Are you confused about how electricity gets safely into your home? You’re not alone. Many homeowners are unaware of the crucial role residential transformers play in powering our daily lives. But what exactly are these devices, and why are they so important for your home’s electrical system?

A residential transformer is a compact power device that steps down high-voltage electricity from utility lines to usable levels (120/240V) for household appliances. It ensures safe, reliable power for homes and is commonly pole-mounted or pad-mounted in suburban and urban areas.

In this comprehensive guide, I’ll walk you through everything you need to know about residential transformers. Whether you’re a homeowner curious about your electrical system or a professional looking to expand your knowledge, this article will provide valuable insights into these essential devices that power our homes.

What Is a Residential Transformer?

Have you ever wondered how the high-voltage electricity from power lines becomes safe to use in your home? This is where residential transformers come in. But what exactly are these devices, and why are they so crucial for your home’s electrical system?

Residential transformers are distribution-level electrical devices designed to convert high-voltage power from utility grids into lower voltages suitable for household use. They play a crucial role in delivering stable energy for lighting, appliances, and HVAC systems. These transformers are the vital link between the power grid and your home’s electrical system.

Understanding Residential Transformers

Let’s break down the key aspects of residential transformers:

- Purpose and Function

- Basic Components

- Voltage Transformation

- Location and Installation

- Safety Features

Purpose and Function

Residential transformers serve a critical role:

- Step down high voltage (typically 7.2kV to 14.4kV) to usable household voltage (120/240V)

- Provide a safe interface between utility power and home electrical systems

- Ensure stable power supply for all household electrical needs

I once visited a newly developed suburban area where the installation of residential transformers was underway. It was fascinating to see how these compact devices were the key to powering entire neighborhoods.

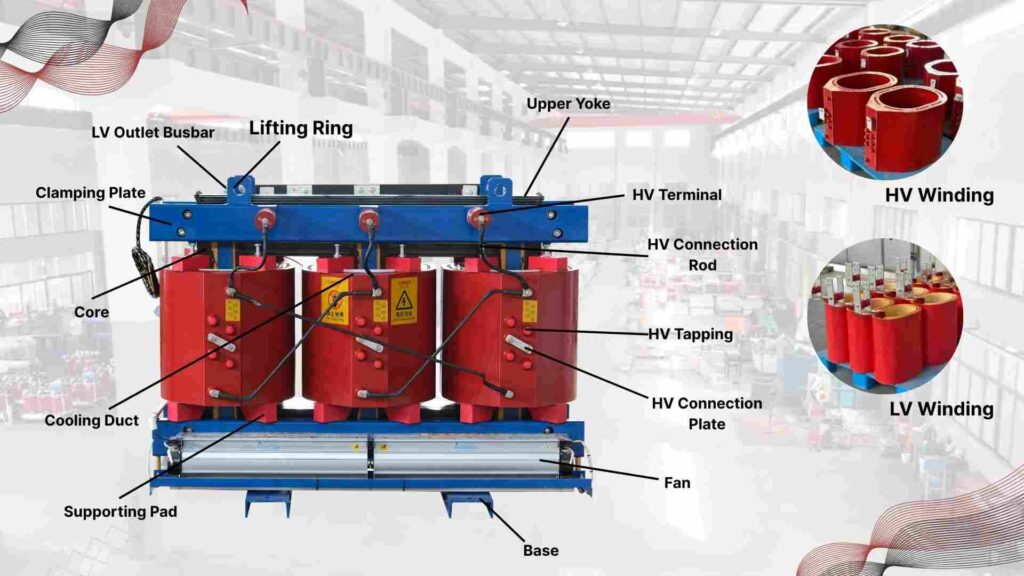

Basic Components

A typical residential transformer consists of:

- Primary winding (connected to high-voltage lines)

- Secondary winding (connected to household circuits)

- Core (usually made of laminated steel)

- Insulating material (oil or dry-type)

- Protective casing

During a recent home renovation project, I had the opportunity to examine a pad-mounted transformer up close. The compact design and robust construction were impressive, considering the critical function it serves.

Voltage Transformation

The transformation process is based on electromagnetic induction:

- High voltage in the primary winding creates a magnetic field

- This field induces a lower voltage in the secondary winding

- The ratio of primary to secondary windings determines the voltage step-down

Here’s a simple breakdown of voltage transformation:

| Input (Primary) Voltage | Output (Secondary) Voltage | Typical Application |

|---|---|---|

| 7,200V | 120/240V | Single-family homes |

| 14,400V | 120/240V | Larger residential areas |

| 4,800V | 120/208V | Multi-unit dwellings |

Location and Installation

Residential transformers are strategically placed:

- Pole-mounted: Common in older neighborhoods and rural areas

- Pad-mounted: Prevalent in newer developments and underground power systems

- Sometimes installed in basements or on roofs in urban high-rises

Safety Features

Modern residential transformers include various safety features:

- Overload protection

- Short-circuit protection

- Thermal monitoring

- Weatherproof enclosures for outdoor units

Key points to remember about residential transformers:

- They are the crucial link between high-voltage power lines and your home’s electrical system

- Transformers step down voltage to safe, usable levels for household appliances

- They come in various types suitable for different residential settings

- Safety features are integral to their design and function

- Proper installation and maintenance are crucial for reliable home power supply

In my experience, understanding the basics of residential transformers can be incredibly useful for homeowners. I’ve seen cases where this knowledge helped residents communicate more effectively with electricians and utility companies during power issues or home renovations.

As we move forward to discuss how these transformers work, keep in mind the critical role they play in safely delivering power to your home. Their function, though often overlooked, is fundamental to our modern, electricity-dependent lifestyles.

How Residential Transformers Work?

Are you curious about the inner workings of the device that safely brings electricity into your home? Understanding how residential transformers function can seem complex, but it’s fascinating once you grasp the basics. So, how exactly do these crucial devices transform dangerous high-voltage electricity into the safe, usable power that runs your household appliances?

Residential transformers work on the principle of electromagnetic induction. They use two coils of wire – primary and secondary – wound around an iron core. When alternating current flows through the primary coil, it creates a changing magnetic field. This field induces a voltage in the secondary coil, which is then distributed to homes at a lower, safer voltage level.

The Inner Workings of Residential Transformers

Let’s break down the operation of residential transformers:

- Electromagnetic Induction Principle

- Core and Windings

- Voltage Step-Down Process

- Insulation and Cooling

- Load Management and Efficiency

Electromagnetic Induction Principle

The fundamental principle behind transformer operation:

- Alternating current in the primary winding creates a changing magnetic field

- This changing field induces voltage in the secondary winding

- The number of turns in each winding determines the voltage ratio

I once explained this concept to a curious homeowner using a simple demonstration with two coils and a magnet. Moving the magnet through one coil induced a small current in the other, illustrating the basic principle of how transformers work.

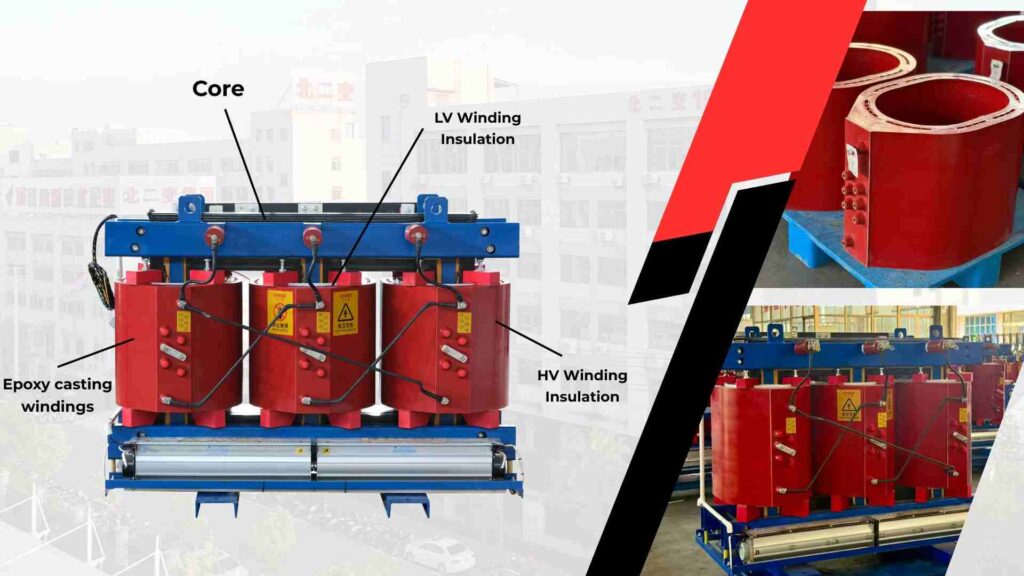

Core and Windings

The physical components that make induction possible:

- Core: Usually made of laminated steel to reduce energy losses

- Primary winding: Connected to the high-voltage power line

- Secondary winding: Delivers lower voltage to residential circuits

During a recent factory tour, I observed the precision involved in winding transformers. The careful layering of windings and core assembly is crucial for efficient operation.

Voltage Step-Down Process

How the voltage is actually reduced:

- Input voltage (e.g., 7,200V) enters the primary winding

- Magnetic field induces voltage in the secondary winding

- Fewer turns in the secondary winding result in lower output voltage (e.g., 240V)

Here’s a simplified example of the step-down process:

| Primary Winding | Secondary Winding | Input Voltage | Output Voltage |

|---|---|---|---|

| 1000 turns | 33 turns | 7,200V | 240V |

Insulation and Cooling

Crucial for safe and efficient operation:

- Oil-immersed: Uses mineral oil for insulation and cooling

- Dry-type: Uses air or solid materials for insulation

I recall a project where we opted for a dry-type transformer in a residential high-rise due to fire safety concerns. The absence of oil made it a safer choice for indoor installation.

Load Management and Efficiency

Transformers must handle varying loads efficiently:

- Designed to operate optimally at average household demand

- Can handle short-term overloads (e.g., during peak usage times)

- Energy efficiency is crucial to minimize losses

Key points to understand about transformer operation:

- The principle of electromagnetic induction is fundamental to transformer function

- The ratio of turns in primary and secondary windings determines voltage step-down

- Proper insulation and cooling are essential for safe, efficient operation

- Transformers are designed to handle varying loads throughout the day

- Energy efficiency in transformers directly impacts household electricity costs

In my experience, grasping these operational principles helps homeowners appreciate the complexity behind their seemingly simple power supply. I’ve seen this understanding lead to more informed decisions about home electrical systems and energy usage.

For instance, during an energy efficiency consultation, explaining how transformer losses affect overall power consumption helped a homeowner understand the importance of using energy-efficient appliances to reduce the load on their local transformer.

As we move on to discuss common types of residential transformers, keep in mind how these operational principles apply to different designs and installations. Understanding the basics of how transformers work sets the foundation for appreciating the various types used in residential settings.

Common Types of Residential Transformers?

Are you aware of the different types of transformers that might be powering your home? The variety of residential transformers can be confusing, but understanding these types is crucial for homeowners and professionals alike. So, what are the common types of residential transformers, and how do they differ in their applications?

Common types of residential transformers include pole-mounted, pad-mounted, and compact substation units. Pole-mounted transformers are typically used in rural or suburban areas, pad-mounted transformers are popular in underground cable systems in urban neighborhoods, and compact substation units are often used in gated communities or apartment complexes. Each type is selected based on factors like grid layout, safety, noise, and maintenance accessibility.

Exploring Residential Transformer Types

Let’s examine the main types of residential transformers:

- Pole-Mounted Transformers

- Pad-Mounted Transformers

- Compact Substation Units

- Specialized Residential Transformers

- Factors Influencing Transformer Selection

Pole-Mounted Transformers

These are the most common in many areas:

- Mounted on utility poles, typically seen in older neighborhoods and rural areas

- Compact design, usually cylindrical

- Easily accessible for maintenance, but exposed to weather elements

I recently worked on a project in a suburban area where pole-mounted transformers were the preferred choice. Their elevated position provided protection from flooding and vandalism, which were concerns in that particular location.

Pad-Mounted Transformers

Increasingly popular in newer developments:

- Installed on concrete pads at ground level

- Enclosed in metal cabinets for safety and aesthetics

- Ideal for areas with underground power distribution

During a recent residential development project, we opted for pad-mounted transformers. Their low profile and ability to blend with landscaping made them an attractive option for the homeowners’ association.

Compact Substation Units

Used in larger residential complexes:

- Combine transformer and switchgear in one unit

- Suitable for apartment buildings or gated communities

- Offer more power capacity and control options

Here’s a comparison of these common transformer types:

| Type | Typical Location | Advantages | Considerations |

|---|---|---|---|

| Pole-Mounted | Rural, suburban areas | Easy maintenance, less ground space | Exposed to elements |

| Pad-Mounted | Urban, new developments | Aesthetically pleasing, protected | Requires ground space |

| Compact Substation | Large residential complexes | Higher capacity, more control | Larger footprint, higher cost |

Specialized Residential Transformers

Some unique situations require specialized transformers:

- Underground vault transformers for dense urban areas

- Submersible transformers for flood-prone regions

- Low-noise transformers for noise-sensitive areas

I once worked on a project in a flood-prone coastal area where we used specially designed submersible transformers. These units could continue operating even when temporarily submerged, ensuring power reliability during severe weather events.

Factors Influencing Transformer Selection

Several factors determine the choice of transformer:

- Local utility standards and preferences

- Environmental conditions (climate, flood risk, etc.)

- Aesthetic considerations of the neighborhood

- Maintenance accessibility

- Future growth and power demand projections

Key considerations when dealing with residential transformer types:

- Understand the specific needs and constraints of the residential area

- Consider long-term maintenance and replacement accessibility

- Factor in environmental conditions and potential hazards

- Balance aesthetics with functionality, especially in residential areas

- Consider future power needs and potential for area growth

In my experience, the choice of transformer type can significantly impact both the reliability of power supply and the overall aesthetics of a residential area. I’ve seen cases where the wrong choice led to maintenance difficulties or community dissatisfaction.

For example, in a recent urban renewal project, switching from older pole-mounted transformers to modern pad-mounted units not only improved the visual appeal of the neighborhood but also enhanced safety and reliability by moving the transformers away from overhead lines and potential vehicle collisions.

As we move forward to discuss the differences between residential and commercial transformers, keep in mind how these various types of residential transformers cater to different needs and environments. Understanding these differences is crucial for making informed decisions in electrical system planning and upgrades.

Residential vs Commercial Transformers: What’s the Difference?

Are you confused about how residential transformers differ from their commercial counterparts? This distinction is crucial for proper electrical system planning and installation. But what exactly sets these two types of transformers apart, and why does it matter for your project?

Residential transformers typically handle lower voltages (120/240V) and smaller loads compared to commercial transformers, which often deal with higher voltages (208V, 480V, or 600V) and larger power demands. Residential units are designed for homes and small apartments, while commercial transformers serve offices, factories, and malls. Size, capacity, and design features also differ to meet the specific needs of residential versus commercial applications.

Key Differences Between Residential and Commercial Transformers

Let’s explore the main distinctions:

- Voltage and Power Capacity

- Size and Design Considerations

- Installation and Location

- Safety and Protection Features

- Maintenance and Lifespan

Voltage and Power Capacity

The most fundamental difference:

- Residential: Typically 120/240V, power ratings usually up to 100 kVA

- Commercial: Often 208V, 480V, or 600V, power ratings can exceed 2000 kVA

I once worked on a project converting a large residential property into a small business center. The existing residential transformer couldn’t handle the increased power demands, necessitating an upgrade to a commercial-grade unit to support the new office equipment and HVAC systems.

Size and Design Considerations

Physical differences are significant:

- Residential: Compact, often designed for aesthetic integration

- Commercial: Larger, focus on functionality and cooling efficiency

During a recent commercial development, we had to carefully plan the transformer location due to its size. Unlike residential units that can often be discreetly placed, the commercial transformer required a dedicated space with specific clearance requirements.

Installation and Location

Installation practices vary:

- Residential: Often pole-mounted or pad-mounted in neighborhoods

- Commercial: Frequently installed in dedicated electrical rooms or outdoor enclosures

Here’s a comparison table of key features:

| Feature | Residential Transformer | Commercial Transformer |

|---|---|---|

| Typical Voltage | 120/240V | 208V, 480V, 600V |

| Power Capacity | Up to 100 kVA | Up to 2000+ kVA |

| Size | Compact | Larger |

| Common Locations | Poles, ground pads | Electrical rooms, outdoor enclosures |

| Noise Level | Lower | Can be higher |

| Cooling | Often natural cooling | May require forced cooling |

Safety and Protection Features

Safety requirements differ:

- Residential: Focus on weatherproofing and basic overload protection

- Commercial: More advanced protection systems, often including remote monitoring

I recall a commercial project where we implemented a sophisticated protection system with real-time monitoring. This level of protection is rarely seen in residential settings but is crucial for ensuring business continuity in commercial applications.

Maintenance and Lifespan

Maintenance needs and expected lifespans vary:

- Residential: Generally lower maintenance, lifespan of 20-30 years

- Commercial: Regular maintenance required, can last 30+ years with proper care

Key points to remember about residential vs commercial transformers:

- Voltage and power capacity are the primary differentiating factors

- Size and design reflect the different application environments

- Installation locations and methods vary significantly

- Safety and protection features are more advanced in commercial units

- Maintenance requirements and expected lifespans differ

In my experience, understanding these differences is crucial for proper system design and planning. I’ve seen projects where underestimating the distinctions led to inadequate power supply or unnecessary over-engineering.

For instance, in a mixed-use development project, we had to carefully balance the needs of residential units with those of ground-floor commercial spaces. This required a hybrid approach, using residential-style transformers for the living spaces and a separate commercial unit for the retail areas.

As we move on to discuss leading brands for residential transformers, keep these differences in mind. Understanding the unique characteristics of residential transformers will help you appreciate the specific features and capabilities offered by different manufacturers.

Leading Brands for Residential Transformers (with Examples)?

Are you overwhelmed by the variety of transformer brands available for residential use? Choosing the right brand can be crucial for the reliability and efficiency of your home’s power supply. But which brands stand out in the residential transformer market, and what makes their products unique?

Leading brands for residential transformers include ABB, Siemens, Schneider Electric, and CHBEB. ABB offers durable, weather-resistant models ideal for outdoor use. Siemens focuses on energy-efficient designs with advanced protection features. Schneider Electric specializes in compact, environmentally friendly units. CHBEB provides cost-effective solutions with a focus on emerging markets. Each brand offers unique features catering to different residential needs and environments.

Analyzing Top Residential Transformer Brands

Let’s explore some leading brands and their offerings:

- ABB

- Siemens

- Schneider Electric

- CHBEB

- General Electric (GE)

ABB

ABB is known for its robust and reliable transformers:

- Model Example: ABB NTR 1P 25 kVA

- Key Features: Oil-immersed, corrosion-resistant, compact for pole-mount use

- Typical Application: Suburban housing projects, especially in harsh environments

I recently specified an ABB transformer for a coastal residential development. Its corrosion-resistant design was crucial for withstanding the salt-laden air, ensuring long-term reliability in the challenging marine environment.

Siemens

Siemens focuses on efficiency and smart features:

- Model Example: Siemens 1PH8137 Series

- Key Features: Quiet operation, overload protection, anti-theft locks

- Typical Application: Urban residential neighborhoods, smart home communities

During a recent smart neighborhood project, we chose Siemens transformers for their compatibility with smart grid technologies and their low noise output, which was essential in the densely populated area.

Schneider Electric

Schneider Electric specializes in eco-friendly solutions:

- Model Example: Trihal Dry Type Transformer 25-250 kVA

- Key Features: Flame-retardant, dry-type, suitable for indoor basements or rooftops

- Typical Application: High-rise residential buildings, eco-conscious developments

Here’s a comparison of these top brands:

| Brand | Key Strength | Typical Model | Best For |

|---|---|---|---|

| ABB | Durability | NTR 1P 25 kVA | Harsh environments |

| Siemens | Smart features | 1PH8137 Series | Urban smart homes |

| Schneider Electric | Eco-friendly | Trihal Dry Type | High-rise buildings |

| CHBEB | Cost-effective | CHBEB-RDT 30 kVA | Emerging markets |

| GE | Reliability | GE Type QL | Suburban developments |

CHBEB

CHBEB offers cost-effective solutions with growing global presence:

- Model Example: CHBEB-RDT 30 kVA Pad Mount

- Key Features: Oil-immersed, high-efficiency, RoHS compliant

- Typical Application: Residential power upgrade projects in developing regions

I recently recommended CHBEB transformers for a large-scale residential electrification project in Southeast Asia. Their combination of affordability and compliance with international standards made them an excellent choice for the project’s budget and technical requirements.

General Electric (GE)

GE is known for its reliable and widely compatible transformers:

- Model Example: GE Type QL Transformer

- Key Features: Versatile design, good overload capacity, low noise

- Typical Application: Suburban developments, residential retrofits

Key considerations when evaluating residential transformer brands:

- Assess the specific environmental conditions of your installation site

- Consider long-term efficiency and potential energy savings

- Look for brands that offer good after-sales support and warranty

- Check for compliance with local standards and regulations

- Evaluate the brand’s track record in your specific application type

In my experience, the choice of brand can significantly impact the long-term performance and reliability of a residential power system. I’ve seen cases where opting for a reputable brand with slightly higher upfront costs led to significant savings in maintenance and energy efficiency over time.

For example, in a recent suburban development project, we chose GE transformers despite their higher initial cost. The decision paid off as these units demonstrated excellent reliability and lower energy losses, resulting in reduced electricity costs for homeowners over the years.

As we move on to discuss key standards and compliance for residential transformers, remember that brand selection should align with these standards. The best brands not only meet but often exceed regulatory requirements, ensuring safety, efficiency, and reliability in residential power distribution.

Key Standards and Compliance?

Are you aware of the critical standards that govern residential transformers? Navigating the world of transformer compliance can be daunting, but understanding these standards is crucial for ensuring safety and efficiency. What are the key standards you need to know about, and why are they so important for residential transformer installations?

Key standards for residential transformers include IEC 60076 for international safety and performance, IEEE C57 for North American installations, and DOE efficiency regulations in the USA. Environmental standards like RoHS and REACH are also crucial, especially in Europe and Asia. Compliance with these standards ensures safety, efficiency, and environmental friendliness of residential transformers, and is often mandatory for installation and operation.

Understanding Key Standards and Compliance

Let’s explore the main standards and compliance requirements:

- International Electrotechnical Commission (IEC) Standards

- Institute of Electrical and Electronics Engineers (IEEE) Standards

- Department of Energy (DOE) Efficiency Regulations

- Environmental and Safety Standards

- Regional and Local Compliance Requirements

International Electrotechnical Commission (IEC) Standards

IEC standards are globally recognized:

- IEC 60076: Covers power transformers, including those used in residential applications

- Focuses on safety, performance, and testing requirements

- Widely adopted internationally, especially in Europe and Asia

I recently worked on a project exporting residential transformers to multiple countries. Adhering to IEC 60076 standards simplified the certification process across different markets, highlighting the importance of these international standards.

Institute of Electrical and Electronics Engineers (IEEE) Standards

IEEE standards are prominent in North America:

- IEEE C57: Comprehensive standards for transformers

- Covers design, manufacturing, and testing aspects

- Widely used in the United States and Canada

During a recent residential development project in Canada, ensuring compliance with IEEE C57 standards was crucial for meeting local regulatory requirements and utility specifications.

Department of Energy (DOE) Efficiency Regulations

DOE regulations focus on energy efficiency:

- Mandatory efficiency standards for distribution transformers in the USA

- Aims to reduce energy losses and promote conservation

- Updated periodically to drive improvements in transformer efficiency

Here’s a quick overview of key standards:

| Standard | Focus Area | Geographical Relevance |

|---|---|---|

| IEC 60076 | Safety and Performance | Global |

| IEEE C57 | Design and Testing | North America |

| DOE Efficiency | Energy Conservation | USA |

| RoHS/REACH | Environmental Safety | EU/Global |

Environmental and Safety Standards

Environmental compliance is increasingly important:

- RoHS (Restriction of Hazardous Substances): Limits use of certain materials

- REACH (Registration, Evaluation, Authorization and Restriction of Chemicals): EU regulation for chemical safety

- UL (Underwriters Laboratories): Safety standards, especially important in North America

I recall a project where we had to redesign a transformer to meet RoHS standards for a European client. This involved finding alternative materials for certain components, demonstrating the far-reaching impact of environmental regulations on transformer design.

Regional and Local Compliance Requirements

Many regions have specific additional requirements:

- National electrical codes

- Utility company specifications

- Local environmental and noise regulations

Key points to remember about standards and compliance:

- International standards like IEC provide a global baseline for safety and performance

- Regional standards such as IEEE C57 address specific market needs

- Energy efficiency regulations are becoming increasingly stringent worldwide

- Environmental compliance is crucial, especially for international markets

- Always check for additional local requirements in your specific installation area

In my experience, thorough compliance with relevant standards is not just about meeting legal requirements – it’s about ensuring the safety, reliability, and efficiency of residential power systems. I’ve seen projects where overlooking a specific standard led to costly redesigns or even rejection by local authorities.

For instance, in a recent residential project in California, we had to ensure compliance not only with national standards but also with state-specific energy efficiency requirements. This meant selecting transformers that exceeded the national DOE standards, ultimately resulting in lower operating costs for homeowners.

As we move to our final section on choosing the right transformer for residential use, keep these standards in mind. Compliance should be a key factor in your selection process, ensuring that your chosen transformer meets all necessary safety, performance, and efficiency requirements.

How to Choose the Right Transformer for Residential Use?

Are you feeling overwhelmed by the process of selecting the perfect transformer for your residential project? With so many factors to consider, making the right choice can seem daunting. But what if you had a clear, step-by-step approach to ensure you select the ideal transformer for your specific needs?

Choosing the right residential transformer involves considering local voltage requirements, installation method (pole vs. pad), insulation type (oil vs. dry), noise sensitivity, space constraints, and compliance with local standards. Key factors include power capacity needs, environmental conditions, future load growth, and energy efficiency ratings. Consulting with electrical professionals and utility companies is crucial for making an informed decision.

Key Steps in Selecting a Residential Transformer

Let’s break down the selection process into manageable steps:

- Assess Power Requirements

- Consider Installation Location and Method

- Evaluate Environmental Factors

- Check Compliance and Standards

- Factor in Long-Term Considerations

Assess Power Requirements

Start by accurately determining your power needs:

- Calculate total kVA required for the residential area

- Consider diversity factor (not all loads operate simultaneously)

- Plan for future load growth

I once worked on a suburban development where underestimating future power needs led to transformer overloading within a few years. Always factor in potential growth and changing energy consumption patterns.

Consider Installation Location and Method

The installation site significantly impacts your choice:

- Pole-mounted vs. pad-mounted options

- Space availability and aesthetic considerations

- Accessibility for maintenance and repairs

During a recent project in a historic neighborhood, we opted for pad-mounted transformers to preserve the area’s aesthetic appeal. This decision required careful planning for ground-level installation sites.

Evaluate Environmental Factors

Environmental conditions play a crucial role:

- Climate considerations (temperature extremes, humidity)

- Exposure to elements (coastal areas, high altitudes)

- Noise sensitivity in residential areas

Here’s a quick reference for environmental considerations:

| Factor | Consideration | Potential Solution |

|---|---|---|

| High Temperatures | Increased cooling needs | Choose units with better heat dissipation |

| Coastal Environment | Corrosion risk | Select corrosion-resistant models |

| Urban Setting | Noise concerns | Opt for low-noise or enclosed designs |

| Flood-prone Areas | Water damage risk | Consider elevated or submersible options |

Check Compliance and Standards

Ensure adherence to relevant standards:

- Local electrical codes and utility requirements

- Energy efficiency standards (e.g., DOE regulations in the USA)

- Environmental compliance (RoHS, REACH where applicable)

I recall a project where overlooking a specific local utility requirement led to delays in transformer installation and additional costs. Always double-check with local authorities and utility companies.

Factor in Long-Term Considerations

Think beyond immediate needs:

- Energy efficiency for long-term cost savings

- Scalability for future expansion

- Reliability and expected lifespan

- Maintenance requirements and costs

Key tips for choosing the right residential transformer:

- Conduct a thorough load analysis, including future projections

- Consult with local utility companies on their specific requirements

- Consider the total cost of ownership, not just the initial purchase price

- Evaluate the transformer’s efficiency ratings and potential energy savings

- Ensure compatibility with existing or planned smart grid technologies

In my experience, successful transformer selection often comes down to balancing immediate needs with long-term considerations. I’ve seen cases where investing in a slightly oversized or more efficient transformer paid off significantly in the long run, accommodating unexpected load growth and reducing energy costs.

For example, in a recent residential complex project, we chose a transformer with higher efficiency ratings despite the higher upfront cost. This decision resulted in noticeable energy savings for residents and easier compliance with evolving energy efficiency regulations.

Remember, selecting the right residential transformer is not just about meeting current needs; it’s about ensuring your power distribution system remains efficient, reliable, and adaptable for years to come. By carefully considering all these factors, you can make an informed decision that will serve your residential project well into the future.

Conclusion

Residential transformers play a crucial role in safely delivering power to our homes. Understanding their types, functions, and selection criteria is essential for homeowners, developers, and electrical professionals. By considering factors like power requirements, installation methods, environmental conditions, and compliance standards, you can ensure the right transformer choice for efficient and reliable residential power distribution.

Remember, at chbeb-ele, we’re not just sharing information – we’re empowering you to be part of the solution in creating a secure, clean, and efficient energy future. Let’s continue this journey together.

Are you struggling to navigate the complex world of dry type transformer standards? You’re not alone. Many engineers and procurement professionals find themselves confused by the various international and regional requirements. But what if you had a clear guide to help you understand and apply these standards effectively?

Dry type distribution transformers must comply with international standards like IEC 60076, IEEE C57, and UL guidelines. This article compares the key technical and safety requirements of each, helping engineers and procurement teams ensure product compliance for export, tender, or installation across global markets.

In this comprehensive guide, I’ll walk you through the main standards for dry type transformers, explaining their scope, requirements, and applications. Whether you’re working on a local project or planning for international exports, this article will provide you with the knowledge to make informed decisions about transformer standards compliance.

What Are the Main Standards for Dry Type Transformers?

Are you wondering which standards are most relevant for dry type transformers? With so many guidelines and regulations out there, it can be overwhelming to determine which ones apply to your project. But what are the key standards you need to know about, and why are they important?

The main standards for dry type transformers include IEC 60076, IEEE C57, and UL guidelines. IEC 60076 is widely used internationally, IEEE C57 is prominent in North America, and UL standards focus on safety aspects. These standards cover design, performance, testing, and safety requirements, ensuring transformers meet global quality and reliability benchmarks.

Understanding Key Transformer Standards

Let’s explore the main standards and their significance:

- IEC 60076 Series

- IEEE C57 Series

- UL Standards (UL 1561 and UL 1562)

- Regional Standards and Adaptations

- Harmonization Efforts and Trends

IEC 60076 Series

The International Electrotechnical Commission (IEC) standards are widely adopted:

- IEC 60076-11 specifically covers dry-type transformers

- Focuses on performance, testing, and safety requirements

- Widely recognized and used globally

I recently worked on a project where compliance with IEC 60076-11 was crucial for exporting transformers to multiple countries. The standard’s global recognition simplified the certification process significantly.

IEEE C57 Series

IEEE standards are prominent in North America:

- IEEE C57.12.01 covers dry-type transformers

- Emphasizes design specifications and test requirements

- Widely used in the United States and Canada

During a recent consultation for a U.S.-based manufacturing plant, adherence to IEEE C57 standards was essential for meeting local regulatory requirements and ensuring compatibility with existing infrastructure.

UL Standards

Underwriters Laboratories (UL) focuses on safety:

- UL 1561 for large dry-type transformers

- UL 1562 for smaller, general-purpose transformers

- Emphasizes fire safety and electrical hazard prevention

Here’s a quick comparison of these main standards:

| Standard | Primary Focus | Geographical Prominence | Key Aspects |

|---|---|---|---|

| IEC 60076 | Performance and Testing | Global | Comprehensive coverage of all aspects |

| IEEE C57 | Design and Testing | North America | Detailed specifications for local requirements |

| UL Standards | Safety | Global (emphasis on U.S.) | Fire resistance and electrical safety |

Regional Standards and Adaptations

Many regions have their own adaptations:

- China: GB standards (often based on IEC)

- India: IS standards (influenced by both IEC and IEEE)

- European Union: EN standards (harmonized with IEC)

Harmonization Efforts and Trends

There’s a growing trend towards harmonization:

- Efforts to align IEC and IEEE standards

- Increased recognition of IEC standards globally

- Development of dual-certified products meeting multiple standards

Key considerations when dealing with transformer standards:

- Understand the specific requirements of your target market

- Consider the need for multiple certifications for international projects

- Stay informed about ongoing harmonization efforts and updates

- Consult with experts or manufacturers for standard interpretation

- Consider the impact of standards on design, testing, and documentation

In my experience, a thorough understanding of these standards is crucial for successful transformer projects. I’ve seen cases where overlooking a specific standard requirement led to costly redesigns and project delays.

As we delve deeper into each standard, keep in mind that compliance is not just about meeting technical specifications – it’s about ensuring safety, reliability, and global market access for your transformer projects.

Overview of IEC 60076: Scope, Requirements, and Applications?

Are you grappling with the complexities of IEC 60076 for your dry type transformer projects? This international standard is crucial for many global markets, but its extensive scope can be overwhelming. What exactly does IEC 60076 cover, and how can you ensure your transformers meet its requirements?

IEC 60076, particularly Part 11 for dry-type transformers, covers design, manufacturing, and testing requirements. It specifies performance criteria, insulation levels, temperature rise limits, and test procedures. The standard applies to transformers with highest voltage for equipment up to 36 kV, ensuring safety, reliability, and performance consistency across international markets.

Key Aspects of IEC 60076 for Dry-Type Transformers

Let’s break down the essential elements of IEC 60076:

- Scope and Application

- Design and Construction Requirements

- Performance Specifications

- Testing Procedures

- Documentation and Marking

Scope and Application

IEC 60076-11 specifically addresses dry-type transformers:

- Covers transformers with highest voltage for equipment up to 36 kV

- Applies to both indoor and outdoor installations

- Includes both general-purpose and special application transformers

I recently consulted on a project where understanding the scope of IEC 60076-11 was crucial in determining whether a specialized transformer for a renewable energy application fell within its purview.

Design and Construction Requirements

The standard sets clear guidelines for transformer design:

- Specifies insulation levels and dielectric strength requirements

- Defines temperature rise limits for different insulation classes

- Outlines requirements for mechanical strength and environmental protection

During a recent manufacturing audit, we focused on ensuring that the core and winding designs met IEC 60076-11 specifications, particularly in terms of insulation class and temperature rise limits.

Performance Specifications

IEC 60076 defines key performance criteria:

- Establishes efficiency requirements and loss evaluation

- Specifies short-circuit withstand capabilities

- Defines noise level limits

Here’s a quick reference for some key performance specifications:

| Aspect | Requirement | Notes |

|---|---|---|

| Temperature Rise | Class B: 80K, Class F: 100K, Class H: 125K | At rated load |

| Insulation Level | Based on highest voltage for equipment | Specified in the standard |

| Short-Circuit Withstand | Mechanical and thermal requirements | Tested as per IEC procedures |

| Noise Levels | Varies based on rating and cooling method | Measured under specified conditions |

Testing Procedures

The standard outlines comprehensive testing requirements:

- Routine tests (applied to all units)

- Type tests (performed on representative units)

- Special tests (as agreed between manufacturer and purchaser)

I recall a project where we had to conduct additional special tests as per IEC 60076-11 to meet specific client requirements for a harsh industrial environment. These tests provided crucial data on the transformer’s performance under extreme conditions.

Documentation and Marking

IEC 60076 specifies clear documentation requirements:

- Detailed nameplate information

- Test reports and certificates

- Installation and maintenance manuals

Key considerations when working with IEC 60076:

- Ensure your design team is familiar with the latest version of the standard

- Pay close attention to the specific requirements for your transformer’s voltage class and application

- Consider the impact of environmental conditions on design choices

- Plan for comprehensive testing as per IEC procedures

- Maintain detailed documentation throughout the design and manufacturing process

In my experience, thorough compliance with IEC 60076 not only ensures regulatory acceptance but often leads to better-performing and more reliable transformers. I’ve seen projects where strict adherence to IEC standards resulted in transformers that significantly outperformed client expectations in terms of efficiency and reliability.

As we move on to discuss IEEE C57 standards, keep in mind the global prominence of IEC 60076. Understanding its requirements is crucial not just for compliance, but for producing high-quality transformers that can compete in international markets.

IEEE C57 Standard: U.S. Norms and Design Expectations?

Are you finding it challenging to navigate the IEEE C57 standards for dry type transformers, especially when dealing with U.S. markets? These standards are crucial for North American projects, but their specific requirements can be complex. What exactly does IEEE C57 entail, and how does it differ from international standards like IEC?

IEEE C57 standards, particularly C57.12.01 for dry-type transformers, define U.S. norms for design, testing, and performance. They specify voltage ratings, BIL levels, impedance ranges, and test procedures tailored to North American power systems. These standards emphasize safety, reliability, and compatibility with U.S. grid characteristics, making them essential for projects in the United States and Canada.

Understanding IEEE C57 Standards for Dry-Type Transformers

Let’s explore the key aspects of IEEE C57 standards:

- Scope and Applicability

- Design and Rating Specifications

- Performance Requirements

- Testing Procedures

- Safety and Environmental Considerations

Scope and Applicability

IEEE C57.12.01 is the primary standard for dry-type transformers:

- Covers transformers rated 601-35000V, up to 500 kVA single-phase and 2500 kVA three-phase

- Applies to both general-purpose and specific application transformers

- Widely recognized in the United States and Canada

I recently worked on a project for a U.S. data center where compliance with IEEE C57.12.01 was mandatory. Understanding its scope was crucial in selecting the right transformer specifications.

Design and Rating Specifications

The standard provides detailed design guidelines:

- Defines standard voltage ratings and taps

- Specifies Basic Impulse Level (BIL) requirements

- Outlines standard impedance ranges

During a recent design review for a transformer destined for the U.S. market, we had to carefully align our specifications with IEEE C57.12.01, particularly in terms of voltage ratings and BIL levels.

Performance Requirements

IEEE C57 sets clear performance criteria:

- Establishes temperature rise limits for different insulation systems

- Defines sound level limits

- Specifies short-circuit withstand capabilities

Here’s a quick reference table for some key performance specifications:

| Aspect | Requirement | Notes |

|---|---|---|

| Temperature Rise | 80°C for 220°C systems, 115°C for 220°C systems | Average winding temperature rise |

| Sound Levels | Varies by kVA rating | Measured at 30cm from transformer surface |

| Short-Circuit Withstand | Mechanical and thermal requirements | Specific duration and current levels defined |

Testing Procedures

The standard outlines comprehensive testing requirements:

- Routine tests (performed on all units)

- Design tests (performed on representative units)

- Other tests (as specified by the purchaser)

I recall a project where we had to conduct additional design tests as per IEEE C57.12.91 to verify the transformer’s performance under specific environmental conditions. These tests were crucial in demonstrating compliance with U.S. utility requirements.

Safety and Environmental Considerations

IEEE C57 emphasizes safety and environmental aspects:

- Specifies requirements for fire resistance and containment

- Addresses environmental considerations, including noise levels

- Outlines safety features and markings

Key considerations when working with IEEE C57 standards:

- Ensure your design team is familiar with the latest version of IEEE C57.12.01 and related standards

- Pay close attention to voltage ratings and BIL levels specific to U.S. requirements

- Consider the impact of U.S. grid characteristics on transformer design

- Plan for comprehensive testing as per IEEE procedures

- Be aware of specific safety and environmental requirements for the U.S. market

In my experience, thorough compliance with IEEE C57 standards is crucial for success in the North American market. I’ve seen cases where transformers designed to IEC standards faced challenges in U.S. projects due to differences in voltage ratings and BIL requirements.

As we move forward to discuss UL standards, keep in mind that while IEEE C57 focuses on performance and design, UL standards will add another layer of safety considerations, particularly important for installations in buildings and public spaces.

UL Standards for Dry Type Transformers: Focus on Safety and Fire Resistance?

Are you concerned about meeting the stringent safety requirements for dry type transformers, especially in North American markets? UL standards play a crucial role in ensuring transformer safety, but their specific requirements can be challenging to navigate. What exactly do UL standards cover for dry type transformers, and how do they complement other international standards?

UL standards, particularly UL 1561 and UL 1562, focus on safety aspects of dry type transformers. They emphasize fire resistance, electrical safety, and environmental protection. These standards specify construction requirements, temperature limits, and extensive safety testing procedures. Compliance with UL standards is often mandatory for installations in buildings and public spaces in North America, ensuring high levels of safety and reliability.

Key Aspects of UL Standards for Dry Type Transformers

Let’s explore the essential elements of UL standards:

- Scope and Application of UL 1561 and UL 1562

- Construction and Materials Requirements

- Safety Testing Procedures

- Fire Resistance and Environmental Considerations

- Labeling and Documentation Requirements

Scope and Application of UL 1561 and UL 1562

UL standards cover different transformer types:

- UL 1561: Larger dry-type general-purpose and power transformers

- UL 1562: Smaller dry-type general-purpose and power transformers

- Both focus on safety aspects and are widely recognized in North America

I recently consulted on a project for a commercial building where UL compliance was mandatory. Understanding the distinction between UL 1561 and UL 1562 was crucial in selecting the appropriate standard for different transformer sizes within the project.

Construction and Materials Requirements

UL standards set strict guidelines for transformer construction:

- Specify requirements for insulation materials and their arrangement

- Define standards for electrical clearances and creepage distances

- Outline requirements for terminals and internal connections

During a recent manufacturing audit for UL compliance, we paid particular attention to the insulation system and clearances. Meeting these requirements often necessitates specific design considerations that may differ from IEC or IEEE standards.

Safety Testing Procedures

UL standards mandate comprehensive safety tests:

- Dielectric voltage-withstand test

- Temperature rise test under various conditions

- Overload and short-circuit tests

- Mechanical stress tests

Here’s a quick reference for some key UL testing requirements:

| Test Type | Purpose | Key Criteria |

|---|---|---|

| Dielectric Withstand | Insulation integrity | No breakdown or flashover |

| Temperature Rise | Thermal performance | Within specified limits for insulation class |

| Overload | Performance under stress | No failure during and after test |

| Short-Circuit | Mechanical and thermal withstand | No deformation or insulation damage |

Fire Resistance and Environmental Considerations

UL standards place high emphasis on fire safety:

- Specify requirements for fire-resistant materials

- Define testing procedures for fire behavior

- Address environmental factors like moisture resistance and corrosion protection

I recall a project where we had to redesign a transformer’s enclosure to meet UL fire resistance requirements. This involved selecting specific materials and redesigning ventilation to ensure fire containment without compromising cooling efficiency.

Labeling and Documentation Requirements

UL standards have strict labeling and documentation rules:

- Detailed nameplate information including UL mark

- Comprehensive installation and safety instructions

- Maintenance and operating guidelines

Key considerations when working with UL standards:

- Ensure your design team understands the specific requirements of UL 1561 or UL 1562

- Pay close attention to material selection, especially for insulation and enclosures

- Plan for extensive safety testing as part of the design and manufacturing process

- Consider the impact of UL requirements on overall transformer design and cost

- Maintain detailed documentation for UL certification and ongoing compliance

In my experience, achieving UL compliance often requires a different approach to transformer design compared to IEC or IEEE standards. I’ve seen projects where transformers designed primarily for international markets needed significant modifications to meet UL requirements, particularly in terms of fire resistance and safety features.

For instance, in a recent project for a U.S. data center, we had to redesign the transformer’s cooling system to meet UL’s stringent fire safety standards while maintaining the required performance. This involved using specially rated materials and implementing additional safety features, which ultimately resulted in a more robust and safer product.

As we move on to discuss the key differences between IEC, IEEE, and UL requirements, keep in mind that UL standards often set the bar for safety considerations. Understanding these requirements is crucial not just for compliance, but for ensuring the highest levels of safety in transformer installations, especially in sensitive environments like commercial buildings and public spaces.

Key Differences Between IEC, IEEE, and UL Requirements?

Are you finding it challenging to navigate the differences between IEC, IEEE, and UL standards for dry type transformers? With projects often requiring compliance with multiple standards, understanding these differences is crucial. But how do these standards differ, and what impact do these differences have on transformer design and application?

Key differences between IEC, IEEE, and UL standards lie in their focus, technical specifications, and geographical application. IEC standards are internationally recognized and focus on performance. IEEE standards cater to North American power systems with specific voltage and BIL requirements. UL standards emphasize safety and fire resistance. These differences affect design parameters, testing procedures, and certification processes for dry type transformers.

Analyzing the Differences Between IEC, IEEE, and UL Standards

Let’s break down the key differences in several areas:

- Scope and Geographical Application

- Technical Specifications and Ratings

- Testing Procedures and Requirements

- Safety and Environmental Considerations

- Documentation and Certification Processes

Scope and Geographical Application

Each standard has a different focus and application:

- IEC: Globally recognized, widely used in Europe, Asia, and many other regions

- IEEE: Primarily used in North America, tailored to U.S. and Canadian power systems

- UL: Focused on safety, mandatory for many North American installations

I recently worked on a multinational project where we had to design transformers compliant with both IEC and UL standards. The challenge was in reconciling the different approaches to performance and safety requirements.

Technical Specifications and Ratings

Significant differences exist in technical specifications:

- Voltage Ratings: IEEE specifies different standard voltages compared to IEC

- BIL (Basic Impulse Level): IEEE generally requires higher BIL ratings than IEC

- Impedance Ranges: IEEE has specific standard impedance ranges not found in IEC

During a recent design review, we had to carefully navigate these differences. For example, a transformer designed for 11kV in an IEC market needed to be adapted to 13.8kV for the IEEE market, affecting various design parameters.

Testing Procedures and Requirements

Testing requirements vary between standards:

- IEC focuses on type tests and routine tests

- IEEE includes design tests which are more extensive than IEC type tests

- UL emphasizes safety-related tests, including fire resistance

Here’s a quick comparison of some key testing differences:

| Aspect | IEC | IEEE | UL |

|---|---|---|---|

| Temperature Rise Test | Specified methods | Similar to IEC, with some variations | Includes additional safety criteria |

| Impulse Test | Required for certain voltage classes | Generally more stringent | Focused on safety aspects |

| Short-Circuit Test | Detailed requirements | Similar to IEC, with some differences | Emphasizes mechanical and thermal withstand |

Safety and Environmental Considerations

Approach to safety varies:

- IEC provides general safety guidelines

- IEEE incorporates safety considerations within performance standards

- UL has the most stringent safety and fire resistance requirements

I recall a project where a transformer designed to IEC standards required significant modifications to meet UL fire safety requirements, including changes to materials and cooling system design.

Documentation and Certification Processes

Documentation requirements differ:

- IEC requires comprehensive type test reports

- IEEE focuses on design test documentation

- UL has specific labeling and documentation requirements for certification

Key considerations when dealing with multiple standards:

- Understand the specific requirements of each standard for your project

- Consider designing to the most stringent requirements if multiple certifications are needed

- Be aware of the impact of different standards on overall transformer cost and design

- Plan for potentially different testing procedures and documentation

- Consult with experts or certification bodies for complex multi-standard projects

In my experience, successfully navigating these differences often requires a deep understanding of each standard and creative engineering solutions. I’ve seen projects where designing to meet multiple standards led to more robust and versatile transformer designs, albeit at a higher initial cost.

For example, in a recent global data center project, we designed transformers to meet the most stringent requirements across IEC, IEEE, and UL standards. While this approach increased upfront costs, it resulted in a product that could be deployed globally, offering significant long-term benefits in terms of standardization and logistics.

As we move forward to discuss which standard you should choose for your project, keep these differences in mind. The choice of standard can significantly impact your transformer’s design, performance, and global applicability.

Which Standard Should You Choose for Your Project?

Are you struggling to decide which transformer standard is most appropriate for your project? With IEC, IEEE, and UL standards each offering different benefits, making the right choice can be challenging. But how do you determine which standard aligns best with your specific project requirements and goals?

Choosing the right standard depends on your project’s location, application, and specific requirements. IEC is ideal for international projects and global compatibility. IEEE is best for North American power systems. UL is crucial for installations prioritizing safety, especially in buildings. Consider factors like geographical location, local regulations, export potential, and specific safety needs when selecting a standard.

Factors to Consider When Choosing a Standard

Let’s explore the key considerations in selecting the right standard:

- Project Location and Market Requirements

- Technical Specifications and Performance Needs

- Safety and Regulatory Compliance

- Future Export or Expansion Plans

- Cost and Design Implications

Project Location and Market Requirements

The geographical location often dictates the standard:

- North America: IEEE and UL are typically required

- Europe and many international markets: IEC is widely accepted

- Some regions may recognize multiple standards

I recently advised on a project in the Middle East where the client initially specified IEEE standards. After analyzing local regulations and future export potential, we recommended designing to IEC standards with UL certification as an option, providing greater flexibility.

Technical Specifications and Performance Needs

Consider your specific technical requirements:

- Voltage levels and system characteristics

- Performance expectations (efficiency, noise levels, etc.)

- Compatibility with existing infrastructure

During a data center project, we chose to follow IEEE standards due to the specific voltage requirements and the need for compatibility with North American UPS systems, despite the project’s international location.

Safety and Regulatory Compliance

Safety requirements can be a deciding factor:

- UL standards for stringent safety needs, especially in buildings

- Local regulatory requirements may dictate standard choice

- Industry-specific safety norms (e.g., for oil and gas, marine applications)

Here’s a quick reference for standard selection based on primary concerns:

| Primary Concern | Recommended Standard | Key Benefit |

|---|---|---|

| Global Compatibility | IEC | Widely recognized internationally |

| North American Power Systems | IEEE | Tailored to U.S. and Canadian requirements |

| Safety in Buildings | UL | Stringent safety and fire resistance standards |

| Export Flexibility | IEC (with options for others) | Broadest international acceptance |

Future Export or Expansion Plans

Consider long-term business strategies:

- IEC offers the most flexibility for global markets

- Dual certification (e.g., IEC and UL) can open more markets

- Regional standards may limit future export opportunities

I recall a manufacturer who initially focused solely on IEEE standards. When they decided to expand internationally, they faced significant challenges. We helped them develop a strategy to incorporate IEC standards into their designs, greatly expanding their market reach.

Cost and Design Implications

Different standards can impact costs and design:

- Designing for multiple standards may increase initial costs

- Some standards may require more expensive materials or components

- Testing and certification costs vary between standards

Key considerations when choosing a standard:

- Analyze your target market and its regulatory requirements

- Consider both immediate needs and long-term business strategy

- Evaluate the cost implications of different standards

- Consult with local authorities or experts in ambiguous cases

- Consider the potential for dual or multiple certifications

In my experience, the choice of standard can have far-reaching implications beyond just technical compliance. I’ve seen projects where the right choice of standard opened new market opportunities, while the wrong choice led to costly redesigns and market entry barriers.

For instance, a European manufacturer I worked with decided to design their transformers to both IEC and UL standards from the outset. While this increased initial development costs, it positioned them to quickly enter the North American market when an opportunity arose, giving them a significant competitive advantage.

As we move on to discuss ensuring compliance for export and tender projects, remember that your choice of standard sets the foundation for your transformer’s design and market potential. Carefully considering all factors can lead to more versatile and marketable products.

How to Ensure Compliance for Export and Tender Projects?

Are you concerned about meeting diverse standard requirements for international export or complex tender projects? Ensuring compliance across different markets can be a daunting task. But how can you effectively navigate the maze of international standards and certification processes to make your transformers globally competitive?

Ensuring compliance for export and tender projects involves understanding target market requirements, potentially designing to multiple standards, and obtaining necessary certifications. Key steps include conducting thorough market research, considering dual certifications (e.g., IEC and UL), working with accredited testing laboratories, and maintaining comprehensive documentation. Flexibility in design and a proactive approach to certification can significantly enhance global market access.

Strategies for Ensuring Global Compliance

Let’s explore key strategies for meeting international standards:

- Market Research and Requirement Analysis

- Design for Multiple Standards

- Testing and Certification Processes

- Documentation and Traceability

- Adapting to Regional Variations

Market Research and Requirement Analysis

Start with thorough market research:

- Identify specific standards required in target markets

- Understand local regulatory requirements and preferences

- Analyze tender documents for standard specifications

I recently assisted a manufacturer in entering the Middle Eastern market. Our detailed analysis revealed that while IEC standards were generally accepted, some countries had additional local requirements. This insight was crucial in developing a compliant product strategy.

Design for Multiple Standards

Consider a flexible design approach:

- Design to the most stringent requirements across relevant standards

- Incorporate features that allow easy adaptation to different markets

- Consider modular designs for easier customization

During a recent project, we developed a transformer design that met both IEC and IEEE standards. While more complex initially, this approach allowed the client to bid on projects globally with minimal design changes.

Testing and Certification Processes

Plan for comprehensive testing and certification:

- Work with internationally recognized testing laboratories

- Consider witness testing options for key markets

- Plan for periodic re-certification as standards evolve

Here’s a quick guide to certification approaches:

| Approach | Description | Best For |

|---|---|---|

| Single Standard Certification | Certify to one primary standard | Focused market strategy |

| Dual Certification | Obtain certifications for two major standards (e.g., IEC and UL) | Broad market access |

| Multiple Certifications | Certify to several standards | Global export strategy |

| Market-Specific Certification | Obtain certifications as needed for each market | Targeted export approach |

Documentation and Traceability

Maintain comprehensive documentation:

- Detailed test reports for all relevant standards

- Clear traceability of components and materials

- Multilingual documentation for international markets

I recall a case where a client lost a major tender due to insufficient documentation of their compliance with local standards. This experience underscores the importance of thorough and well-organized compliance documentation.

Adapting to Regional Variations

Be prepared to adapt to regional differences:

- Understand and accommodate local voltage and frequency variations

- Consider climate-specific design modifications (e.g., for extreme temperatures)

- Be aware of regional preferences in features or specifications

Key strategies for ensuring compliance in export and tender projects:

- Develop a comprehensive understanding of target market requirements

- Consider a flexible design approach that can meet multiple standards

- Invest in robust testing and certification processes

- Maintain meticulous documentation and traceability

- Stay informed about evolving standards and regional variations

In my experience, success in international markets often comes down to a combination of technical excellence and strategic compliance planning. I’ve seen companies gain significant competitive advantages by proactively addressing compliance issues.

For example, a transformer manufacturer I worked with implemented a "global design" strategy, where their base models were designed to meet the most stringent requirements across IEC, IEEE, and UL standards. This approach, while initially more costly, allowed them to quickly respond to tenders worldwide and significantly expanded their market reach.

As we move to our final section on brand compliance examples, remember that ensuring compliance is an ongoing process. Staying ahead of regulatory changes and maintaining flexibility in your approach can open doors to new markets and opportunities.

Brand Compliance Examples: ABB, TBEA, Schneider, and More?

Are you curious about how leading transformer manufacturers navigate the complex landscape of international standards? Understanding how top brands approach compliance can provide valuable insights for your own projects. But what specific strategies do companies like ABB, TBEA, and Schneider Electric employ to meet diverse global standards?

Leading brands like ABB, TBEA, and Schneider Electric employ comprehensive strategies to meet global standards. ABB focuses on dual IEC and UL certifications for broad market access. TBEA emphasizes IEC compliance with adaptations for specific markets like the Middle East. Schneider Electric maintains a portfolio of products certified to multiple standards, allowing flexibility in global projects. These approaches demonstrate the importance of strategic standard compliance in international markets.

Analyzing Compliance Strategies of Major Brands

Let’s explore how different brands approach standard compliance:

- ABB’s Global Compliance Strategy

- TBEA’s Approach to International Markets

- Schneider Electric’s Multi-Standard Portfolio

- Siemens’ Focus on Regional Adaptations

- Emerging Trends in Brand Compliance Strategies

ABB’s Global Compliance Strategy

ABB emphasizes versatility in standard compliance:

- Designs often meet both IEC and IEEE/ANSI standards

- UL certification for products targeting North American markets

- Focus on energy efficiency standards across regions

I recently worked with a client who chose ABB transformers for a global data center project. ABB’s ability to provide units compliant with both IEC and UL standards was a key factor in their selection, simplifying the procurement process across multiple countries.

TBEA’s Approach to International Markets

TBEA focuses on adaptability to different markets:

- Strong emphasis on IEC standards for international projects

- Customization capabilities for specific regional requirements

- Particular focus on emerging markets and Belt and Road Initiative countries

During a consultation for a power infrastructure project in Central Asia, TBEA’s experience with adapting IEC-compliant designs to local conditions proved invaluable, especially in dealing with extreme environmental factors.

Schneider Electric’s Multi-Standard Portfolio

Schneider Electric maintains a diverse product range:

- Products certified to IEC, IEEE, and UL standards

- Emphasis on eco-design and energy efficiency across all standards

- Solutions tailored for specific applications (e.g., data centers, renewable energy)

Here’s a quick overview of these brands’ compliance strategies:

| Brand | Primary Standards | Key Strategy | Notable Strength |

|---|---|---|---|

| ABB | IEC, UL, IEEE | Dual certification | Global market flexibility |

| TBEA | IEC with regional adaptations | Market-specific customization | Strong in emerging markets |

| Schneider Electric | IEC, UL, IEEE | Application-specific solutions | Diverse product portfolio |

| Siemens | IEC, IEEE, regional standards | Regional focus | Strong in industrial applications |

Siemens’ Focus on Regional Adaptations

Siemens emphasizes regional expertise:

- Strong compliance with both IEC and IEEE standards

- Particular focus on industry-specific standards (e.g., for oil and gas, marine applications)

- Adaptations for regional grid characteristics and environmental conditions

I recall a project where Siemens’ ability to provide transformers meeting both European and North American standards was crucial for a multinational manufacturing company standardizing its global operations.

Emerging Trends in Brand Compliance Strategies

Observing these major brands reveals emerging trends:

- Increasing focus on dual or multi-standard certifications

- Integration of smart features compliant with various regional requirements

- Emphasis on sustainability and energy efficiency across all standards

Key takeaways from brand compliance strategies:

- Major brands prioritize flexibility in standard compliance for global competitiveness

- Customization capabilities for regional requirements are increasingly important

- Energy efficiency and environmental standards are becoming universal priorities

- Smart and IoT-enabled features are being integrated while maintaining compliance

- Brands are balancing global standardization with regional customization

In my experience, studying these brand strategies offers valuable lessons for any company looking to expand its transformer business globally. I’ve seen smaller manufacturers successfully adopt similar approaches, tailoring them to their specific capabilities and target markets.

For instance, a mid-sized manufacturer I advised recently adopted a strategy similar to ABB’s, focusing on obtaining both IEC and UL certifications for their key product lines. This approach, while initially resource-intensive, significantly expanded their ability to bid on international projects and enter new markets.

Another interesting case involved a company that took inspiration from TBEA’s approach. They focused on IEC compliance but developed a systematic process for adapting their designs to specific regional requirements, particularly for harsh environments. This strategy allowed them to successfully enter several challenging markets in Africa and the Middle East.

These brand examples highlight a crucial point: successful compliance strategies go beyond mere adherence to standards. They involve a deep understanding of market needs, a flexible approach to design and manufacturing, and a commitment to continuous adaptation as standards and market requirements evolve.

As we conclude this comprehensive guide to dry type transformer standards, remember that understanding and strategically implementing these standards is not just about compliance – it’s about opening doors to global opportunities and ensuring your products meet the diverse needs of a rapidly evolving energy landscape.

Conclusion

Navigating the complex world of dry type transformer standards is crucial for success in the global market. IEC, IEEE, and UL standards each offer unique benefits and cater to different regional and application needs. Understanding their differences, choosing the right standard for your project, and ensuring compliance for export and tender projects are key to expanding your market reach. By learning from the strategies of leading brands and adapting to evolving standards, you can enhance your competitive edge in the international transformer market.

Remember, at chbeb-ele, we’re not just sharing information – we’re empowering you to be part of the solution in creating a secure, clean, and efficient energy future. Let’s continue this journey together.

Are you struggling with the complexities of installing and maintaining dry type distribution transformers? You’re not alone. Many engineers and facility managers find themselves overwhelmed by the technical requirements and potential pitfalls. But what if you had a comprehensive guide to ensure your transformer installation and maintenance are always up to par?

Proper installation and maintenance of dry type distribution transformers are crucial for optimal performance and longevity. Best practices include thorough pre-installation checks, correct positioning, proper connection setup, comprehensive commissioning, regular maintenance schedules, and avoiding common mistakes. Following these guidelines ensures safety, efficiency, and reliability of your transformer installations.

In this comprehensive guide, I’ll walk you through the essential steps and best practices for installing and maintaining dry type distribution transformers. Whether you’re a seasoned engineer or a facility manager new to transformer management, this article will provide you with valuable insights to ensure your transformers operate efficiently and reliably for years to come.

Pre-Installation Checks: Site Conditions and Mounting Requirements?