Step Up Transformers: Boosting Voltage for Efficient Transmission?

Are you puzzled by how electricity travels hundreds of miles without significant loss? The secret lies in a crucial device: the step up transformer.

Step up transformers are essential components in power transmission systems. They increase voltage levels, allowing electricity to travel efficiently over long distances. These transformers play a vital role in minimizing power losses and ensuring reliable energy distribution across vast areas.

In my years working with power systems, I’ve seen firsthand the critical role step up transformers play in our energy infrastructure. This article will explore their unique design, diverse applications, and efficiency considerations. Whether you’re a curious student or an industry professional, you’ll gain valuable insights into these powerful devices that keep our modern world running.

Structural Characteristics: What Makes Step Up Transformers Unique?

Have you ever wondered why step up transformers look so different from the ones you see on utility poles? Their unique structure is key to their voltage-boosting ability.

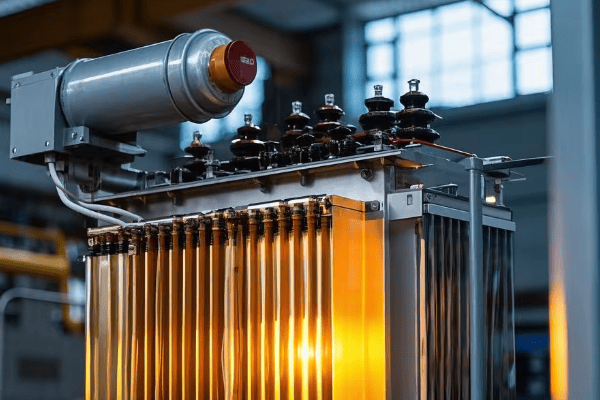

Step up transformers have a distinctive design optimized for high voltage output. They feature more secondary windings than primary, specialized insulation systems, and robust cooling mechanisms. This structure allows them to efficiently increase voltage while managing the associated challenges of heat and electrical stress.

I remember my first encounter with a large step up transformer at a power plant. Its massive size and complex design left a lasting impression, sparking my fascination with power transmission technology.

Core Design

The heart of a step up transformer is its core:

- Material: High-grade silicon steel or amorphous metal to minimize core losses.

- Construction: Often uses a shell-type or core-type design for optimal magnetic flux distribution.

- Laminations: Thin layers to reduce eddy current losses.

Winding Configuration

The winding arrangement is crucial for voltage step-up:

- Primary Winding: Fewer turns of thicker wire to handle higher current.

- Secondary Winding: More turns of thinner wire for higher voltage output.

- Insulation: Advanced materials like oil-impregnated paper or SF6 gas for high voltage isolation.

Cooling Systems

Effective cooling is vital due to the high power levels involved:

- Oil Immersion: Most large step up transformers use oil for both cooling and insulation.

- Radiators: External fins or tubes for heat dissipation.

- Forced Cooling: Fans or oil pumps for enhanced cooling in high-capacity units.

Structural Comparison Table

| Feature | Step Up Transformer | Distribution Transformer |

|---|---|---|

| Core Size | Larger | Smaller |

| Winding Ratio | Secondary > Primary | Often close to 1:1 |

| Insulation | Heavy-duty | Standard |

| Cooling System | Advanced (often forced) | Basic (often natural) |

| Size and Weight | Significantly larger | Compact and lighter |

Understanding these structural characteristics is crucial for designing and maintaining step up transformers. In my experience, paying attention to these details can significantly impact a transformer’s performance, efficiency, and lifespan.

Application Areas: Where Do We Use Step Up Transformers?

Have you ever considered why we don’t just generate electricity at the same voltage used for transmission? The answer lies in the diverse applications of step up transformers.

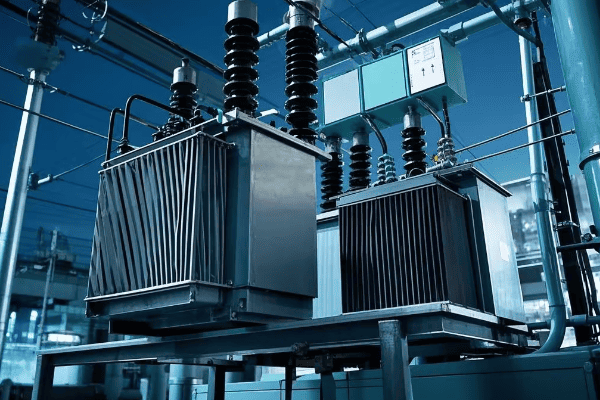

Step up transformers are primarily used in power generation and transmission systems. They increase voltage at power plants for efficient long-distance transmission, in renewable energy installations to match grid voltages, and in some industrial settings for specific high-voltage processes.

I once worked on a project integrating a new wind farm into the existing grid. The step up transformer was the key component that made it possible to connect the variable, low-voltage wind turbine output to the high-voltage transmission lines.

Power Generation Plants

Step up transformers are crucial at the start of the power journey:

- Voltage Increase: Typically from 15-25 kV generator output to 138-765 kV transmission voltages.

- Power Plant Types: Used in thermal, nuclear, hydroelectric, and other large-scale generation facilities.

- Capacity: Can handle enormous power levels, often in the hundreds of MVA.

Renewable Energy Systems

As renewable energy grows, so does the importance of step up transformers in this sector:

- Solar Farms: Convert low DC voltage to high AC for grid integration.

- Wind Farms: Step up the variable output from wind turbines to grid-compatible levels.

- Offshore Wind: Specialized designs to withstand marine environments while boosting voltage for undersea transmission.

Industrial Applications

Some industries require high voltages for specific processes:

- Electric Arc Furnaces: Step up transformers provide the high voltages needed for metal melting.

- Particle Accelerators: Scientific research facilities use step up transformers to achieve extremely high voltages.

- High-Voltage Testing Facilities: For testing insulation and equipment designed for high-voltage environments.

Application Comparison Table

| Application | Input Voltage | Output Voltage | Typical Capacity |

|---|---|---|---|

| Coal Power Plant | 22 kV | 345 kV | 500 MVA |

| Solar Farm | 1 kV (DC) | 138 kV (AC) | 50 MVA |

| Offshore Wind | 33 kV | 220 kV | 200 MVA |

| Electric Arc Furnace | 13.8 kV | 700-900 V | 100 MVA |

Understanding these applications is crucial for electrical engineers and power system designers. In my career, I’ve seen how the right step up transformer can make or break a project’s success, whether it’s a massive power plant or a small renewable energy installation.

Efficiency Considerations: How Do We Reduce Long-Distance Transmission Losses?

Have you ever wondered how we manage to send electricity across vast distances without losing most of it along the way? The efficiency of step up transformers plays a crucial role in this feat.

Efficiency in step up transformers is key to reducing long-distance transmission losses. By increasing voltage and decreasing current, these transformers minimize resistive losses in power lines. Advanced core materials, optimized winding designs, and effective cooling systems all contribute to maximizing efficiency.

I once worked on a project to upgrade an aging transmission system. By replacing old step up transformers with more efficient models, we reduced transmission losses by 15%, saving millions in energy costs annually.

Core Loss Reduction

Minimizing core losses is crucial for transformer efficiency:

- Material Selection: Use of high-grade silicon steel or amorphous metal cores.

- Lamination Thickness: Thinner laminations to reduce eddy current losses.

- Grain-Oriented Steel: Aligning magnetic domains for better performance.

Winding Loss Minimization

Efficient winding design can significantly reduce copper losses:

- Conductor Material: Use of high-conductivity copper or aluminum.

- Winding Geometry: Optimized designs to reduce proximity effects and circulating currents.

- Transposition Techniques: Special winding methods to equalize current distribution.

Cooling System Optimization

Effective cooling is essential for maintaining efficiency:

- Oil Quality: Use of high-grade insulating oils with good thermal properties.

- Radiator Design: Optimized for maximum heat dissipation.

- Forced Cooling: Implementation of fans or oil pumps for enhanced cooling in high-load conditions.

Efficiency Comparison Table

| Aspect | Traditional Design | Modern Efficient Design |

|---|---|---|

| Core Material | Standard Silicon Steel | Amorphous Metal or Hi-B Steel |

| Core Loss | 0.8-1.0 W/kg | 0.2-0.3 W/kg |

| Winding Material | Standard Copper | High-Conductivity Copper Alloys |

| Cooling System | Natural Oil Circulation | Forced Oil-Directed/Forced Air |

| Overall Efficiency | 98-98.5% | 99-99.5% |

Improving efficiency in step up transformers is an ongoing challenge. In my experience, even small improvements can lead to significant energy savings over time, especially in large-scale power transmission systems.

Conclusion

Step up transformers are crucial for efficient power transmission. Their unique design, diverse applications, and focus on efficiency make them indispensable in our modern electrical grid. Understanding and optimizing these transformers is key to a reliable and sustainable energy future.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group