VPI vs Cast Resin vs SCB | Dry-Type Transformer Selection Guide 2025 | CHBEB

VPI vs. Cast Resin vs. SCB: Your Ultimate Guide to Dry Transformer Selection

Introduction

Picking the wrong dry transformer could cause it to overheat, make noise, and go over budget. A lot of people get the VPI transformer, cast resin transformer, and SCB transformer mixed up. This book explains technologies, analyzes their costs and performance, and gives you a useful decision tree to help you choose with confidence.

In-Depth Analysis: The Core Technology & Manufacturing Process of All Three

Misunderstanding fundamental technology results in incorrect specifications and the need for rework. Not being clear about insulation, heat routes, and production stages raises risk. The answer is to learn how each process works and what it means in real life before asking for estimates.

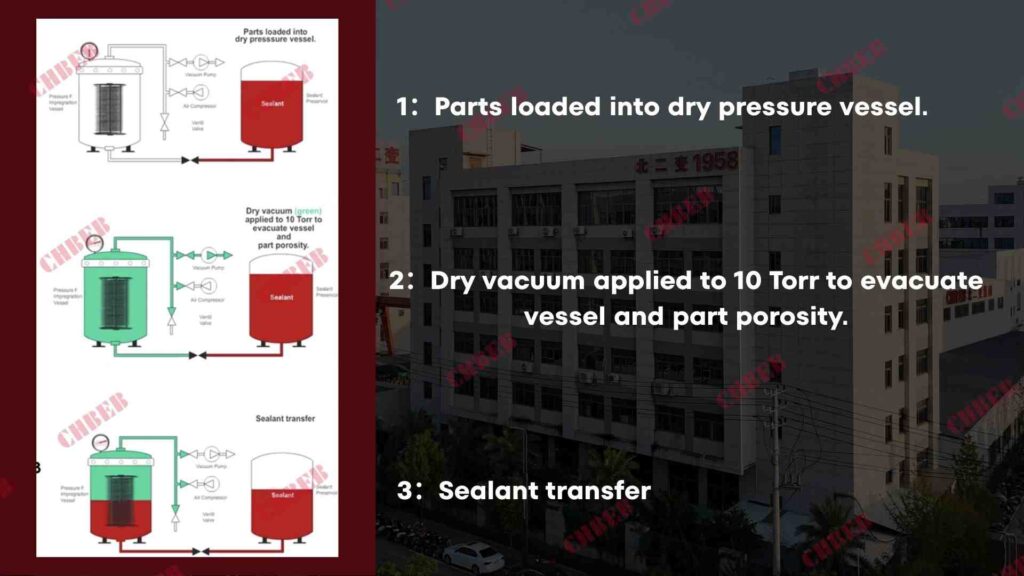

The Benefits of Vacuum Pressure Impregnation for VPI Dry Transformers1

Step 1: Coils are dried in a vacuum. Step 2: They are then varnished under pressure. Step 3: They are baked several times to make a winding that is bonded and resistant to moisture.

- Open windings let heat escape easily.

- With the right process control, there is less partial discharge.

- Coils can be fixed, and field re-impregnation is possible.

Where it works best: industrial plants, retrofits, moderate pollution, and places where serviceability and value are important.

Cast Resin Transformers: Epoxy Resin Casting Works Better

Process: Under vacuum, epoxy is cast around the primary and secondary coils, making solid insulation with no holes that has great dielectric strength.

- Resistant to high levels of moisture and contaminants.

- Very little partial discharge; stable shape when short-circuit pressures are applied.

- Great fire behavior; less smoke and toxicity when the right resin systems are used.

Where it works best: indoor, fire-sensitive places like data centers, metros, hospitals, and commercial skyscrapers.

The SCB Series Transformers: The New Choice That Balances Cost and Performance

Process/Context: “SCB” usually stands for epoxy cast-resin dry transformers (such the SCB10/SCB11/SCB13 series) that are made to be as quiet and efficient as possible according to Chinese and IEC requirements..

- Levels of efficiency and sound quality that are best for building services.

- A lot of local supplies, low prices, and quick delivery timeframes.

- A good mix of performance, safety, and cost over the life of the product.

Where it shines: campuses, stores, light industry—projects that want to lose as little money as possible and get good value.

Performance, Cost & Application: A Multi-Dimensional Comparison for Better Decisions

If you solely look at unit price, your OPEX and downtime will go up. When people don’t understand ratings and surroundings, acceptance testing can go wrong. The solution is to compare on the criteria that matter for the whole life cycle, not just the initial cost.

At a Glance: Key Performance Metrics Comparison Table for Insulation and Noise

| Metric | VPI Transformer | Cast Resin Transformer | SCB Transformer2 (Cast Resin Families) |

|---|---|---|---|

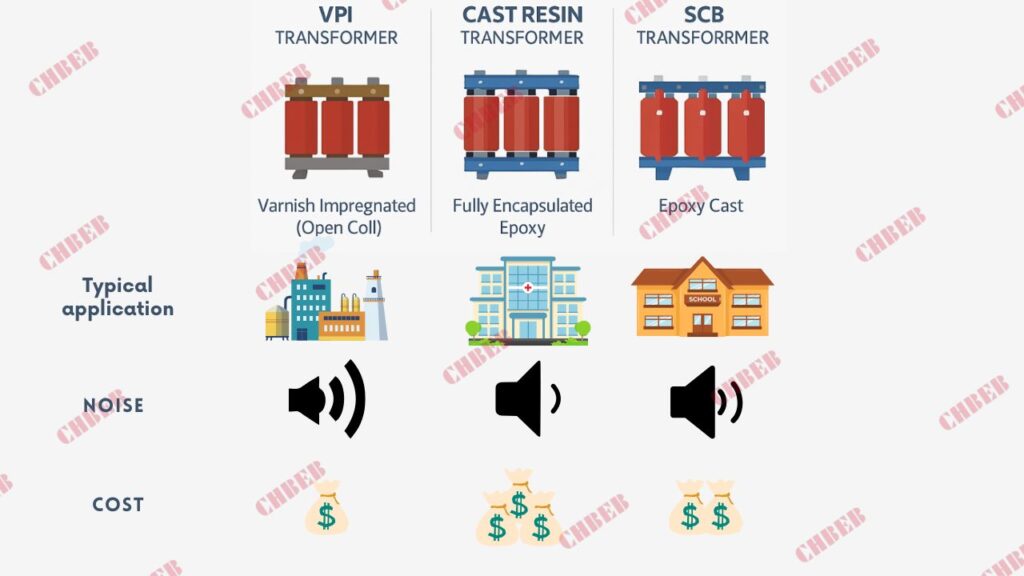

| Insulation System | Varnish impregnated (open coil) | Fully encapsulated epoxy | Epoxy cast (series-optimized) |

| Moisture/Contamination | Good, needs ventilation discipline | Excellent, sealed coil faces | Excellent, building-optimized |

| Thermal Dissipation | Very good (air paths) | Good (through resin & ducts) | Good, optimized for low rise |

| Partial Discharge | Low with robust process | Very low; geometry is rigid | Very low; standard PD controls |

| Short-Circuit Strength | Good (mechanical bracing key) | Excellent (solid coil form) | Excellent (series-tested) |

| Fire Behavior/Smoke | No oil; low fire load | Superior with low-smoke resins | Superior in building services |

| Noise | Low–moderate (design dependent) | Low (rigid coils reduce hum) | Low (series acoustic focus) |

| Maintenance/Repair | Serviceable; rewinding possible | Minimal; repairs are harder | Minimal; field-proven spares |

| Lead Time | Short–medium | Medium | Short (common ratings stocked) |

| Relative CAPEX | $ | $$ | $–$$ (value-optimized) |

| Typical Price | ~USD 20–35/kVA | ~USD 30–50/kVA | ~USD 25–45/kVA |

| Best Fit | Industrial retrofits, value | Mission-critical indoor safety | Building MEP, campuses, light industry |

Buyer’s Quick Takeaway:

• Pick the VPI transformer if you want it to be easy to use and cheap.

• Choose a Cast Resin transformer if safety and fire resistance are your main priorities.

• Pick the SCB transformer if you want a good combination of performance and price.

• All three are widely used in Belt and Road projects in Southeast Asia, Africa, and the Middle East, where buyers seek quick delivery and conformity with IEC standards.

Typical Application Scenarios: Exactly What Your Project Needs

- For low fire load, low PD, and silent operation in data centers, hospitals, and subways, use Cast Resin or SCB.

- VPI for industrial and process lines where airflow is good, serviceability is important, and value is vital.

- SCB series for efficiency, sound quality, and low prices in universities, campuses, and commercial towers.

- Coastal areas or areas with high humidity: Cast Resin/SCB with anti-condensation procedures.

- For small spaces, make sure to choose ventilation plans that have been tested and that keep noise and temperature rise to a minimum.

- In Southeast Asian metro projects, SCB transformers are very popular. In African industrial retrofits, VPI transformers are utilized a lot. In Middle Eastern hospitals, Cast Resin transformers are becoming more popular for fire safety compliance.

Quick Selection Guide: Your Tree of Choices for Dry Transformers

- Define duty and risk: mission-critical indoor (Cast/SCB) vs. serviceable industrial (VPI).

- Check the environment: pollution/humidity → favor Cast/SCB; clean/ventilated → VPI is possible.

- Set goals for loss and noise: Cast/SCB series has strict restrictions, whereas VPI is cost-effective.

- Check the limits: room size, airflow, cable runs, fire code, and seismic class.

- Set the final specs: kVA, voltage, impedance, temperature rise, PD level, enclosure IP, and tests.

Common Questions & Purchasing Advice

Vague quotes and unclear specs lead to disputes and overruns. Not testing, PD limitations, or ventilation can cause failures. The answer is exact RFQs, verifiable paperwork, and terms of the contract that can be enforced.

FAQ: Answering Your Most Important Questions About Selection

Q1: Which is safer for buildings that are open to the public?

A cast resin transformer or a SCB transformer. They are great for hospitals, metros, and high-rise MEP rooms since they have solid epoxy coils, low smoke and toxicity, and low PD.

Q2: When is the VPI transformer better than the Cast Resin transformer?

VPI works well for industrial lines, retrofits, and projects that are on a tight budget and need good airflow and serviceability. It also makes repairs easier.

Q3: What PD (partial discharge) levels do I need to set?

Most purchasers want insulation that lasts longer and makes less noise, therefore follow IEC/GB standards and keep the voltage below 10 pC.

Q4: What should I do about areas near the seaside or with high humidity?

Use a Cast Resin or SCB transformer with heaters, IP enclosures, and regular checks.

Q5: How much does a typical dry type transformer cost in 2025?

The price of dry type transformers is between $20 and $50 per kVA, FOB China. A 1000 kVA SCB transformer (11/0.4 kV) usually costs between $25,000 and $40,000.

Q6: What tests should be included in the contract?

List the types of tests—routine, type, and special tests—along with explicit acceptance criteria.

Purchasing tips:

• Send out a one-page RFQ including kVA, voltages, impedance, temp rise, PD limit, noise, enclosure, cooling (AN/AF), testing, standards, and accessories.

• Ask for detailed quotes that include guaranteed losses (W), delivery, Incoterms, parts, and a warranty.

• Include the right to inspect (FAT/third-party), late delivery fees, and fines for going over budget.

• Verify certifications (ISO/IEC) and project references; request recent PD and temperature-rise reports.

👉 These practices help global buyers source reliable dry type transformers from China with confidence.

Conclusion

Choosing the right dry transformer is about matching technology to duty, environment, and lifecycle cost targets—not just picking the lowest bid.

- VPI transformers excel in industrial retrofits and value-focused projects where airflow and serviceability matter.

- Cast Resin transformers are the safest choice for hospitals, metros, and data centers, thanks to superior fire resistance and low PD.

- SCB series transformers balance efficiency, noise, and cost, making them ideal for campuses, commercial towers, and light industry.

✅ Final takeaway: Define your load, safety, and efficiency requirements, then select the transformer type that minimizes risk and maximizes ROI. Lock specifications, losses, and test guarantees in your contract to protect performance.

👉 Contact us for a tailored dry transformer selection plan with pricing, lead times, and technical advice—so your 2025 projects stay on budget, on schedule, and reliable.

- Understanding Vacuum Pressure Impregnation (VPI) Transformers ↩︎

- Global Transformer Market Analysis 2025 ↩︎

Learn More

Looking for the right dry-type transformer for your project? Download our latest product catalog or browse our product categories to find reliable solutions tailored to your needs.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group