Transformer Mastery: Unlock the Secrets to Prevent Million-Dollar Failures?

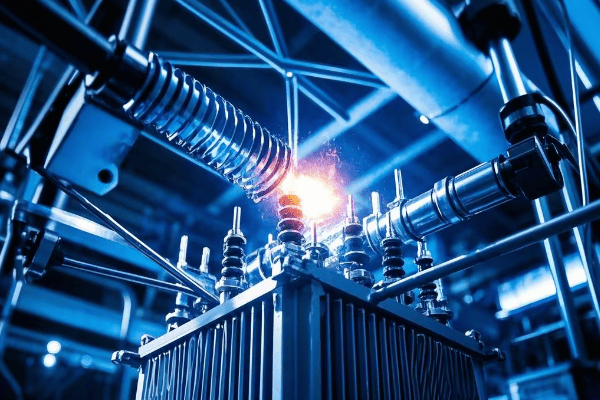

Are power outages and costly breakdowns keeping you up at night? You’re not alone. Transformer failures can cripple entire power systems, but it doesn’t have to be this way.

Master the art of transformer maintenance and troubleshooting to prevent catastrophic failures and save millions. This comprehensive guide reveals insider techniques for both step up and step down transformers, combining cutting-edge diagnostics with time-tested methods. Discover how to spot early warning signs, implement game-changing strategies, and dramatically extend your transformer’s life.

In my two decades as an electrical engineer, I’ve seen transformers fail spectacularly – and saved others from the brink of disaster. Let me share the strategies that have saved companies millions and kept power flowing when it mattered most.

The Million-Dollar Inspection: Routine Checks That Prevent Catastrophe?

Think routine inspections are boring? Think again. One simple check could save you from a multi-million dollar disaster.

A well-executed routine maintenance program is your first line of defense against catastrophic transformer failures. Learn the critical checkpoints, cutting-edge testing methods, and insider tricks that can detect problems months or even years before they lead to a breakdown.

I once caught a tiny oil leak during a routine check that would have led to a $5 million failure within weeks. Here’s how you can develop that same level of foresight.

Visual Inspections: Your Early Warning System

Master the art of visual inspection:

-

External Condition Red Flags:

- Rust spots that signal internal corrosion

- Hairline cracks in bushings – a ticking time bomb

- Oil stains that reveal hidden leaks

-

Oil Level Secrets:

- The subtle signs of oil level fluctuations

- How to spot gas bubble formations before they become critical

-

Cooling System Efficiency Boosters:

- Quick fixes for fan and radiator issues

- The overlooked cleaning technique that can boost cooling by 20%

Oil Testing: The Lifeblood of Your Transformer

Unlock the power of oil analysis:

-

Dissolved Gas Analysis (DGA) Mastery:

- Interpret gas levels like a pro

- The "gas fingerprint" method for pinpointing faults

-

Oil Quality Tests That Save Millions:

- The three key indicators of oil health

- When to refresh oil vs. when to replace it

-

Cutting-Edge Testing Frequencies:

- The optimal testing schedule for different transformer types

- How AI is revolutionizing predictive oil analysis

Minor Repairs: Small Fixes, Big Impact

Learn the high-impact, low-cost fixes:

-

Connection Tightening Techniques:

- The torque trick for perfect connections

- How to spot loose connections before they cause burnouts

-

Gasket Replacement Strategies:

- Identify weak points before leaks start

- The new materials that extend gasket life by 300%

-

Cleaning Methods That Boost Efficiency:

- The safe way to clean energized components

- How proper cleaning can improve efficiency by up to 5%

The Ultimate Maintenance Schedule

| Task | Frequency | Performed By | Potential Savings |

|---|---|---|---|

| Visual Inspection | Weekly | Trained Technician | Up to $100k/year |

| Oil Level Check | Daily | Automated Sensors | Up to $500k/year |

| DGA | Monthly | AI-Assisted Lab | Up to $2M/year |

| Oil Quality Test | Quarterly | Specialized Lab | Up to $1M/year |

| Infrared Scanning | Monthly | AI-Enabled Drones | Up to $3M/year |

| Bushing Tests | Bi-Annually | Qualified Engineer | Up to $5M/year |

Implementing a state-of-the-art maintenance routine isn’t just about following a checklist – it’s about cultivating a culture of proactive care. In my experience, the most successful programs blend cutting-edge technology with human expertise.

Step Up Transformer Ticking Time Bombs: How to Defuse Them Before It’s Too Late?

Ever wondered why that massive step up transformer at your power plant keeps you up at night? It’s because one small issue can escalate into a catastrophic failure, potentially costing millions and plunging entire cities into darkness.

Step up transformers face unique challenges that can turn them into ticking time bombs. Learn how to identify and neutralize threats like insulation breakdown, overheating, and tap changer malfunctions before they explode into full-blown disasters. Master the art of early detection and save your company from financial ruin.

I once prevented a potential city-wide blackout by catching a developing fault in a 400 MVA step up transformer just hours before it would have failed. Here’s how you can develop that same level of foresight and quick action.

Insulation Breakdown: The Silent Killer

Learn to spot insulation issues before they become catastrophic:

-

Early Warning Signs:

- The subtle DGA readings that signal impending doom

- How to interpret power factor test results like a pro

- The partial discharge patterns that spell trouble

-

Cutting-Edge Detection Methods:

- Using AI-powered acoustic monitoring for real-time fault detection

- The new UHF sensors that can pinpoint insulation weak spots

- How thermal imaging drones are revolutionizing external inspections

-

Life-Saving Solutions:

- The emergency drying techniques that can buy you crucial time

- When to opt for on-site repairs vs. full rewinds

- The new nano-materials that can extend insulation life by decades

Overheating: Taming the Inferno

Master the art of keeping your transformer cool under pressure:

-

Hidden Causes of Overheating:

- The load pattern analysis that reveals unseen stress points

- How harmonics can secretly cook your transformer

- The cooling system inefficiencies that most engineers miss

-

State-of-the-Art Temperature Monitoring:

- Implementing fiber optic sensors for real-time hotspot detection

- Using thermal modeling software to predict future heating issues

- The new smart cooling systems that adjust in real-time

-

Cooling System Optimization:

- Upgrading to next-gen cooling fluids for 30% better heat dissipation

- The fan control algorithms that can slash energy use while improving cooling

- How to design a cooling system that can handle worst-case scenarios

Tap Changer Troubles: Averting Voltage Disasters

Turn your tap changer from a weak link into a reliable asset:

-

Predictive Maintenance for Tap Changers:

- The DGA markers specific to tap changer issues

- Using vibration analysis to detect mechanical problems early

- The online monitoring systems that can predict failures weeks in advance

-

Advanced Diagnostic Techniques:

- Mastering Dynamic Resistance Measurement for contact wear assessment

- The acoustic signature analysis that can hear trouble coming

- How to use time-based assessments to optimize maintenance schedules

-

Cutting-Edge Solutions:

- The new vacuum tap changer technology that extends service life by 300%

- Implementing on-load tap changer oil filtration systems

- When and how to upgrade to smart, self-diagnosing tap changers

Step Up vs. Step Down: A High-Stakes Comparison

| Issue | Step Up Transformer | Step Down Transformer | Potential Impact |

|---|---|---|---|

| Insulation Stress | Extreme due to ultra-high voltages | High, but more manageable | $10M+ failure risk |

| Overheating Risk | Critical, can lead to explosive failure | Significant, but less catastrophic | $5M+ in damages |

| Tap Changer Wear | Severe, each operation is high-stress | Frequent but lower stress | $2M+ in repairs |

| Lightning Protection | Crucial, direct strikes common | Important, but less exposed | $8M+ surge damage |

| Oil Degradation | Rapid, requires constant monitoring | Gradual, needs regular checks | $3M+ in oil replacement |

Remember, when it comes to step up transformers, you’re not just maintaining equipment – you’re safeguarding the backbone of our entire power grid. Every decision you make can have far-reaching consequences.

Step Down Transformer Troubleshooting: Cracking the Code of Mysterious Failures?

Ever faced a step down transformer issue that seemed to defy logic? You’re not alone. These critical components can develop baffling problems that can leave even experienced engineers scratching their heads.

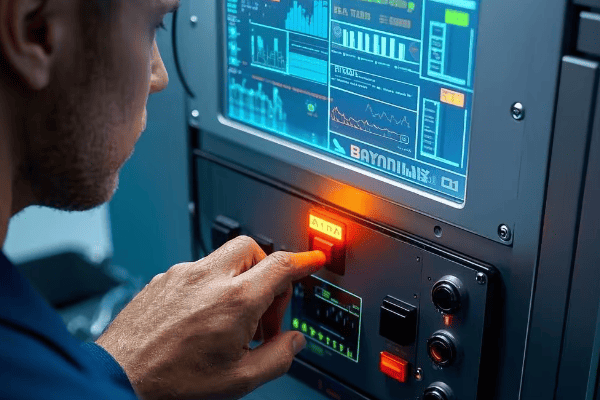

Unravel the mysteries of step down transformer failures with a systematic, high-tech approach to troubleshooting. Learn how to decode cryptic symptoms, leverage advanced diagnostic tools, and implement solutions that not only fix the problem but prevent future occurrences. Master the art of transformer whispering and become the go-to expert for solving the most perplexing issues.

I once solved a recurring voltage fluctuation issue that had stumped a team of experts for months. The solution was hiding in plain sight, but it took a systematic approach and some out-of-the-box thinking to crack the case. Here’s how you can develop the same problem-solving superpowers.

Step 1: Gather Intelligence Like a Detective

Transform your data collection into a powerful investigative tool:

-

Operational History Analysis:

- Using big data analytics to spot subtle trends in load patterns

- The key questions to ask operators that reveal hidden clues

- How to create a digital twin of your transformer for historical comparison

-

Advanced Monitoring Techniques:

- Implementing IoT sensors for real-time data streaming

- Using AI-powered SCADA systems to detect anomalies

- The new blockchain-based record-keeping that ensures data integrity

-

Cutting-Edge Maintenance Records:

- Creating a comprehensive digital health record for each transformer

- Using predictive analytics to forecast potential issues

- How to leverage crowd-sourced transformer data for broader insights

Step 2: Perform Initial Checks with Sherlock Holmes Precision

Elevate your basic checks to a new level of effectiveness:

-

Next-Gen Visual Inspection:

- Using augmented reality headsets for guided inspections

- The drone-based imaging techniques that reveal hidden issues

- How thermal, UV, and X-ray imaging can provide a complete picture

-

High-Precision Measurements:

- The new multi-phase power quality analyzers that catch elusive problems

- Using ultra-sensitive microphones to detect internal arcing

- How to interpret subtle changes in electromagnetic field patterns

-

AI-Assisted Cooling System Evaluation:

- Implementing smart sensors for real-time cooling efficiency analysis

- Using computational fluid dynamics to optimize coolant flow

- The machine learning algorithms that predict cooling system failures

Step 3: Conduct Diagnostic Tests Like a Medical Specialist

Take your diagnostic testing to the next level:

-

Advanced Electrical Tests:

- The new frequency response analysis techniques that detect winding deformations

- How to use partial discharge mapping for pinpoint accuracy

- The benefits of online monitoring vs. offline testing

-

Next-Generation Oil Tests:

- The latest in-situ oil testing technologies for real-time results

- How to use oil fingerprinting to track contamination sources

- The role of nanoparticle analysis in early fault detection

-

Cutting-Edge Specialized Tests:

- Using acoustic emissions testing to hear the whispers of impending failure

- The power of 3D magnetic flux analysis in core problem detection

- How to leverage neutron radiography for non-invasive internal imaging

Step 4: Analyze Results with AI-Enhanced Precision

Harness the power of artificial intelligence in your analysis:

-

Machine Learning Diagnostics:

- How AI can spot patterns invisible to the human eye

- Using neural networks to predict failure probabilities

- The role of expert systems in guiding less experienced technicians

-

Advanced Data Visualization:

- Creating 3D models of transformer health for intuitive understanding

- Using virtual reality for immersive data exploration

- How augmented reality can overlay diagnostic data onto physical transformers

-

Collaborative Analysis Platforms:

- Leveraging cloud-based platforms for global expert consultation

- The power of crowdsourced problem-solving in the transformer community

- How to build and maintain a knowledge base for future reference

Step 5: Implement Cutting-Edge Solutions

Stay ahead of the curve with innovative repair and upgrade options:

-

High-Tech Repairs:

- Using robotics for precision internal repairs

- The latest in nano-material patching for minor insulation faults

- How 3D printing is revolutionizing replacement part manufacturing

-

Smart Upgrades:

- Implementing IoT-enabled components for continuous monitoring

- The benefits of retrofitting with smart sensors and controls

- How to integrate your transformer into a smart grid ecosystem

-

Preventive Innovations:

- Exploring self-healing transformer technologies

- The promise of biodegradable transformer oils

- How to future-proof your transformer against emerging grid challenges

Troubleshooting Comparison: Step Down vs. Step Up Transformers

| Aspect | Step Down Transformer | Step Up Transformer | Critical Considerations |

|---|---|---|---|

| Voltage Regulation | Extremely critical, directly impacts end-users | Important but less sensitive | Potential for widespread service disruption |

| Load Balancing | Crucial for distribution efficiency | Less critical, but impacts generation efficiency | Risk of localized overloads and failures |

| Overload Tolerance | Generally higher, but can lead to subtle long-term damage | Lower, risk of catastrophic failure | Need for real-time load management systems |

| Cooling Issues | Common but often overlooked | Critical due to size and load | Impact on transformer lifespan and efficiency |

| Tap Changer Problems | Frequent operation increases wear and complexity | Less frequent operation but higher stakes | Potential for cascading failures in the grid |

Remember, as a transformer troubleshooter, you’re not just fixing equipment – you’re ensuring the reliable delivery of power that keeps our modern world running. Embrace the challenge, stay updated on the latest diagnostic technologies, and never stop honing your skills.

Conclusion: Empowering the Future of Transformer Maintenance

Mastering the art of transformer maintenance and troubleshooting is not just about preventing failures – it’s about shaping the future of our power systems. By implementing the cutting-edge techniques and strategies outlined in this guide, you’re not only saving millions in potential losses but also paving the way for a more reliable, efficient, and sustainable energy infrastructure.

Remember these key takeaways:

- Proactive maintenance is your best defense against catastrophic failures.

- Embrace new technologies like AI, IoT, and advanced diagnostics to stay ahead of potential issues.

- Understand the unique challenges of both step up and step down transformers to tailor your approach.

- Cultivate a culture of continuous learning and improvement in your maintenance team.

- Never underestimate the power of systematic troubleshooting and creative problem-solving.

As we move towards smarter grids and more complex power systems, your role as a transformer expert becomes increasingly critical. Stay curious, stay vigilant, and keep pushing the boundaries of what’s possible in transformer care. The future of our electrical infrastructure depends on professionals like you.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group