Why Are Transformer Prices So High Recently? | 2025 Buyer’s Guide|CHBEB

Why Are Transformer Prices So High Recently?

Introduction

There are delays in delivery and budgets are tight. Why? Prices for transformers have gone up a lot lately, which has shocked purchasers all across the world. This buyer’s guide for 2025 explains why transformer prices are so expensive and how to find dependable transformer suppliers in China who can offer you a good deal.

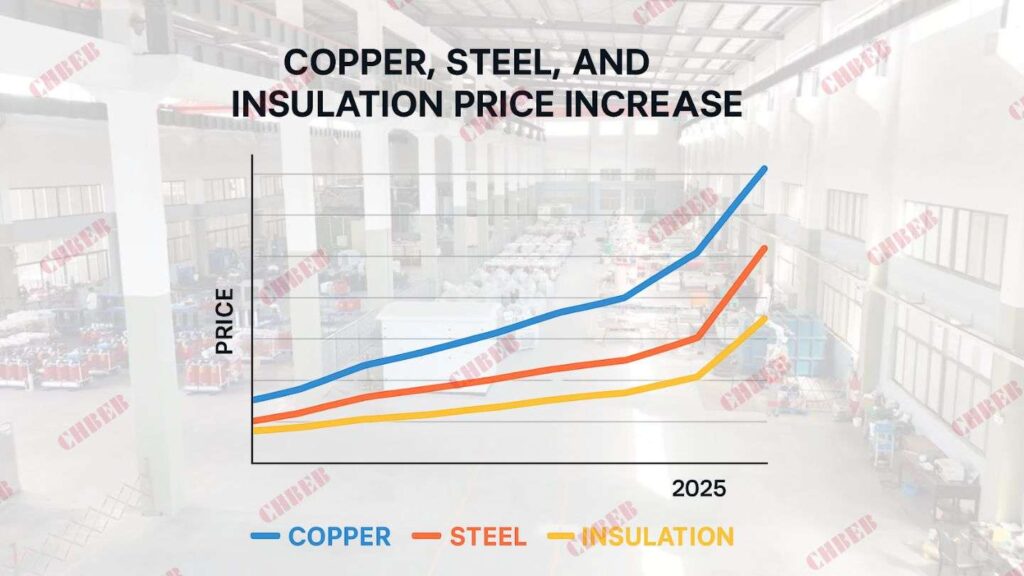

1) The cost of raw materials is going up

Copper, electrical steel, and insulation materials are the main parts of making transformers, and all of them have gotten more expensive:

- Copper1: The prices of copper windings are still close to their highest levels in years.

- Grain-oriented2 silicon steel is in short supply, which raises the cost of cores.

- Insulation and resin: Epoxy, kraft paper, and other dielectrics follow the rise in petrochemical and energy prices

This means that the base cost of all oil-immersed transformers and dry-type transformers goes up.

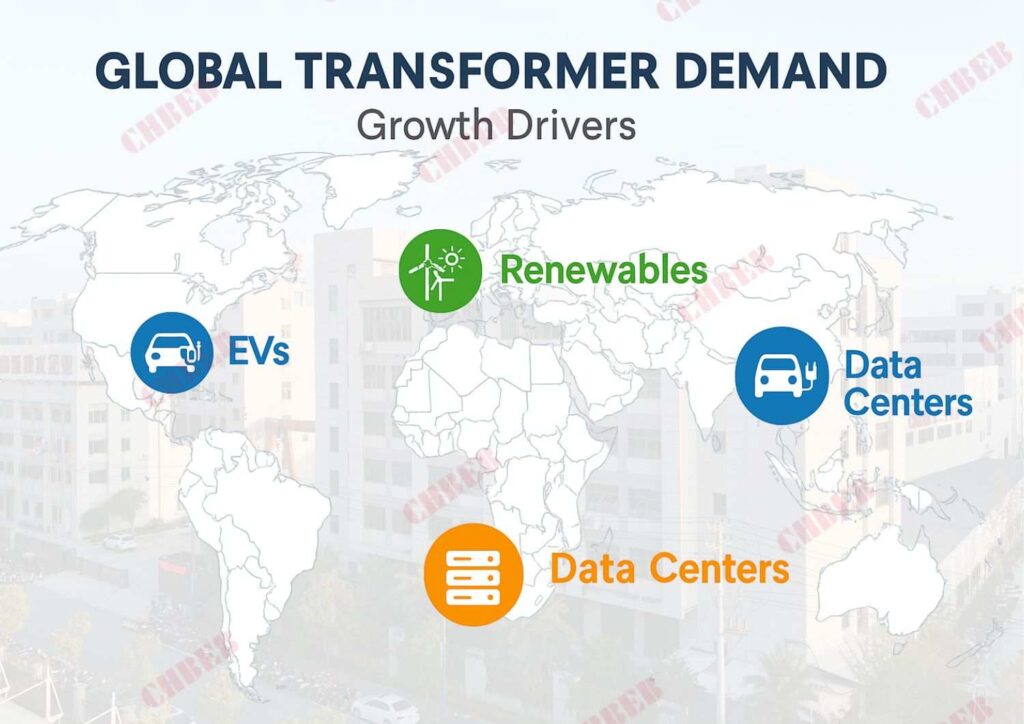

2) Growing demand over the world

Worldwide, demand is greater than supply:

- Solar, wind, and storage projects all need step-up/step-down transformers.

- Charging networks and distribution upgrades bring extra load to EV infrastructure.

- Hyperscale developments in the U.S. and Southeast Asia are causing record orders in data centers.

The spike raises transformer prices in 2025 and makes lead times longer.

3) Problems in the supply chain

Production hasn’t grown fast enough to keep up with demand:

- The time it takes to get massive power transformers has gone from 6–12 months to 18–36 months.

- There are always choke points since there isn’t enough core steel and huge units around the world.

- Shipping prices, port congestion, and logistical costs are still high.

4) More strict rules and standards

- Efficiency rules (IEC/DOE) call for more copper and steel of a better grade.

- Fire safety standards make cast-resin dry-type units more popular for interior projects, although they cost more.

- Tariffs and export controls on electrical steel or finished transformers make things more expensive in the area.

5) The cost of energy and inflation

- Inputs for factories: more electricity, labor, and overhead.

- Transport: Shipping heavy equipment and getting it to the last mile are both a lot more expensive than they were before 2020.

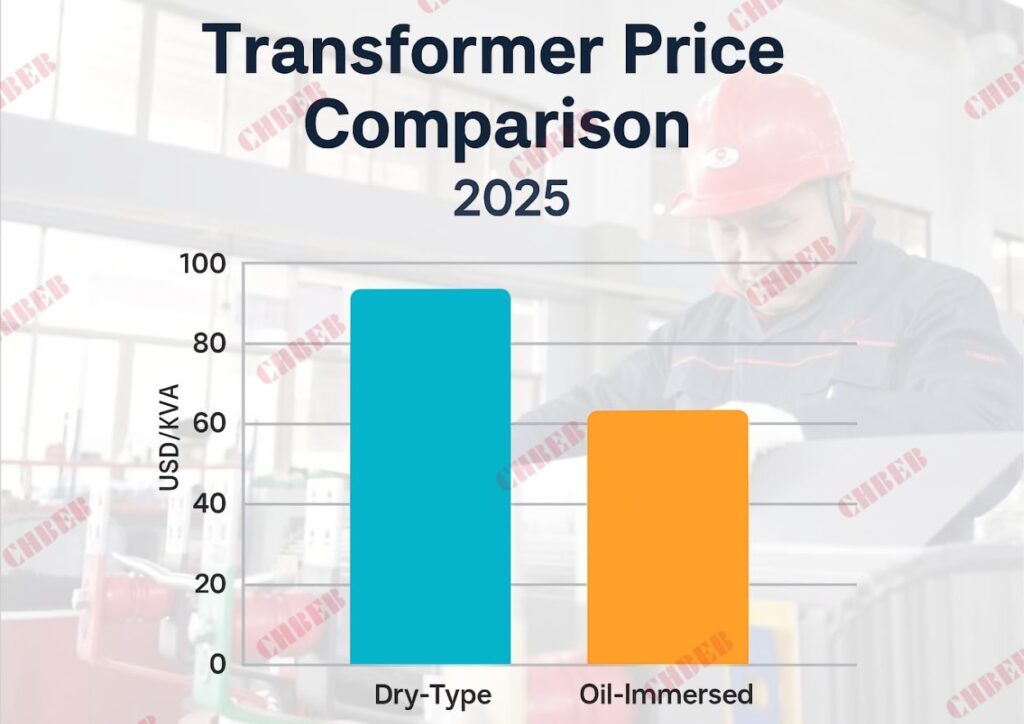

A look at transformer prices in 2025

| Transformer Type | Typical Capacity | Price Range (FOB China) | Notes |

|---|---|---|---|

| Dry-Type (Cast Resin)3 | 50–3150 kVA | USD 40–90/kVA | Hospitals, metros, data centers |

| Oil-Immersed | 50–25,000 kVA | USD 20–50/kVA | Utilities, substations |

| Example: 1000 kVA Dry-Type (11/0.4 kV) | – | USD 40,000–70,000 | IEC/UL certified |

| Example: 1000 kVA Oil-Immersed (11/0.4 kV) | – | USD 25,000–40,000 | Widely used in grids |

Prices depend on the type of copper or aluminum windings, the level of loss (0.6 vs. 1.1), and whether the product has IEC or UL certification.

What Buyers Will Be Able to Do in 2025

- Plan ahead: Place your order 6 to 12 months in advance to make sure you get a production slot.

- Look at 2–3 quotes from well-known transformer providers in China and compare them.

- Say what materials to use: Pick the insulation class, copper or aluminum windings, and core loss level.

- Lock pricing: Use fixed-price clauses to keep prices from changing too much.

- Check certifications like IEC, ISO, and UL to make sure they are compliant and accepted by the grid.

Quick Takeaway for the Buyer

- Prices are high because of the cost of raw materials, strong demand, and little supply.

- Expect things to be unstable until 2025.

- Smart sourcing from trustworthy suppliers helps lower the danger of transformer price 2025.

Emerging Chinese Manufacturers

CHBEB — Reliable Partner for Distribution Transformers

With over 60 years of transformer manufacturing expertise, CHBEB has become one of China’s most trusted distribution transformer suppliers. The company operates two factories in Wenzhou, one in Nanjing, and an office in Beijing, ensuring both strong production capacity and responsive customer support.

What makes CHBEB stand out:

- Strict Quality Commitment: All raw materials are 100% new and high-grade — no recycled or downgraded components.

- Proven Reliability: A qualified supplier for the State Grid Corporation of China, with a spotless record of zero major accidents.

- 100% Product Testing: Every unit is fully tested before delivery to guarantee safety, efficiency, and long service life.

- Fast-Track Orders: Ability to fulfill urgent orders in as little as one week, helping customers meet tight project deadlines.

- Custom Inventory Planning: Flexible stocking and supply strategies designed to align with customer procurement schedules.

- Global Outlook: Rooted in China and expanding worldwide, CHBEB actively supports local agents and partners, including assistance with market-specific certifications.

- Flexible Customization: Tailored transformer designs for utilities, contractors, and industrial clients, with reliable quality and fast delivery.

👉 Looking for a distribution transformer manufacturer that combines Chinese manufacturing strength with international standards?Contact CHBEB for a tailored solution or Download our full transformer catalog here.

FAQ

Q1: Why are transformer prices rising in 2025?

Copper/steel and insulation costs are higher, while demand from renewables, EVs, and data centers exceeds available supply.

Q2: How much do transformers cost now?

Oil-immersed: USD 20–50/kVA; Dry-type: USD 40–90/kVA. Example: 1000 kVA oil-immersed is USD 25,000–40,000.

Q3: Will prices go down soon?

Not immediately. Most analysts expect prices to stay high through 2025 due to persistent supply-demand imbalance.

Q4: How can buyers reduce costs?

Order early, compare multiple transformer suppliers in China, specify materials clearly, and negotiate fixed contracts.

Q5: Where to buy transformers in 2025?

Many buyers source from Asia—working with a vetted transformer supplier China offers competitive pricing, IEC-certified quality, and reliable lead times.

Q6: How long is transformer delivery in 2025?

Small units typically deliver in 2–3 months, while large power transformers may require 12–24 months, depending on supplier capacity.

Conclusion

Transformer prices remain high in 2025, but disciplined sourcing gives buyers control:

- Time: Place orders 6–12 months in advance to secure production slots and delivery dates.

- Technical: Specify winding material (copper/aluminum), loss class (0.6/1.1), and insulation grade to avoid vague quotations.

- Contractual: Request fixed-price clauses, IEC/UL reports, and third-party inspections to reduce risks.

- Service: Look beyond the initial price—evaluate after-sales support and spare parts availability.

✅ Key point: In an uncertain market, true competitiveness is not about chasing the lowest unit price, but about partnering with suppliers that ensure certified quality, predictable delivery, and long-term peace of mind.

With over 60 years of expertise, CHBEB has supported Belt and Road and global clients with tailored transformer solutions, helping buyers secure cost stability and reliable delivery despite volatile market conditions.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group