Types of Fuses Explained: Cartridge, Blade, Resettable, and More?

At first glance, a fuse might seem like a simple electrical component. But walk into any industrial warehouse or browse an electronics catalog, and you’ll quickly realize there are dozens of fuse types—each with different shapes, sizes, voltage ratings, and response times.

Fuses come in various types to meet diverse electrical protection needs. Common types include cartridge fuses for high-current industrial applications, blade fuses for automotive use, and resettable fuses for consumer electronics. Each type offers unique features like high interrupting capacity, compact size, or reusability. Specialized fuses exist for high-voltage systems, surface-mount devices, and utility applications. Choosing the right fuse type depends on factors like voltage, current, installation space, and specific application requirements.

In this guide, I’ll walk you through the main fuse types available on the market, their core features, typical applications, and how to confidently choose the right one for your project or product. Whether you’re a procurement manager, maintenance technician, or electrical engineer, understanding these differences is crucial for ensuring proper circuit protection and equipment safety.

Overview: Why Different Fuse Types Exist?

Have you ever wondered why there are so many different types of fuses? Or perhaps you’ve been confused about which fuse to use in a specific application? The variety of fuse types can be overwhelming, but there’s a good reason for this diversity.

Different fuse types exist because of the wide range of electrical protection needs across various industries and applications. Factors like voltage levels, current requirements, physical space constraints, and specific operating conditions necessitate specialized fuse designs. For example, automotive systems need compact, easily replaceable fuses, while industrial equipment requires high-capacity fuses that can handle large fault currents. The diversity in fuse types ensures optimal protection for each unique electrical system.

Key Factors Driving Fuse Diversity

Let’s explore the main reasons behind the variety of fuse types:

- Voltage and Current Ratings

- Physical Size and Installation Requirements

- Response Time and Interrupting Capacity

- Environmental Considerations

- Industry-Specific Standards

Voltage and Current Ratings

Meeting diverse electrical system needs:

- Low voltage DC for automotive (12-24V)

- Household AC (120-240V)

- Industrial power systems (up to 600V or higher)

I recall a project where we had to retrofit an old industrial control panel. The challenge was finding fuses that could handle the high voltage while fitting into the limited space of the existing fuseholders. This experience highlighted how crucial it is to have fuses designed for specific voltage and current ranges.

Physical Size and Installation Requirements

Adapting to various equipment designs:

- Compact blade fuses for automotive applications

- Cylindrical cartridge fuses for industrial panels

- Surface-mount fuses for printed circuit boards

During a recent electric vehicle design consultation, we had to balance the need for high-current protection with the limited space in the vehicle’s fuse box. This led us to choose specialized compact high-current fuses, showcasing how physical constraints drive fuse design innovation.

Response Time and Interrupting Capacity

Matching protection to load characteristics:

- Fast-acting fuses for sensitive electronics

- Time-delay fuses for motors with inrush currents

- High interrupting capacity for potential high fault currents

Here’s a quick comparison of fuse response characteristics:

| Fuse Type | Response Time | Typical Application |

|---|---|---|

| Fast-Acting | < 1 ms | Electronics, Semiconductors |

| Time-Delay | 10-30 ms | Motors, Transformers |

| Very Fast-Acting | < 0.1 ms | Power Semiconductors |

Environmental Considerations

Designing for specific operating conditions:

- High-temperature fuses for engine compartments

- Sealed fuses for outdoor or marine applications

- Vibration-resistant designs for mobile equipment

Industry-Specific Standards

Meeting regulatory and safety requirements:

- UL standards for North American markets

- IEC standards for international applications

- Specialized standards for automotive, aerospace, etc.

Key points about fuse type diversity:

- Voltage and current requirements vary widely across applications

- Physical size constraints necessitate different fuse form factors

- Load characteristics demand various response times and capacities

- Environmental factors influence fuse design and materials

- Industry standards drive specific fuse type developments

In my experience, understanding the reasons behind fuse diversity is crucial for proper selection. I once consulted on a solar power installation where the initial design used standard AC fuses for DC circuits. This oversight could have led to dangerous arcing in fault conditions. By explaining the need for specialized DC fuses designed for photovoltaic systems, we ensured a safer and more reliable installation.

For example, in a recent smart home project, we had to integrate protection for both high-power appliances and sensitive IoT devices. This required a mix of fuse types, from robust time-delay fuses for HVAC systems to ultra-fast, low-current fuses for smart sensors. This diversity in a single application underscores why different fuse types are not just useful, but essential for comprehensive electrical protection.

As we move on to discuss specific fuse types in detail, keep in mind that each type has been developed to address particular protection needs. Understanding these nuances is key to selecting the right fuse for your application.

Cartridge Fuses: Reliable Protection for High-Current Circuits?

Have you ever wondered what protects large industrial machines or power distribution panels from electrical overloads? Or perhaps you’ve seen those cylindrical fuses in your home’s main electrical panel and wondered why they’re shaped that way? Cartridge fuses play a crucial role in high-current circuit protection, but what makes them so reliable?

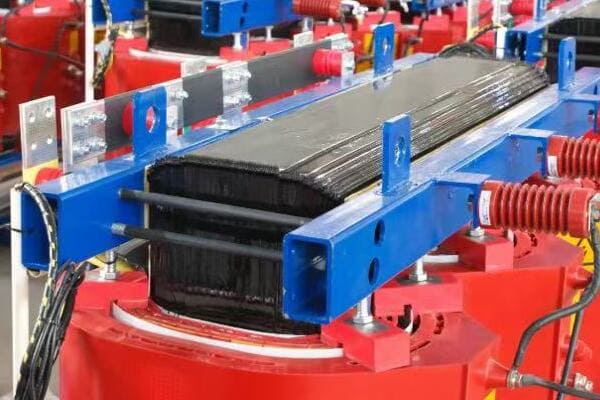

Cartridge fuses are cylindrical protective devices designed for high-current and high-voltage applications. They consist of a fuse element enclosed in a ceramic or glass body with metal end caps. These fuses offer high interrupting capacity, typically up to 200kA or more, making them ideal for industrial and commercial power systems. Cartridge fuses come in various sizes and ratings, from small 1/4" x 1-1/4" glass fuses for household use to large 3" x 15" fuses for industrial applications. Their robust construction and standardized dimensions make them reliable and easy to replace in a wide range of electrical systems.

Key Aspects of Cartridge Fuses

Let’s explore the main features and applications of cartridge fuses:

- Structure and Design

- Types and Ratings

- Applications in Various Industries

- Advantages and Limitations

- Installation and Replacement Considerations

Structure and Design

The anatomy of a cartridge fuse:

- Ceramic or glass body for insulation and arc suppression

- Metal end caps for electrical contact

- Internal fuse element (usually silver or copper)

- Sand or other arc-quenching material (in some types)

I recently had the opportunity to dissect a blown cartridge fuse during a training session. The intricate design of the fuse element and the way it was surrounded by arc-quenching material really highlighted the engineering that goes into these seemingly simple devices.

Types and Ratings

Variety to meet different needs:

- Voltage ratings from 250V to 600V AC (or higher for special types)

- Current ratings from less than 1A to over 1000A

- Time-delay or fast-acting characteristics

- Class designations (e.g., Class CC, J, L) for specific applications

During a recent industrial automation project, we had to carefully select cartridge fuses for motor protection. The challenge was finding fuses that could handle the motor’s startup current without nuisance tripping, while still providing fast protection against short circuits. This experience underscored the importance of understanding different fuse characteristics.

Applications in Various Industries

Wide range of uses:

- Industrial control panels and motor circuits

- Commercial and residential electrical distribution

- HVAC systems and large appliances

- Renewable energy systems (solar, wind)

Here’s a quick reference for common cartridge fuse applications:

| Industry | Typical Application | Fuse Class | Current Range |

|---|---|---|---|

| Industrial | Motor Protection | Class RK5 | 1-600A |

| Commercial | Main Distribution | Class J | 1-600A |

| Residential | Service Entrance | Class T | 1-1200A |

| Renewable Energy | Solar Inverters | Class gPV | 1-400A |

Advantages and Limitations

Weighing the pros and cons:

- Advantages: High interrupting capacity, wide range of ratings, robust construction

- Limitations: One-time use, can be larger than some alternatives

Installation and Replacement Considerations

Ensuring proper use and maintenance:

- Importance of using the correct fuse class and rating

- Safety procedures for fuse replacement

- Considerations for fuse coordination in a system

Key points about cartridge fuses:

- They offer high interrupting capacity for industrial applications

- Various types and ratings are available for different needs

- Cartridge fuses are used across multiple industries

- They provide reliable protection but are one-time use devices

- Proper selection and installation are crucial for effective protection

In my experience, the versatility of cartridge fuses makes them indispensable in many electrical systems. I recall a project where we were upgrading an old factory’s electrical system. The existing fuses were a mix of outdated types, some of which were no longer manufactured. By standardizing on modern cartridge fuses, we not only improved the system’s safety and reliability but also simplified maintenance and replacement procedures for the facility staff.

For example, in a recent data center project, we implemented a tiered protection scheme using different classes of cartridge fuses. Class L fuses protected the main feeders, while Class J fuses safeguarded branch circuits. This approach allowed for excellent coordination between protective devices, ensuring that faults were isolated at the lowest possible level, minimizing disruption to the data center’s critical operations.

As we move on to discuss blade fuses, remember that while cartridge fuses excel in high-current applications, each fuse type has its own strengths and ideal use cases. Understanding these differences is key to designing safe and efficient electrical systems.

Blade Fuses: Compact and Standardized for Automotive Use?

Have you ever popped the hood of your car and noticed those colorful plastic components in the fuse box? Or perhaps you’ve had to replace a fuse in your vehicle and were surprised by its small, flat design? These are blade fuses, but what makes them so well-suited for automotive applications?

Blade fuses are compact, plug-in style fuses primarily used in automotive electrical systems. They feature a plastic housing with two prong-like terminals and a visible fusible link. Blade fuses are color-coded for easy identification of their amperage rating, ranging typically from 2A to 40A. Their standardized design allows for quick, tool-free replacement and compact fuse box layouts. While primarily used in vehicles, blade fuses have also found applications in marine, recreational vehicles, and some small appliances due to their reliability and ease of use in low-voltage DC systems.

Key Aspects of Blade Fuses

Let’s explore the main features and applications of blade fuses:

- Design and Construction

- Types and Ratings

- Advantages in Automotive Applications

- Color Coding System

- Installation and Troubleshooting

Design and Construction

The anatomy of a blade fuse:

- Plastic housing for insulation and color coding

- Two blade-like terminals for easy insertion and removal

- Visible fusible link for quick inspection

- Compact, space-saving design

I remember the first time I worked on a car’s electrical system as a young engineer. The simplicity and accessibility of blade fuses made the task much less daunting than I had anticipated. This experience really highlighted the user-friendly design of these components.

Types and Ratings

Variety to meet different automotive needs:

- Standard blade fuses (ATO/ATC): Most common type

- Mini blade fuses: For tight spaces in modern vehicles

- Maxi blade fuses: For higher current applications

- Current ratings typically from 2A to 40A (up to 100A for some maxi types)

- Voltage rating usually 32V DC

During a recent electric vehicle (EV) design consultation, we had to carefully select blade fuses for various circuits. The challenge was balancing the need for higher current capacities in some EV-specific systems while maintaining compatibility with standard automotive fuse boxes. This project showcased the evolving needs in automotive electrical protection.

Advantages in Automotive Applications

Why blade fuses excel in vehicles:

- Compact size allows for dense fuse box layouts

- Easy to inspect and replace without tools

- Resistant to vibration and temperature fluctuations

- Standardized design across manufacturers

Here’s a quick comparison of common blade fuse types:

| Type | Size (mm) | Current Range | Typical Use |

|---|---|---|---|

| Mini | 10.9 x 3.6 | 2A – 30A | Modern vehicles, tight spaces |

| Standard (ATO) | 19.1 x 5.1 | 2A – 40A | Most automotive applications |

| Maxi | 29.2 x 8.5 | 20A – 100A | High-current vehicle systems |

Color Coding System

Simplifying identification and replacement:

- Each amperage rating has a specific color

- Universal across manufacturers for easy identification

- Ranges from gray (2A) to orange (40A) in standard types

Installation and Troubleshooting

Ensuring proper use and maintenance:

- Importance of using the correct amperage rating

- How to safely check and replace blade fuses

- Common signs of electrical issues in automotive systems

Key points about blade fuses:

- They are designed specifically for automotive electrical systems

- Blade fuses come in various sizes for different current needs

- Their compact and standardized design offers many advantages in vehicles

- Color coding simplifies identification and replacement

- Proper selection and installation are crucial for vehicle electrical safety

In my experience, the standardization of blade fuses has greatly simplified automotive electrical maintenance. I recall a project where we were retrofitting classic cars with modern electrical systems. The switch to blade fuses not only improved reliability but also made it much easier for owners to perform basic electrical troubleshooting and maintenance.

For example, in a recent marine electrical system design, we adapted automotive-style blade fuses for use in boats. The compact size and ease of replacement made them ideal for the tight spaces in marine applications. We even implemented a custom fuse box design that maintained the benefits of blade fuses while ensuring protection against the corrosive marine environment.

As we move on to discuss resettable fuses, remember that while blade fuses are primarily associated with automotive use, their design principles of compactness and ease of use have influenced other areas of electrical protection as well.

Resettable Fuses (PTC): Smart Reusability for Consumer Electronics?

Have you ever wondered why some electronic devices seem to recover on their own after an electrical fault? Or perhaps you’ve heard of "self-healing" circuits and wondered how they work? Resettable fuses, also known as polymeric positive temperature coefficient (PTC) devices, are behind this smart protection. But what makes them so unique and suitable for consumer electronics?

Resettable fuses, or PTC devices, are polymer-based components that increase their resistance dramatically when heated by excessive current. Unlike traditional fuses, they don’t need replacement after activation. Once the fault is cleared and power removed, they cool down and return to a low-resistance state. This self-resetting feature makes them ideal for consumer electronics, USB ports, and battery protection circuits. PTC fuses typically handle currents from a few milliamps to several amps and voltages up to 60V, providing reliable, maintenance-free protection for low-power circuits.

Key Aspects of Resettable Fuses

Let’s explore the main features and applications of PTC fuses:

- Working Principle

- Types and Ratings

- Advantages in Consumer Electronics

- Limitations and Considerations

- Common Applications

Working Principle

How PTC fuses protect circuits:

- Normal state: Low resistance, allows current flow

- Fault condition: Heats up, resistance increases dramatically

- After fault: Cools down, returns to low resistance state

I remember being fascinated when I first encountered a PTC fuse in a lab setting. Watching it react to an overcurrent condition and then reset itself seemed almost magical, especially compared to traditional fuses.

Types and Ratings

Variety to meet different protection needs:

- Radial leaded PTCs for through-hole PCB mounting

- Surface mount PTCs for compact designs

- Strap PTCs for higher current applications

- Current ratings typically from 50mA to 9A

- Voltage ratings usually up to 60V (some special types go higher)During a recent project designing a power bank, we had to carefully select PTC fuses for each USB port. The challenge was finding devices that could handle the normal charging current but react quickly to potential short circuits from damaged cables. This experience highlighted the importance of understanding both the steady-state and trip characteristics of PTC fuses.

Advantages in Consumer Electronics

Why PTC fuses excel in modern devices:

- Self-resetting capability reduces maintenance

- No need for fuse replacement, improving user experience

- Can handle repeated fault conditions

- Compact size ideal for crowded PCBs

Here’s a quick comparison of PTC fuses with traditional fuses:

| Aspect | PTC Fuse | Traditional Fuse |

|---|---|---|

| Reusability | Self-resetting | One-time use |

| Size | Very compact | Varies, often larger |

| Response to Faults | Gradual resistance increase | Immediate open circuit |

| Typical Applications | USB ports, battery packs | High power circuits |

| Current Range | mA to few A | mA to hundreds of A |

Limitations and Considerations

Understanding the trade-offs:

- Higher resistance in normal operation compared to traditional fuses

- Response time can be slower than fast-acting traditional fuses

- Limited to lower voltage and current applications

- Performance can be affected by ambient temperature

Common Applications

Where you’ll find PTC fuses:

- USB ports and computer peripherals

- Rechargeable battery packs

- Automotive sensor circuits

- Audio equipment

- Telecom line protection

Key points about resettable fuses:

- They provide self-resetting protection for low-power circuits

- PTC fuses are ideal for repeated fault conditions

- Their compact size is perfect for modern electronic devices

- They offer maintenance-free protection, improving user experience

- PTC fuses have limitations in high-power applications

In my experience, the adoption of PTC fuses has significantly improved the reliability and user-friendliness of many consumer devices. I recall a project where we were redesigning a line of portable speakers. By replacing traditional fuses with PTCs, we not only reduced warranty claims due to blown fuses but also eliminated the need for users to ever replace a fuse, greatly enhancing the product’s perceived quality and ease of use.

For example, in a recent IoT device development, we implemented PTC fuses in various sensing circuits. This choice allowed the device to recover from temporary fault conditions automatically, ensuring continuous operation in remote deployments where manual resets would be impractical. The self-resetting nature of PTCs proved crucial in maintaining the reliability of the distributed sensor network.

As we move on to discuss other specialized fuses, remember that while PTC fuses excel in low-power, consumer-oriented applications, each fuse type has its own niche where it provides optimal protection. Understanding these specializations is key to designing robust and reliable electrical systems across various industries.

Other Specialized Fuses: High-Voltage, SMD, and Drop-Out Fuses?

Have you ever wondered how massive power transformers are protected from electrical faults? Or perhaps you’ve looked at a tiny smartphone circuit board and wondered how such miniature components can provide overcurrent protection? The world of specialized fuses extends far beyond the common types we’ve discussed, addressing unique protection needs across various industries. But what makes these specialized fuses so crucial in their respective applications?

Specialized fuses cater to specific protection requirements in diverse electrical systems. High-voltage fuses, designed for voltages from 1kV to over 100kV, protect power distribution equipment. Surface Mount Device (SMD) fuses, incredibly small and suitable for automated assembly, safeguard densely packed electronic circuits. Drop-out fuses, used in overhead power lines, provide visible indication of operation and easy replacement. Each type offers unique features like extreme voltage handling, miniaturization, or specific operational characteristics, making them indispensable in their respective fields of application.

Key Types of Specialized Fuses

Let’s explore some of the most important specialized fuse types:

- High-Voltage Fuses

- Surface Mount Device (SMD) Fuses

- Drop-Out Fuses

- Semiconductor Fuses

- Photovoltaic (PV) Fuses

High-Voltage Fuses

Protecting power distribution systems:

- Designed for voltages from 1kV to over 100kV

- Used in transformer protection, switchgear, and power factor correction equipment

- Capable of interrupting extremely high fault currents

I once visited a high-voltage substation where I saw these massive fuses in action. The sheer size and engineering behind these devices, designed to safely interrupt fault currents that could power a small city, was awe-inspiring.

Surface Mount Device (SMD) Fuses

Miniature protection for modern electronics:

- Extremely small, suitable for densely packed PCBs

- Available in various package sizes (e.g., 0603, 1206)

- Used in smartphones, tablets, and other compact electronic devices

During a recent smartphone design project, the challenge of fitting adequate protection into an incredibly tight space really highlighted the importance of SMD fuses. Their miniature size allowed us to implement robust protection without compromising the sleek design of the device.

Drop-Out Fuses

Visible protection for overhead power lines:

- Designed to physically "drop out" when activated

- Provides clear visual indication of operation

- Easily replaceable from the ground using hot sticks

Here’s a quick comparison of these specialized fuse types:

| Fuse Type | Voltage Range | Key Feature | Typical Application |

|---|---|---|---|

| High-Voltage | 1kV – 100kV+ | Extreme interrupting capacity | Power transformers |

| SMD | Up to 250V | Ultra-compact size | Smartphones, wearables |

| Drop-Out | 11kV – 33kV | Visible operation | Overhead power lines |

| Semiconductor | Up to 1500V | Ultra-fast acting | Power electronics |

| PV | Up to 1500V DC | DC current interruption | Solar panel arrays |

Semiconductor Fuses

Protecting sensitive power electronics:

- Ultra-fast acting to protect semiconductors like thyristors and IGBTs

- Designed to operate before the semiconductor device is damaged

- Used in inverters, motor drives, and power conversion equipment

Photovoltaic (PV) Fuses

Safeguarding solar power systems:

- Specifically designed for DC circuits in solar installations

- Capable of interrupting DC arcs, which are more persistent than AC

- Used in combiner boxes, inverters, and battery systems in solar setups

Key points about specialized fuses:

- High-voltage fuses protect critical power distribution equipment

- SMD fuses enable protection in extremely compact electronic devices

- Drop-out fuses offer easy visual inspection and replacement in overhead lines

- Semiconductor fuses provide ultra-fast protection for sensitive electronics

- PV fuses are crucial for the safety of solar power systems

In my experience, the importance of these specialized fuses often becomes most apparent in extreme situations. I recall a project involving a large solar farm where standard DC fuses were initially specified. After a thorough risk assessment, we switched to specialized PV fuses. This decision proved crucial when a severe weather event caused multiple fault conditions across the array. The PV fuses successfully prevented what could have been a catastrophic failure, showcasing the value of application-specific protection.

For example, in a recent industrial automation project, we implemented semiconductor fuses to protect high-speed switching circuits in motor drives. The ultra-fast response of these fuses was critical in preventing damage to expensive IGBT modules during fault conditions, significantly reducing downtime and replacement costs for the facility.

As we conclude our overview of fuse types, it’s clear that the world of electrical protection is diverse and specialized. Each fuse type, from the common cartridge fuse to the highly specialized PV fuse, plays a crucial role in ensuring the safety and reliability of electrical systems across various industries and applications.

How to Select the Right Fuse Type for Your Application?

Are you feeling overwhelmed by the variety of fuse options available for your project? Or perhaps you’re unsure about which factors are most critical when choosing a fuse? Selecting the right fuse is crucial for ensuring the safety and reliability of your electrical system, but with so many types and specifications, how can you be confident in your choice?

Selecting the right fuse involves considering several key factors: voltage rating, current rating, interrupting capacity, response time, and physical size. First, match the fuse’s voltage rating to your system’s voltage. Then, choose a current rating slightly above the circuit’s normal operating current. Consider the potential fault current to ensure adequate interrupting capacity. Determine if you need a fast-acting or time-delay response. Finally, ensure the fuse’s physical size and type are compatible with your installation. Always consult manufacturer specifications and relevant electrical codes for precise selection.

Key Steps in Fuse Selection

Let’s break down the process of choosing the right fuse:

- Determine System Voltage and Current

- Consider Potential Fault Current

- Evaluate Response Time Needs

- Account for Environmental Factors

- Check Physical Compatibility

Determine System Voltage and Current

Matching fuse ratings to your system:

- Voltage rating must be equal to or greater than system voltage

- Current rating typically 125% of maximum continuous current

- Consider both normal operation and startup conditions

I recently consulted on a project where the initial fuse selection was causing nuisance tripping. By carefully analyzing the load profile, including inrush currents, we were able to select fuses that provided proper protection without unnecessary interruptions.

Consider Potential Fault Current

Ensuring adequate interrupting capacity:

- Determine the maximum potential fault current at the fuse location

- Choose a fuse with an interrupting rating higher than this value

- Consider both AC and DC interrupting capacities for DC applications

During a recent industrial power system upgrade, we had to recalculate fault currents due to changes in the utility supply. This led to upgrading several fuses to higher interrupting capacity models, ensuring the system remained protected under the new conditions.

Evaluate Response Time Needs

Matching fuse characteristics to load behavior:

- Fast-acting fuses for sensitive electronics and semiconductor protection

- Time-delay fuses for motors and other high inrush current loads

- Consider coordination with other protective devices

Here’s a quick guide for choosing fuse response times:

| Load Type | Recommended Fuse Response | Reason |

|---|---|---|

| Electronics | Fast-acting | Sensitive components need quick protection |

| Motors | Time-delay | Allows for startup inrush current |

| Lighting | Fast-acting or Time-delay | Depends on type (LED vs. HID) |

| General Purpose | Dual-element | Balances fast short circuit and overload protection |

Account for Environmental Factors

Adapting to operating conditions:

- Temperature derating for high ambient temperatures

- Vibration resistance for mobile or industrial applications

- Moisture and corrosion resistance for outdoor installations

Check Physical Compatibility

Ensuring proper fit and installation:

- Verify fuse size matches holder or clip dimensions

- Consider accessibility for maintenance and replacement

- Check for any special mounting requirements

Key points for fuse selection:

- Match voltage and current ratings to your system requirements

- Ensure adequate interrupting capacity for potential fault currents

- Choose appropriate response time based on load characteristics

- Consider environmental factors that may affect fuse performance

- Verify physical compatibility with your installation

In my experience, thorough fuse selection often requires looking beyond basic ratings. I recall a project involving a critical process control system where standard fuses were initially specified. After a detailed analysis of the potential consequences of downtime, we opted for an upgraded fuse type with indicator features. This choice not only provided better protection but also allowed for quicker troubleshooting, significantly reducing potential downtime costs.

For example, in a recent renewable energy project, we had to select fuses for a hybrid solar-wind system. This required careful consideration of both AC and DC protection needs, varying environmental conditions, and the need for easy maintenance in remote locations. By meticulously evaluating each factor, we developed a comprehensive protection scheme that ensured reliable operation across diverse operating conditions.

As we move on to discuss recommended fuse models and suppliers, remember that proper fuse selection is not just about meeting minimum specifications—it’s about optimizing protection for your specific application to ensure safety, reliability, and efficiency.

Recommended Fuse Models and Suppliers from China?

Are you looking for reliable fuse suppliers for your next project? Or perhaps you’re wondering which specific fuse models are best suited for common applications? Sourcing the right fuses from reputable manufacturers is crucial for ensuring the quality and reliability of your electrical protection. But with so many options available, how can you identify the best choices?

When sourcing fuses from China, consider reputable manufacturers like CHBEB, CHINT, and TBEA. For industrial applications, CHBEB’s NT00 series (500V/100A) cartridge fuses are excellent for control panels. CHINT’s NH2 blade fuses (32V/30A) are ideal for automotive use. For utility-scale applications, TBEA’s 11kV/100A dropout fuses are well-suited for transformer protection. These manufacturers offer a range of fuses meeting international standards like IEC and UL, ensuring quality and reliability. Always verify certifications and test reports when selecting fuses for critical applications.

Recommended Fuse Models and Suppliers

Let’s explore some top fuse options from Chinese manufacturers:

- CHBEB Fuse Models

- CHINT Electric Offerings

- TBEA Fuse Products

- Comparison of Key Features

- Considerations When Sourcing from China

CHBEB Fuse Models

Specializing in industrial and power distribution fuses:

- CHBEB-NT00 Series: 500V/100A cartridge fuses for industrial control panels

- CHBEB-PV1000 Series: 1000VDC/30A fuses for solar applications

- CHBEB-SMD Series: Surface mount fuses for electronics manufacturing

I recently specified CHBEB-NT00 fuses for a large industrial automation project. Their high interrupting capacity and reliable performance were crucial in ensuring the safety of the control systems.

CHINT Electric Offerings

Known for a wide range of electrical components:

- CHINT NH2 Blade Fuses: 32V/30A for automotive and low-voltage DC systems

- CHINT RT14 Series: Time-delay fuses for motor protection

- CHINT NM1 Series: Miniature circuit breaker alternative to traditional fuses

During a recent electric vehicle charging station project, we utilized CHINT NH2 blade fuses for the low-voltage distribution system. Their standardized design and reliable performance made them an excellent choice for this application.

TBEA Fuse Products

Excelling in high-voltage and utility-scale fuses:

- TBEA Dropout 11kV/100A: Ideal for overhead distribution transformer protection

- TBEA HV Fuse Links: For high-voltage switchgear and transformer applications

- TBEA DC Fuses: Specialized for HVDC transmission systems

Here’s a comparison of recommended fuse models:

| Model | Type | Voltage/Current | Best For | Available From |

|---|---|---|---|---|

| CHBEB-NT00 | Cartridge | 500V/100A | Industrial control panels | CHBEB |

| CHINT NH2 | Blade | 32V/30A | Automotive, Low-voltage DC | CHINT |

| TBEA Dropout | High-voltage | 11kV/100A | Utility transformer protection | TBEA |

| CHBEB-PV1000 | Solar | 1000VDC/30A | Photovoltaic systems | CHBEB |

| CHINT RT14 | Time-delay | 690V/32A | Motor circuits | CHINT |

Comparison of Key Features

Evaluating crucial aspects:

- Compliance with international standards (IEC, UL, etc.)

- Availability of technical support and documentation

- Range of ratings and sizes available

- Special features (e.g., indicator flags, high breaking capacity)

Considerations When Sourcing from China

Ensuring quality and reliability:

- Verify manufacturer certifications and test reports

- Consider lead times and minimum order quantities

- Evaluate after-sales support and warranty terms

- Be aware of potential communication and shipping challenges

Key points about sourcing fuses from China:

- CHBEB offers reliable options for industrial and power distribution applications

- CHINT provides a wide range of fuses for various low-voltage applications

- TBEA specializes in high-voltage and utility-scale fuse solutions

- Verify compliance with relevant standards when selecting fuses

- Consider factors beyond price, such as support and reliability, when sourcing

In my experience, successful sourcing of fuses from China requires careful evaluation beyond just specifications and price. I recall a project where we initially chose fuses based primarily on cost. However, after experiencing inconsistent quality and poorafter-sales support, we switched to a slightly more expensive but more reliable supplier. This decision ultimately saved time and money by reducing downtime and replacement costs.

For example, in a recent large-scale solar farm project, we sourced specialized PV fuses from CHBEB. Their ability to provide detailed technical documentation and support throughout the design phase was crucial. When we encountered an unexpected issue during installation, their responsive technical team helped us quickly resolve the problem, minimizing project delays.

As we move on to address some frequently asked questions about choosing and using different fuse types, remember that while price is important, factors like reliability, support, and long-term performance should be key considerations in your fuse selection and sourcing decisions.

FAQs: Choosing and Using Different Fuse Types?

Are you still unsure about some aspects of fuse selection and usage? You’re not alone. Many engineers and technicians have questions when it comes to choosing and applying different fuse types. Let’s address some of the most common queries to help clarify your understanding and improve your fuse selection process.

Choosing and using the right fuse type involves understanding their differences, applications, and limitations. Key considerations include the electrical characteristics of your circuit, environmental factors, and specific protection needs. Proper fuse selection ensures optimal protection, while incorrect choices can lead to equipment damage or safety hazards. It’s crucial to match the fuse type to your application, considering factors like voltage, current, interrupting capacity, and response time. Always consult manufacturer specifications and relevant electrical codes for the most accurate guidance.

Frequently Asked Questions About Fuses

Let’s address some common questions about choosing and using different fuse types:

- What is the difference between cartridge and blade fuses?

- Can I replace a glass fuse with a blade fuse?

- When should I use a resettable fuse instead of a standard fuse?

- What fuse is used in 11kV transformers?

- How do I know if a fuse is blown?

What is the difference between cartridge and blade fuses?

Understanding the key distinctions:

- Cartridge fuses: Cylindrical design, higher voltage and current ratings, used in industrial and high-power applications

- Blade fuses: Flat, plug-in design, lower ratings, primarily used in automotive and low-voltage DC systems

I once had to explain this difference to a client who was confused about why we couldn’t use automotive-style blade fuses in their industrial control panel. Demonstrating the higher voltage and interrupting capacity of cartridge fuses helped them understand the importance of using the right fuse type for each application.

Can I replace a glass fuse with a blade fuse?

Addressing compatibility concerns:

- Generally not recommended due to differences in size, ratings, and mounting

- Glass fuses are typically used in household appliances and electronics

- Blade fuses are designed for automotive systems with different voltage and current characteristics

During a recent DIY electronics workshop, a participant asked about substituting a blade fuse for a glass fuse in their project. I explained that while it might physically fit, the electrical characteristics and protection level would likely be inappropriate, potentially leading to inadequate protection or nuisance tripping.

When should I use a resettable fuse instead of a standard fuse?

Choosing between one-time and resettable protection:

- Resettable fuses (PTCs) are ideal for:

- Frequent overcurrent events (e.g., USB ports)

- Hard-to-access locations where replacement is difficult

- Consumer electronics where user-serviceability is not desired

- Standard fuses are better for:

- High-current applications

- Situations requiring a definite open circuit after a fault

Here’s a quick comparison:

| Aspect | Resettable Fuse (PTC) | Standard Fuse |

|---|---|---|

| Reusability | Self-resetting | One-time use |

| Current Range | Typically < 9A | mA to 1000s of A |

| Response Time | Generally slower | Can be very fast |

| Voltage Rating | Usually ≤ 60V | Up to kV range |

| Best For | Low-power electronics | Wide range of applications |

What fuse is used in 11kV transformers?

Protecting high-voltage equipment:

- Typically, high-voltage fuses or dropout fuses are used

- Examples include expulsion fuses or current-limiting fuses designed for 11kV systems

- Often part of a coordinated protection scheme with other devices

I recently worked on an 11kV substation upgrade where we implemented a combination of high-voltage fuses for transformer protection and reclosers for line protection. This layered approach provided comprehensive protection while allowing for temporary faults to clear without permanent interruption.

How do I know if a fuse is blown?

Identifying a failed fuse:

- Visual inspection: Look for a broken filament in glass fuses or a tripped indicator in some cartridge fuses

- Continuity test: Use a multimeter to check for an open circuit

- For blade fuses: Check for a broken metal strip visible through the plastic body

Key points about choosing and using fuses:

- Different fuse types are designed for specific applications and cannot always be interchanged

- Resettable fuses offer advantages in certain low-power, frequent-fault scenarios

- High-voltage applications require specialized fuses designed for those voltage levels

- Visual inspection and electrical testing can help identify blown fuses

- Always match the fuse type and rating to your specific application requirements

In my experience, understanding these nuances can prevent many common mistakes in fuse application. I recall a project where a maintenance team was repeatedly replacing blown fuses in a motor circuit. Upon investigation, we discovered they were using fast-acting fuses instead of time-delay types, causing nuisance trips during motor startup. Switching to the correct fuse type resolved the issue and improved system reliability.

For example, in a recent smart home installation, we opted for resettable PTCs in several low-current circuits prone to occasional overloads. This choice eliminated the need for homeowners to replace fuses, enhancing the system’s user-friendliness and reducing maintenance calls.

Conclusion

Understanding the various types of fuses and their applications is crucial for designing safe and reliable electrical systems. From cartridge fuses in industrial settings to blade fuses in automotive applications, and from resettable PTCs in consumer electronics to specialized high-voltage fuses in power distribution, each type serves a specific purpose. Proper selection and application of fuses ensure optimal protection against overcurrent conditions, enhancing safety and equipment longevity across diverse electrical systems.

Thank you for joining me in this exploration of fuse types and their applications. Stay curious, stay informed, and let’s keep pushing the boundaries of what’s possible in power distribution and electrical engineering.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group