VPI vs Cast Resin vs SCB Transformer: 2025 Dry-Type Technology Comparison Guide | CHBEB

Introduction

It shouldn’t feel like a gamble to pick the correct transformer. But one small detail—the type of insulation—can cause projects to lose money or put people at risk. If you’re building an industrial plant or a public building, knowing the distinctions between VPI, Cast Resin, and SCB dry-type transformers will help you make a decision that you can be sure is safe.

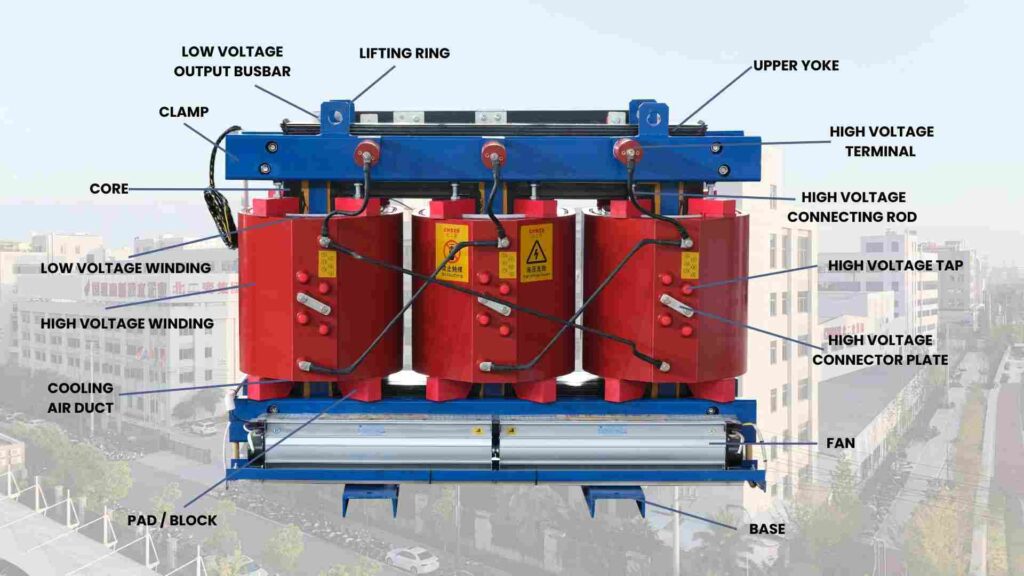

Understanding the Basics: What “Dry-Type Transformer” Really Means

Transformers don’t always need oil to work. “Dry-type” just indicates that the windings are insulated and cooled by air or solid materials instead of oil. These units are safer to use inside, better for the environment, and need less upkeep.

Some of the most common dry-type technologies are:

VPI (Vacuum Pressure Impregnation)

Cast Resin (Epoxy Encapsulated)

SCB Series: Standard Dry-Type Distribution Transformers

They all do the same electrical job: move power. However, they differ in the materials they are made of, how they are made, and how well they work over time.

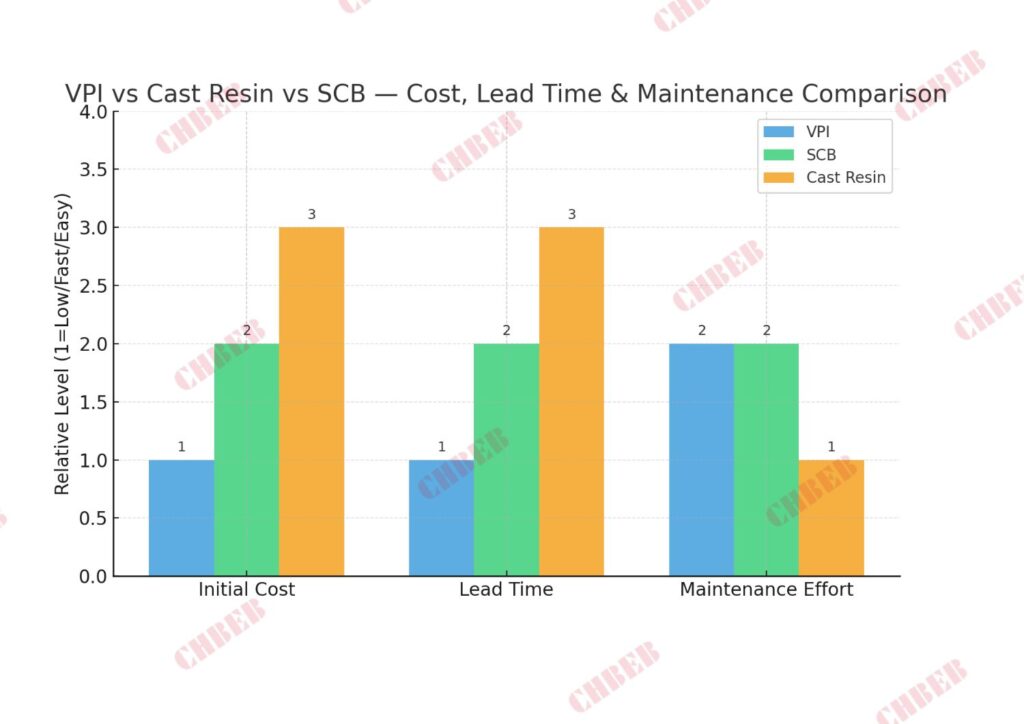

Cost & Procurement: How Each Technology Affects Your Budget and Timeline

When time is short, price and lead time are important. But a cheap bid up front doesn’t always guarantee the lowest long-term expense.

VPI: Quick and Cheap

VPI transformers1 are manufactured by putting varnish on the windings while they are under vacuum and pressure. This makes a strong coating.

Pros: Cheap, quick shipping, and easy to fix.

Cons: It doesn’t resist fire and water very well.

💰 Usually 10–25% less expensive than cast resin kinds, making them great for tasks that need to balance speed and cost.

Cast Resin: Strong and Fire-Safe

When epoxy resin is put into molds and hardens around the windings, it makes a completely sealed system.

Pros: Very safe from fire, doesn’t attract moisture, and puts itself out.

Cons: More expensive, takes longer to make, and is harder to fix.

🔥 Best for hospitals, tunnels, and metro systems where uptime and fire risk are very important.

The Balanced Option in the SCB Series

The SCB family includes both VPI and cast resin technologies:

- SCB10/11 → VPI-based for flexibility and low cost

- SCB12: Made of cast resin for more safety and dependability

| Feature | VPI Transformer | Cast Resin Transformer | SCB Series |

|---|---|---|---|

| Insulation Medium | Varnish impregnation | Solid epoxy resin | Both types |

| Fire Resistance | Good | Excellent | Depends on model |

| Moisture Resistance | Medium | Excellent | Varies |

| Maintenance | Simple | Minimal | Moderate |

| Cost | Lower | Higher | Mid-range |

Risk and Reliability: What Happens After Commissioning

You can see the cost, but you can’t see the risk. After it is turned on, the reliability of your transformer depends on the weather and how well it works in a fire.

Fire and Safety Performance

Choose Cast Resin if your site has severe fire restrictions.

It has epoxy insulation that puts itself out and doesn’t make much smoke when it breaks down.

VPI systems can catch fire, but they won’t burn up at high temperatures. They are good for factories and regular commercial buildings.

Resistant to Moisture and the Environment

VPI transformers work best in clean, indoor areas.

High humidity can steadily damage varnish insulation, though, especially in coastal, tropical, or underground areas.

Cast resin units are completely sealed, making them great for hard or corrosive settings since they keep out dust and moisture.

Time for Maintenance and Downtime

- VPI: Easier to keep up with or re-impregnate during an overhaul.

- Cast resin: Doesn’t need much care, but it’s hard to fix if it gets broken.

Cast resin makes your site more stable for longer and causes fewer service interruptions if you can’t get to it easily.

Life-Cycle Economics: Beyond Initial CAPEX

The cost up front is simply one element of the situation. Over the course of 20 years, differences in efficiency, loss level, and downtime might affect the picture of the real cost.

| Factor | VPI | Cast Resin |

|---|---|---|

| Initial Cost | Lower | Higher |

| Fire & Moisture Risk | Medium | Very Low |

| Maintainability | Easy | Limited |

| Expected Lifespan | 20–25 years | 25–30 years |

| Best Application | Industrial / Commercial | Public or Mission-Critical Sites |

💡 TCO Insight:

Think about how much energy is lost (when the machine is not running and when it is), how often it needs maintenance, and how long it takes to replace it.

Sometimes spending more money on capital expenses today can save you money over the long term and cause fewer problems.

Choosing Smart: Match Type to Your Project

There is no one “best” transformer for everyone; there is just the one that works best for your needs and budget.

When to Choose VPI

- You need transformers that are cheap or can be delivered quickly.

- The place is dry, clean, and easy to get to.

- There is a moderate risk of fire, and maintenance access is possible.

When to Use Cast Resin

- Safety from fire or water is a must.

- The area is near the seaside, humid, or partly outside.

- The expenses of downtime are higher than the savings up front.

When to Choose SCB Series

- You want a dry-type solution that is standardized and meets IEC standards.

- The facility has indoor distribution for offices, malls, and data centers.

- You want a good mix between safety, expense, and upkeep.

Practical Examples

🏭 Factory (Inland Industrial Zone):

Select VPI for cost efficiency and simple maintenance.

🚇 Metro Tunnel (Coastal City):

Select Cast Resin for moisture immunity and fire safety.

🏢 Commercial Data Center:

Select SCB12 Cast Resin for high reliability and silent operation.

Each choice fits the environment — not just the budget.

⚙️ CHBEB — Reliable Partner for Cast Resin Dry Type Transformers

With over 60 years of transformer manufacturing experience, CHBEB specializes in Cast Resin Dry Type Transformers — delivering high safety, low maintenance, and long-term reliability for modern power distribution systems. The company also provides VPI and SCB series solutions to meet the diverse technical and budgetary needs of global clients.

Operating two factories in Wenzhou, one in Nanjing, and a technical & export office in Beijing, CHBEB ensures engineering precision, fast OEM customization, and responsive international support.

- Core Expertise: Cast Resin dry-type transformers from 100 kVA to 5000 kVA, designed for hospitals, data centers, tunnels, and renewable projects.

- Certified Quality: Built under IEC 60076 and ISO 9001 standards, with 100% factory routine and type testing before shipment.

- High-Grade Materials: 100% new copper windings, Class F/H epoxy resin, and premium silicon steel to ensure low losses and long service life.

- Fast Delivery: Standard models ready within 7–10 days; urgent OEM orders fulfilled within one week.

- Global Projects: Proven reliability across the Middle East, Southeast Asia, Africa, and CIS, with CE/CB certifications and full export documentation.

Whether your project requires VPI for cost efficiency or Cast Resin for fire safety and durability, CHBEB provides the right dry-type transformer engineered for total lifecycle performance.

👉 Contact CHBEB today for a customized Cast Resin transformer2 solution, or download our 2025 Dry Type Transformer Catalog.

Conclusion

VPI offers flexibility and cost control. Cast Resin ensures safety and durability. SCB bridges the two with balance and standardization.

The smartest engineers don’t ask which is “best” — they ask which aligns with their environment, safety standards, and long-term reliability goals.

In a world where uptime, sustainability, and compliance define project success, choosing the right dry-type technology isn’t just a technical decision — it’s a strategic investment in safety and performance that lasts for decades.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group