What Is a Box Type Transformer? Structure, Function, and Working Principle Explained?| CHBEB

Are you struggling to design safe, efficient power distribution in compact spaces? Many engineers face delays, high costs, and safety risks. A box type transformer solves these issues by combining transformer, HV/LV switchgear, and protection in one compact unit—cutting footprint, simplifying installation, and ensuring reliable power for residential, commercial, and temporary grids.

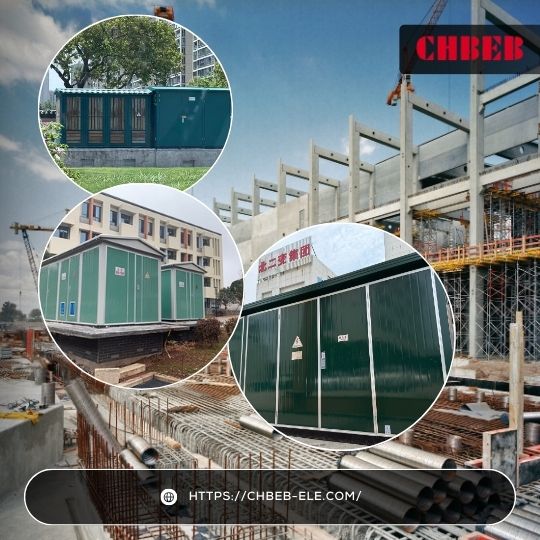

A box type transformer is a compact outdoor power distribution unit that combines transformer, HV/LV switchgear, and protection systems in one enclosure. It’s widely used in residential, commercial, and temporary grid installations for easy deployment and safe, efficient power conversion. This all-in-one solution simplifies installation, reduces footprint, and enhances safety in various power distribution scenarios.

In this comprehensive guide, I’ll walk you through everything you need to know about box type transformers. We’ll explore their structure, function, and working principles, giving you a clear understanding of this innovative power distribution solution. Whether you’re an experienced engineer or new to the field, this article will provide valuable insights into the world of compact substations1.

What Is a Box Type Transformer? Definition & Buyer Guide

Have you ever wondered how modern urban developments manage to distribute power efficiently without large, unsightly substations? The answer often lies in box type transformers. But what exactly is a box type transformer, and why is it gaining popularity in the power distribution sector?

A box type transformer, also known as a compact substation or 箱式变电站 in Chinese, is an all-in-one power distribution unit. It integrates a transformer, high and low voltage switchgear, and protection systems into a single, weatherproof enclosure. This compact design allows for efficient power transformation and distribution in limited spaces, making it ideal for urban and temporary power needs.

Understanding Box Type Transformers

Let’s break down the key aspects:

- Definition and Basic Concept

- Key Features

- Advantages Over Traditional Substations

- Common Industry Terms

- Evolution of Box Type Transformers

Definition and Basic Concept

A box type transformer is:

- A self-contained power distribution unit

- Housed in a compact, typically metal enclosure

- Combines transformer, switchgear, and protection systems

I recently visited a new residential complex where a box type transformer was neatly tucked away in a corner, efficiently powering the entire development without taking up valuable real estate.

Key Features

These transformers offer several unique features:

- Compact design for space-saving installation

- Weatherproof enclosure for outdoor use

- Integrated safety and protection systems

- Easy to transport and install

During a recent project, I was impressed by how quickly we could deploy a box type transformer, significantly reducing installation time compared to traditional substations.

Advantages Over Traditional Substations

Box type transformers offer several benefits:

- Reduced footprint

- Lower installation costs

- Improved safety due to enclosed design

- Easier maintenance and replacement

Here’s a quick comparison:

| Aspect | Box Type Transformer | Traditional Substation |

|---|---|---|

| Size | Compact | Large |

| Installation Time | Days | Weeks to Months |

| Safety | Fully enclosed | Open components |

| Mobility | Easily relocatable | Fixed installation |

Common Industry Terms

It’s important to understand various names used:

- Compact substation

- Packaged substation

- Unitized substation

- 箱式变电站 (Chinese term)

Evolution of Box Type Transformers

The concept has evolved over time:

- Originally developed for temporary power needs

- Now widely used in permanent installations

- Continuous improvements in design and efficiency

Key points to remember about box type transformers:

- All-in-one solution for power distribution

- Compact and space-saving design

- Integrates transformer, switchgear, and protection systems

- Ideal for urban and temporary power needs

- Offers advantages in safety, installation, and maintenance

In my experience, the versatility of box type transformers makes them invaluable in various projects. I’ve seen them used in everything from urban renewal projects to remote construction sites, showcasing their adaptability to different environments and requirements.

For instance, in a recent urban redevelopment project, we used a box type transformer to power a mixed-use complex. Its compact design allowed us to maximize the usable space for commercial and residential purposes while ensuring reliable power distribution.

As we move on to discuss the internal structure and main components, keep in mind how this compact, integrated design influences the arrangement and functionality of its parts. Understanding this structure is key to appreciating the efficiency and versatility of box type transformers in modern power distribution systems.

Box Type Transformer Structure: Inside Layout & Core Components

Are you curious about what’s inside a box type transformer? Understanding its internal structure is crucial for anyone involved in power distribution projects. But what are the key components that make up this compact powerhouse, and how are they arranged to ensure efficient and safe operation?

A box type transformer typically consists of three main compartments: the high-voltage section, the transformer section, and the low-voltage section. These are housed within a protective enclosure designed for outdoor use. Key components include the transformer itself, HV and LV switchgear, protection relays, and cooling systems. The layout is optimized for safety, efficiency, and ease of maintenance.

Exploring the Internal Structure

Let’s break down the main components:

- High-Voltage (HV) Compartment

- Transformer Compartment

- Low-Voltage (LV) Compartment

- Protective Enclosure

- Auxiliary Systems

High-Voltage (HV) Compartment

This section handles the incoming power:

- Contains HV switchgear (circuit breakers, disconnectors)

- Houses protection relays and metering equipment

- Often uses SF6 gas or vacuum technology for insulation

I recently inspected the HV compartment of a box type transformer and was impressed by the compact arrangement of the switchgear, which efficiently managed the incoming 11kV supply.

Transformer Compartment

The heart of the unit:

- Houses the main transformer (typically oil-immersed)

- Includes cooling systems (radiators, fans)

- May have on-load tap changers for voltage regulation

During a factory tour, I observed how the transformer compartment was designed for easy access during maintenance, a crucial feature for long-term reliability.

Low-Voltage (LV) Compartment

Manages the transformed power output:

- Contains LV switchgear and distribution panels

- Includes metering and power quality monitoring equipment

- Often incorporates smart grid technologies

Here’s a quick overview of the main compartments:

| Compartment | Key Components | Function |

|---|---|---|

| HV | Switchgear, Protection Relays | Manages incoming high voltage |

| Transformer | Transformer, Cooling System | Converts voltage |

| LV | Switchgear, Distribution Panels | Distributes transformed power |

Protective Enclosure

The outer shell that houses all components:

- Typically made of galvanized steel or stainless steel

- Designed to meet specific IP (Ingress Protection) ratings

- Includes ventilation systems and access doors

Auxiliary Systems

Supporting equipment for optimal operation:

- Temperature monitoring devices

- Pressure relief systems

- Fire suppression equipment in some models

Key points about the internal structure:

- Compartmentalized design enhances safety and maintenance ease

- HV and LV sections are separated for safety and operational efficiency

- Transformer compartment is central, often with dedicated cooling systems

- Protective enclosure ensures weather resistance and security

- Auxiliary systems support safe and efficient operation

In my experience, the internal layout of box type transformers is a marvel of engineering efficiency. I’ve seen how this compact arrangement allows for quick installation and easy maintenance, crucial factors in both urban and remote settings.

For example, during a recent project in a densely populated urban area, the compartmentalized design of our box type transformer allowed us to perform routine maintenance on the LV section without powering down the entire unit, minimizing disruption to the local power supply.

As we move on to discuss how box type transformers work, keep in mind how this internal structure facilitates the flow of power and the various safety and control mechanisms in place. Understanding this structure is key to appreciating the sophisticated yet efficient operation of these compact substations.

How Does a Box Type Transformer Work? Step-by-Step Operation

Have you ever wondered about the inner workings of a box type transformer? Understanding its operation is crucial for anyone involved in power distribution. But how exactly does this compact unit transform and distribute electricity efficiently and safely?

A box type transformer works by receiving high-voltage power, transforming it to a lower voltage, and distributing it safely. The process involves the HV compartment receiving power, the transformer stepping down the voltage, and the LV compartment distributing it. Throughout this process, various protection and control systems ensure safe and efficient operation, all within a compact, integrated unit.

Box Type Transformer Operation Flow

Step-by-Step Operation Flow

Let’s break down the operation into key stages:

- High-Voltage Power Reception

- Voltage Transformation

- Low-Voltage Power Distribution

- Protection and Control Mechanisms

- Monitoring and Maintenance

High-Voltage Power Reception

The process begins at the HV compartment:

- Incoming high-voltage power enters through HV bushings

- HV switchgear manages the input

- Protection relays monitor for any abnormalities

I recently observed the operation of a box type transformer during commissioning. The smooth transition of power from the HV line to the transformer was impressive, showcasing the efficiency of the HV compartment design.

Voltage Transformation

The core function occurs in the transformer compartment:

- Power is transferred to the transformer’s primary winding

- The transformer steps down the voltage to the required level

- Cooling systems manage the heat generated during this process

During a recent project, we used a transformer with on-load tap changing capability, allowing for real-time voltage adjustment to maintain stable output despite fluctuating input voltages.

Low-Voltage Power Distribution

The transformed power is managed in the LV compartment:

- Stepped-down voltage is received by the LV switchgear

- Power is distributed through various feeders

- Metering equipment monitors the output

Here’s a simplified flow of the operation:

| Stage | Component | Action |

|---|---|---|

| 1 | HV Compartment | Receives and manages high-voltage input |

| 2 | Transformer | Steps down voltage |

| 3 | LV Compartment | Distributes transformed power |

| 4 | Protection Systems | Monitor and protect at each stage |

Protection and Control Mechanisms

Throughout the process, various systems ensure safe operation:

- Circuit breakers in both HV and LV sections for fault protection

- Temperature and pressure monitoring in the transformer compartment

- Automated systems for load management and voltage regulation

Monitoring and Maintenance

Ongoing monitoring ensures efficient operation:

- SCADA systems for real-time monitoring and control

- Regular maintenance checks on oil levels, connections, and insulation

- Periodic testing of protection systems and switchgear

Key points about the operation flow:

- Power flows seamlessly from HV to LV through the transformer

- Multiple protection layers ensure safe operation at each stage

- Cooling systems manage heat generation during transformation

- Automated controls maintain voltage stability and load balance

- Continuous monitoring allows for proactive maintenance

In my experience, the efficiency of this operation flow is what makes box type transformers so valuable in modern power distribution. I’ve seen how their integrated design allows for rapid response to load changes and fault conditions, crucial in maintaining stable power supply.

For instance, during a recent installation at a data center, the box type transformer’s ability to quickly respond to sudden load fluctuations was crucial in maintaining the consistent power supply needed for sensitive equipment. The integrated protection systems also provided an additional layer of security, essential for such critical infrastructure.

As we move on to discuss where box type transformers are used, keep in mind how this efficient operation flow makes them suitable for a wide range of applications. The combination of compact design and sophisticated operation makes these transformers adaptable to various environments and power distribution needs.

Where Are Box Type Transformers Used? Top Application Scenarios

Are you wondering about the practical applications of box type transformers? Their versatility makes them suitable for a wide range of scenarios, but where exactly do they shine? Understanding their key applications can help you determine if a box type transformer is the right solution for your power distribution needs.

Box type transformers find wide application in urban residential areas, commercial complexes, industrial sites, and temporary power setups. They’re particularly useful in space-constrained environments, rapid deployment scenarios, and situations requiring easy relocation. Common uses include powering residential communities, shopping centers, construction sites, and providing temporary grid support for events or emergency situations.

Key Application Scenarios

Let’s explore the main areas where box type transformers are commonly used:

- Urban Residential Developments

- Commercial and Retail Complexes

- Industrial Sites and Factories

- Temporary and Mobile Power Solutions

- Renewable Energy Integration

Urban Residential Developments

Box type transformers are ideal for urban settings:

- Compact design fits well in limited spaces

- Aesthetic appearance blends with urban landscapes

- Suitable for both high-rise apartments and suburban communities

I recently worked on a project where we installed a box type transformer in a new residential complex. Its compact size allowed us to place it discreetly while efficiently powering over 200 apartments.

Commercial and Retail Complexes

These transformers excel in commercial applications:

- Can handle varying load profiles of shopping centers

- Easy to scale for expanding business districts

- Provide reliable power for critical systems like elevators and air conditioning

During a recent mall renovation project, we replaced an old substation with a box type transformer, significantly reducing the space required and improving overall power reliability.

Industrial Sites and Factories

In industrial settings, box type transformers offer several advantages:

- Can be placed close to load centers, reducing power losses

- Modular design allows for easy capacity expansion

- Robust construction suitable for harsh industrial environments

Here’s a quick overview of applications in different sectors:

| Sector | Application | Key Benefit |

|---|---|---|

| Residential | Urban housing complexes | Space-saving, aesthetic |

| Commercial | Shopping malls, office buildings | Reliable, scalable power |

| Industrial | Factories, warehouses | Robust, close to load centers |

| Temporary | Construction sites, events | Easy deployment and relocation |

| Renewable | Solar/wind farms | Efficient integration with grid |

Temporary and Mobile Power Solutions

Box type transformers are excellent for temporary needs:

- Construction sites requiring temporary power

- Outdoor events and festivals

- Emergency power restoration after natural disasters

I recall a project where we used a box type transformer to provide power for a large outdoor music festival. Its easy installation and removal made it perfect for this temporary, high-demand application.

Renewable Energy Integration

These transformers play a crucial role in renewable energy projects:

- Solar farms for efficient power conversion and distribution

- Wind energy projects, often in remote locations

- Small-scale hydroelectric installations

Key points about application scenarios:

- Versatile use across residential, commercial, and industrial sectors

- Ideal for space-constrained urban environments

- Excellent for temporary and mobile power needs

- Suitable for harsh industrial settings

- Facilitates integration of renewable energy sources

In my experience, the adaptability of box type transformers makes them invaluable across a wide range of projects. I’ve seen them successfully deployed in everything from bustling city centers to remote construction sites, showcasing their versatility.

For example, in a recent project for a rapidly expanding industrial park, we used multiple box type transformers to create a scalable power distribution network. This approach allowed for easy expansion as new businesses moved in, without requiring major infrastructure overhauls.

As we move on to compare box type transformers with traditional outdoor substations, keep in mind the diverse applications we’ve explored. This versatility is a key factor in understanding why box type transformers are increasingly preferred over conventional solutions in many scenarios.

Box Type Transformer vs Outdoor Substation: Cost, Efficiency & Maintenance

Are you weighing the pros and cons of box type transformers against traditional outdoor substations? This decision can significantly impact your project’s efficiency, cost, and long-term performance. But how do these two options really compare, and what factors should you consider when choosing between them?

Box type transformers offer several advantages over traditional outdoor substations, including a smaller footprint, faster installation, lower maintenance requirements, and enhanced safety. They’re more cost-effective for smaller to medium-sized applications and offer greater flexibility in placement. However, traditional substations may still be preferred for very high capacity needs or in areas with specific regulatory requirements.

Comparing Box Type and Traditional Substations

Let’s break down the comparison into key areas:

- Size and Space Requirements

- Installation Time and Complexity

- Cost Considerations

- Maintenance and Accessibility

- Safety and Environmental Impact

Size and Space Requirements

Box type transformers excel in space efficiency:

- Compact, integrated design

- Typically 30-50% smaller footprint than traditional substations

- Ideal for urban or space-constrained environments

I recently worked on a project where replacing a traditional substation with a box type transformer freed up valuable real estate for additional parking spaces in a crowded urban area.

Installation Time and Complexity

Box type transformers offer significant advantages in installation:

- Pre-assembled and factory-tested, reducing on-site work

- Can be installed in days rather than weeks or months

- Minimal civil works required

During a recent industrial expansion project, we installed a box type transformer in just three days, compared to the several weeks it would have taken for a traditional substation.

Cost Considerations

The cost comparison varies based on capacity and location:

- Initial costs often lower for box type transformers

- Reduced installation and civil works costs

- Potential long-term savings in maintenance and land use

Here’s a simplified cost comparison:

| Aspect | Box Type Transformer | Traditional Substation |

|---|---|---|

| Initial Equipment Cost | Moderate to High | High |

| Installation Cost | Low | High |

| Land Use Cost | Low | High |

| Maintenance Cost | Low to Moderate | Moderate to High |

| Long-term Operating Cost | Generally Lower | Generally Higher |

Maintenance and Accessibility

Box type transformers often have advantages in maintenance:

- All components easily accessible in one unit

- Modular design allows for easier replacements

- Often equipped with advanced monitoring systems

I recall a case where a faulty component in a box type transformer was replaced in hours, a task that would have taken days in a traditional substation setup.

Safety and Environmental Impact

Safety considerations differ between the two:

- Box type transformers offer enhanced safety with fully enclosed design

- Traditional substations may have exposed components

- Box type units often have better containment for potential oil leaks

Key points in comparing box type transformers and traditional substations:

- Box type transformers offer significant space savings

- Installation is typically faster and simpler for box type units

- Cost-effectiveness depends on capacity and specific project needs

- Maintenance is often easier and less frequent with box type transformers

- Safety and environmental protection can be superior in box type designs

In my experience, the choice between a box type transformer and a traditional substation often comes down to specific project requirements and constraints. I’ve seen cases where the compact, integrated nature of box type transformers made them the clear choice for urban renewal projects, while traditional substations remained preferable for very high capacity needs in less constrained areas.

For instance, in a recent project revitalizing a historic district, we opted for box type transformers due to their minimal visual impact and space efficiency. This choice allowed us to upgrade the power infrastructure without compromising the area’s aesthetic character, a crucial factor in heritage zones.

As we move on to discuss popular brands and export models, keep in mind how these comparative advantages of box type transformers have influenced their growing popularity in various applications. Understanding these benefits will help you appreciate why certain brands and models have gained prominence in the global market.

Box Type Transformer Suppliers & Export Brands to Know

Box Type Transformer Suppliers & Export Brands to Know

Are you curious about which brands lead the box type transformer market and what makes their export models stand out? In the global power distribution landscape, certain manufacturers have established themselves as leaders in box type transformer technology. But which brands should you consider for your project, and what unique features do their export models offer?

Leading brands in the box type transformer market include ABB, Siemens, Schneider Electric, Eaton, and TBEA. ABB is known for its robust designs suitable for harsh environments, Siemens for smart grid integration, Schneider for eco-friendly solutions, Eaton for modular substations, and TBEA for cost-effective customization in large-scale projects. These brands offer various export models tailored to different regional requirements and applications.

Analyzing Top Brands and Their Export Models

Let’s examine some of the leading manufacturers:

- ABB

- Siemens

- Schneider Electric

- Eaton

- TBEA

ABB

- Known for robust designs suitable for extreme conditions

- Offers models with advanced monitoring and control systems

- Popular in Middle Eastern markets due to sand and dust-resistant designs

I recently inspected an ABB box type transformer installed in a coastal industrial zone. Its corrosion-resistant 304 stainless steel enclosure was particularly impressive, showcasing ABB’s focus on durability in harsh environments.

Siemens

- Emphasizes integration with smart grid technologies

- Offers models with high energy efficiency ratings

- Popular in European markets for compliance with stringent efficiency standards

During a recent project, we chose a Siemens model for its advanced IEC 61850 communication interface, which seamlessly integrated with the client’s smart grid infrastructure.

Schneider Electric

- Offers eco-friendly designs with biodegradable transformer oils2

- Focuses on compact models for urban applications

- Strong presence in retrofitting projects in developed markets

I worked on a retrofitting project in a dense urban area where Schneider’s compact, eco-friendly box type transformer proved ideal. It met both space restrictions and environmental regulations, while ensuring reliable power delivery.

Eaton

- Known for compact, easy-to-install modular/prefabricated substations

- Strong presence in North American and Middle Eastern markets

- Models designed for rapid deployment in utility and industrial projects

For example, in a utility upgrade project, an Eaton prefabricated unit was deployed in record time, allowing the grid to resume stable operations with minimal disruption.

TBEA

- Offers cost-effective large-scale customization

- Widely used in EPC projects across Asia, Africa, and Latin America

- Provides strong technical support and flexible configurations for regional standards

In one large-scale renewable project in Africa, TBEA supplied multiple box type substations customized for local grid codes, proving both cost-efficient and reliable.

Brand Comparison Table

| Brand | Key Strength | Notable Export Feature | Popular Markets |

|---|---|---|---|

| ABB | Durability | Sand and dust-resistant models | Middle East, Africa |

| Siemens | Smart Technology | IEC 61850 compatibility | Europe, North America |

| Schneider | Sustainability | Eco-friendly, compact urban models | Global urban centers |

| Eaton | Modular Design | Prefabricated compact substations | North America, Middle East |

| TBEA | Customization | Large-scale EPC and grid projects | Asia, Africa, Latin America |

Key Takeaways

- ABB excels in durable designs for challenging environments.

- Siemens leads in smart grid integration and efficiency.

- Schneider Electric focuses on sustainable and urban-friendly solutions.

- Eaton provides modular, prefabricated substations for rapid deployment.

- TBEA delivers cost-effective, customizable solutions for large-scale projects.

As we conclude our exploration of box type transformers, remember that brand selection should be based on a careful analysis of your specific needs, local regulations, and long-term maintenance considerations.iency of your power distribution project.

Why Choose CHBEB for Your Box-Type Substation Projects?

In today’s box-type substation market, buyers face three persistent challenges: unclear pricing, high operating costs from inefficient cooling, and complex on-site installation & maintenance. CHBEB addresses these head-on with solutions backed by 60+ years of transformer manufacturing expertise.

- Transparent Value — Qualified supplier to the State Grid of China. We offer standardized designs and factory-direct pricing to eliminate middleman markups and keep cost–quality consistent.

- Energy-Efficient Technology — Advanced cooling designs and strict new-material selection help reduce energy losses and extend service life, lowering your total cost of ownership (TCO).

- Modular & Fast Deployment — With three plants (two in Wenzhou, one in Nanjing), our modular substations shorten installation time, improving project speed and on-site safety.

- Global Reliability — 100% factory testing before shipment plus international certifications (IEC, ISO, CE, etc.) to meet local compliance requirements worldwide.

With CHBEB, you don’t just purchase equipment—you gain a partner that combines factory-direct transparency, energy-saving innovation, and long-term reliability to protect your power-infrastructure investment.

Conclusion: Why Choose a Box Type Transformer for Your Project?

Box type transformers represent a significant advancement in power distribution technology, offering compact, efficient, and versatile solutions for various applications. From their internal structure to their operational principles and diverse use cases, these units provide numerous advantages over traditional substations. As the energy landscape evolves, box type transformers continue to play a crucial role in meeting modern power distribution challenges across urban, industrial, and temporary power needs.

Remember, at chbeb-ele, we’re not just sharing information – we’re empowering you to be part of the solution in creating a secure, clean, and efficient energy future. Let’s continue this journey together.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group