Unlocking Transformer Oil’s Superpowers: Why Is Oil Essential for Transformer Operation? | CHBEB

Why do transformers get immersed in oil?

Introduction

Transformers can get too hot, break down, and cost a lot of money to fix if they don’t have oil. People often ask why transformers “sit in oil.” The answer is that transformer oil is important because it keeps systems cool, stops arcs, and makes sure that power projects around the world work safely and well for a long time.

What Is an Oil-Immersed Transformer?

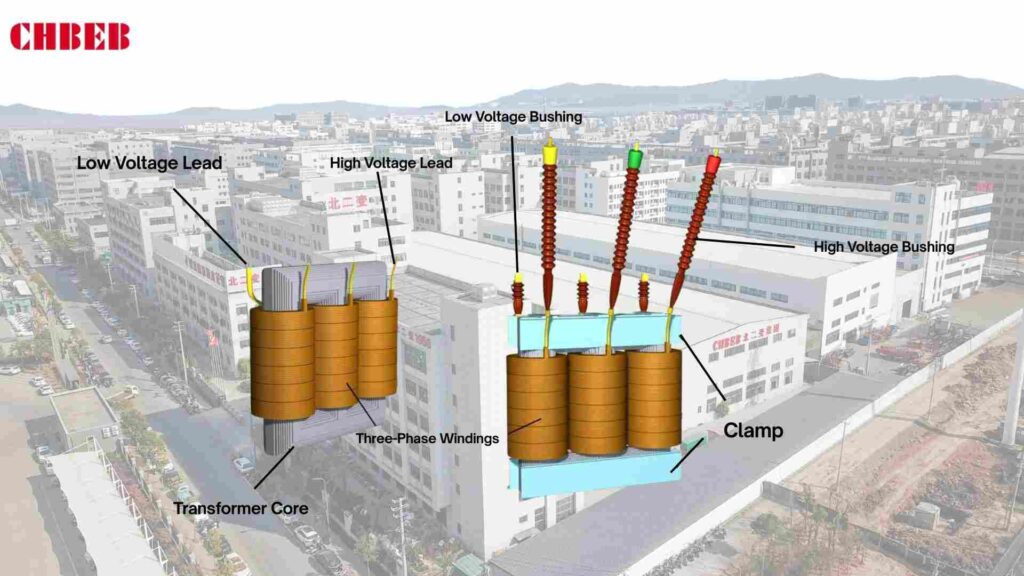

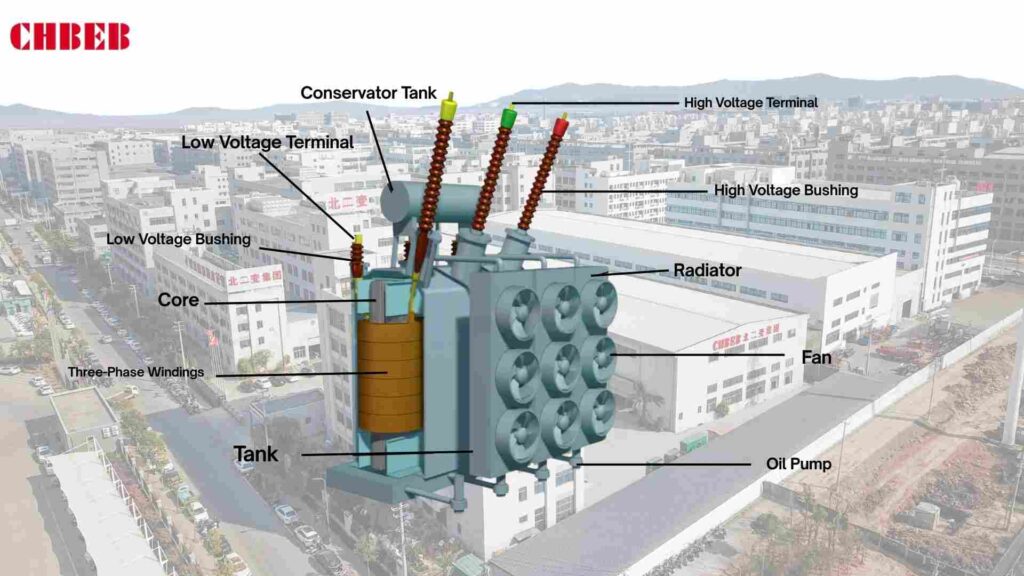

A lot of buyers don’t know what “oil-immersed” means. Without this information, it’s hard to choose the right transformer. An oil-immersed transformer is a power transformer that has insulating oil all over its core and windings.

- Function: Changes the voltage levels in grids and systems used in industry

- Structure: An iron core with primary and secondary coils inside oil

- Oil’s job is to keep things cool and insulated, which keeps them safe for a long time.

- The capacity ranges from a few kVA to hundreds of MVA.

- Uses: networks for transmission, factories, substations, building sites, mining operations, data centers, and networks for distributing goods in cities

👉 To put it simply, oil immersion makes transformers with a lot of power safe, reliable, and long-lasting.

The Oil’s Dual Mission: The Science Behind Its Essential Functions

Transformers would get too hot or break down without oil. Oil does both cooling and insulating, which are two important things for safe functioning.

Mission 1: Super-Efficient Cooling (The Transformer’s “Coolant System”)

Too much heat can harm insulation and limit its life. This heat is absorbed by the transformer oil and sent to the radiator fins and tank walls, where it can be released.

👉Like radiator fluid in a car, transformer oil keeps the temperature stable and makes the equipment last longer.

Mission 2: Electrical insulation, which is the “safety barrier” against short circuits

Arcing and incomplete discharge put safety inside at risk. Oil surrounds the windings and core, making a dielectric shield.

👉The insulating oil has a very high dielectric strength1, which stops arcs and discharges from happening and keeps the transformer running safely and steadily even when the voltage is high.

Practical Trade-Offs: Oil vs. Air

Some people question, “Why oil when there are dry-type transformers?” If you don’t have a clear comparison, you can make the wrong choice for your project.

| Factor | Oil-Immersed Transformer | Dry-Type Transformer |

|---|---|---|

| Cooling | High efficiency, supports heavy loads | Limited by air flow |

| Insulation | Oil dielectric ~15 kV/mm | Relies on solid resin |

| Size & Cost | Compact, USD 20–60/kVA FOB China (2025 typical price) | Bulkier, higher unit cost |

| Applications | Power plants, factories, mines, data centers, city distribution | Buildings, tunnels, metro |

| Lifespan | 25–35 years (with proper maintenance) | 20–25 years |

👉 The price of a typical oil-immersed transformer unit in 2025 will be between USD 20 and 60 per kVA FOB China, depending on the voltage and capacity.

– Mineral oil units: cheaper to buy up front and used a lot in Africa.

– Synthetic/Natural ester oil units are 10–20% more expensive, but they are fire-resistant and good for the environment, hence they are popular in Europe and in cities.

Safety and the Future: Types of Transformer Oil and Green Trends

People are becoming more worried about the risk of fire and the effect on the environment. Buyers are hesitant without standards and safe oils. New oils and rules around the world offer answers.

- Mineral Oil (IEC 60296): cheap, common, but flammable and bad for the environment

- Synthetic Ester Oil (IEC 61099): Doesn’t break down easily, doesn’t catch fire, and is great for metropolitan areas.

- Natural Ester Oil (IEC 62770): Made from plants, renewable, and good for the environment for green projects

Regional insights:

– Mineral oil units are the most common in Africa since they are cheap.

– Eco-regulations say that ester oils are better for urban substations in Europe.

– Utilities in the Middle East use mineral oil for grids and ester oil for oil and gas projects.

👉 The future is clear: eco-friendly ester oils are taking the place of mineral oils more and more, notably in cities and renewable energy projects.

Maintenance & Risk Reminders: Extending Transformer Lifespan

Not doing maintenance on transformers shortens their life and costs more. You need to check oil often and take steps to keep it from breaking down.

- You should regularly test transformer oil for its acid value, moisture content, breakdown voltage, and DGA (Dissolved Gas Analysis)2.

- Testing cycle: Utilities test once a year, whereas data centers and other critical sites test every 6 to 12 months.

- Replacement cost: Oil changes and treatments add to OPEX, but they stop failures that cost a lot more.

- Enclosure cleaning: The external tank and cooling fins of oil-immersed transformers should be cleaned regularly to remove dust, oil stains, and salt deposits. This improves cooling efficiency and prevents corrosion, especially in coastal or industrial environments.

- Life expectancy: Units that are immersed in oil usually last 25–35 years, while dry-type units last 20–25 years.

- Risks: Oil spills can damage soil and water; fire safety systems must be in place according to IEC and local requirements.

👉 Taking care of transformer oil properly not only makes it last longer, but it also decreases the total cost of ownership.

CHBEB — Reliable Partner for Distribution Transformers

With over 60 years of transformer manufacturing expertise, CHBEB has become one of China’s most trusted distribution transformer suppliers. The company operates two factories in Wenzhou, one in Nanjing, and an office in Beijing, ensuring both strong production capacity and responsive customer support.

What makes CHBEB stand out:

- Strict Quality Commitment: All raw materials are 100% new and high-grade — no recycled or downgraded components.

- Proven Reliability: A qualified supplier for the State Grid Corporation of China, with a spotless record of zero major accidents.

- 100% Product Testing: Every unit is fully tested before delivery to guarantee safety, efficiency, and long service life.

- Fast-Track Orders: Ability to fulfill urgent orders in as little as one week, helping customers meet tight project deadlines.

- Custom Inventory Planning: Flexible stocking and supply strategies designed to align with customer procurement schedules.

- Global Outlook: Rooted in China and expanding worldwide, CHBEB actively supports local agents and partners, including assistance with market-specific certifications.

- Flexible Customization: Tailored transformer designs for utilities, contractors, and industrial clients, with reliable quality and fast delivery.

👉 Looking for a distribution transformer manufacturer that combines Chinese manufacturing strength with international standards?Contact CHBEB for a tailored solution or Download our full transformer catalog here.

Conclusion

Transformer oil is not just a liquid filler—it is the core element that determines cooling, insulation, cost, and service life of an oil-immersed transformer. Choosing the right oil type (mineral, synthetic ester, or natural ester) directly affects fire safety, environmental compliance, and OPEX. Regular oil testing—such as DGA tests, breakdown voltage checks, and moisture analysis—helps extend lifespan from 25–35 years and prevents costly failures.

Key Takeaways for Global Buyers

- Price: 2025 FOB China ranges USD 20–60/kVA, with ester oils costing 10–20% more.

- Safety: Ester oils are increasingly replacing mineral oil in cities and green projects.

- Maintenance: Proper oil monitoring reduces total cost of ownership.

From African mining sites to European substations and Middle Eastern grids, oil-immersed transformers remain the backbone of reliable power distribution.

📞 Contact CHBEB for 2025 oil-immersed transformer price lists, oil-type comparisons, and export-ready solutions tailored for your project in Southeast Asia, Africa, or the Middle East.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group