Three-Phase vs. Single-Phase Pad-Mounted Transformer: A Comprehensive Guide to Specs, Applications, and Quotes | CHBEB

Introduction

If you choose the improper phase type, you will have to deal with losses, outages, and more effort. As loads get bigger, those pains get worse. This tutorial compares three-phase and single-phase pad-mounted transformers1, explains important specs, and teaches how to use and quote them effectively.

The Core Analysis: Understanding the Key Differences for Your Project

Confusing phase types leads to downtime and wrong sizes. If you don’t keep an eye on them, budgets grow and dependability goes down. We explain the functional differences and how they affect design, protection, and O&M so you can make an informed choice for today’s loads and tomorrow’s growth.

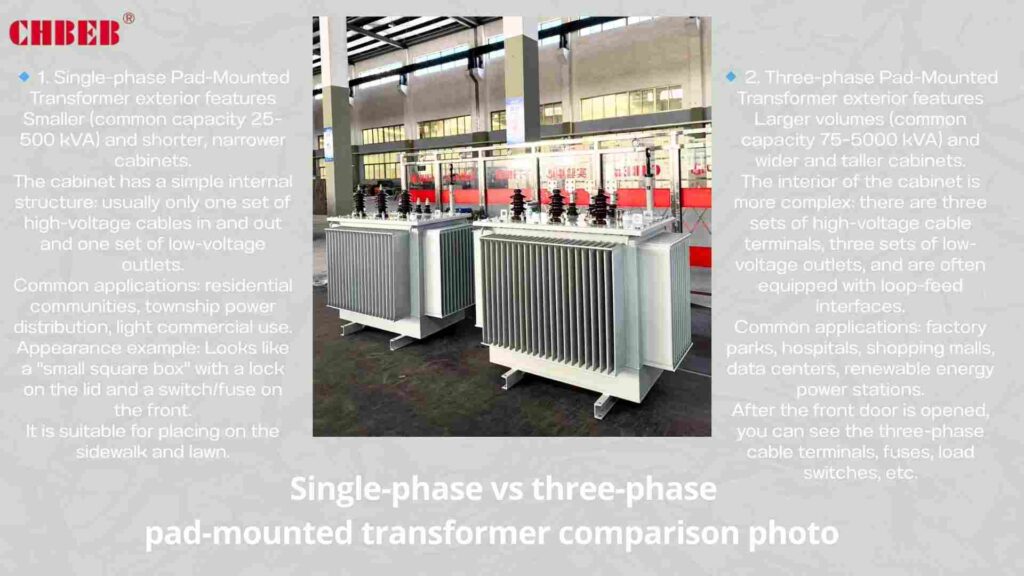

Three-Phase vs. Single-Phase2: Which Transformer is Right for You?

The “phase” of a pad-mounted transformer decides how it sends electricity to your loads and how it works with the medium-voltage network above it. Single-phase units work best in locations with low to moderate demand, whereas three-phase units work best in places with a lot of motors, high density, or power quality issues.

| Criterion | Single-Phase Pad-Mounted | Three-Phase Pad-Mounted |

|---|---|---|

| Typical kVA | 25–500 kVA (common) | 75–5000 kVA (common) |

| Best-Fit Loads | Residential feeders, light commercial | Industrial plants, malls, campuses, renewables |

| Voltage Balance | Serves split-phase / single-phase loads | Inherently balanced for three-phase equipment |

| Motor Loads / VFDs | Limited; risk of flicker/voltage dip | Robust; better for large motors and VFDs |

| Footprint / Cost | Smaller footprint, lower initial cost | Larger, higher capex but greater capacity |

| Future Expansion | Constrained; step-ups may be needed later | Scalable; simpler to add feeders/loads |

| Power Quality | Adequate for simple, steady loads | Superior for harmonic, unbalance, and flicker control |

| Common Secondaries | 240/120 V, 480/240 V | 480/277 V, 400/230 V, 415/240 V, 208/120 V |

Three-phase often offers a higher lifecycle value in mixed-use parks or expansion corridors, even if the initial load is small. Single-phase is easier and cheaper in stable, low-density communities, as long as you think about variety and potential EV/HVAC expansion.

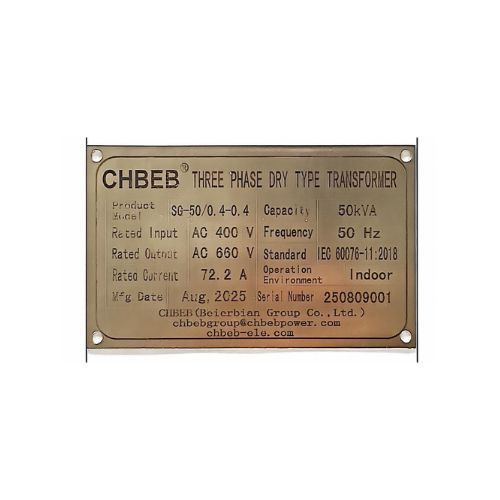

A Guide to Key Technical Parameters: Decoding the Specs

Specifications set the standards for safety, uptime, and operating costs. A few things that affect most results are capacity, impedance, losses, vector group, and protection. Read them as a whole, not as separate checks, and make sure they meet your utility’s criteria.

- kVA Rating: Size to peak plus expansion, which is usually 15–25%. If you make it too little, it will generate thermal stress; if you make it too big, it will increase losses.

- Primary/Secondary Voltage: Make sure the MV (for example, 11/22/33/35 kV) and the utilization voltage (for example, 480/277 V) are the same. Check the tap ranges to see whether they change with the seasons or the length of the feeder.

- % Impedance: Sets the level of fault and the voltage regulation. Too low means high fault duty or flicker, while too high means too much voltage drop.

- Vector Group3: Determines the phase shift and availability of the neutral (for example, Dyn for 4-wire secondaries). Affects how harmonics work and how grounding works.

- Losses (No-Load / Load): Guaranteed watts are directly related to energy costs and heat, which you can use to make TCO decisions.

- ONAN/ONAF stages set the thermal headroom for cooling and temperature rise. In hot or high-altitude places, use derating or extra fans.

- BIL and surge coordination: Make sure the insulation level matches the arrester MCOV and the projected switching surges on the feeder.

- Dead-front elbows, bayonet and current-limiting fuses, fault indicators, and MV surge arresters are all examples of terminations and protection.

- Sound Level: When near homes or workplaces, use low-noise cores and clamps to avoid complaints.

How to Use It and How to Buy It

Using the wrong topology costs money and could get you in trouble. If you don’t pay attention, rework and callbacks will pile up. This part shows you how to get the correct transformer at the right price by mapping out typical use cases and then walking you through scoping, customizing, and bidding.

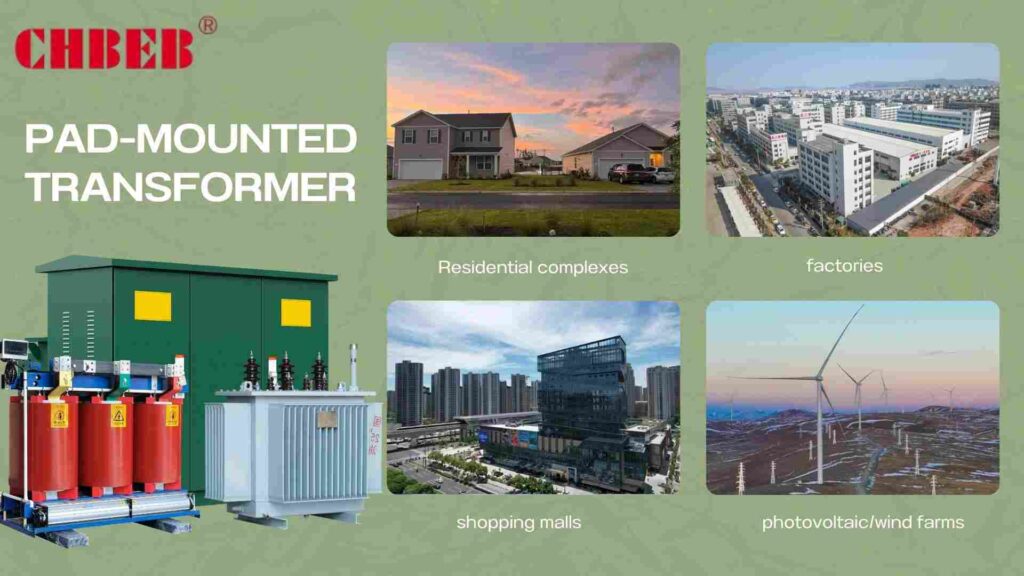

Common Uses: When Pad-Mounted Transformers Are Necessary

Pad-mounted transformers work best in places where safety, access, and looks are important. Their lockable cabinets, dead-front terminations, and small pads make it possible to put them in public areas while yet providing utility-grade protection and ease of maintenance.

- Residential Subdivisions: Single-phase units provide quiet and safe service to neighborhoods. Plan for EV charging and heat-pump use.

- Three-phase provides different daytime peaks, escalators, HVAC, kitchens, and IT loads with balanced voltage in commercial centers and campuses.

- Hospitals and other facilities near data centers can offer more reliable vital services without needing massive substations thanks to redundancy and loop-feed possibilities.

- Three-phase withstands motor starters, welders, and VFD harmonics in industrial sites. Copper windings and strong impedance should be used.

- Renewables (PV/Wind) Blocks: Three-phase units combine inverter/generator output with MV collection systems in the right vector groups.

- Public Venues and Transit: Designs that are quiet and guard against corrosion (C4/C5-M) work well in cities and on the coast.

Getting a Quote and Customization: The Way to a Personalized Solution

A generic BOM doesn’t always fit perfectly. Not doing scoping and options leads to gear that doesn’t fit, hot areas, and change orders. A disciplined quote package makes sure that you follow the rules, know the pricing, and get your order on time.

What Should Be in Your RFQ

- Load Data: peak/diversified kVA, duty cycle, presence of motor/VFD, harmonic limitations, and growth prediction.

- Electrical Spec: MV/LV voltages, vector group, %Z target, tap range, grounding method, BIL, and sound limitations.

- Environment: ambient/altitude, corrosion category, animal guards, ingress protection, and footprint limits.

- Protection and Terminations: dead-front elbows rating, fusing system, surge arrester class, and fault indicators.

- Compliance and Tests: relevant IEC/IEEE standards, regular, type, and special tests, and documentation deliverables.

- Logistics and Schedule: the date the ship needs to leave, the weight limitations for lifting, the details of the pad, how to get to the delivery, the guarantee, and the spare parts.

Customization Options That Often Pay Off

- Loss Packages: Lower assured losses lower the cost of energy over a lifetime and the temperature of the cabinets.

- Cooling Upgrades: ONAF stages and RTDs keep hotspots stable in hot or congested settings.

- Material Choices: Copper windings for strength against heat; aluminum for loads that aren’t too heavy and don’t cost too much.

- Noise Reduction: Low-flux-density cores and dampening near homes or hospitals.

- Corrosion systems include marine-grade coatings and sealed bushings in coastal and arid areas.

- Loop-Feed Cabinets: For campuses that need to stay up, they can transition between sections and alternate sources.

Looking at Quotes Beyond the Price Tag

Turn predicted availability and assured losses into cash. When you factor in the cost of electricity, the danger of downtime, and maintenance, two “equal” bids can be tens of thousands of dollars apart over 20 years.

Basic TCO4: Capex + Civil/Installation + Energy Losses + Maintenance + Downtime Risk − Residual Value

Conclusion

Choosing a pad-mounted transformer is not only about single-phase or three-phase. The right choice means it fits your load, is safe to use, and won’t create hidden costs later.

Single-phase works well for homes and small communities.

Three-phase is better for factories, hospitals, and solar or wind projects.

Oil-filled units are cheaper and strong outdoors; dry-type is safer indoors or where fire risk matters.

Always check the basic specs: kVA size, voltage, and losses. Don’t just look at price — think about energy costs, service, and warranty.

In short: the right transformer is the one that matches your project, is safe, and keeps costs low over time.

- Pad-mounted transformer — Wikipedia ↩︎

- Single-Phase vs. Three-Phase Power — All About Circuits ↩︎

- Transformer Vector Groups — All About Circuits ↩︎

- Total Cost of Ownership — Schneider Electric ↩︎

Learn More About Our Transformers

Want to explore more transformer solutions? Download our latest product catalog or browse our product categories to find the right fit for your project.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group