The Power of Auto Transformers: Revolutionizing Electrical Systems?

Are you struggling with power distribution efficiency in your electrical systems? You’re not alone. Many engineers face this challenge daily.

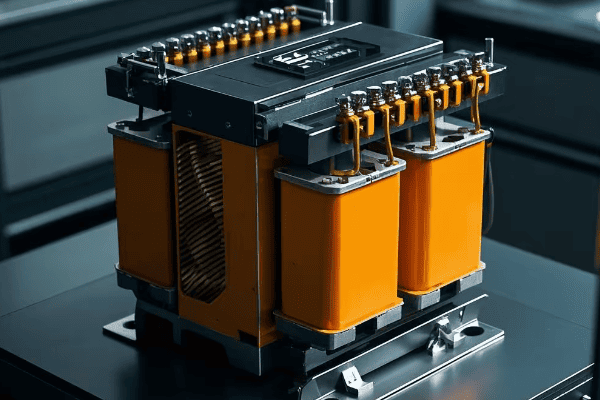

Auto transformers are revolutionizing electrical systems with their single-winding design. They offer improved efficiency, compact size, and cost-effectiveness, making them game-changers in power distribution across various industries.

As an electrical engineer with over two decades of experience, I’ve seen auto transformers transform power systems. Let’s explore how these devices can benefit your projects.

Understanding Auto Transformers: The Basics of Single-Winding Technology?

Ever wondered how some transformers achieve efficiency in such a compact package? The secret lies in the unique design of auto transformers.

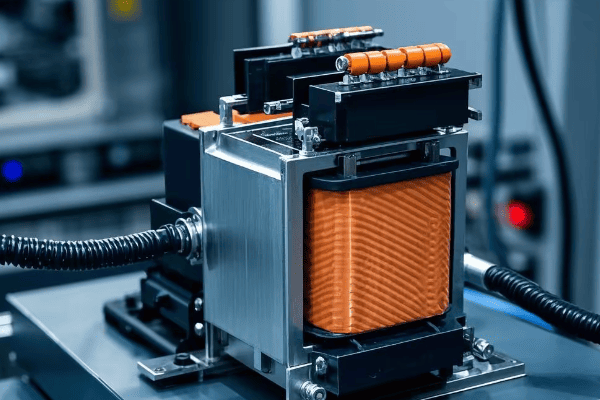

Auto transformers use a single winding for both primary and secondary circuits, allowing for more efficient power transfer and voltage regulation. This design is the key to their compact size and high efficiency.

Key components:

- Single Winding: One continuous coil serves as both primary and secondary.

- Taps: Connection points along the winding for different voltage ratios.

- Core: Concentrates the magnetic field.

Think of an auto transformer as a long water pipe with multiple outlets at different heights. The water pressure (voltage) varies depending on which outlet you use, but it’s all part of the same system.

How Auto Transformers Work: Principles and Mechanisms Explained?

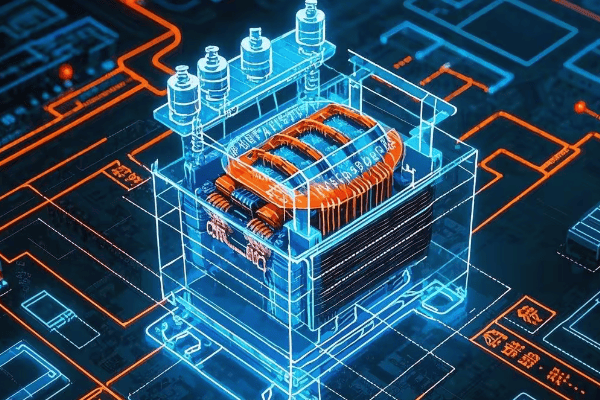

Auto transformers operate on a simple yet ingenious principle:

They work through electromagnetic induction, using a single winding to transfer power between circuits. The voltage transformation is achieved by tapping the winding at different points.

- When AC voltage is applied, it creates a changing magnetic field.

- This field induces voltage across the entire winding.

- By selecting different taps, we can obtain various output voltages.

Efficiency boost: Auto transformers transfer power both electromagnetically and conductively, leading to higher efficiency, especially for small voltage changes.

Advantages of Auto Transformers: Efficiency, Size, and Cost Benefits?

Why are auto transformers gaining popularity? The answer lies in their numerous advantages:

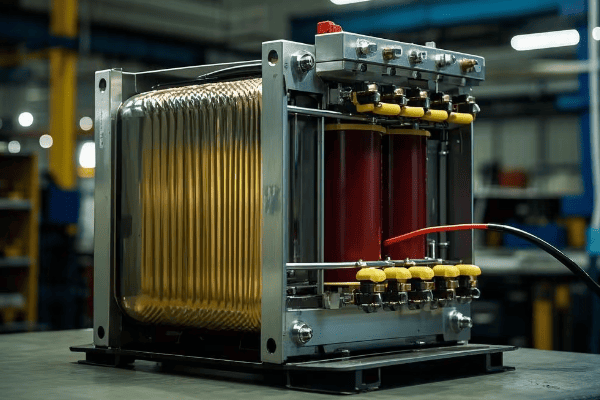

Auto transformers offer higher efficiency (up to 99% for small changes), more compact size, and lower costs compared to traditional transformers. These benefits make them ideal for many modern applications.

Key advantages:

- Higher efficiency: Less power loss, especially for small voltage changes.

- Compact size: Smaller footprint, easier installation.

- Cost-effective: Less material used, lower manufacturing and operational costs.

Case Study: Factory Upgrade

In a recent project, we replaced several traditional transformers with auto transformers in a manufacturing plant. The results were impressive:

- 3% increase in overall system efficiency

- 40% reduction in transformer footprint

- 15% decrease in energy costs

Applications Across Industries: Where Auto Transformers Shine?

Auto transformers find their place in numerous sectors:

They excel in power distribution, industrial processes, transportation systems, and even consumer electronics. Their versatility makes them crucial in various applications requiring efficient voltage regulation.

Key applications:

- Power Distribution: Voltage regulation in substations, grid interconnection.

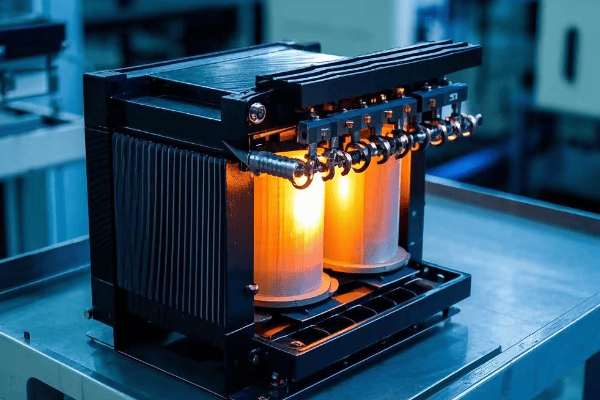

- Industrial: Motor starting, welding equipment, furnace control.

- Transportation: Railway electrification, electric vehicle charging.

- Renewable Energy: Grid integration for solar and wind power.

Real-world Impact: Rural Power Stabilization

We tackled voltage fluctuations in a rural area using strategically placed auto transformers. The outcome:

- 40% reduction in voltage fluctuations

- Significant improvement in power quality for residents

- Reduced equipment failures due to stable voltage

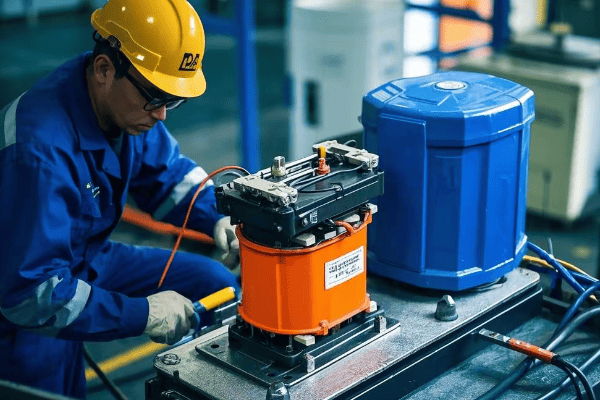

Designing with Auto Transformers: Key Considerations for Engineers?

For engineers, designing with auto transformers requires careful consideration:

Key factors include voltage ratios, power ratings, efficiency requirements, cooling methods, and environmental conditions. Safety standards and future system expansions must also be accounted for.

Design checklist:

- Voltage Ratio: Determine input/output voltages and optimal tap positions.

- Power Rating: Calculate max load, including future expansion (add 20-30%).

- Efficiency: Choose high-quality core materials to minimize losses.

- Cooling: Select between air-cooled or oil-immersed designs based on application.

- Environment: Consider temperature, humidity, and altitude.

- Safety: Implement proper grounding and protection mechanisms.

Pro Tip: Always design with future needs in mind. I once worked on a project where we underestimated future power requirements, leading to premature system upgrades.

Safety First: Precautions and Best Practices in Auto Transformer Usage?

Safety is paramount when working with auto transformers:

Key safety measures include proper grounding, overcurrent protection, regular maintenance, and adherence to electrical codes. Auto transformers require special attention due to their lack of electrical isolation.

Essential safety practices:

- Grounding: Ensure proper grounding of the transformer chassis and system.

- Overcurrent Protection: Install appropriately sized circuit breakers or fuses.

- Regular Inspections: Check for signs of wear, damage, or overheating.

- Personnel Training: Educate staff on safe operation and emergency procedures.

Safety Checklist:

- [ ] Verify grounding connections monthly

- [ ] Test overcurrent protection devices quarterly

- [ ] Conduct thermal imaging scans semi-annually

- [ ] Perform insulation resistance tests annually

- [ ] Review and update safety procedures yearly

Remember: A small investment in safety can prevent costly accidents and downtime.

Future Trends and Environmental Impact

As we look to the future, auto transformer technology continues to evolve:

Emerging trends include smart transformers with IoT integration, use of advanced materials for higher efficiency, and designs optimized for renewable energy systems. Environmental considerations are also shaping development.

Future developments:

- Smart Auto Transformers: Real-time monitoring and predictive maintenance.

- Eco-friendly Materials: Biodegradable insulating oils and recycled core materials.

- Efficiency Improvements: Pushing efficiency beyond 99% for all load conditions.

- Renewable Energy Integration: Specialized designs for wind and solar power systems.

Environmental Impact:

- Energy Efficiency: Higher efficiency means lower energy waste and reduced carbon footprint.

- Material Usage: Compact design leads to less material consumption in manufacturing.

- Lifecycle Assessment: Focus on recyclability and end-of-life management.

Conclusion

Auto transformers are powerful tools revolutionizing electrical systems across industries. Their efficiency, compact size, and cost-effectiveness make them ideal for many applications. By understanding their principles, advantages, and proper usage, engineers and facility managers can leverage auto transformers to enhance power distribution systems while ensuring safety and reliability.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group