The Core of Transformer Selection: kVA Calculation, Starting Factors & Key Parameters| CHBEB

Introduction

If you choose the wrong transformer, you could end up with overloads, voltage drops, and expensive downtime. A lot of purchasers have trouble with kVA, starting variables, and picking the right materials. This guide goes over the basics so you can choose the right transformer size and design for your project.

Transformer Capacity Basics: What kVA and the Starting Factor Mean

People commonly mix up kVA and kW or forget how much power a motor needs to start. This causes units to be too small and to break down. Before making decisions about materials or costs, you need to know the basics of capacity.

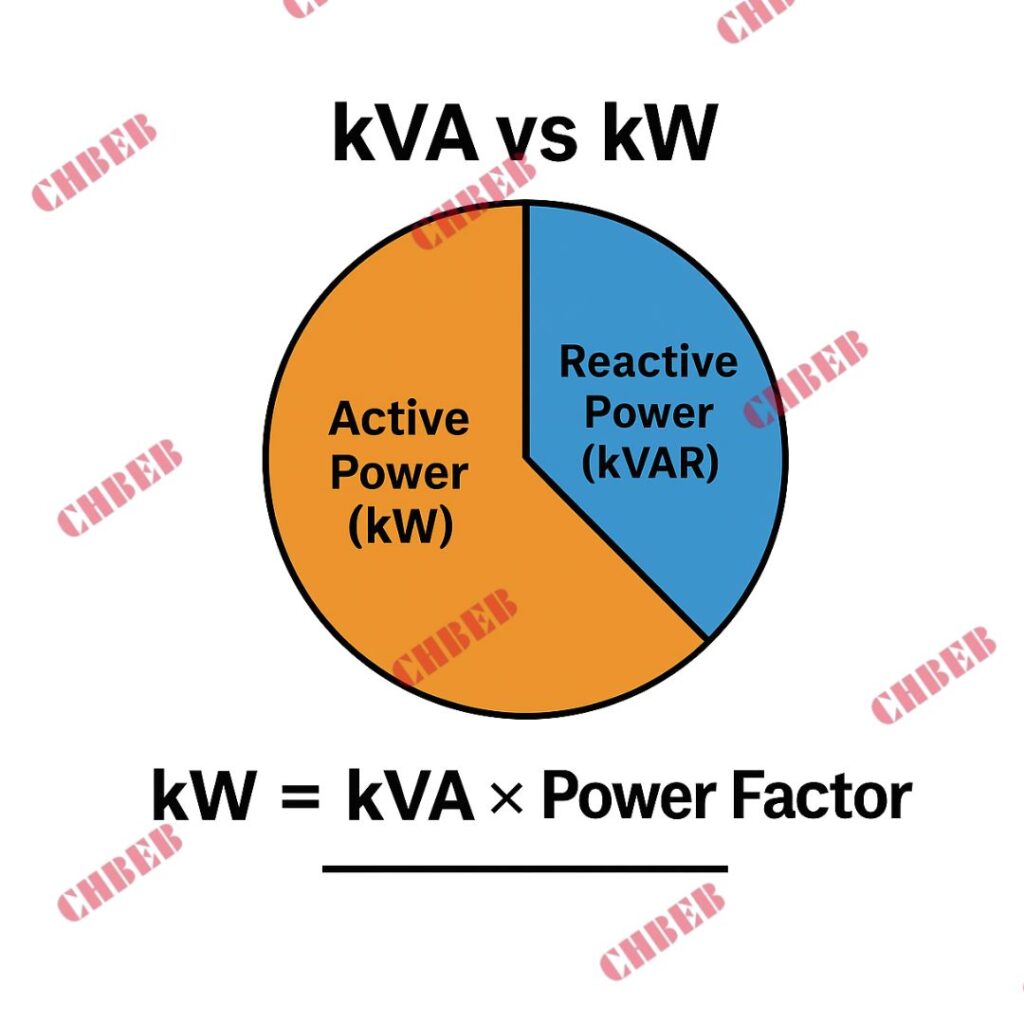

What do kVA and kW1 mean? Why do we rate transformers in kVA?

Transformers are rated in kVA (kilovolt-ampere) instead of kW since they give off both active power (kW) and reactive power (kVAR). Power factor (PF) determines how much power can be used.

- The formula for kW is kVA × PF.

- For instance, a 100 kVA transformer with a 0.8 PF gives forth 80 kW of real power.

Transformers are always rated in kVA since the power factor (PF) changes depending on the kind of load (motors, lighting, electronics).

Formulas for calculating the kVA of a transformer (single-phase and three-phase)

If you don’t use formulas, you could end up with too big or too small of a size, which could be dangerous. The answer is to use the proper formula for each situation.

- Single-phase: kVA=V×I1000kVA = \frac{V × I}{1000}kVA=1000V×I Example: 240 V × 100 A = 24,000 VA = 24 kVA

- Three-phase: kVA=3×V×I1000kVA = \frac{\sqrt{3} × V × I}{1000}kVA=10003×V×I Example: 415 V × 100 A × 1.732 = 71,800 VA = 71.8 kVA

What is a factor that starts? How to Figure Out How Much kVA You Need to Start a Motor

Underrated designs break down when motors start up, when the inrush might be 4–7 times the entire load current. To figure out the kVA of a transformer, you need to use a beginning factor.

- kVAneeded = MotorHP × 0.746Efficiency × PF × Starting Factor kVA_{required} = Motor HP × 0.746{Efficiency × PF} × Starting FactorkVAneeded=Efficiency×PFMotorHP × 0.746 × Starting Factor

- For a reliable starter, a 75 HP motor with 0.9 efficiency, 0.85 PF, and 6× inrush needs a transformer with a capacity of about 440 kVA.

Case Study: How to Figure Out the Total Load and Transformer Capacity for an Industrial Workshop

A workshop has:

- 2 × 50 HP motors

- 1 × 30 HP motor

- Lighting load 20 kW

Step 1: Convert motor HP to kW

- 50 HP = 37.3 kW × 2 = 74.6 kW

- 30 HP = 22.4 kW

- Lighting = 20 kW

- Total = 117 kW

Step 2: Use PF (0.85) and Efficiency (0.9) 117 ÷ (0.85 × 0.9) = 153 kVA

Step 3: Add a starting factor for motors (with a safety margin of ×1.25)

Final transformer capacity needed is about 190 kVA.

Result: Pick a 200 kVA transformer to handle the starting and load g

Balancing Performance & Cost: Choosing Winding Material & Cooling Method

A lot of buyers pay too much for copper or don’t think about how much cooling they need. Both errors raise costs or shorten the life of the product. The best way to get the right balance is to look at winding and cooling simultaneously.

A Close Look at the Pros, Cons, and Costs of Copper and Aluminum Windings

- Windings of copper

- More conductivity means less loss.

- Smaller size, better in handling overloads

- More expensive at first

- Windings made of aluminum

- Less expensive, lighter

- Needs bigger cross-sections to match copper

- Losses that are a little higher

Comparison Table

| Factor | Copper | Aluminum |

|---|---|---|

| Conductivity | High | ~61% of copper |

| Size & Weight | Smaller, heavier density | Larger, lighter metal |

| Cost | Higher | Lower |

| Durability | Superior | Good with modern alloys |

| Best Fit | Critical/continuous loads | Cost-sensitive projects |

A Full Guide to Transformer Cooling: Natural vs. Forced, Dry-Type vs. Oil-Immersed

Mistakes in cooling might lead to overheating and insulation failure. The answer is to match the type of cooling to the conditions at the site.

- Dry-Type Transformers

- Air cooling (natural or forced)

- Safer indoors, higher cost, lower ratings

- Oil-Immersed Transformers

- Mineral oil or ester fluid

- Efficient cooling, outdoor use, fire precautions needed

Cooling Methods:

- ONAN stands for “Oil Natural Air Natural.”

- ONAF (Oil Natural Air Forced)

- Oil Directed Air Forced (ODAF)

- AN/AF (Air Natural/Air Forced for dry types)

How to Choose the Best Material and Cooling Method for Your Needs

Hospital or high-rise building inside? Pick the dry variety with copper windings.

Substation or renewable farm outside? Choose oil with aluminum in it (this is the cheapest option).

Heavy industry with burdens that don’t stop? Copper + oil for the best durability.

Ensuring Long-Term Reliability: Other Critical Selection Factors

A lot of purchasers only look at kVA and material. Not taking into account power factor, voltage, and the environment might cause early failures. The answer is to think about important details that were missed.

The Importance of Power Factor and How to Fix It

Bad PF equals wasted space and fines. Using capacitor banks or active filters to fix things makes transformers smaller, lowers losses, and makes the system work better.

Ambient Conditions, Voltage, and Losses: The Details That Are Often Missed When Choosing

- High temperatures necessitate derating.

- Altitude: More over 1000 m makes cooling less effective.

- Voltage Changes: Make sure the tap changer range meets the stability of the grid.

- Losses: Ask for guaranteed no-load/load losses; these add to the cost of energy over time.

Your FAQs and Transformer Selection Checklist

List of things to do:

- ✔ Figure out kVA (beginning factors included)

- ✔ Check PF and make any necessary changes

- ✔ Pick between aluminum and copper windings

- Choose cooling based on the conditions at the place.

- ✔ Think about the weather: the temperature, the height, and the humidity

- ✔ Look for IEC, ANSI, and GB certifications.

- ✔ Compare capital expenditures to operating expenses during the life of the project

Questions and Answers:

- Why do we rate transformers in kVA instead of kW? This is because they give both active and reactive power.

- Copper windings are cheaper than aluminum windings, but aluminum is bigger.

- Which lasts longer, dry type or oil immersed? With the right care, oil-immersed things usually endure longer.

Conclusion

Choosing the right transformer is not just about picking a size off the shelf—it requires a structured approach.

- Start with capacity: Calculate the kVA correctly, including motor starting factors, to prevent overloads and hidden downtime costs.

- Balance materials and cooling: Copper vs. aluminum windings2 and dry-type vs. oil-immersed designs should be chosen based on application, cost targets, and safety needs.

- Account for operating conditions: Power factor, temperature, altitude, and guaranteed loss values directly impact lifetime performance and energy costs.

- Think lifecycle, not just purchase price: Compare CAPEX with OPEX over 20–30 years to secure the best ROI.

✅ Final takeaway: The best transformer is the one that matches your kVA demand, starting profile, and site environment, while balancing safety, performance, and cost. A well-specified design ensures reliable operation and long-term savings.

Learn More

Looking for the right dry-type transformer for your project? Download our latest product catalog or browse our product categories to find reliable solutions tailored to your needs.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group