What is an Oil Surge Relay: The Unsung Hero of Transformer Protection?

Is your transformer at risk of a catastrophic failure? You might be overlooking a critical component that could save your entire power system.

An oil surge relay, also known as a Buchholz relay, is a vital safety device for oil-immersed transformers. It detects faults by monitoring gas accumulation and oil flow changes, providing early warning and protection against potentially disastrous transformer failures.

I’ve seen firsthand how these small devices can prevent major disasters. In this article, I’ll share my insights on oil surge relays, from basic principles to cutting-edge digital versions. Whether you’re a seasoned engineer or new to the field, you’ll discover why these devices are crucial for transformer health.

How Does an Oil Surge Relay Work: The Guardian of Your Transformer?

Have you ever wondered what happens inside a transformer when something goes wrong? The oil surge relay is your first line of defense, but how does it actually work?

Oil surge relays operate on a simple yet effective principle. They detect gas buildup or sudden oil movements caused by internal faults. When triggered, they can activate alarms or even shut down the transformer, preventing further damage.

I remember the first time I saw an oil surge relay in action. It was during a routine maintenance check, and the relay had just prevented a major breakdown. Let me break down how these devices work and why they’re so important.

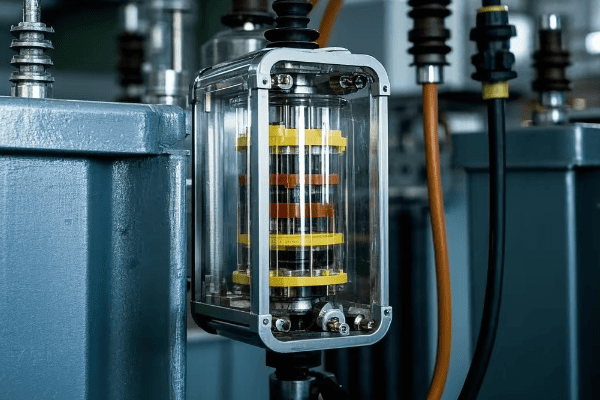

The Anatomy of an Oil Surge Relay

To understand how oil surge relays work, we need to look at their key components:

-

Float Chamber:

- Contains two floats: upper and lower

- Filled with transformer oil during normal operation

- Sensitive to oil level changes and gas accumulation

-

Mercury Switches:

- Connected to the floats

- Activate when floats move due to oil level changes or gas buildup

-

Alarm and Trip Contacts:

- Linked to the mercury switches

- Trigger alarms or transformer shutdown when activated

Operating Principles

The oil surge relay works in two main stages:

-

Slow Accumulation of Gas:

- Gas bubbles rise and collect in the relay’s chamber

- The upper float drops as oil is displaced by gas

- This triggers the alarm contact

-

Sudden Oil Surge:

- Rapid oil movement pushes the lower float upwards

- This activates the trip contact

- The transformer is immediately shut down to prevent damage

Types of Faults Detected

Oil surge relays can identify various transformer issues:

-

Partial Discharges:

- Small electrical discharges in insulation

- Produce hydrogen gas, detected by the relay

-

Overheating:

- Causes oil and paper insulation to break down

- Generates gases like methane and ethylene

-

Arcing:

- Produces large amounts of hydrogen and acetylene

- Triggers rapid relay response

-

Oil Leaks:

- Detected by sudden changes in oil level

| Fault Type | Gas Produced | Relay Response |

|---|---|---|

| Partial Discharge | Hydrogen | Slow alarm |

| Overheating | Methane, Ethylene | Slow alarm |

| Arcing | Hydrogen, Acetylene | Rapid trip |

| Oil Leak | N/A | Rapid trip |

In my years of working with transformers, I’ve seen oil surge relays prevent countless potential disasters. One particularly memorable incident involved a large power transformer at a substation. The oil surge relay detected a small gas buildup, which turned out to be the early stages of a winding insulation failure. By catching this early, we avoided a catastrophic failure that could have cost millions and left thousands without power.

However, it’s important to note that while oil surge relays are incredibly useful, they’re not infallible. Regular maintenance and testing are crucial to ensure they function correctly when needed. I always advise my clients to include oil surge relay checks in their routine transformer maintenance schedules.

What Are the Latest Developments in Oil Surge Relay Technology: The Digital Revolution?

Are you still relying on old-school mechanical relays? The world of oil surge relays is undergoing a digital transformation that you can’t afford to ignore.

Modern oil surge relays are embracing digital technology. These new devices offer enhanced precision, real-time monitoring, and integration with smart grid systems. They’re revolutionizing how we protect and manage transformers.

I recently upgraded a substation with the latest digital oil surge relays, and the improvement in monitoring and response time was remarkable. Let me share what I’ve learned about these cutting-edge devices and how they’re changing the game.

Features of Digital Oil Surge Relays

Digital oil surge relays bring several advancements to the table:

-

Precision Sensing:

- Advanced sensors for accurate gas and oil flow detection

- Ability to differentiate between different types of gases

-

Real-time Monitoring:

- Continuous data streaming on transformer health

- Remote access for engineers to diagnose issues

-

Data Analytics:

- AI-powered analysis of transformer performance trends

- Predictive maintenance capabilities

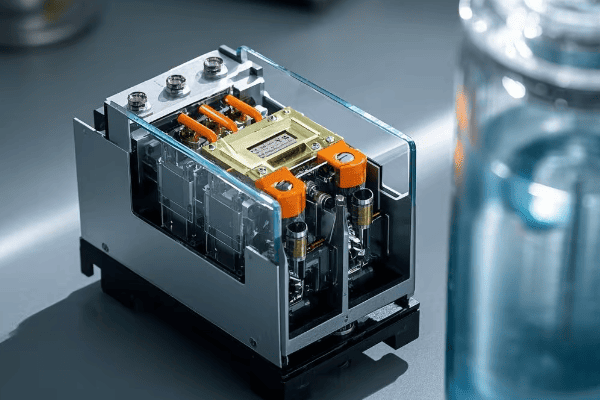

Components of a Digital Oil Surge Relay System

A typical digital system includes:

-

Oil Flow Transmitter:

- Installed in the oil pipeline

- Uses advanced flow detection mechanisms

-

Sensor Array:

- Multiple sensors for gas, temperature, and pressure

- Provides comprehensive transformer health data

-

Digital Controller:

- Processes sensor data

- Runs diagnostic algorithms

- Manages communication with control systems

Advantages Over Traditional Relays

Digital relays offer significant benefits:

-

Increased Sensitivity:

- Can detect smaller changes in gas levels and oil flow

- Allows for earlier fault detection

-

Reduced False Alarms:

- Intelligent algorithms filter out normal fluctuations

- Improves reliability and reduces unnecessary shutdowns

-

Integration with Smart Grids:

- Seamless communication with broader power management systems

- Enables coordinated responses to grid-wide issues

-

Enhanced Diagnostics:

- Detailed fault analysis and reporting

- Aids in root cause identification and preventive maintenance

| Feature | Traditional Relay | Digital Relay |

|---|---|---|

| Sensitivity | Moderate | High |

| False Alarm Rate | Higher | Lower |

| Data Analysis | Limited | Advanced |

| Remote Monitoring | Not Available | Available |

| Smart Grid Integration | Not Possible | Fully Integrated |

The shift to digital oil surge relays is more than just a technological upgrade; it’s a fundamental change in how we approach transformer protection. In my experience, facilities that have adopted these systems have seen a significant reduction in unplanned outages and maintenance costs.

One project I worked on involved retrofitting a large industrial complex with digital oil surge relays. Within the first year, the system detected early signs of insulation breakdown in two transformers. This early warning allowed for planned maintenance during off-peak hours, avoiding costly emergency repairs and production downtime.

However, it’s important to note that implementing digital systems requires careful planning. Cybersecurity becomes a critical concern when your transformer protection is connected to networks. I always emphasize the need for robust security measures and regular software updates when installing these systems.

As we move towards smarter, more interconnected power grids, I believe digital oil surge relays will become standard equipment. Their ability to provide real-time, detailed insights into transformer health is invaluable for modern power systems. For anyone managing critical power infrastructure, considering an upgrade to digital oil surge relays should be a top priority.

Conclusion

Oil surge relays, from traditional mechanical designs to modern digital systems, are crucial for transformer protection. They offer early fault detection, prevent catastrophic failures, and enhance overall grid reliability. Embracing these technologies is essential for a robust, efficient power system.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group