Why Do Distribution Transformer Manufacturers Play a Crucial Role in Power Grids?

Power outages are frustrating. They disrupt our lives and businesses. But have you ever wondered who keeps our lights on most of the time?

Distribution transformer manufacturers play a crucial role in power grids by producing the essential equipment that steps down high-voltage electricity to usable levels for homes and businesses. Their innovations in efficiency, reliability, and adaptability are key to maintaining a stable and effective power supply.

I’ve worked closely with transformer manufacturers for years. I’ve seen firsthand how their work shapes our power systems. Let’s explore why these manufacturers are so important to our daily lives.

Driving Grid Efficiency: The Impact of Innovative Transformer Manufacturing Techniques?

Energy waste costs money and harms the environment. How are transformer makers helping to solve this problem?

Innovative transformer manufacturing techniques are driving grid efficiency by reducing energy losses, improving material utilization, and enhancing overall performance. These advancements result in transformers that waste less energy and operate more effectively.

In my years working with power systems, I’ve seen remarkable improvements in transformer efficiency. Here’s how manufacturers are making a difference:

Advanced Core Materials

The core is the heart of a transformer. New manufacturing techniques are making these cores better:

- Amorphous Metal Casting: This creates cores with much lower losses.

- Laser Cutting of Silicon Steel: This improves the alignment of grain-oriented steel.

- Nanocrystalline Material Production: This promises even greater efficiency.

I once visited a factory that had just started using amorphous metal cores. The energy savings were so significant that utilities were lining up to buy their transformers.

Precision Winding Techniques

How transformers are wound affects their efficiency:

| Technique | Benefit |

|---|---|

| Continuous Disc Winding | Reduces eddy current losses |

| Foil Winding | Improves current distribution |

| Interleaved Winding | Minimizes leakage inductance |

At a recent trade show, I saw a demonstration of a new foil winding machine. It could produce windings with such precision that it reduced losses by an additional 5% compared to traditional methods.

Advanced Insulation Systems

Better insulation means transformers can operate more efficiently:

- Vacuum Pressure Impregnation: This removes air bubbles from insulation.

- Ester Fluid Filling: This uses biodegradable fluids for better cooling.

- Hybrid Insulation: This combines different materials for optimal performance.

I worked with a manufacturer who switched to ester fluids. Their transformers could now operate at higher temperatures safely, increasing efficiency and lifespan.

Automated Quality Control

Modern manufacturing uses advanced testing to ensure efficiency:

- Automated Core Loss Testing: This catches inefficiencies early.

- Winding Resistance Measurement: This ensures consistent wire quality.

- Thermal Imaging in Production: This identifies hot spots before assembly.

In a recent factory tour, I saw robots performing these tests. They could detect tiny variations that human inspectors might miss, ensuring every transformer met the highest efficiency standards.

Advancing Power Distribution: How Manufacturers Push the Boundaries of Transformer Technology?

Power needs are always changing. How do transformer makers keep up with new demands?

Transformer manufacturers push the boundaries of technology by investing in research and development, adopting new materials, and integrating smart features. These advancements lead to transformers that are more powerful, compact, and adaptable to modern grid requirements.

I’ve watched transformer technology evolve rapidly. Here’s how manufacturers are staying ahead:

Smart Transformer Development

Modern transformers are getting brains:

- Integrated Sensors: These monitor transformer health in real-time.

- Communication Modules: These allow transformers to talk to the grid.

- Self-Diagnostic Systems: These can predict and prevent failures.

I recently consulted on a project where we installed smart transformers across a city. They could adjust their output based on real-time demand, significantly improving grid stability.

Compact and Modular Designs

Space is often at a premium. Manufacturers are responding:

| Design Approach | Benefit |

|---|---|

| Shell-Type Cores | More power in less space |

| Modular Construction | Easier transport and installation |

| 3D Printed Components | Complex shapes for better efficiency |

At an industry conference, I saw a presentation on a new modular transformer. It could be assembled on-site, making it perfect for urban areas with limited access.

High-Temperature Superconductors

Some manufacturers are exploring cutting-edge materials:

- Bismuth-based Compounds: These can carry more current with less loss.

- Yttrium-based Coated Conductors: These work well in strong magnetic fields.

- MgB2 Wires: These are cheaper to produce than other superconductors.

While visiting a research lab, I saw prototypes of superconducting transformers. They were incredibly efficient, though still expensive for widespread use.

Digital Twin Technology

Some advanced manufacturers use digital replicas:

- Design Optimization: This tests designs virtually before building.

- Predictive Maintenance: This simulates wear and tear over time.

- Performance Tuning: This helps adjust transformers for specific environments.

I worked with a manufacturer who used digital twins to customize transformers for different climates. They could simulate years of operation in various conditions, ensuring optimal performance anywhere in the world.

Meeting Emerging Challenges: Transformer Manufacturers’ Role in Adapting to Modern Grid Demands?

Our power grids face new challenges every day. How are transformer makers helping to solve these problems?

Transformer manufacturers play a crucial role in adapting to modern grid demands by developing products that integrate renewable energy, support electric vehicle charging, and enhance grid resilience. Their innovations are essential for creating a flexible and future-proof power infrastructure.

I’ve been involved in many projects addressing new grid challenges. Here’s how manufacturers are stepping up:

Renewable Energy Integration

More solar and wind power means new transformer needs:

- Bi-Directional Power Flow: This handles power going both ways.

- Harmonic Mitigation: This cleans up power from renewable sources.

- Voltage Regulation: This keeps voltage steady despite variable inputs.

I once worked on a large solar farm project. The manufacturer provided transformers specifically designed to handle the variable output of solar panels, ensuring stable power delivery to the grid.

Electric Vehicle (EV) Charging Support

The rise of EVs is changing power demands:

| Feature | Benefit |

|---|---|

| High Capacity Design | Handles increased load from EV charging |

| Fast Response to Load Changes | Manages sudden spikes when cars plug in |

| Smart Load Management | Balances charging with other power needs |

In a recent urban development project, we installed transformers ready for widespread EV adoption. They could handle the extra load and even communicate with charging stations to optimize power use.

Grid Resilience Enhancement

Extreme weather and cyber threats require tougher transformers:

- Enhanced Surge Protection: This guards against lightning and other power spikes.

- Cybersecurity Features: These protect against digital attacks.

- Extreme Weather Ratings: These ensure operation in severe conditions.

After a series of storms caused outages, I worked with a manufacturer to develop transformers with enhanced weather resistance. They’ve since been installed in hurricane-prone areas with great success.

Energy Storage Integration

Some transformers now work with battery systems:

- Hybrid Transformer-Battery Units: These combine transformation and storage.

- Storage-Ready Designs: These easily connect to separate battery systems.

- Intelligent Energy Management: This optimizes the use of stored energy.

For a microgrid project, we used transformers with integrated battery storage. They could store excess renewable energy and release it during peak demand, greatly improving grid stability.

Customized Solutions: Manufacturers’ Approach to Diverse Transformer Requirements Worldwide?

Different places need different transformers. How do manufacturers meet such varied needs?

Transformer manufacturers provide customized solutions by tailoring their products to specific regional requirements, environmental conditions, and regulatory standards. This approach ensures that transformers perform optimally in diverse settings worldwide.

I’ve worked on projects across the globe. Each place has unique needs. Here’s how manufacturers address this:

Climate-Specific Designs

Weather can greatly affect transformer performance:

- Desert Models: These handle extreme heat and sand.

- Tropical Versions: These resist high humidity and heavy rain.

- Arctic Designs: These operate in extreme cold.

I once helped install transformers in a desert region. The manufacturer used special cooling systems and sand-resistant seals to ensure reliable operation in the harsh environment.

Voltage and Frequency Adaptations

Different countries have different power standards:

| Adaptation | Purpose |

|---|---|

| Multi-Tap Design | Adjusts to various voltage levels |

| Dual Frequency Capability | Works with both 50Hz and 60Hz systems |

| Special Winding Configurations | Meets unique local requirements |

For an international company’s global expansion, we sourced transformers that could adapt to different voltage standards. This flexibility was crucial for their operations across multiple countries.

Regulatory Compliance

Manufacturers must meet various standards:

- Energy Efficiency Ratings: These vary by country or region.

- Safety Standards: These differ in fire resistance requirements.

- Environmental Regulations: These affect materials and disposal.

I worked with a manufacturer to develop transformers for a European market with strict efficiency standards. They had to redesign several components to meet the new regulations while maintaining performance.

Size and Installation Constraints

Space limitations require creative solutions:

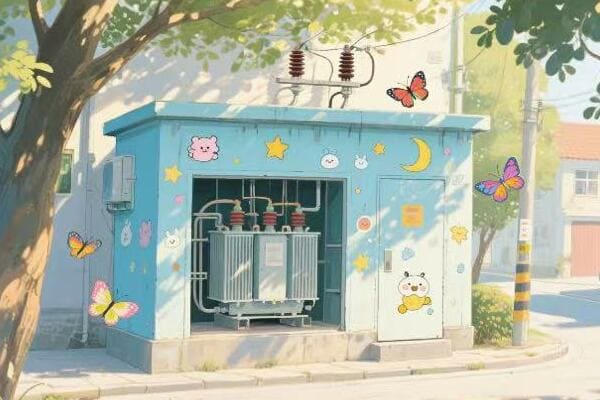

- Compact Designs: These fit in tight urban spaces.

- Modular Systems: These are easier to transport and install.

- Special Mounting Options: These adapt to unique installation sites.

For a project in a crowded city center, the manufacturer created a specially shaped transformer to fit in an awkward space between buildings. It was a perfect example of customization meeting real-world challenges.

Sustainable Power Distribution: Transformer Manufacturers’ Contributions to Green Energy Goals?

Climate change is a big concern. How are transformer makers helping to create a greener grid?

Transformer manufacturers contribute to green energy goals by producing more efficient units, using eco-friendly materials, and designing products that support renewable energy integration. Their efforts are crucial in reducing the carbon footprint of power distribution systems.

I’ve seen a big shift towards sustainability in the industry. Here’s how manufacturers are making a difference:

Eco-Friendly Materials

New materials are making transformers greener:

- Biodegradable Transformer Oils: These are safer for the environment.

- Recycled Core Materials: These reduce the need for new resources.

- Low-Carbon Footprint Insulation: This reduces overall environmental impact.

I recently visited a factory that had switched to plant-based transformer oils. The change significantly reduced their environmental impact without compromising performance.

Energy-Efficient Designs

Reducing energy loss is a top priority:

| Design Feature | Environmental Benefit |

|---|---|

| Amorphous Metal Cores | Up to 70% less energy loss |

| Advanced Winding Techniques | Reduced copper loss |

| Optimized Cooling Systems | Less energy used for cooling |

At a recent trade show, I saw a demonstration of a new high-efficiency transformer. It could save enough energy over its lifetime to power hundreds of homes for a year.

Support for Renewable Energy

Manufacturers are adapting to clean energy needs:

- Grid-Tie Inverter Compatibility: This helps integrate solar and wind power.

- Energy Storage Integration: This supports the use of batteries with renewables.

- Smart Grid Features: These help balance variable renewable inputs.

I worked on a project where we installed transformers specially designed for a wind farm. They could handle the variable input and help smooth out power delivery to the grid.

Lifecycle Management

Manufacturers are thinking long-term:

- Longer Lifespan Designs: These reduce the need for replacements.

- Easy-to-Recycle Components: These minimize waste at end-of-life.

- Upgrade-Friendly Models: These can be updated rather than replaced.

In a recent retrofit project, we used transformers designed for easy upgrades. This approach saved materials and reduced waste compared to full replacements.

Conclusion

Distribution transformer manufacturers are crucial to power grids. They drive efficiency, advance technology, meet modern challenges, provide customized solutions, and support sustainability. Their work is essential for reliable, efficient, and green power distribution.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group