How to Choose the Right Substation Transformer for Your Project | CHBEB

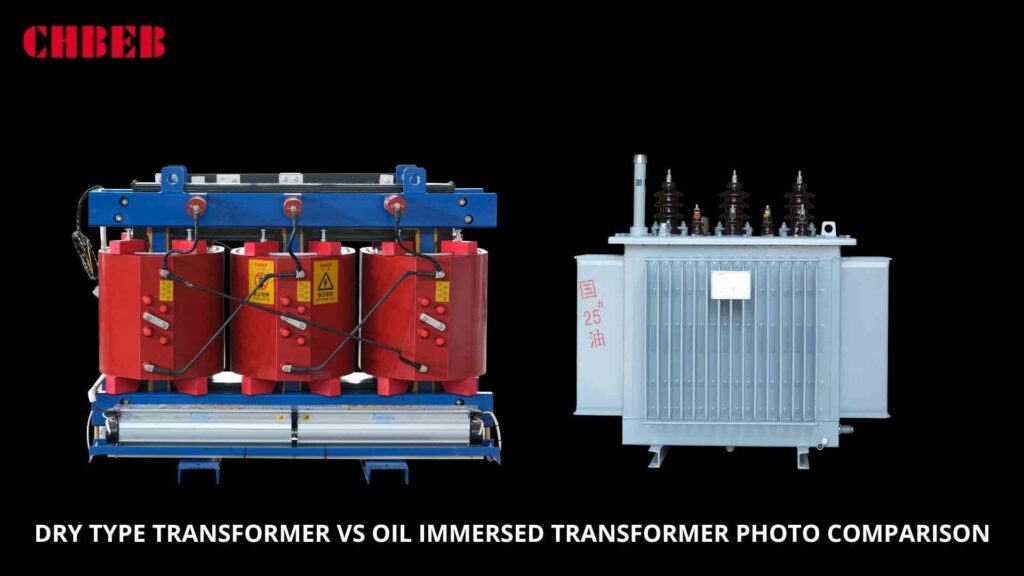

Substation Transformer Selection: The Ultimate Trade-Off Between Dry and Oil-Immersed Technologies | CHBEB

Introduction

Choosing the right transformer for a substation project is the most important decision that every project has to make.

Should you choose a transformer that is dry or one that is immersed in oil?

This choice affects not only performance but also safety, maintenance, and the cost of running the machine over the long term.

Engineers, EPC contractors, and investors may make decisions that last by knowing these trade-offs.

Performance & Safety: Cooling Efficiency, Capacity Limits, and Environmental Risks

Transformers at substations operate under high stress and must deliver exceptional reliability. The right technology for each application depends on cooling method, installation environment, and safety requirements.

Thermal Difference: Oil’s High-Capacity Advantage vs. Dry-Type’s Safety First

The key distinction between the two technologies lies in how they manage heat.

Oil-Immersed Transformers use mineral or ester-based oil for both cooling and insulation.

The oil circulates naturally (ONAN) or through pumps and fans (ONAF, OFAF) to maintain optimal temperature and thermal conductivity1.

Best for:

- Substations with a lot of power, up to 1,000 MVA

- Long-term use in industry or transmission

- Harsh conditions outside or near the coast

Pros:

- Better at getting rid of heat

- Ability to handle a lot of extra work

- Performance that stays stable over long periods of use

On the other hand, dry-type transformers use air or resin insulation technologies such as VPI (Vacuum Pressure Impregnation) or Cast Resin.

They are typically rated below 20 MVA, making them ideal for indoor or fire-sensitive environments.

Pros:

- No chance of oil leaking

- Very good fire safety

- Little upkeep

| Parameter | Oil-Immersed Transformer | Dry-Type Transformer |

|---|---|---|

| Cooling Medium | Mineral / Ester Oil | Air / Epoxy Resin |

| Typical Capacity | 5–1000 MVA | ≤20 MVA |

| Cooling Efficiency | High | Moderate |

| Fire Safety | Medium (improved with ester oil) | High |

| Maintenance | Regular oil checks | Minimal |

| Best Use Case | Outdoor substations, plants | Indoor or public areas |

👉In short, oil-immersed models have a higher power density, whereas dry-type units put safety and environmental compliance first.

Environmental Compliance: Noise, Fire Rating, and Installation Requirements

Modern substation designs must meet regulations for noise, fire, and the environment.

Noise:

Oil-immersed transformers are quieter because the oil absorbs vibrations in the core.

Step-lap silicon steel designs keep noise levels below 55 dB, meeting IEC 60076 standards2.

Dry-type transformers can be a little louder, but enclosures or vibration mounts can reduce the noise easily.

Fire safety:

Dry-type transformers are suitable for indoor use because they use Class F/H resin that puts out fires on its own.

Oil units now use synthetic ester oils, which are biodegradable and non-flammable, greatly reducing fire risks.

IRequirements for installation:

Oil-immersed: needs fire walls and containment pits to ensure safety.

Also requires ventilation for cooling, especially in confined spaces.

Typical applications:

- High-load outdoor sites → Oil-immersed

- Indoor, compact, or public areas → Dry-type

Insurance companies and regulators are increasingly favoring low-risk transformer installations, which is why dry-type units are becoming more common in modern infrastructure.

Economics: Balancing CAPEX and OPEX

Total ownership cost (TCO) — not just the initial price — is an important factor when choosing a substation transformer.

Oil-immersed transformers

- Lower initial cost (about 20–30% less for the same capacity)

- Require oil sampling, filtering, and replacement every 3–5 years

- Have slightly higher insurance and containment costs

Dry-Type Transformers

- Higher initial cost due to resin and insulation materials

- Minimal maintenance — only air filter cleaning and temperature checks

- No oil waste or disposal costs, ideal for areas with strict environmental regulations

| Cost Element | Oil-Immersed | Dry-Type |

|---|---|---|

| Purchase Price | Lower | Higher |

| Maintenance | Regular oil service | Minimal |

| Installation | Fire wall & oil pit | Simple indoor setup |

| Efficiency | Higher (liquid cooling) | Slightly lower |

| Lifetime | 30–40 years | 25–30 years |

✅ Conclusion: After 25 years, both have about the same TCO. Oil kinds are better in terms of capacity and cost, whereas dry types are better in terms of safety and ease of use.

Scenario-Based Selection: Matching Type to Application

Every project has its own set of rules and conditions.

Here’s how to choose the right transformer technology for your situation:

| Scenario | Recommended Type | Reason |

|---|---|---|

| Underground / Metro | Dry-Type | Fire-safe and compact |

| Data Center / Hospital | Dry-Type | Clean operation, low noise |

| Power Plant / Utility Substation | Oil-Immersed | High capacity and durability |

| Coastal or Outdoor Areas | Oil-Immersed (Ester Oil) | Weather-resistant and eco-safe |

| Urban Commercial Building | Dry-Type | Safe for people, zero leakage |

Ester oil-filled transformers are a new type of hybrid design that combines liquid cooling with fire-resistant performance. They are part of the global drive toward greener, higher-capacity systems.

🔎 Learn more about dry-type transformer selection and design in our in-depth Dry Type Transformer Guide 2025 — covering insulation types, VPI vs. cast resin, and IEC 60076 standards.

⚙️ CHBEB — Reliable Partner for Substation Transformer Solutions

For over 60 years, CHBEB has specialized in substation and distribution transformer engineering, offering both dry-type and oil-immersed solutions designed to meet global standards.

Why Choose CHBEB

- 🏭 Manufacturing Strength: Factories in Wenzhou and Nanjing, plus a logistics hub in Beijing, enabling fast production and delivery.

- 🔬 Engineering Expertise: All products tested under IEC 60076 and ISO 9001, ensuring reliability in every voltage class.

- 🌍 Global Reach: Trusted by utilities and EPCs in Russia, Southeast Asia, Africa, and Belt & Road countries.

- ⚡ Customized Design: From 50 kVA to 1000 MVA — tailored for your voltage, climate, and project needs.

- 📈 End-to-End Support: From selection consultation to installation guidance and certification documentation.

At CHBEB, we don’t just build transformers — we engineer reliability into every grid we power.

👉 Looking for a distribution transformer manufacturer that combines Chinese manufacturing strength with international standards?Contact CHBEB for a tailored solution or Download our full transformer catalog here.

🔍 Frequently Asked Questions (FAQ): Substation Transformer Selection

1. What’s the main difference between dry and oil-immersed substation transformers?

Oil-immersed transformers use liquid insulation for higher capacity and better heat dissipation.

Dry types rely on resin or air, offering fire safety and minimal maintenance — ideal for indoor or compact setups.

2. Which type is more suitable for high-voltage substations?

Oil-immersed transformers (ONAF/OFAF) handle up to 1000 MVA and are preferred for 110–500 kV systems.

Dry types are typically used below 35 kV.

3. Which transformer is safer for populated areas?

Dry-type transformers, thanks to their non-flammable insulation, are safer for metro, hospital, or commercial installations.

4. How long does each type last?

Oil-immersed: 30–40 years with proper oil monitoring and OLTC care.

Dry-type: 25–30 years with minimal servicing.

5. Can CHBEB help me choose the right substation transformer?

Absolutely. Our engineering team provides technical selection reports, thermal simulations, and custom designs for your project environment.

Conclusion

The choice between dry-type and oil-immersed transformers isn’t about which is superior — it’s about which fits your substation’s voltage, environment, and safety requirements.

Oil-immersed designs remain the benchmark for high-capacity and outdoor installations, providing excellent thermal efficiency and long service life. Dry-type transformers, on the other hand, are the preferred option for indoor, public, or fire-sensitive sites where safety and simplicity outweigh raw capacity.

For EPCs, utilities, and engineers, the smartest decision lies in evaluating total cost of ownership, installation context, and compliance standards — not just initial price.

When reliability, certification, and lifecycle performance truly matter, CHBEB’s engineering team stands ready to help you select, customize, and deliver substation transformers that keep your grid safe, efficient, and future-ready.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group