Have you ever wondered how electricity travels from power plants to your home? It’s a journey that involves two unsung heroes: power transformers and distribution transformers.

Power transformers and distribution transformers are the backbone of our electrical grid. They work together to ensure efficient power transmission and distribution, making it possible for us to enjoy reliable electricity in our daily lives.

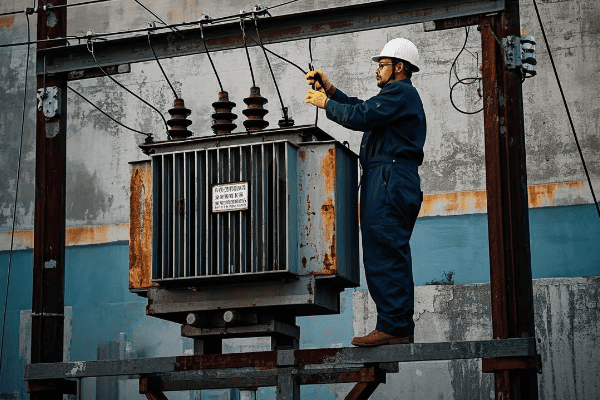

As an electrical engineer with years of experience in the power industry, I’ve seen firsthand how crucial these transformers are. Let’s dive deeper into their roles and why they’re so important for our modern electrical systems.

What Sets Power Transformers Apart from Distribution Transformers in Grid Operations?

Picture this: a massive power plant generating electricity, but how does that power reach your neighborhood? That’s where power transformers and distribution transformers come into play.

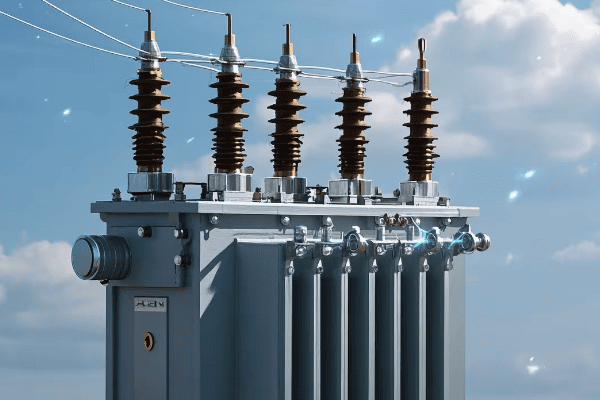

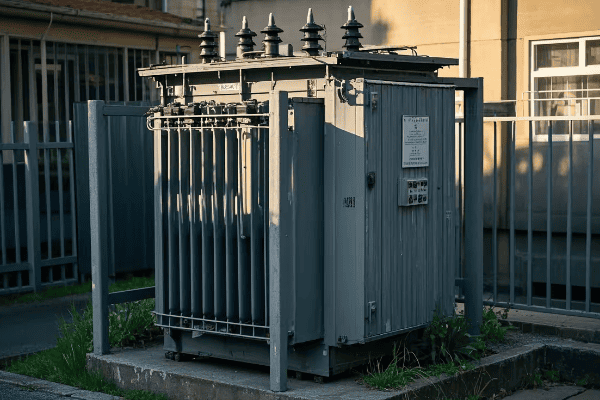

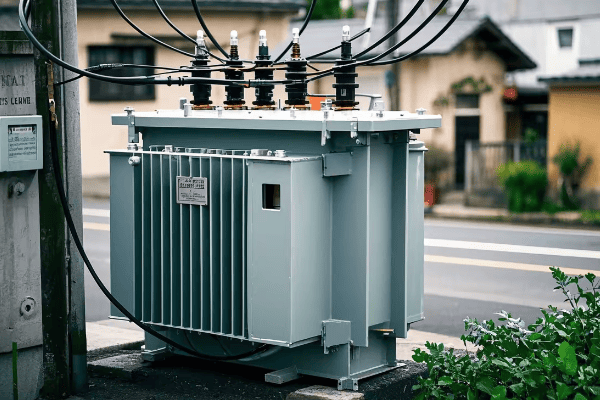

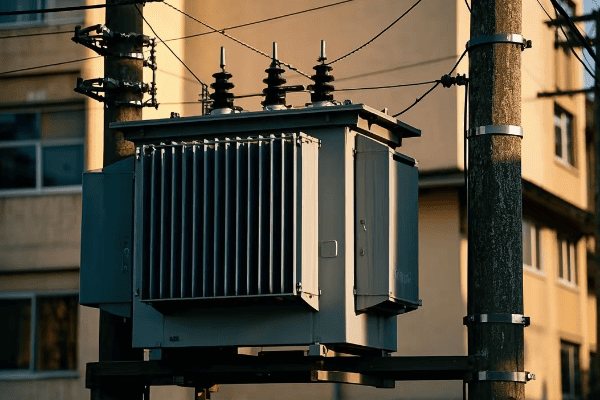

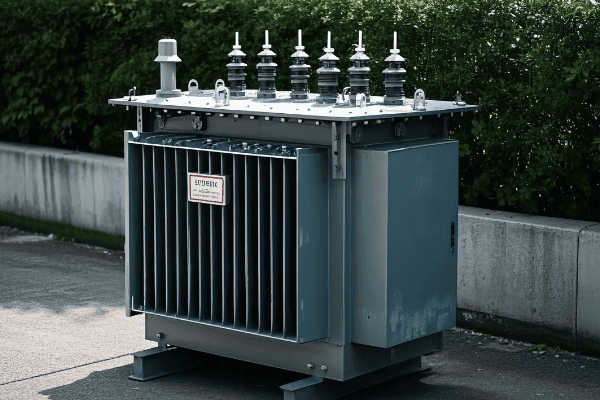

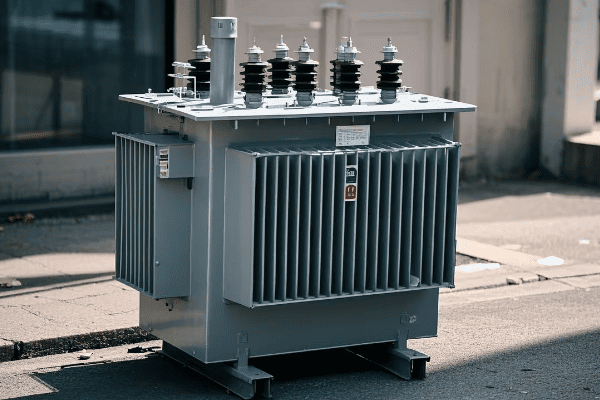

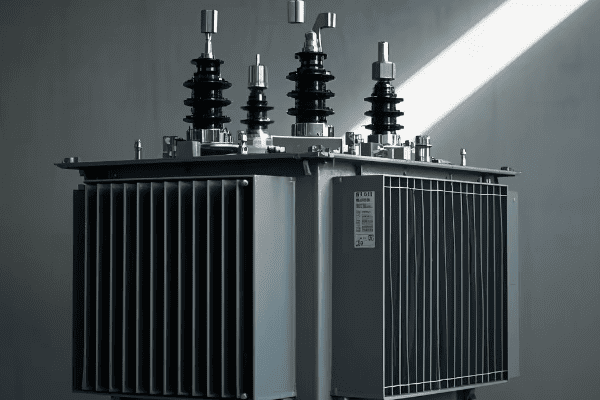

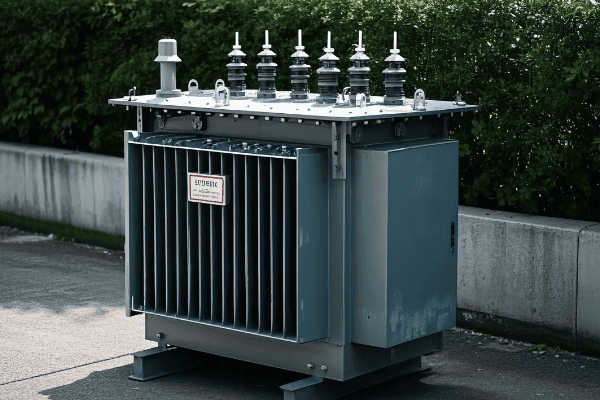

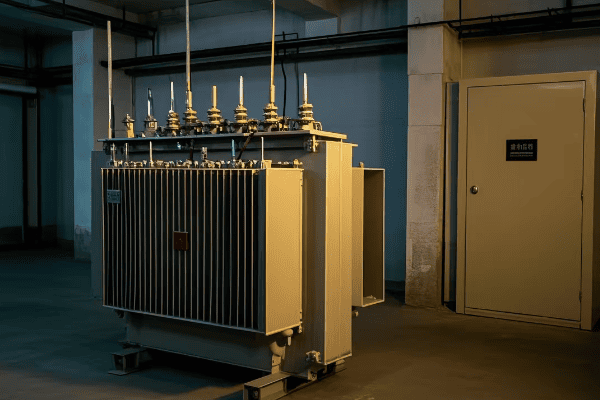

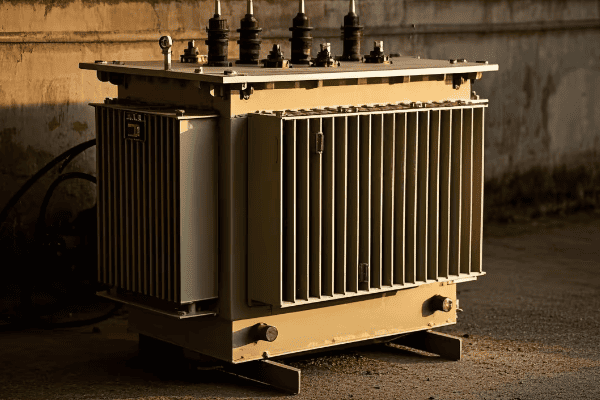

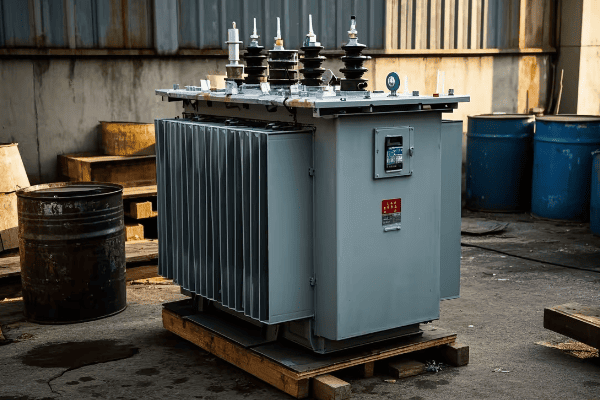

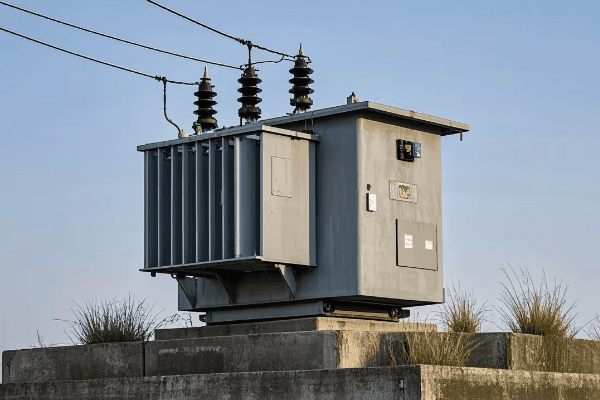

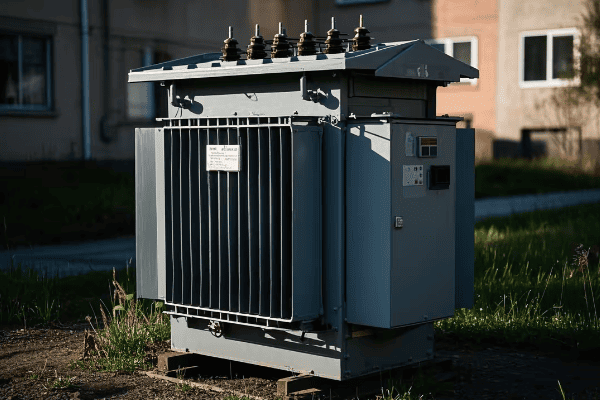

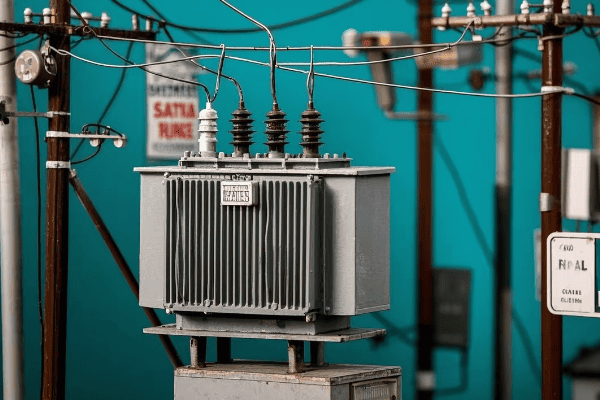

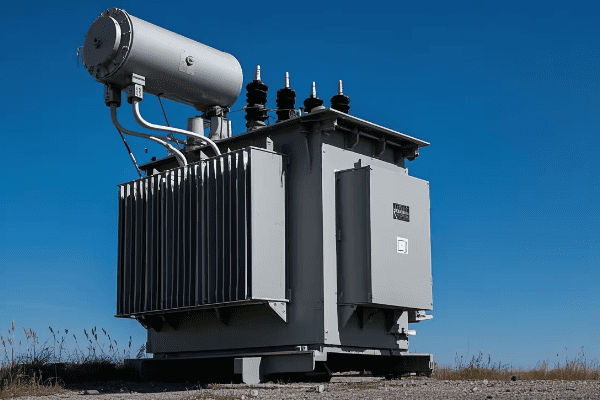

Power transformers handle high voltages at power plants and substations, while distribution transformers lower the voltage for safe use in homes and businesses. They differ in size, capacity, and placement within the electrical grid.

Let’s break down the key differences between these two types of transformers:

Size and Capacity

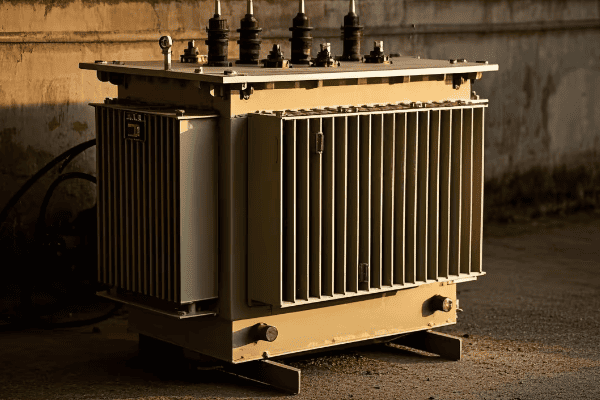

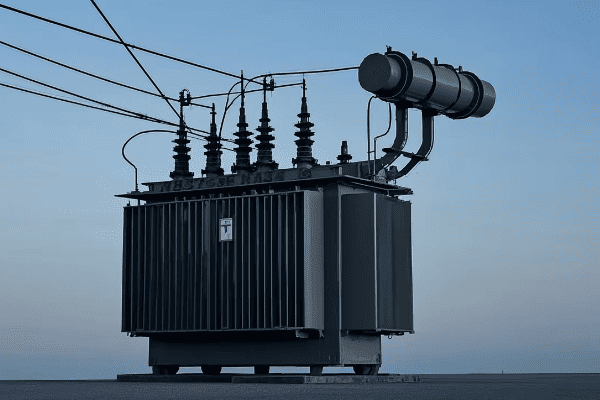

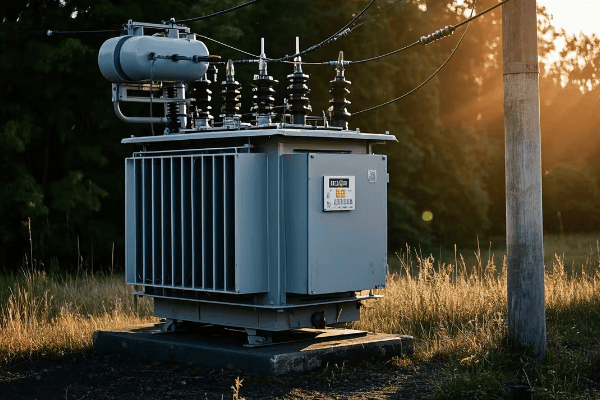

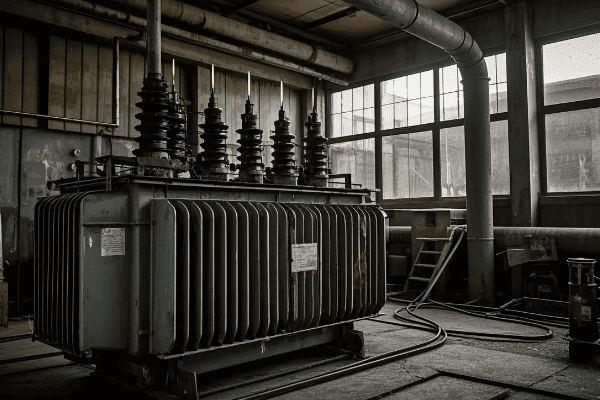

Power transformers are the giants of the transformer world. I remember the first time I saw one up close – it was as big as a small house! They’re designed to handle enormous amounts of power, often in the range of hundreds of megavolt-amperes (MVA).

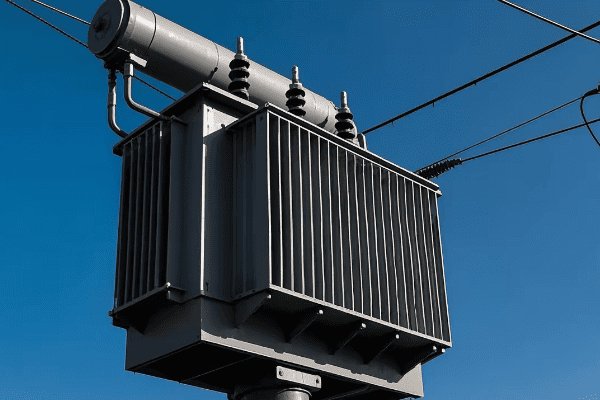

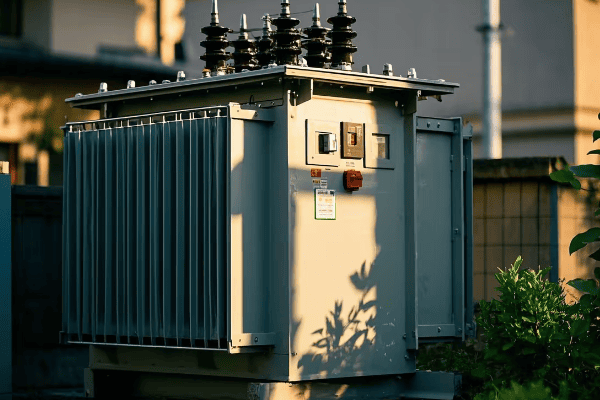

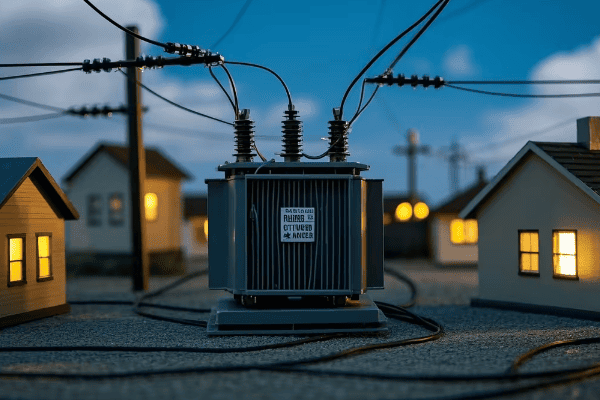

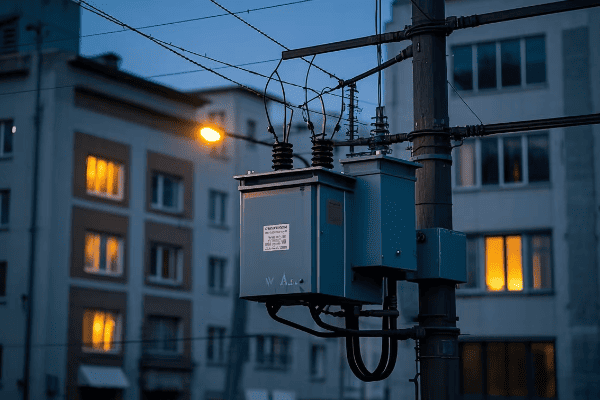

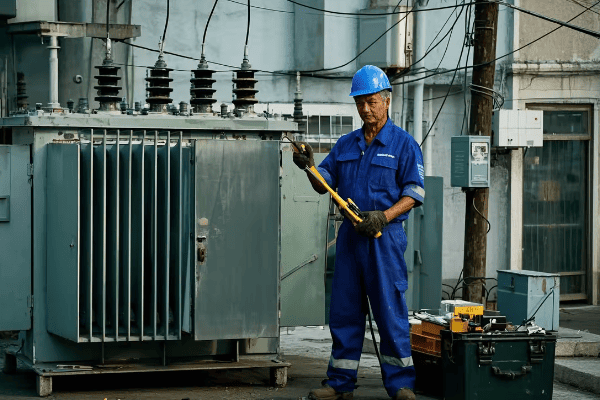

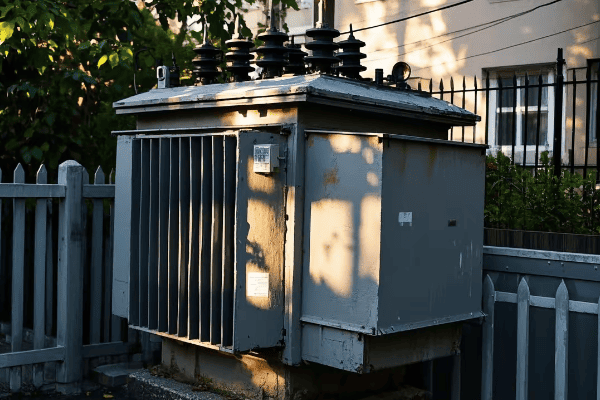

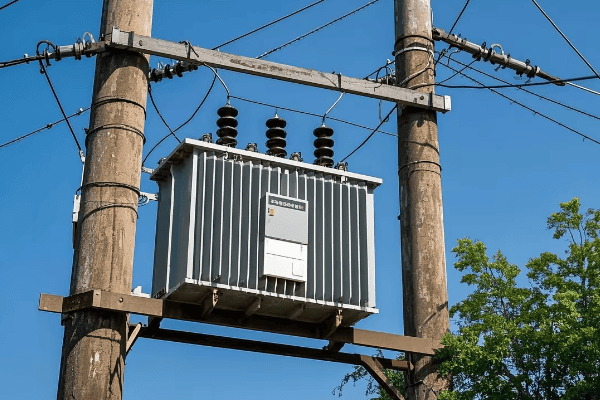

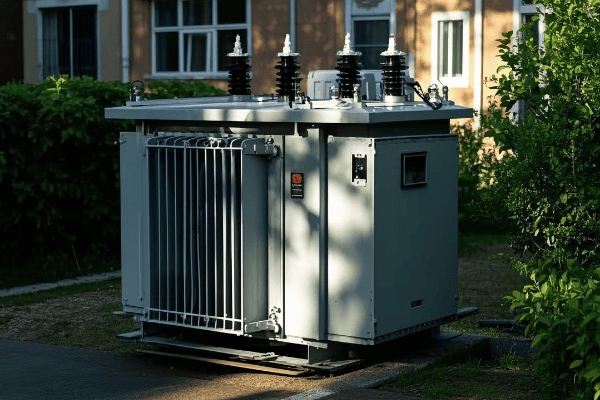

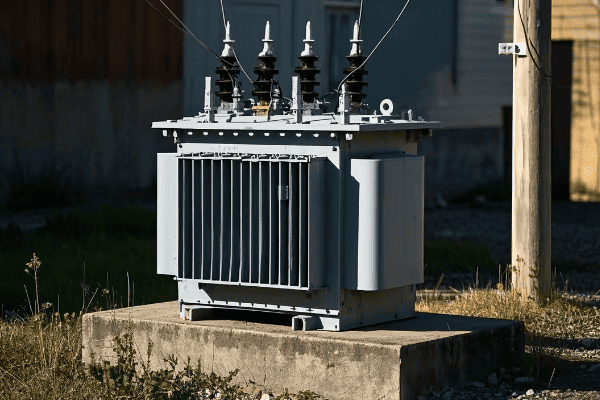

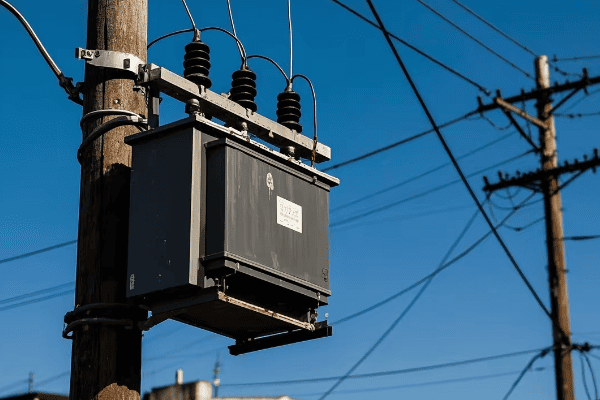

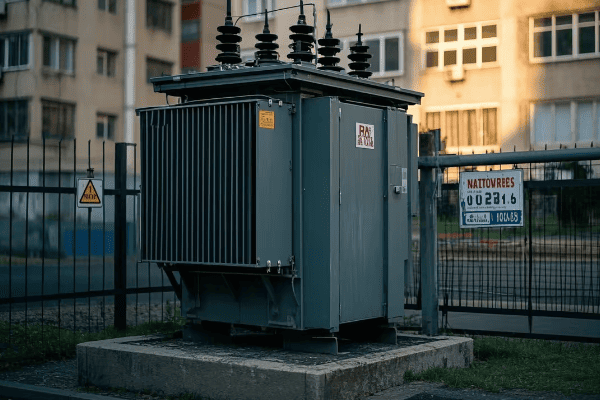

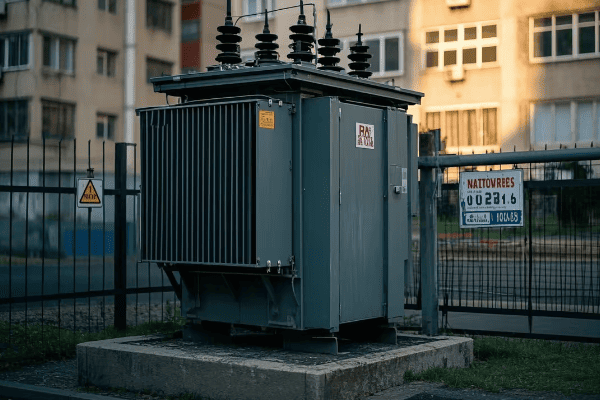

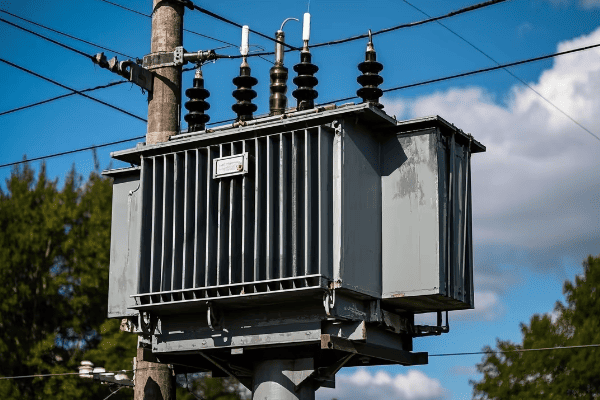

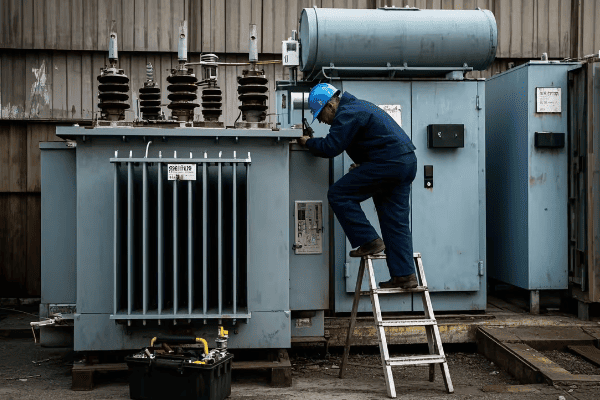

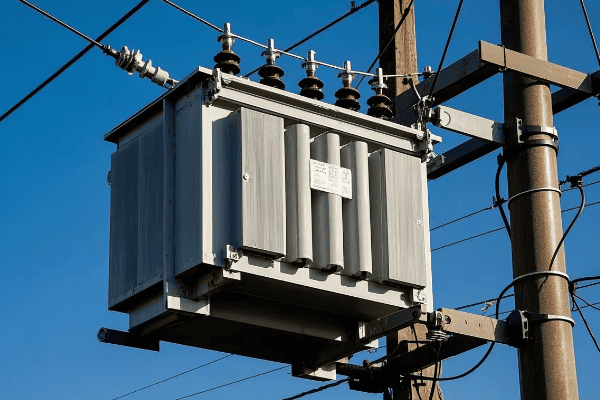

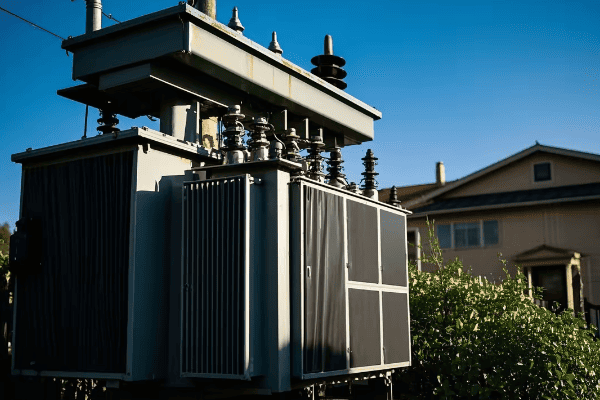

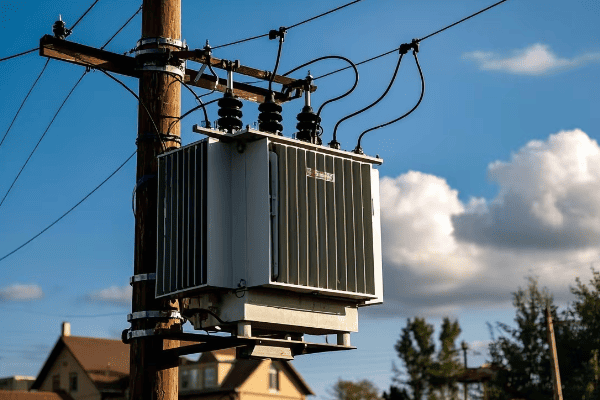

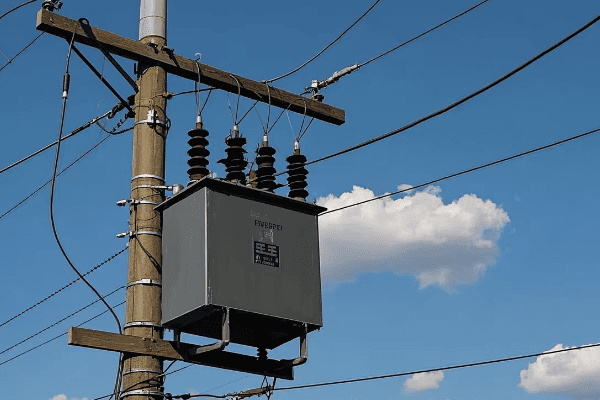

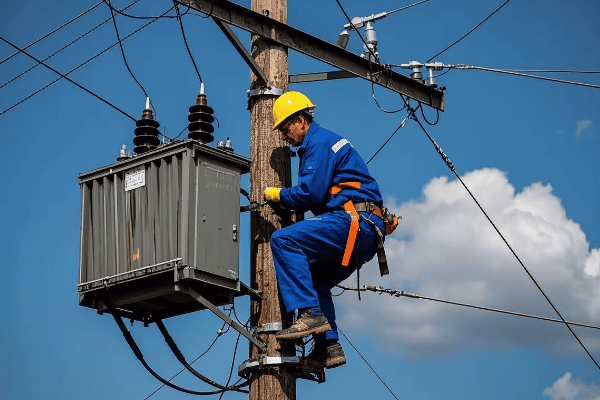

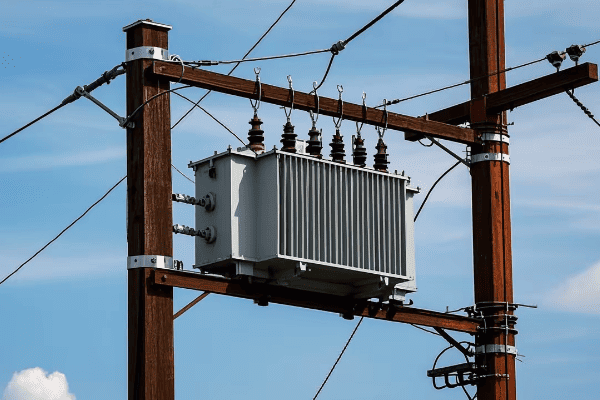

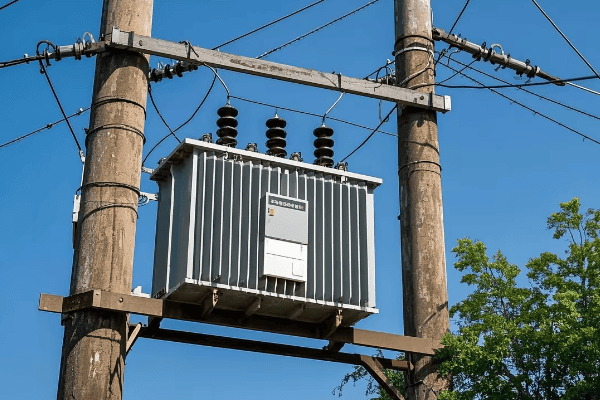

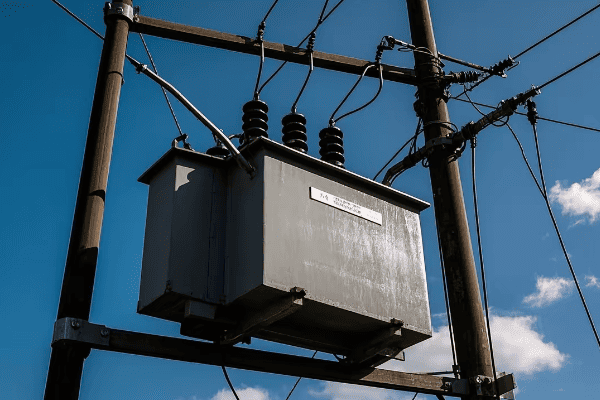

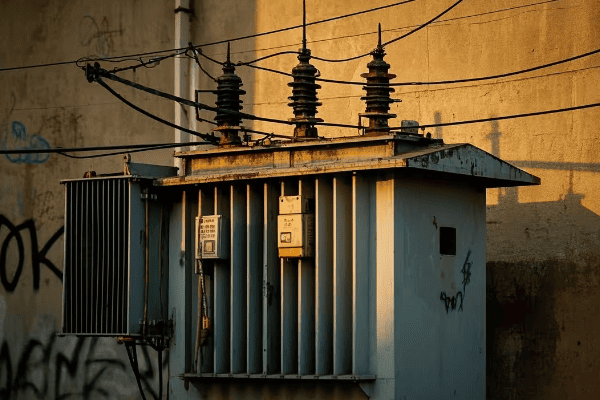

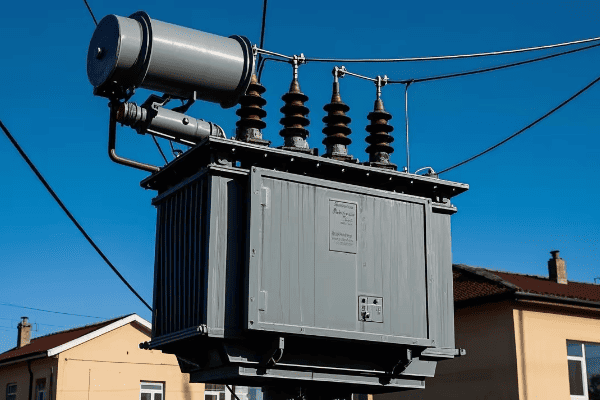

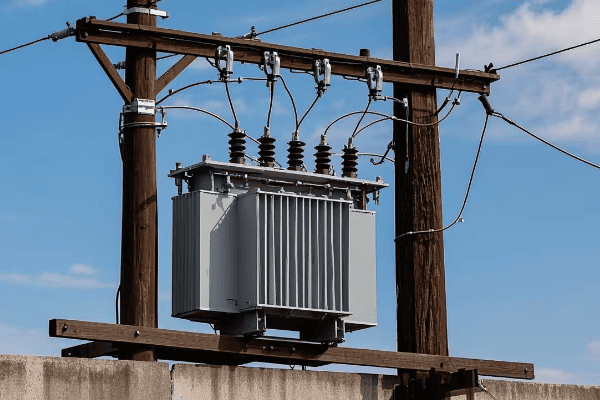

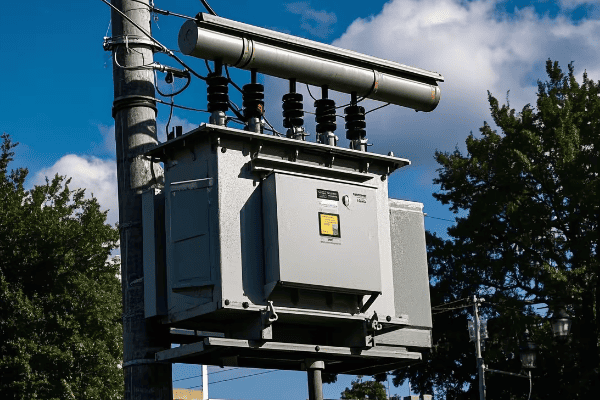

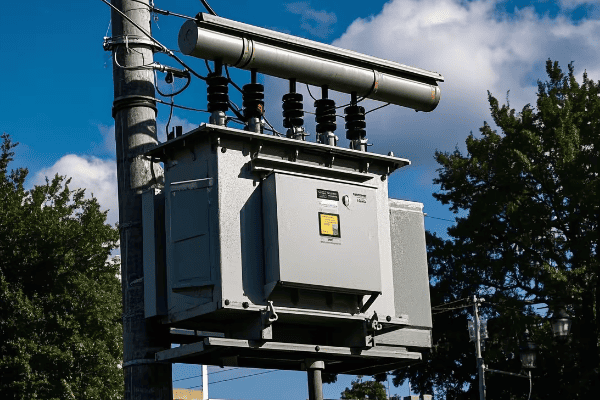

Distribution transformers, on the other hand, are much smaller. You’ve probably seen them mounted on utility poles or in green boxes in your neighborhood. They typically handle power in the range of 5 to 500 kVA.

Voltage Levels

Here’s where the real magic happens:

| Transformer Type | Input Voltage | Output Voltage |

|---|---|---|

| Power Transformer | 100kV – 1000kV | 20kV – 100kV |

| Distribution Transformer | 4kV – 35kV | 120V – 600V |

Power transformers work with extremely high voltages, stepping them down for long-distance transmission. Distribution transformers take that stepped-down voltage and reduce it further to levels safe for household use.

Location in the Grid

Power transformers are found at power plants and major substations. They’re the first step in the journey of electricity from generation to consumption.

Distribution transformers are the last step before power reaches the end-user. You’ll find them closer to residential and commercial areas.

Efficiency and Losses

Both types of transformers strive for high efficiency, but power transformers generally have higher efficiency ratings due to their larger size and the critical nature of their role. Even a small improvement in efficiency can result in significant energy savings given the large amounts of power they handle.

Distribution transformers, while also efficient, may have slightly lower efficiency ratings. However, their efficiency is crucial too, as losses at this stage directly affect the end-user’s power quality and electricity costs.

How Do Power and Distribution Transformers Synergize to Enhance Grid Performance?

Imagine an orchestra where each instrument plays its part perfectly, but they’re not in sync. The result would be chaos, not music. The same principle applies to our electrical grid.

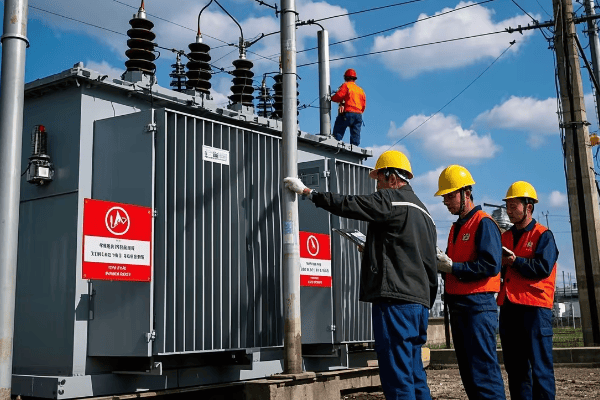

Power and distribution transformers work in harmony to ensure efficient power transmission. Power transformers step up voltage for long-distance transmission, while distribution transformers step it down for local use, minimizing energy losses and ensuring stable power supply.

Let’s explore how these two types of transformers work together:

The Power Journey

- Generation: At the power plant, electricity is generated at relatively low voltages.

- Step-Up: Power transformers increase this voltage to very high levels (often 400kV or more) for efficient long-distance transmission.

- Transmission: High-voltage power travels through transmission lines, minimizing losses over long distances.

- Step-Down: At substations, power transformers reduce the voltage to medium levels (typically 33kV or 11kV).

- Distribution: Distribution transformers further reduce the voltage to levels suitable for homes and businesses (120V/240V in the US).

Balancing Act

The synergy between power and distribution transformers is all about balance. Power transformers handle the bulk power transfer, while distribution transformers manage the final delivery. This division of labor ensures that each type of transformer can be optimized for its specific role.

Load Management

Distribution transformers play a crucial role in load management. They’re designed to handle the varying power demands of local areas throughout the day. Power transformers, meanwhile, ensure that there’s always enough power available to meet these changing demands.

Fault Protection

Both types of transformers incorporate protective measures, but they work together to isolate faults and prevent widespread outages. A fault at the distribution level can be isolated without affecting the entire grid, thanks to this hierarchical system.

Efficiency Optimization

By working in tandem, power and distribution transformers optimize the overall efficiency of the grid. The high voltages used in transmission (thanks to power transformers) minimize line losses, while the lower voltages at the distribution level (courtesy of distribution transformers) ensure safe and efficient power use by consumers.

The Impact of Power and Distribution Transformers on Energy Efficiency: A Detailed Analysis

As an engineer, I’m always excited about efficiency. It’s not just about saving money – it’s about making the most of our resources and reducing our environmental impact.

Power and distribution transformers significantly impact energy efficiency by minimizing transmission losses and optimizing voltage levels. Their combined efficiency determines how much of the generated power actually reaches end-users, directly affecting energy costs and environmental impact.

Let’s dive into the numbers and see how these transformers affect energy efficiency:

Efficiency Ratings

Transformer efficiency is typically very high, but even small improvements can have a big impact:

| Transformer Type | Typical Efficiency |

|---|---|

| Power Transformer | 99.5% – 99.9% |

| Distribution Transformer | 98% – 99% |

These might seem like small differences, but when you’re dealing with massive amounts of power, every fraction of a percent counts.

Losses in Transformers

Transformers experience two main types of losses:

- No-load losses: These occur even when the transformer is energized but not supplying load. They’re mainly due to the magnetization of the core.

- Load losses: These increase with the load and are primarily due to resistance in the windings.

Power transformers, due to their size and continuous operation, focus more on minimizing no-load losses. Distribution transformers, with their varying loads, need to balance both types of losses.

Impact on Grid Efficiency

Let’s consider a simplified example:

- A power plant generates 100 MW of power.

- It passes through a power transformer (99.7% efficient) for transmission.

- At the substation, it goes through another power transformer (99.7% efficient).

- Finally, it passes through a distribution transformer (98.5% efficient) to reach homes.

The total efficiency would be: 0.997 0.997 0.985 = 0.979 or 97.9%

This means that out of the 100 MW generated, only about 97.9 MW reaches the end-users. The 2.1 MW lost is enough to power thousands of homes!

Economic and Environmental Impact

The efficiency of transformers has a direct impact on:

- Energy Costs: Higher efficiency means less power needs to be generated to meet demand, reducing fuel costs and potentially lowering electricity prices for consumers.

- Carbon Emissions: Improved efficiency reduces the amount of fuel burned for power generation, directly lowering carbon emissions.

- Grid Stability: Efficient transformers help maintain voltage stability, reducing the risk of power quality issues and outages.

Regulatory Push for Efficiency

Recognizing the importance of transformer efficiency, many countries have implemented minimum efficiency standards. For example, the U.S. Department of Energy’s standards for distribution transformers are expected to save 3.63 quads of energy over 30 years – that’s equivalent to the annual energy use of 27 million homes!

Smart Grid Integration: The Evolution of Power and Distribution Transformer Technologies

The term "smart grid" used to sound like science fiction to me. Now, it’s becoming a reality, and transformers are at the heart of this revolution.

Smart grid integration is transforming power and distribution transformers into intelligent, communicative devices. These advanced transformers can monitor their own health, adjust to changing loads, and communicate with other grid components, enhancing overall grid efficiency and reliability.

Let’s explore how transformer technology is evolving to support smart grids:

Smart Features in Modern Transformers

-

Real-time Monitoring: Advanced sensors in transformers can now monitor:

- Oil temperature

- Winding temperature

- Load current

- Voltage levels

- Dissolved gas content

-

Data Analytics: This data is processed to:

- Predict potential failures

- Optimize load distribution

- Schedule maintenance

-

Communication Capabilities: Transformers can now communicate with control centers, allowing for:

- Remote monitoring

- Automatic alerts

- Integration with other smart grid components

-

Adaptive Features: Some advanced transformers can:

- Automatically adjust voltage levels

- Respond to changes in power quality

- Self-diagnose issues

Benefits of Smart Transformer Technology

-

Improved Reliability: By predicting and preventing failures, smart transformers can significantly reduce outages.

-

Enhanced Efficiency: Real-time load management and voltage optimization lead to reduced losses.

-

Extended Lifespan: Predictive maintenance helps extend the life of transformers, reducing replacement costs.

-

Better Integration of Renewable Energy: Smart transformers can help manage the variable nature of renewable energy sources.

-

Faster Outage Response: When issues do occur, smart transformers can pinpoint the problem, allowing for faster repairs.

Challenges in Smart Grid Integration

While the benefits are clear, there are challenges to overcome:

-

Cost: Smart transformers are more expensive than traditional ones. The challenge is justifying this cost against long-term benefits.

-

Cybersecurity: With increased connectivity comes increased vulnerability to cyber attacks. Robust security measures are crucial.

-

Data Management: The sheer volume of data generated by smart transformers requires advanced data management and analysis systems.

-

Standardization: For a truly integrated smart grid, we need standardized communication protocols across different manufacturers and systems.

Future Prospects

The future of transformer technology in smart grids is exciting. Some areas of development include:

-

AI Integration: Using artificial intelligence for more advanced predictive maintenance and grid optimization.

-

Solid-State Transformers: These could offer even more flexibility and control in power distribution.

-

Energy Storage Integration: Combining transformers with energy storage systems for better load balancing and renewable energy integration.

-

Self-Healing Grids: Advanced transformers could play a key role in creating grids that can automatically detect, isolate, and repair faults.

Maintenance Strategies for Power and Distribution Transformers: Ensuring Long-term Grid Reliability

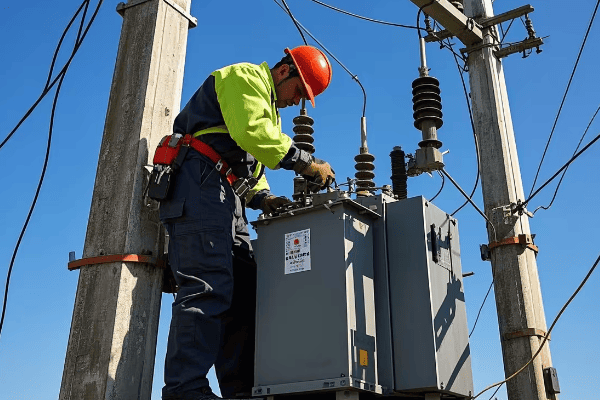

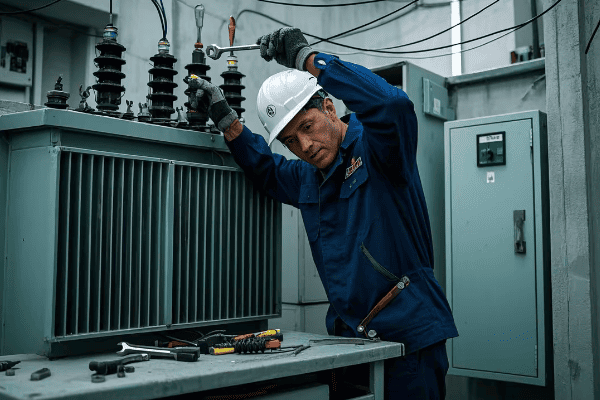

In my years working with transformers, I’ve learned one crucial lesson: proper maintenance is not just about preventing failures – it’s about ensuring the long-term health of our entire power grid.

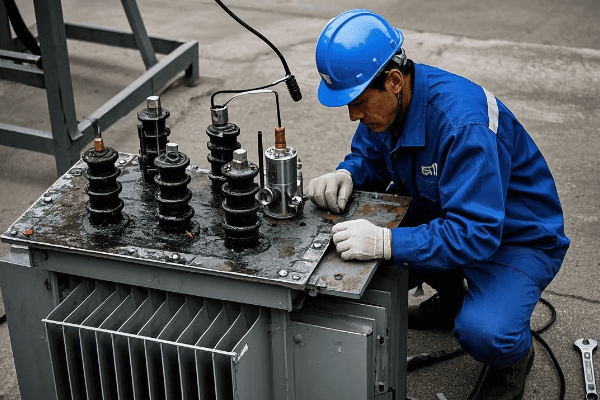

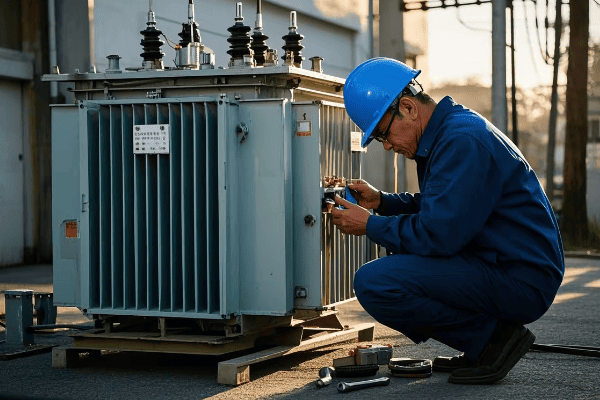

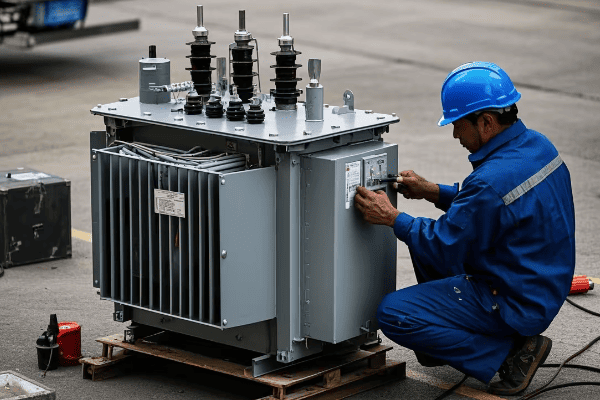

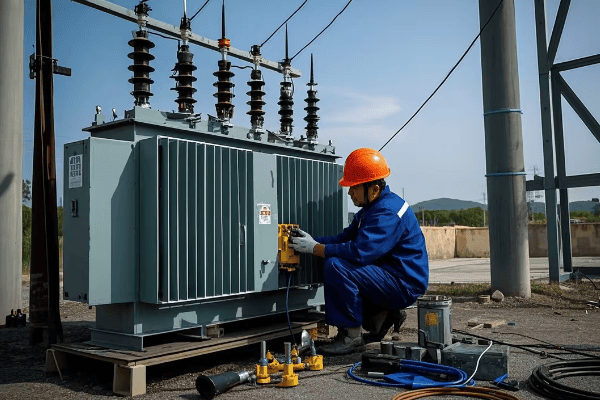

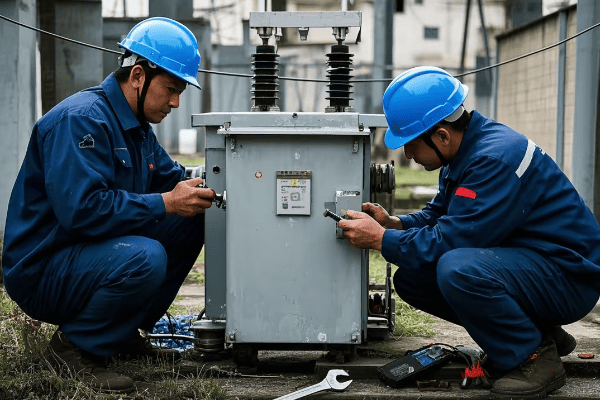

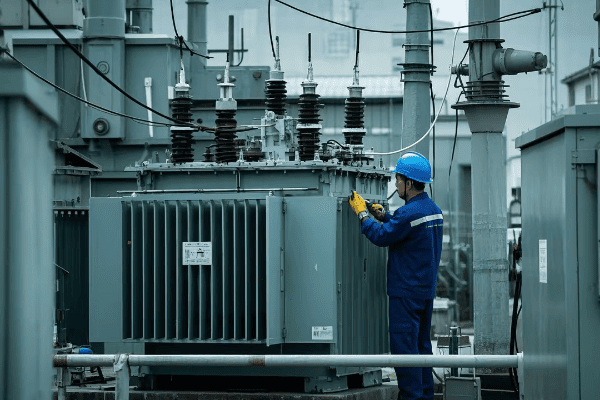

Effective maintenance of power and distribution transformers is crucial for grid reliability. Strategies include regular inspections, oil analysis, thermal imaging, and predictive maintenance techniques. These practices extend transformer life, prevent unexpected failures, and ensure consistent power quality.

Let’s explore the key maintenance strategies for both power and distribution transformers:

Regular Inspections

-

Visual Inspections:

- Frequency: Monthly for power transformers, quarterly for distribution transformers

- Check for: Oil leaks, rust, damaged bushings, unusual sounds

-

Thermal Imaging:

- Frequency: Annually

- Purpose: Detect hot spots that could indicate problems

-

Acoustic Emissions Testing:

- Frequency: Annually for critical transformers

- Purpose: Detect partial discharges and other internal issues

Oil Analysis

Oil is the lifeblood of a transformer. Regular analysis can reveal a lot about a transformer’s health:

-

Dissolved Gas Analysis (DGA):

- Frequency: Annually for power transformers, every 3-5 years for distribution transformers

- Purpose: Detect internal faults, overheating, and insulation breakdown

-

Oil Quality Tests:

- Frequency: Annually

- Check for: Acidity, moisture content, dielectric strength

-

Furan Analysis:

- Frequency: Every 3-5 years

- Purpose: Assess the condition of paper insulation

Electrical Testing

-

Insulation Resistance Test:

- Frequency: Annually

- Purpose: Check the condition of insulation

-

Power Factor Testing:

- Frequency: Every 3-5 years

- Purpose: Detect deterioration in insulation

-

Turns Ratio Test:

- Frequency: During commissioning and after any suspected impact

- Purpose: Verify the transformer’s turns ratio

Predictive Maintenance Techniques

-

Online Monitoring Systems:

- Continuous monitoring of key parameters

- Real-time alerts for abnormal conditions

-

Data Analytics:

- Use historical data to predict potential failures

- Optimize maintenance schedules

-

Condition-Based Maintenance:

- Schedule maintenance based on actual condition rather than fixed intervals

Maintenance Challenges and Solutions

-

Aging Infrastructure:

- Challenge: Many transformers are nearing the end of their designed lifespan

- Solution: Life extension programs, strategic replacement planning

-

Skill Gap:

- Challenge: Shortage of experienced maintenance personnel

- Solution: Training programs, knowledge transfer from retiring experts

-

Balancing Cost and Reliability:

- Challenge: Justifying maintenance costs

- Solution: Risk-based maintenance strategies, demonstrating long-term cost savings

-

Environmental Concerns:

- Challenge: Handling of transformer oil, PCB contamination in older units

- Solution: Use of environmentally friendly oils, proper disposal procedures

Best Practices for Transformer Maintenance

-

Develop a Comprehensive Maintenance Plan: Tailor plans to each transformer’s criticality and condition.

-

Implement a Robust Record-Keeping System: Track all maintenance activities and test results.

-

Invest in Training: Ensure maintenance personnel are up-to-date with the latest techniques and safety procedures.

-

Utilize Technology: Implement online monitoring and data analytics for more efficient maintenance.

-

Regular Review and Update: Continuously assess and improve maintenance strategies based on outcomes and new technologies.

Conclusion

Power and distribution transformers are indeed the unsung heroes of our electrical grid. Their efficient operation and proper maintenance are crucial for the reliable power supply we often take for granted. As we move towards smarter, more efficient grids, the role of these transformers will only become more important.

Are you struggling with energy inefficiencies in your power system? You’re not alone. Many utilities and industries face challenges in optimizing their power distribution networks.

Power and distribution transformers are revolutionizing modern power systems by enhancing energy efficiency and enabling smart grid integration. These advanced transformers incorporate cutting-edge technologies to reduce energy losses, improve power quality, and facilitate the integration of renewable energy sources. They play a crucial role in creating more resilient, flexible, and sustainable power networks.

As someone who has spent years working with power and distribution transformers, I’ve witnessed firsthand the remarkable advancements in this field. In this article, I’ll guide you through the latest innovations and explain how these transformers are shaping the future of our power systems.

How Are Advanced Power and Distribution Transformers Boosting Energy Efficiency in Modern Grids?

Are you concerned about energy losses in your power distribution network? You should be. Energy efficiency is crucial for both cost savings and environmental sustainability.

Advanced power and distribution transformers boost energy efficiency through improved core materials, optimized winding designs, and smart load management systems. They significantly reduce no-load and load losses, enhance voltage regulation, and maintain high efficiency across varying load conditions. These improvements lead to substantial energy savings and reduced operational costs in modern grids.

Let’s dive deeper into how these transformers are enhancing energy efficiency:

Advanced Core Materials

Modern transformers use cutting-edge materials to minimize core losses.

Core Innovations:

- Amorphous metal cores for ultra-low no-load losses

- High-grade silicon steel with thinner laminations

- Nanocrystalline materials for improved magnetic properties

Optimized Winding Designs

Innovative winding techniques reduce copper losses and improve efficiency.

Winding Advancements:

- Foil windings for better current distribution

- Continuously transposed conductors to minimize eddy currents

- Advanced insulation materials for improved heat dissipation

Smart Load Management

Intelligent systems optimize transformer performance under varying loads.

Smart Features:

- Real-time load monitoring and adjustment

- Automatic voltage regulation

- Dynamic tap changing for optimal efficiency

Enhanced Cooling Systems

Improved cooling designs contribute to overall efficiency.

Cooling Innovations:

- Advanced oil circulation techniques

- Use of biodegradable and more efficient cooling fluids

- Integration of heat recovery systems for energy reuse

| Efficiency Feature | Energy Saving Potential | Implementation Complexity |

|---|---|---|

| Advanced Core Materials | High | Moderate |

| Optimized Windings | Moderate to High | Low to Moderate |

| Smart Load Management | High | High |

| Enhanced Cooling | Moderate | Moderate |

In my experience working with utilities and industrial clients, the impact of these efficiency improvements can be substantial. I recall a project where we replaced an aging transformer fleet for a large manufacturing plant. By implementing transformers with amorphous metal cores and advanced winding designs, we achieved a 30% reduction in energy losses. This translated to significant cost savings for the client and a notable decrease in their carbon footprint.

It’s important to note that efficiency gains aren’t just about the hardware. In one case, I worked on integrating smart load management systems into a utility’s transformer network. The ability to dynamically adjust transformer settings based on real-time load conditions led to an additional 10% improvement in overall grid efficiency. This not only reduced energy waste but also extended the lifespan of the transformers by optimizing their operation.

Don’t overlook the importance of proper sizing and selection in maximizing efficiency. I’ve developed a comprehensive assessment process that considers load profiles, environmental conditions, and future growth projections. This approach ensures that each transformer operates at its optimal efficiency point, maximizing energy savings over its lifetime.

Another crucial aspect is the role of enhanced cooling systems in maintaining high efficiency. I recently worked on a project implementing a novel heat recovery system in a substation. The waste heat from the transformers was used to heat nearby buildings, turning an efficiency challenge into an energy-saving opportunity.

Lastly, it’s exciting to see how advancements in materials science are pushing the boundaries of transformer efficiency. I’m currently involved in a research project exploring the use of graphene-based materials in transformer cores. While still in the experimental stage, these materials show promise for even lower losses and higher efficiency than current technologies.

The energy efficiency enhancements offered by advanced power and distribution transformers are not just incremental improvements – they represent a significant leap forward in grid optimization. From innovative materials to smart management systems, these transformers are key to creating more sustainable and cost-effective power networks. As we continue to face global energy challenges, the role of high-efficiency transformers in building a more energy-efficient future cannot be overstated.

What Key Features Enable Power and Distribution Transformers to Support Smart Grid Integration?

Are you struggling to adapt your power infrastructure to the demands of smart grids? You’re not alone. The transition to intelligent power systems presents unique challenges for traditional equipment.

Power and distribution transformers support smart grid integration through advanced monitoring systems, communication capabilities, and adaptive control features. They incorporate sensors for real-time data collection, bidirectional power flow management, and voltage regulation technologies. These features enable seamless integration with grid management systems, facilitating efficient energy distribution and responsive grid operations.

Let’s explore the key features that make modern transformers smart grid-ready:

Advanced Monitoring Systems

Smart transformers provide real-time insights into their operation and grid conditions.

Monitoring Capabilities:

- Temperature and oil condition sensors

- Load and power quality analyzers

- Partial discharge detection systems

Communication Interfaces

These transformers can exchange data with grid management systems.

Communication Features:

- Integration with SCADA systems

- Support for various protocols (e.g., IEC 61850, DNP3)

- Secure data transmission capabilities

Adaptive Control Mechanisms

Smart transformers can adjust their operation based on grid conditions.

Adaptive Features:

- On-load tap changers for voltage regulation

- Reactive power compensation

- Fault current limiting capabilities

Bidirectional Power Flow Management

These transformers can handle power flow in both directions, crucial for renewable integration.

Bidirectional Capabilities:

- Management of distributed energy resources

- Support for microgrid operations

- Enhanced harmonics management

| Smart Grid Feature | Transformer Capability | Grid Benefit |

|---|---|---|

| Real-time Monitoring | Advanced Sensors | Improved Reliability |

| Data Communication | Multiple Interfaces | Enhanced Grid Management |

| Adaptive Control | Dynamic Adjustments | Increased Stability |

| Bidirectional Power | Flexible Power Handling | Renewable Integration |

In my years of working on smart grid projects, I’ve seen how these features transform the role of transformers from passive components to active grid management tools. I remember a project where we upgraded a suburban substation with smart transformers. The real-time monitoring and communication capabilities allowed the utility to detect and respond to voltage fluctuations caused by rooftop solar installations, significantly improving power quality in the area.

It’s important to note that implementing these smart features often requires a holistic approach to grid modernization. In one case, I worked with a utility to develop a phased smart grid rollout plan. We started by upgrading key transformers with advanced monitoring systems, then gradually implemented communication and control features. This step-by-step approach allowed for a smoother transition and helped the utility staff adapt to the new technologies.

Don’t overlook the importance of cybersecurity in smart grid-enabled transformers. I recently led a team in developing security protocols for a network of smart transformers. We implemented multi-layer encryption, secure boot processes, and intrusion detection systems to protect against potential cyber threats. This aspect of smart grid integration is becoming increasingly critical as our power systems become more interconnected and data-driven.

Another crucial aspect is the role of these transformers in enabling microgrid capabilities. I’m currently advising on a project where smart transformers are key components in a community microgrid. These transformers can seamlessly switch between grid-connected and island modes, providing resilience during main grid outages while also optimizing local energy use and generation.

Lastly, it’s exciting to see how the integration of artificial intelligence is taking transformer capabilities to new levels. I’m part of a research team exploring the use of machine learning algorithms to predict grid disturbances based on data from smart transformers. This predictive capability could revolutionize grid management, allowing for proactive measures to maintain stability and efficiency.

The key features that enable power and distribution transformers to support smart grid integration are transforming these devices from simple power conversion units to intelligent nodes in our energy networks. As we continue to develop and implement smart grid technologies, the role of these advanced transformers will be crucial in creating more resilient, efficient, and flexible power systems capable of meeting the complex energy needs of the future.

How Are Power and Distribution Transformers Evolving to Meet the Demands of Modern Power Systems?

Are you finding it challenging to keep up with the rapidly changing needs of modern power systems? You’re not alone. The evolution of our energy landscape is pushing transformer technology to new limits.

Power and distribution transformers are evolving through the integration of digital technologies, advanced materials, and flexible designs. They now feature enhanced power electronics, improved insulation systems, and modular architectures. These evolutions enable transformers to handle variable loads, integrate renewable sources, and provide ancillary services to the grid, meeting the complex demands of modern power systems.

Let’s explore how transformers are adapting to meet modern power system demands:

Integration of Power Electronics

Modern transformers incorporate advanced power electronic components.

Power Electronic Features:

- Solid-state tap changers for faster voltage regulation

- Active harmonic filtering capabilities

- Fault current limiting functionalities

Advanced Insulation Systems

New insulation technologies enhance performance and reliability.

Insulation Advancements:

- Nano-composite materials for improved thermal management

- Biodegradable insulating fluids

- Self-healing insulation technologies

Modular and Scalable Designs

Transformers are becoming more adaptable to changing system needs.

Modular Advantages:

- Easily upgradable components

- Customizable configurations for specific applications

- Reduced downtime for maintenance and repairs

Enhanced Grid Support Capabilities

Modern transformers provide various ancillary services to the grid.

Grid Support Features:

- Reactive power compensation

- Voltage and frequency regulation support

- Black start capabilities for grid restoration

| Evolution Area | Key Innovation | System Benefit |

|---|---|---|

| Power Electronics | Solid-State Components | Improved Power Quality |

| Insulation | Nano-materials | Enhanced Reliability |

| Design Approach | Modularity | Increased Flexibility |

| Grid Support | Ancillary Services | Better System Stability |

In my experience working with utilities and manufacturers, these evolutions are reshaping how we approach power system design and operation. I recall a project where we implemented a new generation of transformers with integrated power electronics in a rapidly growing urban area. The ability of these units to quickly adjust to load changes and provide power quality improvements significantly reduced the need for additional infrastructure upgrades, saving the utility millions in capital expenditure.

It’s important to note that the evolution of transformers is not just about adding new features – it’s about rethinking their fundamental role in the power system. In one case, I worked on developing a hybrid transformer-converter unit for a renewable energy integration project. This innovative design combined the traditional step-up/step-down functionality with DC-AC conversion capabilities, streamlining the integration of large-scale solar farms into the grid.

Don’t overlook the impact of advanced insulation systems on transformer evolution. I recently consulted on a project using new nano-composite insulation materials. These materials not only improved the thermal performance of the transformers but also allowed for a more compact design, crucial for installations in space-constrained urban substations.

Another crucial aspect is the shift towards modular designs. I’m currently advising on a transformer fleet modernization program where modularity is a key requirement. This approach not only simplifies maintenance and upgrades but also allows the utility to quickly adapt their transformer capabilities as grid needs evolve, providing a future-proof solution.

Lastly, it’s exciting to see how transformers are taking on new roles in grid support and stability. I’m part of a research team exploring the use of transformers as active participants in grid frequency regulation. By leveraging their power electronic components and energy storage integration, these advanced transformers can respond to frequency deviations in milliseconds, enhancing overall grid stability.

The evolution of power and distribution transformers to meet the demands of modern power systems is not just about incremental improvements – it’s a fundamental reimagining of their role in our energy infrastructure. From integrating advanced technologies to providing critical grid support services, these evolving transformers are becoming the cornerstone of more flexible, reliable, and efficient power systems. As we continue to face new challenges in our energy landscape, the ongoing evolution of transformer technology will be crucial in shaping the power systems of the future.

What Cutting-Edge Technologies Are Being Incorporated into Transformers for Enhanced Grid Management?

Are you wondering how to improve your grid management capabilities? You’re not alone. Many utilities are seeking advanced solutions to handle the complexities of modern power systems.

Cutting-edge technologies being incorporated into transformers for enhanced grid management include IoT sensors, AI-driven analytics, blockchain for secure data management, and advanced power electronics. These innovations enable real-time monitoring, predictive maintenance, improved cybersecurity, and dynamic power flow control, significantly enhancing overall grid efficiency and reliability.

Let’s explore these cutting-edge technologies in detail:

Internet of Things (IoT) Integration

IoT sensors and connectivity are revolutionizing transformer monitoring.

IoT Capabilities:

- Real-time data collection on various parameters

- Remote monitoring and control

- Integration with broader smart grid systems

Artificial Intelligence and Machine Learning

AI is enhancing transformer diagnostics and decision-making.

AI Applications:

- Predictive maintenance algorithms

- Load forecasting and optimization

- Anomaly detection and fault prediction

Blockchain Technology

Blockchain is improving data security and transaction management.

Blockchain Benefits:

- Secure and transparent data logging

- Improved traceability for regulatory compliance

- Potential for peer-to-peer energy trading support

Advanced Power Electronics

New power electronic solutions are enhancing transformer functionality.

Power Electronic Innovations:

- Solid-state transformers for improved power quality

- Dynamic reactive power compensation

- High-frequency power conversion for size reduction

| Technology | Primary Function | Grid Management Benefit |

|---|---|---|

| IoT | Data Collection | Enhanced Visibility |

| AI/ML | Analytics and Prediction | Improved Decision Making |

| Blockchain | Data Security | Increased Trust and Efficiency |

| Power Electronics | Power Flow Control | Better System Stability |

In my years of working with grid management technologies, I’ve seen how these innovations can transform network operations. I remember a project where we implemented an IoT-based monitoring system across a utility’s transformer fleet. Within months, we were able to reduce unplanned outages by 40% through early detection of developing faults. The real-time data also allowed for more efficient load balancing, improving overall grid stability.

It’s important to note that while these technologies offer powerful capabilities, their implementation often requires a holistic approach. In one case, I worked with a utility to develop an AI-driven asset management system. We had to carefully integrate data from various sources, including transformer IoT sensors, weather patterns, and historical performance records. The resulting system not only optimized maintenance schedules but also provided valuable insights for long-term infrastructure planning.

Don’t overlook the potential of blockchain in enhancing grid management. I recently consulted on a pilot project using blockchain for managing distributed energy resources. The technology provided a secure and transparent way to track energy contributions from various sources, including transformer-level data. This not only improved grid management but also opened up possibilities for new energy trading models.

Another crucial aspect is the role of advanced power electronics in transformer design. I’m currently advising on a project implementing solid-state transformers in a urban microgrid. These devices offer unprecedented control over power flow and quality, allowing for seamless integration of renewable sources and electric vehicle charging stations.

Lastly, it’s exciting to see how these technologies are coming together to create truly intelligent grid management systems. I’m part of a research team developing a next-generation grid control system that combines IoT data, AI analytics, and blockchain security. This system promises to provide a level of grid awareness and responsiveness that was previously unimaginable, potentially revolutionizing how we manage and optimize our power networks.

The incorporation of cutting-edge technologies into transformers is not just enhancing grid management – it’s redefining what’s possible in power system operation. From IoT-enabled real-time monitoring to AI-driven predictive maintenance and blockchain-secured data management, these innovations are creating smarter, more efficient, and more reliable grids. As we continue to face new challenges in our evolving energy landscape, these advanced transformer technologies will play a crucial role in building the resilient and responsive power systems of the future.

How Do Power and Distribution Transformers Facilitate the Integration of Renewable Energy Sources?

Are you struggling to integrate renewable energy sources into your power grid? You’re not alone. Many utilities face challenges in managing the variable nature of renewables.

Power and distribution transformers facilitate renewable energy integration through advanced voltage regulation, bidirectional power flow capabilities, and smart grid functionalities. They handle the intermittent nature of renewable sources, manage power quality issues, and enable efficient energy distribution. These transformers also support microgrid operations and energy storage integration, crucial for maximizing renewable energy utilization.

Let’s dive deeper into how transformers are enabling renewable energy integration:

Advanced Voltage Regulation

Modern transformers provide dynamic voltage support for variable renewable inputs.

Voltage Regulation Features:

- On-load tap changers with rapid response times

- Automatic voltage regulators for real-time adjustments

- Reactive power compensation capabilities

Bidirectional Power Flow Management

Transformers now handle power flow in both directions, essential for distributed generation.

Bidirectional Capabilities:

- Redesigned windings to support reverse power flow

- Enhanced protection systems for backfeed scenarios

- Smart inverter integration for seamless power management

Power Quality Management

Transformers address power quality issues associated with renewable sources.

Power Quality Solutions:

- Harmonic mitigation technologies

- Flicker reduction capabilities

- Fault ride-through features for grid stability

Microgrid and Energy Storage Support

Modern transformers enable microgrid operations and integrate with storage systems.

Microgrid and Storage Features:

- Islanding detection and support

- Seamless transition between grid-connected and island modes

- Interfaces for battery energy storage systems

| Integration Aspect | Transformer Function | Renewable Energy Benefit |

|---|---|---|

| Voltage Regulation | Dynamic Adjustment | Stable Grid Operation |

| Bidirectional Flow | Flexible Power Handling | Enables Distributed Generation |

| Power Quality | Disturbance Mitigation | Improved System Reliability |

| Microgrid Support | Operational Flexibility | Enhanced Energy Resilience |

In my experience working with renewable energy projects, the role of advanced transformers has been crucial. I recall a large-scale solar farm integration project where we faced significant challenges with voltage fluctuations. By implementing transformers with fast-acting on-load tap changers and reactive power compensation, we were able to maintain grid stability even during rapid changes in solar output. This solution not only enabled the successful integration of the solar farm but also improved overall power quality in the region.

It’s important to note that the benefits of these advanced transformers extend beyond just technical performance. In one case, I worked with a utility to develop a comprehensive renewable integration strategy. The flexibility offered by modern transformers allowed for a phased approach to renewable adoption, significantly reducing the upfront costs and risks associated with the transition to cleaner energy sources.

Don’t overlook the importance of transformer design in addressing specific renewable energy challenges. I recently consulted on a wind farm project where we custom-designed transformers to handle the unique load profiles and environmental conditions of offshore wind turbines. These specialized units incorporated enhanced cooling systems and corrosion-resistant materials, ensuring reliable operation in harsh marine environments.

Another crucial aspect is the role of transformers in enabling community-scale renewable projects. I’m currently advising on a microgrid initiative that uses advanced transformers as key nodes in a neighborhood-level renewable energy network. These transformers not only manage the integration of rooftop solar and small wind turbines but also facilitate energy sharing among community members, creating a more resilient and sustainable local energy ecosystem.

Lastly, it’s exciting to see how transformers are evolving to support emerging renewable technologies. I’m part of a research team exploring the integration of next-generation solar and storage systems. We’re developing transformer designs that can efficiently handle DC inputs from solar panels and batteries, potentially eliminating the need for multiple conversion stages and improving overall system efficiency.

The facilitation of renewable energy integration by power and distribution transformers is not just a technical achievement – it’s a key enabler of our transition to a more sustainable energy future. These advanced transformers are bridging the gap between traditional grid infrastructure and the dynamic, distributed nature of renewable energy sources. As we continue to increase our reliance on clean energy, the ongoing evolution of transformer technology will be crucial in creating more flexible, efficient, and resilient power systems capable of maximizing the potential of renewable resources.

What Challenges Do Manufacturers Face in Balancing Efficiency and Cost in Modern Transformer Design?

Are you struggling to find transformers that offer high efficiency without breaking the bank? You’re not alone. Manufacturers face significant challenges in balancing performance and affordability.

Manufacturers face challenges in balancing efficiency and cost in modern transformer design, including material selection trade-offs, increased complexity of smart features, and evolving regulatory standards. They must optimize between using advanced, costly materials for higher efficiency and maintaining competitive pricing. Balancing long-term energy savings with upfront costs while meeting diverse market demands adds to the complexity.

Let’s explore the key challenges manufacturers face:

Material Selection Trade-offs

Choosing between standard and advanced materials impacts both efficiency and cost.

Material Considerations:

- High-grade silicon steel vs. amorphous metals for cores

- Copper vs. aluminum for windings

- Advanced insulation materials vs. traditional options

Smart Feature Integration Costs

Adding smart capabilities increases functionality but also raises production costs.

Smart Feature Challenges:

- Incorporating sensors and monitoring systems

- Implementing communication interfaces

- Developing and integrating control software

Regulatory Compliance and Efficiency Standards

Meeting evolving efficiency standards while maintaining cost-effectiveness.

Regulatory Impacts:

- Stricter efficiency requirements driving up production costs

- Varied standards across different markets complicating design processes

- Balancing efficiency improvements with cost constraints

Market Demand Variability

Addressing diverse customer needs while maintaining economies of scale.

Market Challenges:

- Customization requests vs. standardized production

- Balancing high-end and budget-friendly options

- Adapting to rapidly changing technology trends

| Challenge Area | Efficiency Impact | Cost Impact |

|---|---|---|

| Material Selection | High | High |

| Smart Features | Moderate to High | High |

| Regulatory Compliance | High | Moderate to High |

| Market Variability | Moderate | High |

In my years of working with transformer manufacturers, I’ve seen firsthand the complexities of balancing efficiency and cost. I remember collaborating with a manufacturer on developing a new line of distribution transformers. We faced a significant dilemma when choosing core materials. Amorphous metal cores offered superior efficiency but at a much higher cost. After extensive analysis and testing, we developed a hybrid design that used amorphous metals in critical areas and high-grade silicon steel in others. This approach allowed us to achieve a 20% efficiency improvement while keeping the cost increase to just 10%.

It’s important to note that the challenge of integrating smart features goes beyond just the additional component costs. In one project, I advised a manufacturer on implementing IoT capabilities in their transformer line. The real challenge was not just in adding sensors and communication modules, but in redesigning the entire production process to accommodate these new elements. This required significant upfront investment in retooling and staff training, which had to be carefully balanced against the long-term market benefits of offering smart transformers.

Don’t overlook the impact of regulatory changes on the efficiency-cost balance. I recently worked with a global manufacturer to develop a strategy for meeting diverse efficiency standards across different markets. We created a modular design approach that allowed for easy customization to meet various regulatory requirements without completely overhauling the production line for each market. This strategy helped in maintaining cost-effectiveness while ensuring compliance with a range of efficiency standards.

Another crucial aspect is addressing the variability in market demands. I’m currently advising a manufacturer on developing a flexible production system that can efficiently handle both high-volume standard orders and smaller batches of customized, high-efficiency units. This approach involves implementing advanced manufacturing technologies like 3D printing for certain components and adopting lean production principles to reduce waste and improve adaptability.

Lastly, it’s exciting to see how some manufacturers are turning these challenges into opportunities for innovation. I’m part of an industry group exploring new business models, such as efficiency-as-a-service, where manufacturers offer high-efficiency transformers at competitive upfront costs and share in the long-term energy savings. This approach could potentially resolve the tension between efficiency and cost by aligning the interests of manufacturers, utilities, and end-users.

The challenges manufacturers face in balancing efficiency and cost in modern transformer design are complex and multifaceted. From material selection to smart feature integration, regulatory compliance, and market variability, each aspect requires careful consideration and innovative solutions. As the demand for more efficient and intelligent transformers continues to grow, manufacturers who can successfully navigate these challenges will be well-positioned to lead in the evolving energy landscape. The key lies in embracing innovation, leveraging new technologies, and developing flexible strategies that can adapt to changing market needs and regulatory requirements.

How Are IoT and AI Technologies Revolutionizing Power and Distribution Transformer Operations?

Are you wondering how to make your transformer operations smarter and more efficient? You’re not alone. Many in the industry are turning to IoT and AI for solutions.

IoT and AI technologies are revolutionizing power and distribution transformer operations through real-time monitoring, predictive maintenance, and intelligent load management. These technologies enable continuous health assessment, automate decision-making processes, and optimize transformer performance. They also facilitate better integration with smart grids, enhancing overall system reliability and efficiency.

Let’s explore how IoT and AI are transforming transformer operations:

Real-Time Monitoring and Diagnostics

IoT sensors provide continuous data on transformer health and performance.

IoT Monitoring Capabilities:

- Temperature and oil level sensing

- Load and power quality monitoring

- Partial discharge detection

Predictive Maintenance

AI algorithms analyze data to predict and prevent failures.

AI-Driven Maintenance:

- Fault prediction based on historical and real-time data

- Optimized maintenance scheduling

- Automated alert systems for potential issues

Intelligent Load Management

AI optimizes transformer operation based on load patterns and grid conditions.

Smart Load Features:

- Dynamic load balancing

- Adaptive voltage regulation

- Energy efficiency optimization

Enhanced Grid Integration

IoT and AI enable better coordination with smart grid systems.

Grid Integration Benefits:

- Improved power flow management

- Support for demand response programs

- Enhanced renewable energy integration

| Technology | Application | Operational Benefit |

|---|---|---|

| IoT Sensors | Data Collection | Improved Visibility |

| AI Analytics | Predictive Maintenance | Reduced Downtime |

| Machine Learning | Load Management | Increased Efficiency |

| Cloud Computing | Data Processing | Enhanced Decision Making |

In my experience implementing IoT and AI solutions for transformer operations, the impact has been transformative. I recall a project with a large utility where we installed IoT sensors across their transformer fleet. Within months, we detected a developing fault in a critical substation transformer that would have otherwise gone unnoticed. This early detection prevented a potential citywide blackout and saved the utility millions in repair costs and potential regulatory fines.

It’s important to note that the benefits of IoT and AI extend beyond just preventing failures. In one case, I worked on implementing an AI-driven load management system for a network of distribution transformers. The system’s ability to predict and balance loads across multiple units led to a 15% improvement in overall energy efficiency and significantly extended the lifespan of the transformers.

Don’t overlook the potential of these technologies in improving maintenance practices. I recently advised a utility on transitioning from time-based to condition-based maintenance using IoT and AI. By analyzing real-time data and historical patterns, we were able to reduce unnecessary maintenance visits by 40% while improving the overall reliability of the transformer fleet.

Another crucial aspect is the role of these technologies in enabling more flexible and resilient grid operations. I’m currently working on a project that uses AI to optimize transformer settings in real-time based on renewable energy inputs and demand patterns. This level of dynamic control is crucial for managing the increasingly complex power flows in modern grids with high renewable penetration.

Lastly, it’s exciting to see how IoT and AI are opening up new possibilities for transformer design and operation. I’m part of a research team exploring the concept of "self-aware" transformers that can not only monitor their own health but also adapt their operation to changing conditions without human intervention. While still in the early stages, this technology could revolutionize how we approach power distribution and grid management.

The revolution brought about by IoT and AI technologies in power and distribution transformer operations is not just about adding new features – it’s about fundamentally changing how we monitor, maintain, and operate these critical components of our power infrastructure. From predictive maintenance to intelligent load management and enhanced grid integration, these technologies are making transformers smarter, more efficient, and more reliable. As we continue to face new challenges in our evolving energy landscape, the ongoing development and implementation of IoT and AI solutions will be crucial in creating more responsive, efficient, and resilient power systems.

What Role Do Power and Distribution Transformers Play in Enhancing Grid Resilience and Reliability?

Are you concerned about the vulnerability of your power grid to disruptions? You’re not alone. Grid resilience and reliability are top priorities for utilities and energy managers worldwide.

Power and distribution transformers play a crucial role in enhancing grid resilience and reliability through advanced protection systems, smart monitoring capabilities, and flexible operating modes. They provide voltage stability, fault isolation, and rapid recovery features. Modern transformers also support microgrid operations and seamless integration of backup power sources, significantly improving overall grid robustness.

Let’s explore the key ways transformers contribute to grid resilience and reliability:

Advanced Protection Systems

Modern transformers incorporate sophisticated protection mechanisms.

Protection Features:

- Rapid fault detection and isolation

- Self-healing capabilities for minor issues

- Enhanced surge protection

Smart Monitoring and Diagnostics

Real-time monitoring enables proactive maintenance and quick response to issues.

Monitoring Capabilities:

- Continuous health assessment

- Early warning systems for developing problems

- Integration with grid-wide monitoring networks

Flexible Operating Modes

Transformers can adapt to various grid conditions to maintain stability.

Operational Flexibility:

- Ability to operate in islanded mode

- Support for bidirectional power flow

- Dynamic load tap changing

Microgrid and Backup Power Support

Transformers enable seamless transitions between different power sources.

Microgrid Features:

- Smooth switching between grid and local power sources

- Support for renewable energy integration in microgrids

- Enhanced local grid stability during main grid outages

| Resilience Aspect | Transformer Function | Grid Benefit |

|---|---|---|

| Protection | Fault Isolation | Reduced Outage Spread |

| Monitoring | Proactive Maintenance | Improved Reliability |

| Flexibility | Adaptive Operation | Enhanced Stability |

| Microgrid Support | Power Source Integration | Increased Resilience |

In my years of working on grid resilience projects, I’ve seen firsthand how advanced transformers can make a significant difference. I remember a project in a region prone to severe weather events. We implemented a network of smart transformers with advanced protection and self-healing capabilities. During a particularly harsh storm season, these transformers were able to isolate faults quickly and reroute power, reducing outage times by over 60% compared to previous years.

It’s important to note that the role of transformers in grid resilience goes beyond just handling disruptions. In one case, I worked with a utility to develop a comprehensive grid hardening strategy. By strategically placing advanced transformers with enhanced monitoring capabilities, we created a network of "sentinel" nodes that could provide early warning of developing issues across the grid. This proactive approach significantly improved the utility’s ability to prevent outages before they occurred.

Don’t overlook the importance of transformer flexibility in enhancing grid resilience. I recently consulted on a project where we integrated flexible transformers into a city’s power network. These units could dynamically adjust their output based on grid conditions, effectively balancing loads and maintaining voltage stability even during significant demand fluctuations. This flexibility proved crucial during several high-stress events, preventing cascading failures that could have led to widespread blackouts.

Another crucial aspect is the role of transformers in enabling microgrid capabilities. I’m currently advising on a community resilience project where advanced transformers serve as key interfaces between the main grid and local microgrids. These transformers can seamlessly transition between grid-connected and islanded modes, ensuring continuous power supply to critical facilities like hospitals and emergency services during main grid outages.

Lastly, it’s exciting to see how innovations in transformer technology are pushing the boundaries of grid resilience. I’m part of a research team exploring the use of solid-state transformers in critical infrastructure protection. These devices offer unprecedented speed in fault response and power quality management, potentially revolutionizing our approach to grid stability and reliability.

The role of power and distribution transformers in enhancing grid resilience and reliability is multifaceted and increasingly critical. From advanced protection systems to smart monitoring and flexible operations, modern transformers are at the forefront of creating more robust and responsive power networks. As we continue to face challenges from extreme weather events, cyber threats, and changing energy landscapes, the ongoing evolution of transformer technology will be crucial in building and maintaining resilient, reliable power grids capable of meeting the demands of our increasingly electrified world.

Conclusion

Power and distribution transformers are pivotal in enhancing energy efficiency and enabling smart grid integration. Through advanced technologies, they improve grid resilience, facilitate renewable energy integration, and optimize power distribution. As the energy landscape evolves, these transformers will continue to play a crucial role in shaping efficient, reliable, and sustainable power systems.

Are you concerned about the safety and efficiency of your power distribution network? You’re not alone. Many industries are seeking better solutions for their electrical infrastructure.

Dry type distribution transformers are revolutionizing power networks by offering enhanced safety features, improved efficiency, and environmental benefits. These transformers eliminate the risk of oil leaks, reduce fire hazards, and provide reliable performance in various environments. They are ideal for indoor installations, urban areas, and applications where safety and low maintenance are crucial.

As someone who has worked extensively with various transformer types, I’ve seen firsthand the impact of dry type transformers on modern power distribution networks. In this article, I’ll guide you through the key features and benefits that make these transformers a game-changer in the industry.

What Key Safety Features Make Dry Type Distribution Transformers Ideal for Modern Power Networks?

Have you ever worried about the safety risks associated with traditional oil-filled transformers? Dry type transformers offer a solution that can put your mind at ease.

Dry type distribution transformers excel in safety due to their fire-resistant design, absence of combustible liquids, and reduced risk of environmental contamination. They feature high-temperature insulation materials, enclosed designs, and inherent arc-resistant properties, making them ideal for indoor installations and areas with strict safety requirements.

Let’s dive deeper into the safety features that set dry type transformers apart:

Fire-Resistant Design

Dry type transformers significantly reduce fire hazards.

Fire Safety Aspects:

- Use of non-flammable insulation materials

- Self-extinguishing properties

- Lower fire insurance premiums for installations

Environmentally Secure

These transformers eliminate the risk of oil leaks and spills.

Environmental Safety:

- No need for oil containment systems

- Reduced risk of soil and water contamination

- Compliance with strict environmental regulations

Enhanced Electrical Safety

Dry type transformers offer improved protection against electrical faults.

Electrical Safety Features:

- Better short-circuit strength

- Reduced partial discharge

- Improved impulse voltage withstand capability

Safe for Indoor Installations

Their design makes them suitable for a wide range of indoor applications.

Indoor Safety Benefits:

- No oil vapor emissions

- Reduced noise levels

- Compact design for space-constrained areas

| Safety Feature | Benefit | Application |

|---|---|---|

| Fire Resistance | Reduced Fire Risk | Hospitals, Schools, High-Rise Buildings |

| Environmental Security | No Oil Leaks | Environmentally Sensitive Areas |

| Electrical Safety | Improved Fault Protection | Industrial Facilities |

| Indoor Suitability | Versatile Installation | Shopping Malls, Data Centers |

In my years of experience with transformer installations, I’ve seen the dramatic impact of dry type transformers on safety standards. I recall a project where we replaced oil-filled transformers in a hospital with dry type units. The hospital administration was initially skeptical about the change, but after seeing the enhanced safety features and the elimination of oil leak risks, they were fully convinced. The peace of mind it brought to both staff and patients was palpable.

It’s important to note that while dry type transformers offer significant safety advantages, proper installation and maintenance are still crucial. In one case, I worked on troubleshooting a dry type transformer that was experiencing overheating issues. We discovered that the ventilation system in the installation room was inadequate, highlighting the importance of considering the entire installation environment, not just the transformer itself.

Don’t overlook the importance of regular inspections, even with the enhanced safety features of dry type transformers. I’ve developed maintenance protocols for several facilities that include thermal imaging and partial discharge testing. These proactive measures have helped catch potential issues before they escalate, further enhancing the overall safety of the power distribution system.

Another crucial aspect is the role of dry type transformers in meeting evolving safety regulations. I recently consulted on a project to upgrade a high-rise building’s electrical system to comply with new fire safety codes. The use of dry type transformers was instrumental in achieving compliance without major structural changes to the building.

Lastly, it’s exciting to see how advancements in insulation materials are further enhancing the safety features of dry type transformers. I’m currently involved in testing a new type of nano-composite insulation that promises even better fire resistance and thermal management properties. These ongoing innovations continue to push the boundaries of what’s possible in transformer safety.

The key safety features of dry type distribution transformers make them an ideal choice for modern power networks, especially in environments where safety is paramount. From fire resistance to environmental security, these transformers offer a comprehensive safety package that addresses many of the concerns associated with traditional oil-filled units. As safety regulations become more stringent and as businesses become more safety-conscious, the role of dry type transformers in power distribution networks is likely to grow even further.

How Do Dry Type Transformers Enhance Energy Efficiency in Power Distribution Systems?

Are you struggling with energy losses in your power distribution system? You’re not alone. Many facilities are looking for ways to improve their energy efficiency.

Dry type transformers enhance energy efficiency through reduced core losses, improved thermal management, and optimized winding designs. They maintain high efficiency across varying load conditions, offer better performance in high temperatures, and have longer operational lifespans. These factors contribute to significant energy savings and reduced operational costs over time.

Let’s explore how dry type transformers boost energy efficiency:

Reduced Core Losses

Advanced core materials and designs minimize energy waste.

Core Efficiency Features:

- Use of high-grade silicon steel

- Amorphous metal cores for ultra-low losses

- Optimized core geometry for magnetic flux distribution

Improved Thermal Management

Better heat dissipation leads to more efficient operation.

Thermal Efficiency Aspects:

- Advanced cooling systems (e.g., forced air cooling)

- High-temperature insulation materials

- Optimized ventilation designs

Optimized Winding Designs

Innovative winding techniques reduce copper losses.

Winding Efficiency Improvements:

- Use of copper windings for lower resistance

- Foil winding technology for better current distribution

- Reduced eddy current losses through optimal conductor arrangement

Load Adaptability

Dry type transformers maintain high efficiency across various load conditions.

Load Efficiency Features:

- Stable performance under fluctuating loads

- Reduced no-load losses

- Better efficiency at partial load conditions

| Efficiency Feature | Energy Saving Potential | Long-Term Benefit |

|---|---|---|

| Advanced Core | High | Reduced Operating Costs |

| Thermal Management | Moderate to High | Extended Lifespan |

| Optimized Windings | Moderate | Improved Performance |

| Load Adaptability | High | Versatility in Applications |

In my experience working with various power distribution systems, the efficiency gains from dry type transformers can be substantial. I remember a project where we replaced conventional transformers with high-efficiency dry type units in a large data center. The energy savings were impressive – we saw a reduction in transformer losses of about 20%, which translated to significant cost savings for the facility. The improved efficiency also meant less heat generation, reducing the load on the data center’s cooling systems.

It’s important to note that the efficiency benefits of dry type transformers extend beyond just energy savings. In one case, I worked with a manufacturing plant that was experiencing production issues due to voltage fluctuations. By installing dry type transformers with advanced voltage regulation capabilities, we not only improved energy efficiency but also enhanced the overall power quality, leading to more reliable operation of sensitive equipment.

Don’t overlook the importance of proper sizing and selection when it comes to maximizing efficiency. I’ve developed a comprehensive assessment process that considers load profiles, environmental conditions, and future growth projections. This approach ensures that the selected transformer operates at its optimal efficiency point, maximizing energy savings over its lifetime.

Another crucial aspect is the role of monitoring and maintenance in maintaining high efficiency. I recently implemented a real-time monitoring system for a network of dry type transformers in an urban substation. This system allows for continuous tracking of efficiency metrics and early detection of any performance degradation, ensuring that the transformers operate at peak efficiency throughout their lifespan.

Lastly, it’s exciting to see how advancements in materials science are pushing the boundaries of transformer efficiency. I’m currently involved in a research project exploring the use of high-temperature superconducting materials in transformer windings. While still in the experimental stage, this technology promises to dramatically reduce losses and could revolutionize transformer efficiency in the future.

The energy efficiency enhancements offered by dry type transformers are not just incremental improvements – they represent a significant leap forward in power distribution technology. From advanced core materials to optimized designs, these transformers offer a comprehensive solution for facilities looking to reduce energy losses and operational costs. As energy efficiency becomes an increasingly critical concern in our power-hungry world, the role of dry type transformers in creating more sustainable and cost-effective power distribution systems will only grow in importance.

What Environmental Advantages Do Dry Type Distribution Transformers Offer Over Traditional Models?

Are you concerned about the environmental impact of your power distribution equipment? You’re not alone. Many organizations are seeking greener alternatives in their electrical infrastructure.

Dry type distribution transformers offer significant environmental advantages over traditional oil-filled models. They eliminate the risk of oil leaks and spills, reduce the need for hazardous waste disposal, and have a lower carbon footprint throughout their lifecycle. These transformers also support green building initiatives and can be more easily recycled at the end of their operational life.

Let’s delve into the environmental benefits of dry type transformers:

Elimination of Oil-Related Risks

Dry type transformers completely remove the environmental hazards associated with oil.

Oil-Free Advantages:

- No risk of soil or water contamination from leaks

- Elimination of oil disposal and recycling issues

- Reduced fire risk and associated environmental damage

Reduced Carbon Footprint

These transformers have a lower environmental impact throughout their lifecycle.

Carbon Reduction Aspects:

- Lower transportation emissions due to lighter weight

- Reduced energy losses leading to lower operational emissions

- Longer lifespan reducing the frequency of replacement and associated manufacturing emissions

Support for Green Building Initiatives

Dry type transformers align well with sustainable construction practices.

Green Building Benefits:

- Contribution to LEED certification points

- Improved indoor air quality due to absence of oil vapors

- Reduced need for extensive fire suppression systems

Enhanced Recyclability

The materials used in dry type transformers are often more recyclable.

Recycling Advantages:

- Easier separation of components at end-of-life

- Higher recoverability of copper and steel

- Absence of hazardous oil simplifies the recycling process

| Environmental Aspect | Advantage Over Traditional Models | Impact on Sustainability |

|---|---|---|

| Oil-Free Design | Eliminates Risk of Contamination | High |

| Carbon Footprint | Lower Lifecycle Emissions | Moderate to High |

| Green Building Support | Aligns with Sustainable Practices | Moderate |

| Recyclability | Easier End-of-Life Management | High |

In my years of working with various transformer types, I’ve seen a significant shift towards dry type transformers in environmentally sensitive applications. I recall a project for a water treatment facility located near a protected wetland. The facility managers were extremely concerned about the potential environmental impact of their electrical equipment. By installing dry type transformers, we eliminated the risk of oil contamination, providing peace of mind to the facility operators and local environmental authorities alike.

It’s important to note that the environmental benefits of dry type transformers extend beyond just eliminating oil-related risks. In one case, I worked on a lifecycle assessment comparing dry type and oil-filled transformers for a large commercial development. The results were eye-opening – the dry type transformers showed a significantly lower carbon footprint over their operational life, primarily due to reduced energy losses and longer lifespan.

Don’t overlook the impact of transformer choice on green building certifications. I recently consulted on a project for a new corporate headquarters aiming for LEED Platinum certification. The use of dry type transformers contributed valuable points towards their energy and environmental quality credits, helping them achieve their sustainability goals.

Another crucial aspect is the end-of-life considerations for transformers. I’ve been involved in developing recycling protocols for electrical equipment, and dry type transformers consistently prove easier to handle and recycle. In a recent decommissioning project, we were able to recover over 95% of the materials from the dry type transformers for recycling or reuse, a figure that would have been much lower with oil-filled units.

Lastly, it’s exciting to see how the environmental advantages of dry type transformers are driving innovation in other areas of electrical engineering. I’m currently part of a research team exploring the use of biodegradable insulation materials in transformer construction. This could further enhance the environmental credentials of dry type transformers, potentially making them one of the most sustainable options in power distribution equipment.

The environmental advantages of dry type distribution transformers over traditional models are clear and significant. From eliminating oil-related risks to supporting green building initiatives and enhancing recyclability, these transformers offer a comprehensive solution for organizations looking to reduce their environmental footprint. As sustainability becomes an increasingly critical factor in infrastructure decisions, the role of dry type transformers in creating more environmentally friendly power distribution systems is set to grow even further.

Dry vs. Oil-Filled Transformers: How Do They Compare in Modern Power Distribution Networks?

Are you torn between choosing dry type or oil-filled transformers for your power distribution needs? You’re not alone. This decision is crucial for many network operators and facility managers.

In modern power distribution networks, dry type transformers offer advantages in safety, environmental protection, and maintenance, while oil-filled transformers excel in cost-effectiveness for higher power ratings and outdoor applications. Dry types are preferred for indoor, urban, and environmentally sensitive locations, while oil-filled remain popular for high-capacity outdoor substations and areas with less stringent fire safety requirements.

Let’s compare these two transformer types across key aspects:

Safety Considerations

Safety is a primary concern in transformer selection.

Safety Comparison:

- Dry Type: Lower fire risk, no oil leakage hazard

- Oil-Filled: Higher fire risk, potential for oil spills

Environmental Impact

Environmental factors are increasingly important in equipment choices.

Environmental Aspects:

- Dry Type: No oil-related environmental risks, easier to recycle

- Oil-Filled: Potential for soil and water contamination, more complex disposal

Maintenance Requirements

Maintenance needs affect long-term operational costs.

Maintenance Comparison:

- Dry Type: Lower maintenance, no oil monitoring or replacement

- Oil-Filled: Regular oil testing and potential replacement, more intensive maintenance

Performance Characteristics

Performance varies depending on the application and environment.

Performance Aspects:

- Dry Type: Better in high temperatures, more suitable for indoor use

- Oil-Filled: Superior cooling properties, better for high-capacity outdoor applications

| Aspect | Dry Type Transformers | Oil-Filled Transformers |

|---|---|---|

| Safety | Higher | Moderate |

| Environmental Impact | Lower | Higher |

| Maintenance | Lower | Higher |

| Indoor Suitability | Excellent | Limited |

| High Power Capacity | Limited | Excellent |

In my experience working with both dry type and oil-filled transformers, I’ve seen how crucial it is to match the right type to the specific application. I remember a project for a new hospital where we initially considered oil-filled transformers due to their lower cost. However, after a comprehensive risk assessment, we opted for dry type units. The enhanced safety features and reduced maintenance needs aligned perfectly with the hospital’s priorities, justifying the higher initial investment.

It’s important to note that while dry type transformers often have advantages in urban and indoor settings, oil-filled transformers still play a vital role in many applications. In a recent substation upgrade project for a rural electric cooperative, we chose oil-filled transformers for their high-capacity capabilities and cost-effectiveness in outdoor installations. The lower population density and reduced fire risk in the area made this a suitable choice.

Don’t overlook the impact of climate on transformer selection. I once worked on a project in a tropical region where the high ambient temperatures and humidity were causing issues with oil-filled transformers. Switching to dry type units resolved these problems, highlighting the importance of considering environmental factors in the selection process.

Another crucial aspect is the total cost of ownership. While dry type transformers often have a higher upfront cost, their reduced maintenance needs and longer lifespan can result in lower long-term expenses. I developed a comprehensive cost analysis tool that factors in initial costs, maintenance, energy efficiency, and expected lifespan. This tool has helped many clients make more informed decisions based on their specific circumstances and priorities.