The Shocking Truth: What Really Causes a Transformer to Blow?

The 5 Main Reasons Why Transformers Fail

Problem: Failures don’t happen by chance. Agitate: When they hit, you have to deal with outages, safety issues, and expensive replacements. Solution: Deal with these five primary problems early on so that “surprise” incidents become regular maintenance tasks.

Overloading: The Quiet Killer

Constant loading above the nameplate rating causes winding hot spots, speeds up the aging of paper, and weakens the dielectric strength. Seasonal peaks, unapproved tie-ins, or growth that is too low might cause a “healthy” unit to go into thermal runaway.

- Make it safer: Plan for capacity growth or install a parallel unit when the trend peak/average load is reached.

- Stay calm: Keep an eye on the temperatures and deaths in hot spots, and turn on the designed fan and pump stages (for example, ONAN → ONAF).

- Plan ahead instead of praying: effective kVA selection and demand control are better than emergency replacements.

Short Circuits: The Quick Rise

Fault currents create enormous electrodynamic forces that change the shape of windings and hardware. Mechanical changes make clearances smaller, which can lead to repeated faults or flashover.

- Your playbook: Set up protection (relays, fuses, and breakers) so that problems clear quickly and only when they need to.

- Look at the skeleton: Torque audits and bracing checks make sure that the insides stay in place.

- After a fault, do a sanity check by running SFRA1 to find any winding movement before you power it back on.

Insulation Failure: The Breakdown Inside

Heat, moisture, and other pollutants break down oil/paper (or resin), which lowers the breakdown voltage. Micro-defects cause partial discharge, which leads to a flashover.

- Stay ahead: Regular testing for DGA2, BDV, moisture (ppm), acidity, and power factor (tan δ).

- Stay dry: Keep breathers, gaskets, and seals in good shape, and patch leaks right away.

- For dry types, keep an eye out for cracks in the resin and dust. You might want to think about doing partial discharge testing.

Lightning Strikes and Outside Surges

Bushings and windings are hit by atmospheric impulses and switching transients that have a steep front. Insulation gets holes in it if there aren’t the right pathways.

- To protect against it, put MOV surge arresters3 next to bushings and check that the grounding is strong.

- Keep it tidy: Check and clean the bushings to stop tracking and surface flashover.

- Use RC snubbers or pre-insertion resistors when you need to to tame switching spikes.

Age and bad upkeep

Oxidation of the oil, sludge, unsecured connections, rusted taps, and worn OLTC contacts all quietly create the stage for disaster. Aging isn’t bad; it’s not taking care of it that is.

- Do the plan: Set clear limits on both time-based and condition-based maintenance.

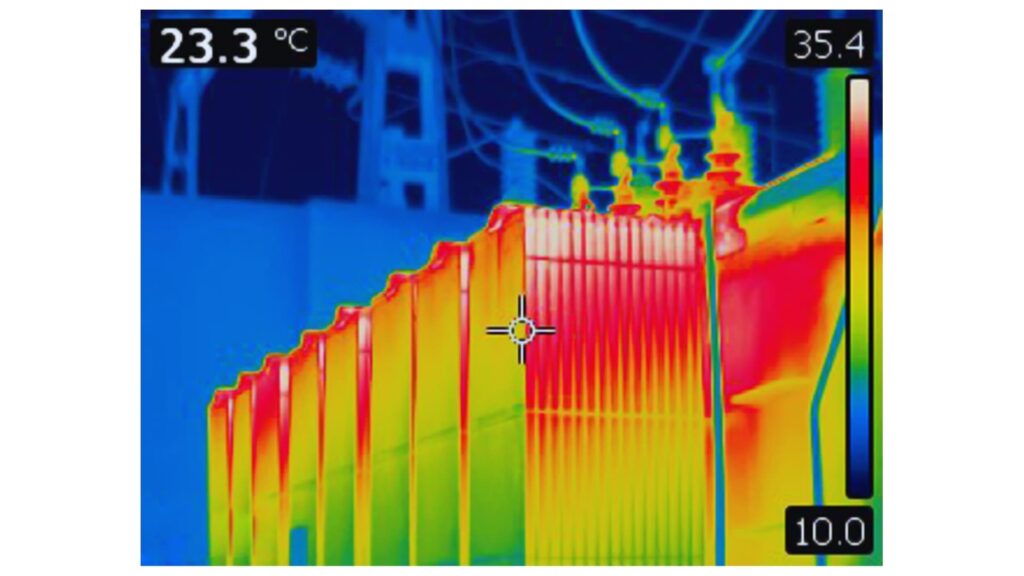

- Look at the heat: Thermography shows heated joints, and torque audits repair them.

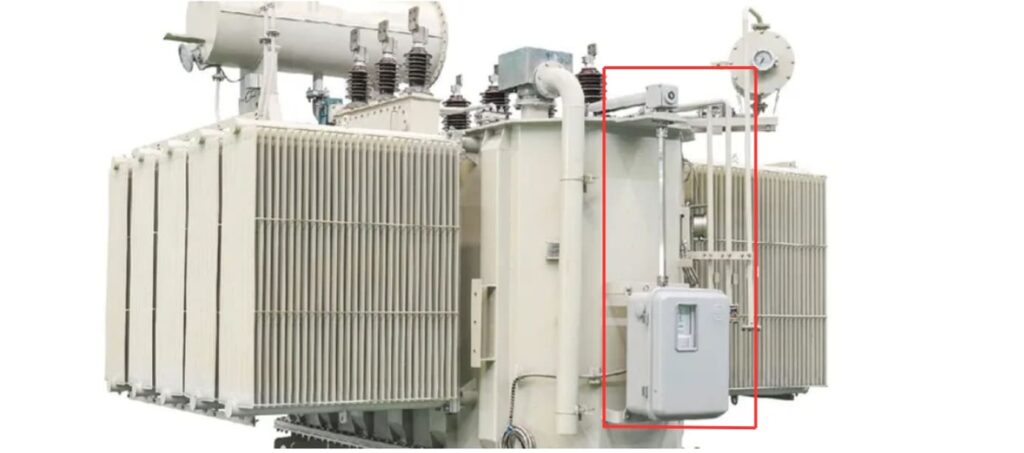

- OLTC4 love: Check contacts, check resistance, and service on time.

Quick Reference: What Causes It, What to Look For, and How to Avoid It

| Cause | The Science | Early Symptoms | How You Stay Safe |

|---|---|---|---|

| Overloading | Thermal aging reduces dielectric strength | High top-oil, frequent fans, thermal alarms | Load studies, uprating/parallel units, cooling upgrades |

| Short Circuits | Electrodynamic forces deform windings | Nuisance trips, abnormal noise, SFRA drift | Protection coordination, bracing checks, post-fault tests |

| Insulation Failure | Moisture/heat/contamination lower BDV | Rising moisture, high tan δ, DGA fault gases | DGA, oil treatment, IR/PI, sealing & breathers |

| Lightning/Surges | Steep impulses puncture insulation | Bushing tracking, arrester operations logged | MOV arresters, earthing, surface cleaning |

| Poor Maintenance/Age | Oxidation, sludge, loose joints | IR hot spots, OLTC arcing, sludge in oil | CBM + TBM, oil care, torque audits, OLTC service |

Beyond the Boom: How to See the Signs and Stay Safe

Problem: Explosions seem to happen right away. Agitate: In real life, clues show up weeks before they should. The greatest way to keep things from happening again is to learn the warning signs and the correct first steps.

Important Signs That a Transformer Is Failing

- Changes in sound: a louder hum, crackling, or random “pops.”

- Heat anomalies: a lot of high top-oil and hot-spot alarms; IR scans showing hot spots that are targeted.

- Electrical signs: tan δ is going up, IR/PI is going down, and SFRA traces are not typical.

- DGA alerts: spikes in hydrogen, acetylene, or ethylene patterns that show arcing or thermal problems.

- Oil/visual signs: Lower BDV, black oil, rising moisture ppm, bushing tracking, and leaks.

- Protection activity: More trips or arrester counter increases.

What Happens After an Explosion? A Quick Guide

- To isolate power, turn it off, lock it up, and make sure the location is safe.

- Set up an exclusion zone: Treat oil fires like Class B fires and execute the emergency plan for the site.

- Tell people and contain the spill: Call the utility or OEM and set up spill kits and environmental barriers.

- Check the PRD, Buchholz5/sudden-pressure relays, bushings, and tank integrity to stop re-energization.

- Record and take samples: pictures, relay logs, arrester counts, and oil/DGA if it’s safe.

- Find the root cause by doing a mechanical check, an SFRA, winding resistance tests, and insulation testing.

If there is a fire or you think there is internal arcing, you should leave the building and allow trained responders put it out.

From Failure to Fix: Real-World Ways to Stop Problems

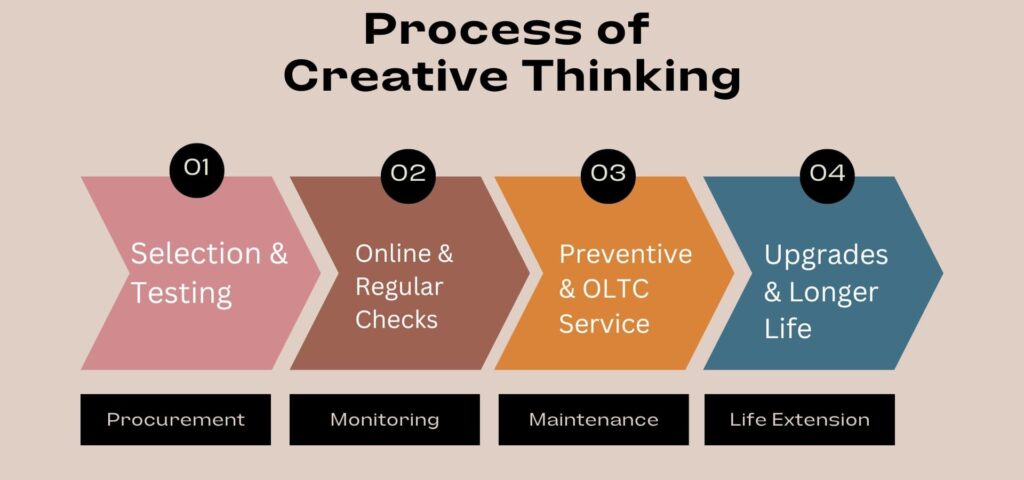

The problem is that replacing broken units takes a long time and costs a lot of money. Agitate: It’s worse to keep making the same mistake. The answer is to use modern monitoring and preventive maintenance to make things last longer and lower the danger.

The Strength of Preventive Maintenance

Make a condition-based maintenance (CBM) strategy that includes regular testing and specific actions and thresholds. This way, decisions are based on evidence, not gut feelings.

- Routine tests: DGA + furan, moisture (ppm), BDV, acidity; IR/PI and tan δ (winding/bushings).

- SFRA and winding resistance are two things that affect mechanical health. Use published torque settings to tighten hardware.

- Check fans and pumps, clean radiators, replace desiccant, and rectify leaks as soon as you find them.

- OLTC maintenance: verify the contacts, verify the contact resistance, and service them according to the OEM’s schedule.

- Trend it: Use dashboards to look at temperatures, DGA gases, test results, and arrester numbers. Don’t just look at snapshots.

How technology is making transformers safer

- DGA (H2, C2H2), moisture-in-oil, bushing leakage current, hot-spot RTDs, and OLTC motor current are all monitored online all the time.

- IIoT alarms: Tickets are triggered by real-time thresholds, and the event context is saved for speedier response.

- Analytics and AI: Pattern recognition can tell you when insulation is getting old, where hotspots are, and when problems are about to happen.

- Better surge protection: High-energy MOV arresters and clean, low-impedance earth pathways help protect against impulse damage.

- Digital twins: Use thermal profiles and load optimization to reduce loss of life.

Do you need a plan for stopping something? We can map tests, intervals, and thresholds to your fleet and then match surge protection and capacity planning to your risk profile.

Conclusion

Transformers don’t usually “blow” without notice. Overloading, malfunctions, insulation breakdown, surges, and not keeping things up to date leave an obvious trail. To protect people and uptime and lower the entire lifetime cost, pay attention to the signals, act on the data, and engage in proactive monitoring.

FAQ

Q1: What is the most common reason a transformer blows?

Overloading and insulation deterioration are leading causes. Heat accelerates paper aging, lowering dielectric strength until a fault occurs.

Q2: Can a transformer fail without warning?

Rarely. Early signs—abnormal noise, hot spots, rising DGA gases, or repeated protection trips—usually appear weeks or months ahead.

Q3: How often should I test transformer oil?

For critical units, perform quarterly DGA and annual comprehensive oil tests (BDV, moisture, acidity). Adjust frequency based on trends.

Q4: Do surge arresters prevent lightning damage completely?

They greatly reduce risk but require correct rating, placement near bushings, solid earthing, and periodic health checks.

Q5: Is replacement always necessary after an explosion?

Not always. After safe isolation and inspection, repairs may be feasible. A full root cause analysis (SFRA, DGA, mechanical checks) guides the decision.

- Sweep Frequency Response Analysis (SFRA) — ↩︎

- Dissolved Gas Analysis (DGA) — ↩︎

- Lightning arrester (MOV surge arresters) — ↩︎

- Tap changer (On-load tap changer, OLTC) — ↩︎

- Buchholz relay — ↩︎

Want to explore more transformer insights or choose the right model for your project? Visit our homepage for full product details, or download our product catalog to see technical specifications and solutions tailored for you.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group