compact due to SF6 insulation |

| SF6 Gas System | Maintain insulation medium | Crucial for GIS operation |

I remember a project where we were upgrading an old air-insulated substation to a GIS. The client was skeptical about fitting all these components into such a small space. We arranged a visit to a GIS manufacturer, and seeing the compact, modular design of each component in person was a game-changer. The client was amazed at how each element was engineered to work seamlessly in the SF6 environment.

One aspect that often surprises people new to GIS technology is the modularity of these components. Unlike traditional substations where components are spread out, GIS components are designed to be interconnected modules. This not only saves space but also allows for easier installation and future upgrades.

When working with GIS, it’s crucial to understand how these components interact:

- The circuit breakers and disconnectors work together to provide both protection and isolation.

- The current and voltage transformers feed critical data to the protection and control systems.

- The SF6 gas system continuously monitors and maintains the insulating medium, ensuring the reliability of all other components.

This integrated design is what makes GIS so powerful. Each component is not just miniaturized but optimized for operation in the SF6 environment. The result is a substation that’s not only compact but also more reliable and efficient than its air-insulated counterpart.

Understanding these components is essential for anyone working with or specifying GIS technology. It’s not just about space-saving; it’s about creating a more efficient, reliable, and flexible power distribution system.

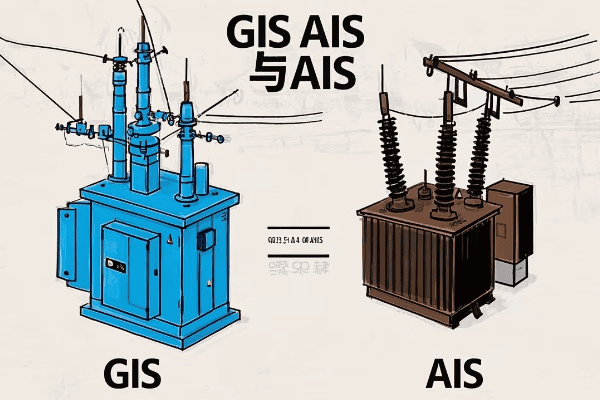

GIS vs AIS: What’s the Difference and Which One Should You Choose?

As someone who’s worked with both Gas Insulated Substations (GIS) and Air Insulated Substations (AIS), I’m often asked about their differences. It’s like comparing a smartphone to a landline – both make calls, but one offers significantly more in a smaller package.

The main difference between GIS and AIS lies in their insulating medium and size. GIS uses SF6 gas and is compact, while AIS uses air and requires more space. GIS is ideal for urban areas or where space is limited, while AIS is often more cost-effective for rural or spacious locations. The choice depends on factors like available space, environmental conditions, and budget.

Let’s dive deeper into the key differences and factors to consider when choosing between GIS and AIS:

Size and Space Requirements

-

GIS

- Typically 10-15% the size of an equivalent AIS

- Can be installed indoors, underground, or in tight spaces

- Ideal for urban areas or where land is expensive

-

AIS

- Requires large open areas

- Typically outdoor installations

- Suitable for rural areas or where land is readily available

Environmental Protection

-

GIS

- Enclosed design protects against environmental factors

- Can operate in harsh conditions (pollution, salt spray, etc.)

- Less affected by weather

-

AIS

- Exposed to environmental elements

- May require additional protection in harsh environments

- Performance can be affected by weather conditions

Maintenance Requirements

-

GIS

- Lower maintenance due to sealed environment

- Less frequent inspections needed

- Specialized skills required for SF6 handling

-

AIS

- Regular cleaning and inspection required

- More susceptible to environmental wear and tear

- Maintenance is generally simpler and doesn’t require specialized gas handling skills

Initial Cost vs. Long-term Cost

-

GIS

- Higher initial investment

- Lower long-term maintenance costs

- Potential savings in land costs in urban areas

-

AIS

- Lower initial cost

- Higher long-term maintenance costs

- May require significant land investment in urban areas

Here’s a comparison table to help visualize the differences:

| Factor | GIS | AIS |

|---|---|---|

| Space Requirement | Low | High |

| Environmental Protection | High | Low |

| Maintenance Frequency | Low | High |

| Initial Cost | High | Low |

| Long-term Cost | Lower | Higher |

| Flexibility in Location | High | Limited |

| Specialized Skills for Maintenance | Required | Not Required |

I recall a project where we were debating between GIS and AIS for a new substation in a growing suburban area. Initially, the client leaned towards AIS due to lower upfront costs. However, when we factored in the rapidly increasing land values and the area’s growth projections, GIS became the clear winner. The compact GIS design allowed for future expansion without additional land purchases, proving to be more cost-effective in the long run.

When choosing between GIS and AIS, consider these factors:

- Available Space: If space is limited, GIS is often the only viable option.

- Environmental Conditions: For harsh environments, GIS offers better protection.

- Future Expansion Plans: GIS offers more flexibility for future upgrades in tight spaces.

- Budget Constraints: Consider both initial and long-term costs.

- Maintenance Capabilities: Ensure you have access to necessary maintenance skills, especially for GIS.

In my experience, the trend is moving towards GIS, especially in urban and suburban areas. However, AIS still has its place, particularly in rural areas or where land is abundant and cheap.

Remember, the choice between GIS and AIS isn’t always black and white. In some cases, a hybrid approach using both technologies in different parts of the substation can provide the best of both worlds. Always consider your specific needs and constraints when making this important decision.

What Are the Advantages and Challenges of Using Gas Insulated Substations?

In my years working with power distribution systems, I’ve seen Gas Insulated Substations (GIS) transform the way we think about electrical infrastructure. But like any technology, GIS comes with its own set of pros and cons.

Gas Insulated Substations offer significant advantages in terms of space-saving, reliability, and environmental protection. However, they also present challenges such as higher initial costs, specialized maintenance requirements, and environmental concerns related to SF6 gas. Understanding these factors is crucial for making informed decisions about substation design and implementation.

Let’s dive deeper into the advantages and challenges of GIS:

Advantages of Gas Insulated Substations

-

Compact Design

- GIS can be up to 90% smaller than equivalent AIS

- Allows for installation in urban areas or indoor locations

- Reduces land acquisition costs

-

Increased Reliability

- Sealed environment protects against environmental factors

- Less exposure to pollution, humidity, and wildlife

- Reduced maintenance needs

-

Enhanced Safety

- Enclosed design minimizes risk of electrical accidents

- Reduced electromagnetic field emissions

- Fire risks are significantly lower

-

Flexibility in Installation

- Can be installed underground, in buildings, or on rooftops

- Modular design allows for easy expansion

- Suitable for harsh environments (coastal areas, industrial zones)

-

Long Lifespan

- Protected components last longer

- Typical lifespan of 40-50 years, compared to 30-40 for AIS

Challenges of Gas Insulated Substations

-

Higher Initial Costs

- GIS equipment is more expensive than AIS

- Specialized installation procedures increase costs

-

Specialized Maintenance

- Requires technicians trained in SF6 handling

- Special equipment needed for gas handling and testing

-

Environmental Concerns

- SF6 is a potent greenhouse gas

- Strict regulations on SF6 handling and disposal

- Potential for fines if gas leaks occur

-

Limited Accessibility

- Enclosed design can make some components hard to access

- Major repairs may require extensive disassembly

-

Technology Lock-in

- Once installed, switching to a different system is costly

- Future upgrades may be limited by the initial design

Here’s a table summarizing the advantages and challenges:

| Aspect | Advantages | Challenges |

|---|---|---|

| Space | Compact design | Limited accessibility |

| Reliability | High due to sealed environment | Specialized maintenance required |

| Safety | Enhanced personnel safety | Environmental risk from SF6 |

| Flexibility | Versatile installation options | Technology lock-in |

| Cost | Lower long-term costs | Higher initial investment |

| Lifespan | Longer than AIS | Disposal of SF6 at end-of-life |

I remember a project where we installed a GIS in a coastal area prone to salt spray and high humidity. The client was initially concerned about the higher upfront cost. However, after five years of operation, the reduced maintenance needs and consistent performance in the harsh environment more than justified the initial investment. The AIS in the same region required frequent cleaning and component replacements due to corrosion.

When considering GIS, it’s crucial to weigh these factors:

- Long-term Planning: Consider future expansion needs and potential technology advancements.

- Environmental Regulations: Stay informed about SF6 regulations in your area.

- Maintenance Capabilities: Ensure you have access to skilled technicians for GIS maintenance.

- Life Cycle Costs: Look beyond initial costs to total ownership costs over the substation’s lifespan.

- Site-Specific Factors: Consider local environmental conditions, space constraints, and reliability requirements.

In my experience, the advantages of GIS often outweigh the challenges, especially in urban or environmentally challenging locations. However, it’s not a one-size-fits-all solution. Each project requires careful consideration of these factors to determine if GIS is the right choice.

As the technology evolves, we’re seeing innovations that address some of these challenges. For example, some manufacturers are developing GIS designs that use alternative gases with lower environmental impact. It’s an exciting time in the industry, and I’m looking forward to seeing how these developments shape the future of power distribution.

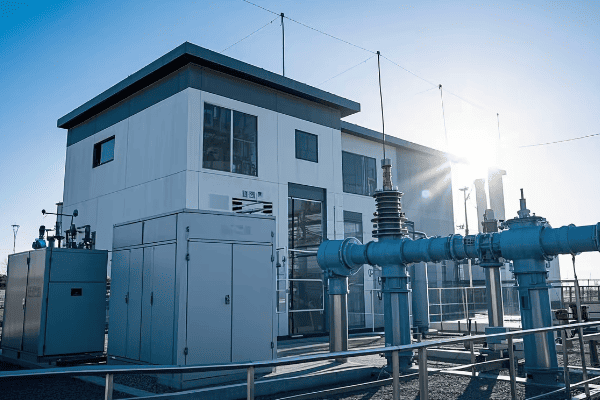

How Do Gas Insulated Substations Impact Urban Power Distribution?

As cities grow taller and denser, the challenge of powering them efficiently becomes more complex. This is where Gas Insulated Substations (GIS) come into play, revolutionizing urban power distribution in ways that were unimaginablejust a few decades ago.

Gas Insulated Substations have a significant impact on urban power distribution by allowing high-voltage substations to be installed in compact spaces within cities. This enables power to be distributed more efficiently, closer to load centers, reducing transmission losses and improving reliability. GIS technology facilitates urban development without compromising on electrical infrastructure.

Let’s explore the various ways GIS impacts urban power distribution:

1. Space Optimization in Dense Urban Areas

In cities where every square foot counts, GIS offers a game-changing solution:

- Compact Footprint: A GIS can be up to 90% smaller than an equivalent AIS.

- Vertical Integration: GIS can be installed in multi-story buildings or underground.

- Repurposing of Space: Areas above or around GIS can be used for other purposes.

I once worked on a project in a major city where we installed a GIS on the ground floor of a new office building. The compact design allowed the developer to use the rest of the building for commercial space, effectively hiding the substation in plain sight.

2. Improved Power Quality and Reliability

GIS technology enhances the reliability of urban power distribution:

- Reduced Outages: Protected from environmental factors, GIS experiences fewer failures.

- Faster Restoration: Modular design allows for quicker repairs when issues do occur.

- Stable Voltage Profiles: Closer proximity to load centers helps maintain consistent voltage levels.

3. Aesthetic and Environmental Considerations

GIS helps cities maintain their aesthetic appeal and environmental standards:

- Visual Impact: Can be housed in buildings that blend with urban architecture.

- Noise Reduction: Enclosed design significantly reduces operational noise.

- EMF Mitigation: Metal enclosures contain electromagnetic fields, addressing public health concerns.

4. Facilitating Smart Grid Integration

GIS plays a crucial role in modernizing urban power grids:

- Digital Integration: Easy to incorporate advanced monitoring and control systems.

- Flexibility: Can accommodate changes in power flow directions, essential for renewable energy integration.

- Future-Proofing: Modular design allows for easier upgrades as technology advances.

Here’s a table comparing urban power distribution before and after GIS implementation:

| Aspect | Before GIS | After GIS |

|---|---|---|

| Substation Location | Outskirts of cities | Within city centers |

| Power Transmission Losses | Higher due to long distances | Reduced due to proximity to load |

| Land Use in Cities | Large areas dedicated to substations | Minimal land use, integration with buildings |

| Reliability | Vulnerable to environmental factors | Enhanced due to protected equipment |

| Aesthetic Impact | Visible, often unsightly | Can be hidden or integrated into architecture |

| Smart Grid Readiness | Limited | High, with easy integration of digital technologies |

I recall a project in a historic European city where installing a traditional substation would have been impossible due to space constraints and preservation laws. By using GIS technology, we were able to fit a high-capacity substation in the basement of a centuries-old building. This not only preserved the city’s character but also significantly improved power reliability in the old town area.

The impact of GIS on urban power distribution extends beyond just technical benefits:

- Economic Growth: Reliable power infrastructure attracts businesses and supports economic development.

- Urban Planning Flexibility: Planners have more options when they’re not constrained by large substation footprints.

- Sustainability: By reducing transmission losses and facilitating renewable energy integration, GIS supports cities’ sustainability goals.

- Public Safety: Enclosed GIS designs enhance safety in densely populated areas.

As cities continue to grow and evolve, the role of GIS in urban power distribution will only become more critical. The ability to provide reliable, high-capacity power in compact spaces is essential for supporting smart cities, electric vehicle charging infrastructure, and the increasing power demands of modern urban life.

What is the Environmental Impact of SF6 Gas in GIS Technology?

As someone deeply involved in the power industry, I’ve seen the tremendous benefits of Gas Insulated Substation (GIS) technology. However, it’s crucial to address the elephant in the room – the environmental impact of sulfur hexafluoride (SF6) gas used in these systems.

SF6 gas, while excellent for electrical insulation, is a potent greenhouse gas with a global warming potential 23,500 times that of CO2. Its use in GIS technology presents environmental challenges, including potential leaks and end-of-life disposal issues. However, proper management and emerging alternatives are helping to mitigate these concerns.

Let’s delve deeper into the environmental aspects of SF6 in GIS:

1. Global Warming Potential

SF6 is the most potent greenhouse gas known:

- High GWP: Global Warming Potential of 23,500 over 100 years.

- Long Atmospheric Lifetime: SF6 can persist in the atmosphere for up to 3,200 years.

- Cumulative Effect: Even small leaks can have a significant long-term impact.

2. Leakage Concerns

While GIS systems are designed to be sealed, leaks can occur:

- Annual Leakage Rate: Typically less than 0.1% per year, but can vary.

- Monitoring: Regular checks are essential to detect and prevent leaks.

- Repair Challenges: Fixing leaks in a live GIS can be complex and costly.

3. End-of-Life Disposal

Proper disposal of SF6 at the end of a GIS’s life is crucial:

- Recycling: SF6 can be reclaimed and purified for reuse.

- Destruction: Technologies exist to destroy SF6, but they’re energy-intensive.

- Regulatory Compliance: Strict regulations govern SF6 disposal in many countries.

4. Mitigation Strategies

The industry is actively working to reduce the environmental impact of SF6:

- Improved Sealing: Advanced designs minimize leakage potential.

- Better Monitoring: New technologies allow for more accurate leak detection.

- Alternative Gases: Research into less harmful insulating gases is ongoing.

Here’s a table summarizing the environmental aspects of SF6 use in GIS:

| Aspect | Impact | Mitigation Strategies |

|---|---|---|

| Global Warming Potential | Very High (23,500 times CO2) | Use of alternative gases, improved containment |

| Atmospheric Lifetime | 3,200 years | Proper disposal and recycling |

| Annual Leakage Rate | Typically <0.1% | Enhanced sealing, regular monitoring |

| End-of-Life Management | Challenging | Recycling, destruction technologies |

| Regulatory Compliance | Strict in many countries | Training, documentation, proper handling procedures |

I remember a project where we were upgrading an old GIS installation. The client was concerned about the environmental impact of the existing SF6. We implemented a comprehensive SF6 management plan, including advanced leak detection systems and a recycling program for the old gas. This not only addressed the environmental concerns but also improved the overall efficiency of the substation.

When dealing with SF6 in GIS, consider these key points:

- Lifecycle Management: Plan for proper handling from installation to decommissioning.

- Regular Monitoring: Implement robust leak detection and monitoring systems.

- Staff Training: Ensure all personnel are trained in proper SF6 handling procedures.

- Alternative Technologies: Stay informed about emerging alternatives to SF6.

- Regulatory Compliance: Keep up-to-date with and adhere to local and international regulations.

The industry is actively working on solutions to reduce the environmental impact of SF6:

- Gas Mixtures: Some manufacturers are developing GIS that use a mixture of SF6 and other gases, reducing the overall SF6 content.

- Alternative Gases: Research is ongoing into gases like fluoronitriles and fluoroketones that have much lower global warming potential.

- Vacuum Technology: For certain applications, vacuum interrupters are being used as an SF6-free alternative.

While the environmental impact of SF6 is a significant concern, it’s important to balance this against the benefits of GIS technology. The compact nature of GIS allows for more efficient power distribution in urban areas, potentially reducing overall energy consumption and associated emissions. Additionally, the reliability of GIS can lead to fewer outages and less energy waste.

As we move towards a more sustainable future, the power industry must continue to innovate and find ways to minimize the environmental impact of essential technologies like GIS. It’s an exciting time in the field, and I’m optimistic about the progress we’re making in developing more environmentally friendly solutions.

How Are Gas Insulated Substations Maintained and What Safety Measures Are Required?

Maintaining a Gas Insulated Substation (GIS) is like performing a delicate ballet – it requires precision, expertise, and a keen awareness of safety. As someone who’s overseen numerous GIS maintenance operations, I can tell you that proper maintenance is crucial for the longevity and reliability of these systems.

Gas Insulated Substations require specialized maintenance procedures focusing on SF6 gas management, component inspection, and electrical testing. Safety measures are critical due to high voltage and the presence of SF6 gas. Key safety requirements include proper personal protective equipment (PPE), SF6 handling protocols, and strict adherence to lockout/tagout procedures.

Let’s break down the maintenance procedures and safety measures:

Maintenance Procedures

-

SF6 Gas Management

- Regular gas quality checks

- Leak detection and repair

- Gas pressure monitoring and top-up if necessary

-

Visual Inspections

- Check for signs of corrosion or damage

- Inspect seals and gaskets

- Verify proper operation of indicators and gauges

-

Electrical Testing

- Partial discharge measurements

- Contact resistance tests

- Insulation resistance tests

-

Mechanical Checks

- Verify proper operation of switches and circuit breakers

- Check alignment of components

- Lubricate moving parts as needed

-

Control and Protection Systems

- Test relay functions

- Calibrate measuring instruments

- Update software if required

Safety Measures

-

Personal Protective Equipment (PPE)

- Insulated gloves and boots

- Arc-flash protective clothing

- Respiratory protection when handling SF6

-

SF6 Handling Protocols

- Use specialized SF6 handling equipment

- Follow proper procedures for gas recovery and recycling

- Ensure adequate ventilation in work areas

-

Lockout/Tagout Procedures

- Implement strict procedures for de-energizing equipment

- Use personal locks and tags to prevent accidental energization

- Verify absence of voltage before work begins

-

Training and Certification

- Ensure all personnel are properly trained in GIS maintenance

- Require certification for SF6 handling

- Conduct regular safety refresher courses

-

Emergency Procedures

- Develop and practice emergency response plans

- Install SF6 gas detectors in GIS rooms

- Provide first aid training specific to electrical and SF6 exposure incidents

Here’s a maintenance and safety checklist table:

| Maintenance Task | Frequency | Safety Measures |

|---|---|---|

| SF6 Quality Check | Annual | PPE, Ventilation |

| Visual Inspection | Monthly | PPE, Lockout/Tagout |

| Electrical Testing | 2-3 Years | PPE, Lockout/Tagout, Training |

| Mechanical Checks | Annual | PPE, Lockout/Tagout |

| Control System Test | 6 Months | Training, Software Security |

| Leak Detection | Continuous | Gas Detectors, Ventilation |

I recall a maintenance operation where we discovered a small SF6 leak during a routine inspection. Thanks to our rigorous safety protocols and well-trained team, we were able to safely isolate the affected compartment, repair the leak, and recharge the system without any safety incidents or significant downtime. This experience reinforced the importance of regular maintenance and strict adherence to safety procedures.

Key considerations for GIS maintenance and safety:

- Predictive Maintenance: Implement condition monitoring systems to predict potential issues before they become critical.

- Documentation: Maintain detailed records of all maintenance activities and gas handling.

- Specialized Tools: Invest in proper tools and equipment designed for GIS maintenance.

- Environmental Compliance: Ensure all maintenance activities comply with environmental regulations regarding SF6 handling.

- Risk Assessment: Conduct thorough risk assessments before any maintenance activity.

Maintaining a GIS requires a different mindset compared to traditional air-insulated substations. The enclosed nature of GIS means that many components are not visible for easy inspection. This makes diagnostic tools and preventive maintenance even more critical.

One aspect that often surprises newcomers to GIS maintenance is the importance of cleanliness. Even tiny particles can compromise the insulating properties of SF6, so maintaining a clean environment during maintenance is crucial.

As technology evolves, we’re seeing new tools that make GIS maintenance safer and more efficient. For example, robotic inspection systems can now perform visual inspections in energized GIS compartments, reducing the need for shutdowns and human exposure to high-voltage environments.

Remember, while GIS technology offers many advantages in terms of reliability and compact design, it requires a specialized approach to maintenance and safety. By following proper procedures and investing in training and equipment, we can ensure that GIS continues to play a crucial role in our power distribution systems for years to come.

Conclusion

Gas Insulated Substations represent a significant advancement in power distribution technology, offering compact, reliable, and efficient solutions for modern electrical needs. While they present challenges, particularly in environmental impact and specialized maintenance, their benefits in urban settings and harsh environments are undeniable. As the technology evolves, GIS will continue to play a crucial role in shaping our electrical infrastructure.

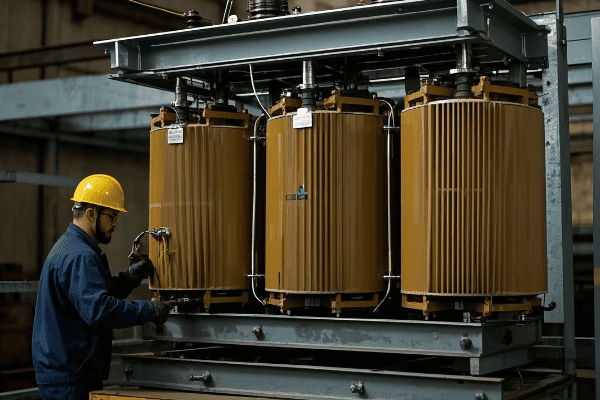

Have you ever wondered how large buildings manage their power distribution in tight spaces? The answer might lie in a clever piece of technology called the triplex core transformer.

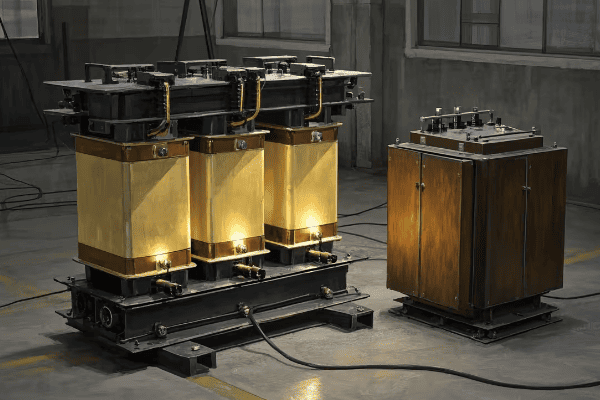

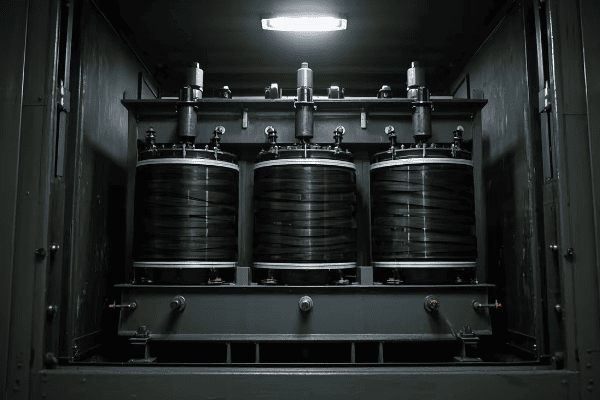

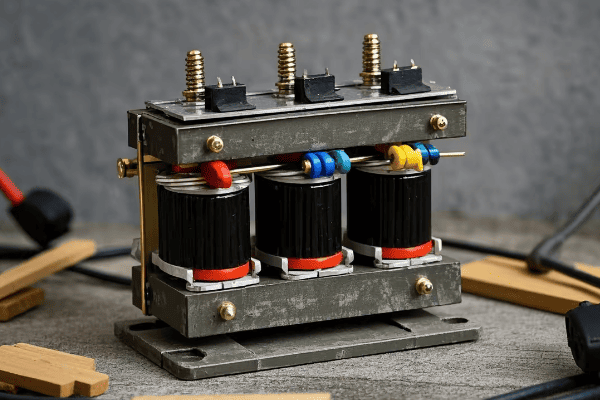

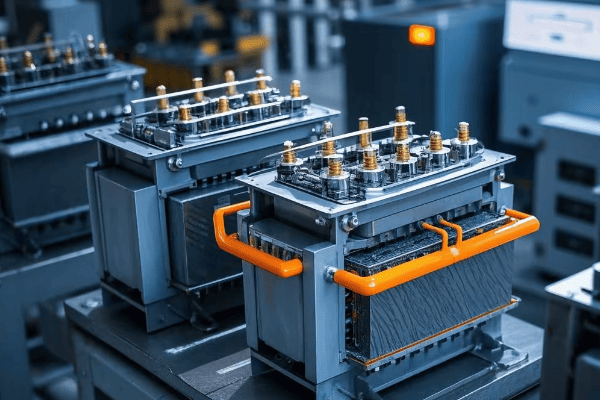

A triplex core transformer is a specialized electrical device that consists of three single-phase transformers in one unit. It’s used in building installations because it can be easily disassembled and reassembled, making it ideal for tight spaces or buildings with limited access.

As someone who’s worked in the power distribution industry for years, I’ve seen firsthand how triplex core transformers can solve complex installation challenges. Let’s dive into the details of this innovative technology and explore why it’s becoming increasingly popular in modern building designs.

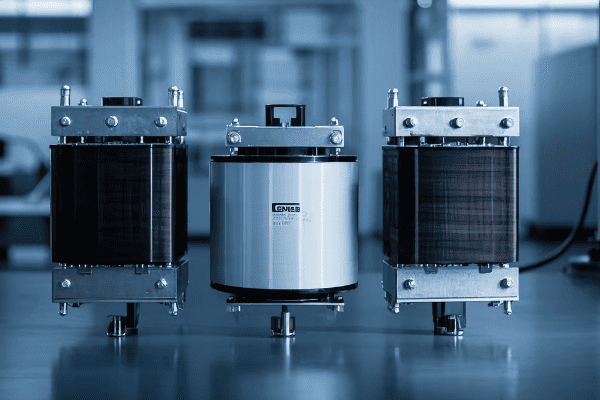

How Does a Triplex Core Transformer Differ from Traditional Transformers?

Imagine trying to fit a large, bulky piece of furniture through a narrow doorway. That’s often the challenge with traditional transformers in building installations. Triplex core transformers offer a solution to this common problem.

Triplex core transformers differ from traditional transformers in their modular design. They consist of three separate single-phase units that can be easily disassembled. Traditional transformers, on the other hand, are typically one large, integrated unit. This key difference allows for much greater flexibility in installation and maintenance.

Let’s break down the key differences:

Design and Structure

-

Triplex Core Transformer

- Three separate single-phase units

- Modular design for easy disassembly

- Compact when assembled

-

Traditional Transformer

- Single integrated unit

- Fixed design

- Often bulkier overall

Installation Flexibility

Triplex core transformers offer significant advantages when it comes to installation. I remember a project where we needed to upgrade the power distribution in an old office building. The service elevator was too small for a traditional transformer, but we easily transported a triplex core transformer piece by piece and assembled it on-site.

Maintenance and Repairs

Another major difference lies in maintenance. With a triplex core transformer, you can often service or replace one phase without shutting down the entire system. This can be a huge advantage in critical applications where downtime is costly.

Here’s a comparison table to illustrate the differences:

| Feature | Triplex Core Transformer | Traditional Transformer |

|---|---|---|

| Design | Modular (3 single-phase units) | Integrated single unit |

| Installation | Easy in tight spaces | Can be challenging in confined areas |

| Maintenance | Can service individual phases | Typically requires full shutdown |

| Size | Compact when assembled | Often larger overall |

| Flexibility | High | Low |

In my experience, the choice between a triplex core and a traditional transformer often comes down to the specific requirements of the installation site. While traditional transformers are still widely used and have their advantages, triplex core transformers are becoming increasingly popular in urban environments where space is at a premium.

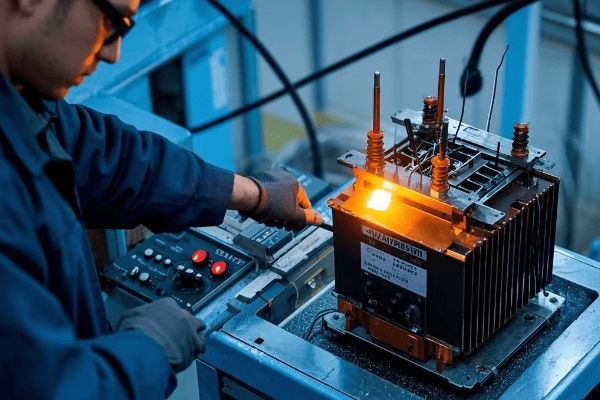

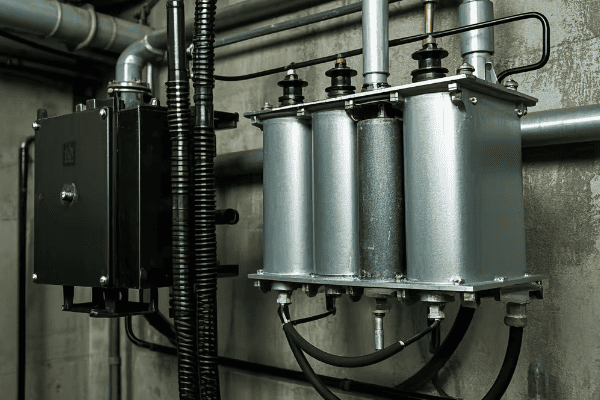

What Are the Key Components of a Triplex Core Transformer?

When I first encountered a triplex core transformer, I was amazed by its ingenious design. Understanding its components is crucial for anyone involved in power distribution or building management.

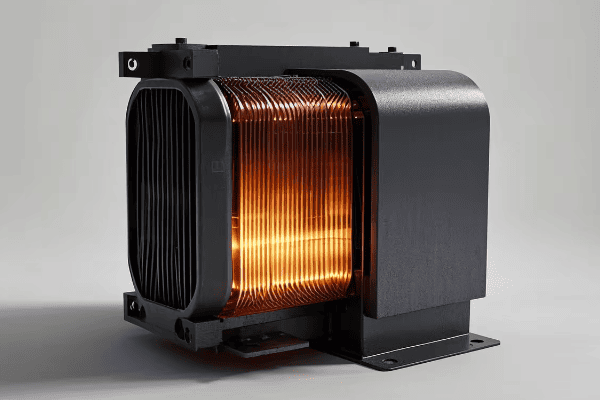

A triplex core transformer consists of three main components: the core, the windings, and the enclosure. Each of the three single-phase units has its own core and windings, all housed within a common enclosure. This design allows for modularity while maintaining the functionality of a three-phase transformer.

Let’s dive deeper into each component:

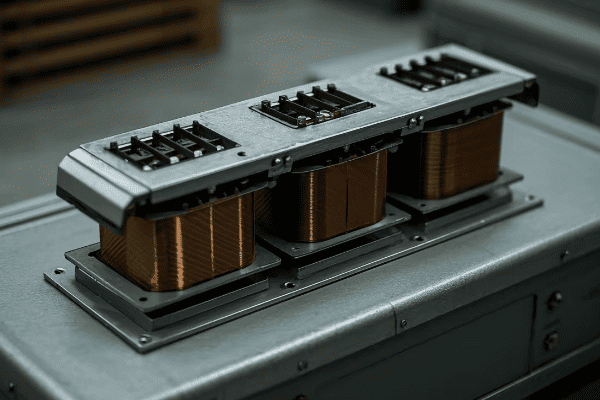

1. The Core

The core is the heart of each single-phase unit in a triplex core transformer. Here’s what you need to know:

- Material: Typically made of high-grade silicon steel

- Design: Usually a shell-type or core-type design

- Function: Provides a path for magnetic flux, crucial for the transformation process

2. The Windings

Each single-phase unit has its own set of windings. These are key to the transformer’s operation:

- Primary Winding: Connects to the input voltage

- Secondary Winding: Delivers the output voltage

- Material: Usually copper or aluminum

- Insulation: High-quality materials to prevent short circuits

3. The Enclosure

The enclosure is what sets triplex core transformers apart. It houses all three single-phase units:

- Design: Modular for easy disassembly

- Material: Usually steel, with proper ventilation

- Features: Often includes cooling systems and monitoring equipment

Here’s a table summarizing the components:

| Component | Function | Key Features |

|---|---|---|

| Core | Magnetic flux path | High-grade silicon steel, efficient design |

| Windings | Voltage transformation | Copper/aluminum, well-insulated |

| Enclosure | Houses components | Modular, steel construction, cooling system |

In my years of working with transformers, I’ve found that the modular nature of triplex core transformers offers unique advantages. For instance, I once worked on a project where we needed to replace a faulty winding. With a traditional transformer, this would have meant replacing the entire unit. But with the triplex core design, we were able to replace just the affected single-phase unit, saving time and money.

Understanding these components is crucial for anyone working with or specifying triplex core transformers. The modular design not only aids in installation but also in maintenance and repairs, making these transformers a versatile choice for many building installations.

Why Are Triplex Core Transformers Ideal for Tight Installation Spaces?

Have you ever tried to squeeze a large appliance through a narrow doorway? That’s often the challenge with installing traditional transformers in existing buildings. This is where triplex core transformers shine.

Triplex core transformers are ideal for tight installation spaces because of their modular design. They can be disassembled into smaller, more manageable parts, making it easier to transport through narrow corridors, small elevators, or tight spaces. Once at the installation site, they can be reassembled quickly.

Let’s explore why this design is so advantageous in confined spaces:

1. Easy Transportation

The modular nature of triplex core transformers makes them much easier to transport. I remember a project in an old downtown building where the service elevator was too small for a traditional transformer. We easily moved the triplex core transformer piece by piece and assembled it on-site.

2. Flexible Installation

Triplex core transformers offer more flexibility in terms of layout. You can arrange the three single-phase units in various configurations to fit the available space. This is particularly useful in buildings with irregular-shaped utility rooms.

3. Reduced Need for Large Access Points

With traditional transformers, you often need to create large access points or even remove walls to get the equipment in place. Triplex core transformers can usually be brought in through standard doorways, reducing installation costs and structural modifications.

4. Easier Future Replacements or Upgrades

If you need to replace or upgrade the transformer in the future, the modular design of triplex core transformers makes this process much simpler. You don’t need to worry about how you’ll remove a large, integrated unit.

Here’s a comparison table of installation considerations:

| Factor | Triplex Core Transformer | Traditional Transformer |

|---|---|---|

| Transportation | Easy, can be moved in parts | Challenging, requires large access |

| Layout Flexibility | High, can be arranged to fit space | Low, fixed configuration |

| Access Requirements | Standard doorways often sufficient | May require wall removal or large openings |

| Future Replacement | Simplified, can replace parts | Complex, may require complete unit removal |

In my experience, the advantages of triplex core transformers in tight spaces go beyond just the initial installation. I once worked on a project where we needed to upgrade the power capacity of an old office building. The existing utility room was cramped, with no easy way to remove the old transformer or bring in a new, larger one. By switching to a triplex core design, we were able to increase capacity without major construction work.

The ability to work within existing spatial constraints is becoming increasingly important as cities grow denser and buildings are repurposed. Triplex core transformers offer a solution that can adapt to these challenges, making them an excellent choice for urban environments and retrofit projects.

How Do You Install and Maintain a Triplex Core Transformer?

Installing and maintaining a triplex core transformer might seem daunting at first, but with the right approach, it can be more straightforward than you might think. Let me walk you through the process based on my years of experience in the field.

Installing a triplex core transformer involves transporting the disassembled units, reassembling them on-site, and connecting them to the power system. Maintenance includes regular inspections, oil testing (for oil-filled units), and occasional part replacements. The modular design allows for easier maintenance compared to traditional transformers.

Let’s break down the installation and maintenance process:

Installation Process

-

Site Preparation

- Ensure the installation area meets size and weight requirements

- Prepare a proper foundation or mounting surface

-

Transportation

- Move the disassembled units to the installation site

- This is often easier than moving a single large transformer

-

Assembly

- Carefully reassemble the three single-phase units

- Follow manufacturer guidelines for proper alignment

-

Connection

- Connect the primary and secondary windings

- Install any necessary cooling systems or monitoring equipment

-

Testing

- Conduct thorough testing before energizing the transformer

Maintenance Procedures

-

Regular Inspections

- Visual checks for any signs of damage or wear

- Listen for unusual noises during operation

-

Oil Testing (for oil-filled units)

- Regular oil sampling and analysis

- Top up or replace oil as needed

-

Thermal Imaging

- Use infrared cameras to detect hot spots

-

Part Replacement

- Replace individual components as needed, without necessarily replacing the entire transformer

Here’s a maintenance schedule table based on my experience:

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Visual Inspection | Monthly | High |

| Oil Testing | Annually | Critical |

| Thermal Imaging | Bi-annually | Medium |

| Winding Resistance Test | Every 3-5 years | High |

| Insulation Resistance Test | Annually | Critical |

I remember a case where we installed a triplex core transformer in a renovated historical building. The narrow staircases and small elevator would have made it impossible to bring in a traditional transformer. We easily transported the triplex core units separately and assembled them in the basement. The modular design not only solved our installation challenge but also made future maintenance much easier.

One key advantage I’ve found with triplex core transformers is the ability to perform maintenance on one phase without necessarily shutting down the entire system. This can be crucial in applications where continuous power supply is critical.

When it comes to maintenance, always follow these best practices:

- Adhere to manufacturer guidelines and local regulations

- Keep detailed maintenance records

- Train personnel in proper handling and safety procedures

- Plan for regular maintenance to prevent unexpected failures

Remember, while the modular design of triplex core transformers can simplify many aspects of installation and maintenance, it’s still crucial to have qualified professionals handle these tasks. Proper installation and maintenance not only ensure optimal performance but also extend the life of your transformer.

What Are the Efficiency and Cost Considerations of Triplex Core Transformers?

When it comes to choosing a transformer, efficiency and cost are always top concerns. As someone who’s worked with various transformer types, I can tell you that triplex core transformers have some unique considerations in these areas.

Triplex core transformers often have slightly lower efficiency than traditional three-phase transformers due to their modular design. However, they can be more cost-effective in certain scenarios, especially when considering installation costs in tight spaces. The total cost of ownership, including maintenance and potential replacement, can be lower for triplex core transformers.

Let’s dive deeper into the efficiency and cost aspects:

Efficiency Considerations

-

Core Losses

- Triplex core transformers may have slightly higher core losses due to the three separate cores

- Modern designs are continually improving efficiency

-

Load Losses

- Generally comparable to traditional transformers

- Can be optimized for specific load profiles

-

Overall Efficiency

- Typically 1-2% lower than equivalent traditional three-phase transformers

- This gap is narrowing with advancements in materials and design

Cost Considerations

-

Initial Purchase Cost

- Often higher than traditional transformers of the same rating

- Price difference is decreasing as triplex core transformers become more common

-

Installation Costs

- Can be significantly lower, especially in tight spaces or existing buildings

- Reduced need for large access points or structural modifications

-

Maintenance Costs

- Potentially lower due to the ability to service or replace individual phases

- Easier access can reduce labor costs for maintenance

-

Replacement Costs

- Lower in the long term, as you can replace individual units rather than the entire transformer

Here’s a comparison table of efficiency and cost factors:

| Factor | Triplex Core Transformer | Traditional Transformer |

|---|---|---|

| Core Losses | Slightly higher | Lower |

| Load Losses | Comparable | Comparable |

| Overall Efficiency | 97-98% | 98-99% |

| Initial Cost | Higher | Lower |

| Installation Cost | Lower in tight spaces | Higher in tight spaces |

| Maintenance Cost | Potentially lower | Potentially higher |

| Replacement Cost | Lower (modular) | Higher (entire unit) |

I remember a project where we were upgrading the electrical system in an old hospital. The initial cost of the triplex core transformer was about 15% higher than a traditional unit. However, when we factored in the reduced installation costs (no need to remove walls) and the potential for easier future maintenance, the total cost of ownership over 20 years was actually lower for the triplex core option.

When considering efficiency and cost, keep these points in mind:

- Look at the total cost of ownership, not just the initial purchase price

- Consider the specific installation environment and how it might affect costs

- Factor in potential savings from easier maintenance and partial replacements

- Evaluate the impact of slightly lower efficiency against other benefits

In my experience, while triplex core transformers might not always be the most efficient option on paper, their practical advantages often make them a cost-effective choice, especially in challenging installation environments. As with any major equipment decision, it’s crucial to analyze your specific needs and constraints to determine the best option for your situation.

In Which Scenarios Should You Choose a Triplex Core Transformer Over Other Types?

Choosing the right transformer for your project can be a complex decision. As someone who’s been in the field for years, I’ve seen triplex core transformers shine in certain scenarios while traditional transformers were better in others.

Triplex core transformers are ideal for installations in tight spaces, buildings with limited access, and situations where future flexibility is crucial. They’re particularly well-suited for urban environments, retrofits of older buildings, and applications where minimizing downtime during maintenance is critical.

Let’s explore the scenarios where triplex core transformers are the best choice:

1. Limited Space Installations

If you’re working with a cramped utility room or a tight basement, triplex core transformers are often the go-to solution. Their modular design allows for easier transportation and installation in confined spaces.

2. Buildings with Restricted Access

For installations in high-rise buildings, historical structures, or any location with narrow corridors or small elevators, the ability to transport the transformer in parts is a huge advantage.

3. Retrofit Projects

When upgrading electrical systems in existing buildings, triplex core transformers can often be installed without major structural modifications, saving time and money.

4. Applications Requiring High Reliability

In scenarios where minimizing downtime is crucial (like hospitals or data centers), the ability to service or replace one phase without shutting down the entire system can be invaluable.

5. Future-Proofing Installations

If you anticipate the need for future capacity upgrades or potential relocation of the transformer, the modular nature of triplex core units offers greater flexibility.

Here’s a decision matrix to help guide your choice:

| Scenario | Triplex Core Transformer | Traditional Transformer | |

|---|---|---|---|

| Tight Installation Space | Ideal | Challenging | |

| Easy Access for Installation | Suitable | Preferred | |

| Critical Uptime Requirements | Excellent | Good | |

| Initial Cost Sensitivity | Less Suitable | More Suitable | |

| Future Flexibility Needs | Excellent | Limited | I recall a project where we were upgrading the electrical system in a busy downtown hotel. The existing transformer room was in the basement, accessible only through a narrow staircase. A traditional transformer would have required extensive and disruptive construction work. We opted for a triplex core transformer, which we easily transported down the stairs in pieces and assembled on-site. This choice minimized disruption to the hotel’s operations and saved significant costs in construction. |

When deciding between a triplex core and a traditional transformer, consider these factors:

-

Installation Environment

- Assess the available space and access routes

- Consider any weight restrictions on floors or elevators

-

Long-term Maintenance Plans

- Evaluate the importance of minimizing downtime during maintenance

- Consider the availability of skilled technicians for each type

-

Future Expansion Plans

- Think about potential needs for increased capacity

- Consider the likelihood of needing to relocate the transformer

-

Budget Constraints

- Look at both initial costs and long-term total cost of ownership

- Factor in potential savings from easier installation and maintenance

-

Efficiency Requirements

- Assess the impact of slightly lower efficiency in triplex core designs

- Consider local energy costs and regulations

Here’s a quick checklist to help you decide:

- [ ] Is the installation space tight or hard to access?

- [ ] Is minimizing future maintenance downtime crucial?

- [ ] Do you anticipate needing to upgrade or move the transformer in the future?

- [ ] Can you accommodate a slightly higher initial cost for long-term benefits?

- [ ] Are the efficiency differences within acceptable limits for your application?