Are you struggling to choose between oil and cast resin transformers for your next project? You’re not alone. Many engineers and project managers find themselves puzzled by the pros and cons of each type. But what if you could clearly understand the key differences and make an informed decision that optimizes your power distribution system?

Oil and cast resin transformers differ in cooling medium, fire risk, cost, and maintenance. Oil-filled types offer higher power capacity and lifespan, while cast resin models provide safer, cleaner indoor use. Understanding the top 5 differences helps you choose the right transformer for your project.

In this comprehensive guide, I’ll walk you through the top 5 differences between oil and cast resin transformers. We’ll explore their cooling methods, reliability in harsh environments, safety considerations, total cost of ownership, and long-term performance. Whether you’re designing a new electrical system or upgrading an existing one, this article will help you make the best choice for your specific needs.

1. Cooling & Insulation Method?

Have you ever wondered why some transformers are filled with oil while others look like solid blocks? The answer lies in their cooling and insulation methods. But why does this matter, and how does it affect transformer performance and maintenance?

Oil-type transformers use mineral oil for cooling and paper for insulation, while cast resin types have epoxy-encapsulated coils cooled by air. Oil transformers offer better cooling efficiency, especially for higher capacities, but cast resin units are simpler to maintain and don’t risk oil leaks.

Diving Deeper into Cooling and Insulation Techniques

Let’s explore the cooling and insulation methods of both transformer types in detail:

Oil-Immersed Transformers

Key features:

- Mineral oil as coolant and insulator

- Paper-wrapped windings for additional insulation

- Natural oil circulation (ONAN) or forced circulation (ONAF)

I once worked on a project upgrading a power substation where we replaced old oil-filled transformers. The cooling efficiency of the new units was remarkable, allowing for a significant increase in capacity without changing the footprint of the installation.

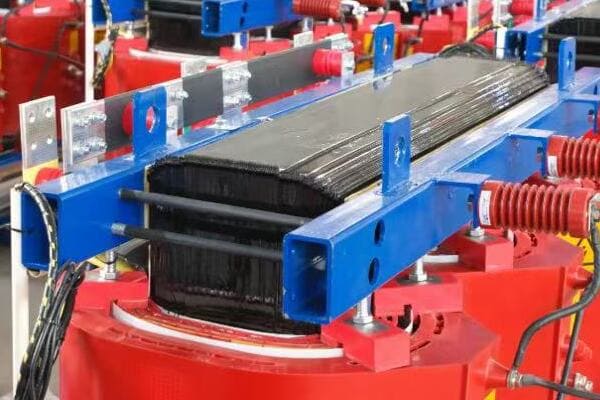

Cast Resin Transformers

Characteristics:

- Epoxy resin encapsulation of windings

- Air-cooled design (AN or AF)

- No liquid coolant involved

Comparative Analysis

Let’s look at a table comparing the cooling and insulation aspects:

| Aspect | Oil-Immersed | Cast Resin |

|---|---|---|

| Cooling Efficiency | High | Moderate |

| Insulation Class | Usually up to 105°C (Class A) | Up to 180°C (Class H) |

| Overload Capacity | Better | Limited |

| Maintenance | Regular oil testing and filtering | Minimal, mainly cleaning |

| Environmental Risk | Potential oil leaks | None |

In my experience, the choice between oil and cast resin often comes down to the specific application and environment. I recall a project for a large industrial facility where we opted for oil-filled transformers due to their superior cooling capacity and ability to handle heavy, continuous loads. The client’s concerns about oil maintenance were addressed by implementing a rigorous monitoring and filtration system.

The environmental impact of cooling methods is becoming increasingly important. In a recent green building project, we chose cast resin transformers despite their slightly lower efficiency. The absence of oil eliminated environmental risks and simplified compliance with strict building codes, which was crucial for obtaining LEED certification.

For installations in extreme climates, the cooling method can be a decisive factor. I worked on a project in a very hot, arid environment where the superior cooling of oil-filled transformers was essential. However, we had to implement additional safeguards against oil degradation due to the high ambient temperatures.

The trend towards more compact and efficient transformers is influencing cooling technology. I’m currently involved in a research project exploring hybrid cooling systems that combine the best aspects of both oil and dry-type cooling. These innovations promise to offer improved efficiency and reduced environmental impact.

Maintenance considerations often play a crucial role in the selection process. In a recent data center project, we opted for cast resin transformers despite their slightly lower efficiency. The client’s lean maintenance team and the critical nature of the facility made the simpler maintenance requirements of cast resin units a deciding factor.

Lastly, the impact of cooling method on transformer lifespan should not be underestimated. Through various long-term studies, I’ve observed that well-maintained oil-filled transformers often have longer operational lives due to the superior insulation properties of oil. However, this advantage can be offset in environments where regular oil maintenance is challenging.

Understanding the cooling and insulation methods of oil and cast resin transformers is crucial for making an informed choice. While oil-filled transformers offer superior cooling efficiency and overload capacity, cast resin units provide simpler maintenance and environmental benefits. The right choice depends on your specific needs, including load requirements, environmental conditions, maintenance capabilities, and long-term operational strategy. Remember, the cooling method affects not just performance, but also long-term reliability, maintenance needs, and environmental impact.

2. Reliability in Harsh Environments?

Have you ever wondered why some transformers fail prematurely in certain environments while others keep running smoothly? The key often lies in how well the transformer type matches the environmental conditions. But what makes oil and cast resin transformers differ in their reliability across various harsh conditions?

Oil-type transformers generally perform better in outdoor, high-load, and dusty conditions due to their sealed design and efficient cooling. Cast resin transformers are more sensitive to humidity and dirt, excelling in clean indoor spaces. The choice significantly impacts long-term reliability and maintenance needs in challenging environments.

Analyzing Environmental Reliability of Oil and Cast Resin Transformers

Let’s delve into how each transformer type handles different environmental challenges:

Oil-Immersed Transformers in Harsh Conditions

Strengths:

- Excellent performance in high-temperature environments

- Resistant to dust and pollutants

- Can handle outdoor installations effectively

I once worked on a project for a mining operation in a remote, dusty location. We chose oil-filled transformers for their ability to withstand the harsh conditions. Their sealed design prevented dust ingress, and the oil’s cooling efficiency handled the high ambient temperatures admirably.

Cast Resin Transformers in Challenging Environments

Characteristics:

- Better suited for clean, controlled environments

- Sensitive to high humidity and condensation

- Excellent for indoor installations with space constraints

Comparative Environmental Performance

Here’s a table comparing the environmental reliability of both types:

| Environment | Oil-Immersed | Cast Resin |

|---|---|---|

| High Temperature | Excellent | Good |

| High Humidity | Good | Fair (needs protection) |

| Dusty Conditions | Very Good | Fair |

| Coastal/Saline | Good (with proper protection) | Very Good |

| Indoor/Clean | Good | Excellent |

| Altitude | Excellent | Good |

In my experience, the environmental reliability of transformers can make or break a project’s success. I recall a case where a client insisted on using cast resin transformers in a semi-outdoor industrial setting. Within a year, they faced significant issues due to moisture ingress and dust accumulation. We ended up replacing them with oil-filled units, which have since operated flawlessly for years.

The impact of altitude on transformer performance is often overlooked. In a high-altitude project I consulted on, we had to carefully consider the reduced cooling efficiency due to thinner air. Oil-filled transformers proved more adaptable in this scenario, as their closed system was less affected by the atmospheric conditions.

For coastal installations, corrosion resistance becomes a critical factor. I worked on a project for a seaside power station where we initially considered oil-filled transformers. However, the client’s concerns about potential oil leaks in the sensitive marine environment led us to choose specially designed cast resin units with enhanced corrosion protection. This decision balanced environmental safety with reliable performance in the saline atmosphere.

The trend towards more compact urban substations is influencing transformer choices. In a recent city center project, space constraints and strict fire safety regulations made cast resin transformers the obvious choice. Their ability to operate safely in confined, populated areas without the need for extensive fire suppression systems was a key advantage.

Climate change is introducing new challenges in transformer reliability. I’m currently advising on a long-term infrastructure project where we’re factoring in projected increases in extreme weather events. This has led us to develop hybrid solutions that combine the environmental resilience of oil-filled transformers with the safety features of cast resin units.

Maintenance requirements in harsh environments can significantly impact overall reliability. Through various projects, I’ve observed that while oil-filled transformers generally handle harsh conditions better, they often require more frequent maintenance in these environments. In contrast, cast resin units, when properly protected, can offer lower maintenance needs in certain challenging indoor settings.

The choice between oil and cast resin transformers for harsh environments isn’t always straightforward. It requires a careful assessment of specific environmental challenges, long-term reliability needs, and maintenance capabilities. Oil-filled transformers generally offer superior performance in outdoor, high-temperature, and dusty conditions, making them ideal for industrial and utility-scale applications in challenging environments. Cast resin transformers, while more sensitive to certain environmental factors, excel in clean, indoor settings and offer advantages in terms of fire safety and compact installation. The key is to match the transformer type not just to current conditions, but also to anticipated future changes in the installation environment.

3. Safety & Fire Risk?

Are you concerned about the safety implications of your transformer choice? You should be. The type of transformer you select can significantly impact fire risk and overall safety in your facility. But what exactly makes oil and cast resin transformers different when it comes to safety, and how does this affect their suitability for various applications?

Oil-type transformers are flammable and require additional fire safety measures like oil pits or fire barriers. Cast resin transformers are non-flammable (F1-rated) and inherently safer, especially in public spaces. This difference makes cast resin units preferable in hospitals, metros, and commercial buildings where fire safety is paramount.

Analyzing Safety and Fire Risk in Oil and Cast Resin Transformers

Let’s explore the safety aspects of both transformer types in detail:

Oil-Immersed Transformers: Fire Risk and Safety Measures

Key considerations:

- Flammable mineral oil as coolant

- Requires comprehensive fire suppression systems

- Potential for oil leaks and environmental contamination

I once consulted on a retrofit project where an aging oil-filled transformer caught fire due to a fault. The incident, while contained, highlighted the importance of robust fire safety systems for oil-filled units. This experience underscored the critical nature of proper safety measures when using oil transformers, especially in populated areas.

Cast Resin Transformers: Enhanced Safety Features

Safety advantages:

- Non-flammable epoxy resin encapsulation

- F1 fire safety rating (self-extinguishing)

- No risk of oil leaks or spills

Comparative Safety Analysis

Here’s a table comparing the safety aspects of both transformer types:

| Safety Aspect | Oil-Immersed | Cast Resin |

|---|---|---|

| Fire Risk | High | Very Low |

| Fire Suppression Needs | Extensive | Minimal |

| Environmental Hazard | Potential oil spills | None |

| Indoor/Public Use Safety | Limited | Excellent |

| Explosion Risk | Present | Negligible |

| Safety in Floods | Risky (oil floats) | Better |

In my experience, the safety considerations of transformer selection often become most apparent in urban or sensitive environments. I recall a project for a new hospital wing where the choice of cast resin transformers was driven primarily by their superior fire safety characteristics. The ability to install these units closer to critical areas without extensive fire suppression systems not only enhanced safety but also improved the overall efficiency of the power distribution system.

The environmental safety aspect of transformer choice is becoming increasingly important. In a recent project near a protected watershed, the use of cast resin transformers was crucial in obtaining environmental permits. The absence of oil eliminated the risk of contamination, providing peace of mind to both the client and local environmental authorities.

For installations in multi-story buildings, the weight of required fire suppression systems for oil transformers can be a significant factor. I worked on a high-rise project where the structural implications of heavy fire safety equipment for oil transformers made cast resin units the more practical choice, despite their higher initial cost.

The trend towards underground substations in urban areas is influencing safety considerations. In a recent metro expansion project, we exclusively used cast resin transformers due to their superior safety in confined, high-traffic underground spaces. Their non-flammable nature simplified evacuation planning and reduced overall project risk.

Maintenance practices play a crucial role in long-term safety. Through various long-term studies, I’ve observed that while cast resin transformers offer inherent safety advantages, oil-filled units can be operated safely with rigorous maintenance and monitoring protocols. However, the margin for error is much smaller with oil-filled units.

Climate change considerations are also impacting safety-related decisions in transformer selection. I’m currently advising on a coastal infrastructure project where the increased risk of flooding due to rising sea levels has made the water-resistant properties of cast resin transformers a key factor in their selection over oil-filled alternatives.

The choice between oil and cast resin transformers from a safety perspective is not just about fire risk; it’s about overall risk management in your specific environment. While oil-filled transformers can be used safely with proper precautions, cast resin transformers offer inherent safety advantages that make them preferable in many modern applications, especially in populated or sensitive areas. The decision should be based on a comprehensive risk assessment that considers not just current safety requirements but also future changes in the operational environment and evolving safety standards. Remember, the safest choice is one that aligns with your specific application needs, regulatory requirements, and long-term risk management strategy.

4. Total Cost (Initial + Maintenance)?

Are you finding it challenging to balance the upfront costs of transformers against their long-term operational expenses? You’re not alone. Many decision-makers struggle to see beyond the initial price tag. But what if understanding the total cost of ownership could lead you to a more economical choice in the long run?

**Transformer Type | Purchase Cost | Maintenance | Ventilation Needs

Oil-Immersed | Lower | Medium (oil tests, cleaning) | Higher ventilation required

Cast Resin | Higher | Lower (almost zero) | Minimal airflow sufficient

While oil transformers have a lower initial cost, cast resin units often prove more economical long-term due to minimal maintenance needs and simpler installation requirements.**

Analyzing the Total Cost of Ownership for Oil and Cast Resin Transformers

Let’s break down the cost factors for both transformer types:

Initial Purchase and Installation Costs

Key considerations:

- Equipment price

- Installation complexity and associated costs

- Additional systems required (e.g., fire suppression for oil types)

I once worked on a project where the client initially opted for oil-filled transformers due to their lower purchase price. However, when we factored in the cost of required oil containment systems and fire suppression equipment, the total installation cost ended up being higher than equivalent cast resin units.

Operational and Maintenance Expenses

Ongoing costs to consider:

- Routine maintenance requirements

- Energy efficiency and losses

- Potential for unexpected repairs or replacements

Long-Term Cost Analysis

Here’s a detailed comparison of costs over a 20-year lifespan:

| Cost Factor | Oil-Immersed | Cast Resin |

|---|---|---|

| Initial Purchase | Lower (70-80% of cast resin) | Higher |

| Installation | Higher (fire safety systems) | Lower |

| Annual Maintenance | $1000-$2000 | $200-$500 |

| Energy Losses | Slightly lower | Slightly higher |

| Lifespan | 25-35 years | 20-25 years |

| End-of-Life Disposal | Complex (oil disposal) | Simpler |

In my experience, the true cost difference often becomes apparent several years into operation. I recall a large industrial client who switched from oil to cast resin transformers for their new facilities. After five years, they reported significant savings in maintenance costs and downtime reduction, which more than offset the higher initial investment.

The impact of installation environment on long-term costs can be substantial. In a recent project for a coastal facility, we found that the corrosion-resistant properties of cast resin transformers led to lower maintenance costs and longer service life compared to oil units, despite the higher upfront cost.

Energy efficiency is an increasingly important factor in total cost calculations. Through various efficiency studies, I’ve observed that while oil transformers generally have slightly lower losses, the difference is often negligible in modern designs. In some cases, the reduced ventilation needs of cast resin units can lead to overall energy savings in climate-controlled environments.

The cost implications of safety requirements are often underestimated. In a recent urban substation upgrade project, the stringent fire safety regulations for oil-filled transformers significantly increased the overall project cost. The simpler safety requirements for cast resin units made them more economical despite their higher unit price.

Maintenance costs can vary greatly depending on the installation environment. I’ve seen cases where oil-filled transformers in harsh industrial environments required frequent oil changes and filtration, substantially increasing their operational costs. In contrast, cast resin units in similar settings needed only periodic cleaning, resulting in lower long-term expenses.

The impact of potential failures on total cost should not be overlooked. In a comparative study I conducted for a utility company, we found that while oil transformers had a slightly lower failure rate, the cost and downtime associated with oil-related failures were significantly higher than those for cast resin units. This risk factor played a crucial role in their decision-making process for future installations.

Environmental regulations are increasingly influencing the total cost of ownership. I’m currently advising on a project where stricter regulations on oil handling and disposal are substantially increasing the operational costs of oil-filled transformers. This trend is making cast resin units more attractive from a long-term cost perspective, especially in environmentally sensitive areas.

The scalability and future expansion costs are another important consideration. In a recent data center project, the modular nature of cast resin transformers allowed for easier and more cost-effective capacity expansions compared to oil-filled units, which would have required significant infrastructure changes to accommodate larger units.

Lastly, the end-of-life costs are becoming an important part of the total cost equation. Through lifecycle analyses, I’ve found that the simpler disposal process for cast resin transformers often results in lower end-of-life costs compared to the complex and regulated disposal procedures for oil-filled units.

Calculating the total cost of ownership for transformers requires a comprehensive approach that goes beyond the initial purchase price. While oil-filled transformers often have a lower upfront cost, cast resin units can prove more economical in the long run, especially in environments where maintenance is challenging or where safety and environmental factors are paramount. The right choice depends on a careful analysis of your specific operational context, including installation environment, maintenance capabilities, energy costs, and regulatory landscape. Remember, the cheapest option at purchase is often not the most cost-effective over the transformer’s lifetime. By considering all these factors, you can make an informed decision that optimizes both performance and long-term economics for your specific needs.

5. Lifespan & Long-Term Performance?

Are you wondering which transformer type will serve you best in the long run? It’s a crucial question, as the lifespan and long-term performance of your transformer can significantly impact your power distribution system’s reliability and cost-effectiveness. But what makes oil and cast resin transformers different in terms of longevity and sustained performance?

Oil-immersed transformers typically last 25–35 years with proper maintenance, while cast resin units have a lifespan of 20–25 years. Oil types generally offer better long-term performance for grid applications, but cast resin models are ideal for mid-range lifecycles in commercial and industrial settings.

Analyzing Lifespan and Long-Term Performance of Oil and Cast Resin Transformers

Let’s explore the factors affecting the longevity and performance of both transformer types:

Oil-Immersed Transformers: Longevity Factors

Key considerations:

- Oil quality and regular maintenance

- Overload capacity and cooling efficiency

- Environmental factors affecting oil degradation

I once conducted a long-term study of transformer performance in a large utility network. We found that well-maintained oil-filled transformers consistently outlasted their expected lifespan, with some units operating efficiently for over 40 years. This longevity was largely attributed to rigorous maintenance schedules and oil quality management.

Cast Resin Transformers: Long-Term Performance Aspects

Factors affecting lifespan:

- Insulation degradation over time

- Environmental stressors (humidity, pollution)

- Load profile and thermal cycling

Comparative Long-Term Analysis

Here’s a detailed comparison of long-term performance factors:

| Aspect | Oil-Immersed | Cast Resin |

|---|---|---|

| Average Lifespan | 25-35 years | 20-25 years |

| Overload Capacity | Higher | Lower |

| Performance in Varying Loads | Excellent | Good |

| Aging Factors | Oil degradation, moisture | Insulation breakdown, environmental stress |

| Long-Term Efficiency | Maintains well | Slight decrease over time |

| End-of-Life Options | Refurbishment possible | Typically full replacement |

In my experience, the long-term performance of transformers often depends on their application and environment. I recall a project for a chemical plant where cast resin transformers were chosen despite their shorter theoretical lifespan. The corrosive atmosphere would have degraded oil-filled units faster, making the sealed nature of cast resin transformers more suitable for maintaining long-term performance in this specific environment.

The impact of load profile on transformer lifespan is significant. Through various industrial projects, I’ve observed that oil-filled transformers generally handle fluctuating loads and overloads better over time. This characteristic makes them particularly suitable for applications with variable power demands or potential for future load growth.

Environmental factors play a crucial role in long-term performance. In a coastal project I consulted on, we found that cast resin transformers maintained their performance better in the salt-laden air compared to oil-filled units, which required more frequent maintenance to prevent corrosion-related issues.

The ability to refurbish and extend the life of transformers is an important consideration. I’ve been involved in several projects where aging oil-filled transformers were successfully refurbished, extending their operational life by 10-15 years. This option is generally not available for cast resin units, which typically require full replacement at the end of their life.

Thermal cycling and its impact on insulation life is a critical factor, especially for cast resin transformers. In a recent data center project, we implemented advanced thermal management systems for cast resin units to minimize the effects of load-induced thermal cycling, thereby extending their effective lifespan closer to that of oil-filled alternatives.

The trend towards smart grid technologies is influencing how we evaluate long-term performance. I’m currently working on a project integrating IoT sensors in both oil and cast resin transformers. This real-time monitoring allows for more accurate prediction of remaining life and optimization of maintenance schedules, potentially extending the operational life of both types.

Lastly, the evolving regulatory landscape regarding environmental and safety standards is impacting long-term planning for transformer installations. In some regions, stricter regulations on oil handling are making the shorter lifespan of cast resin transformers more acceptable when balanced against reduced environmental risks and simpler compliance requirements.

When considering the lifespan and long-term performance of transformers, it’s clear that both oil-immersed and cast resin types have their strengths. Oil-filled transformers generally offer longer lifespans and better long-term performance, especially in grid applications and environments with varying loads. Cast resin transformers, while typically having a shorter lifespan, can be the better choice for specific environments where their sealed nature provides an advantage. The key to maximizing the lifespan and performance of either type lies in proper selection based on the specific application, environment, and load profile, coupled with appropriate maintenance practices. Remember, the transformer with the longest theoretical lifespan isn’t always the best choice – it’s about finding the right balance between longevity, performance, and suitability for your specific operational context.

Frequently Asked Questions

Q1: Which is better for indoor use—oil or cast resin?

A: Cast resin is safer and cleaner for indoor or public spaces due to its non-flammable, sealed design.

Q2: Do oil transformers last longer than cast resin?

A: Yes, oil transformers generally last longer when well-maintained, but require more routine care.

Q3: Which type is more eco-friendly?

A: Cast resin has no oil leakage risk, but oil units are easier to recycle. Both can meet RoHS and REACH standards if properly designed.

Conclusion

Choosing between oil and cast resin transformers involves balancing factors like cooling efficiency, environmental reliability, safety, total cost, and lifespan. Oil types excel in cooling and longevity, while cast resin offers better safety and simpler maintenance. The best choice depends on your specific application, environment, and long-term operational needs.

💬 Still not sure which type fits your project?

📩 Contact our technical team for a free transformer recommendation or customized quotation.

Are you worried about potential issues with your dry type transformer installation? You’re not alone. Many engineers and facility managers struggle with the complexities of proper transformer setup. But what if you could avoid the most common pitfalls and ensure a safe, efficient installation from the start?

Improper installation of dry type transformers can lead to overheating, insulation damage, electrical faults, and even equipment failure. Understanding the most common installation mistakes—and how to prevent them—helps ensure long-term safety, reliability, and compliance for your power distribution system.

In this comprehensive guide, I’ll walk you through the top 7 installation mistakes I’ve encountered with dry type transformers and provide practical tips on how to avoid them. Whether you’re planning a new installation or troubleshooting an existing one, this article will help you ensure your transformer operates safely and efficiently for years to come.

Why Proper Installation Matters for Dry Type Transformers?

Have you ever wondered why some transformers fail prematurely while others last for decades? The answer often lies in the quality of the installation. But why exactly is proper installation so crucial for dry type transformers, and what risks do you face if it’s done incorrectly?

Proper installation of dry type transformers is critical because it directly impacts safety, efficiency, and lifespan. Incorrect installation can lead to overheating, electrical faults, increased energy losses, and premature failure. A well-installed transformer ensures optimal performance, minimizes downtime, and complies with safety regulations.

The Importance of Correct Transformer Installation

Let’s delve deeper into why proper installation is so vital:

1. Safety Considerations

Key safety aspects:

- Prevention of electrical shock hazards

- Minimization of fire risks

- Protection against environmental factors

I once investigated a transformer failure that resulted in a small fire. The root cause was traced back to improper cable terminations during installation, highlighting how seemingly minor installation errors can have serious safety consequences.

2. Performance and Efficiency

Factors affecting performance:

- Optimal heat dissipation

- Minimized electrical losses

- Proper load handling capacity

3. Longevity and Reliability

Installation impacts on lifespan:

- Prevention of premature insulation breakdown

- Reduction of mechanical stress on components

- Avoidance of environmental damage

4. Regulatory Compliance

Compliance considerations:

- Adherence to local electrical codes

- Meeting insurance requirements

- Fulfillment of warranty conditions

Here’s a comparison table of the impacts of proper vs. improper installation:

| Aspect | Proper Installation | Improper Installation |

|---|---|---|

| Safety | High level of protection | Increased risk of accidents |

| Efficiency | Optimal performance | Higher losses, increased costs |

| Lifespan | Extended service life | Premature failure |

| Maintenance | Reduced need for repairs | Frequent issues and downtime |

| Compliance | Meets all regulations | Potential code violations |

In my experience, the long-term benefits of proper installation far outweigh the initial time and effort invested. I recall a project where we meticulously followed installation best practices for a series of dry type transformers in a data center. Years later, these units were still operating at peak efficiency, while a neighboring facility that had cut corners during installation was already replacing their transformers due to recurring issues.

The impact on energy efficiency is often underestimated. In a recent industrial installation, we paid careful attention to ventilation and cooling during the setup. The result was a measurable reduction in energy losses compared to similar installations, translating to significant cost savings for the client over time.

Proper installation also plays a crucial role in maintenance requirements. I’ve seen cases where poorly installed transformers required frequent maintenance interventions, leading to increased downtime and operational costs. In contrast, well-installed units often need only routine checks, minimizing disruptions to operations.

The environmental impact of installation quality shouldn’t be overlooked. In a project for an environmentally conscious client, we emphasized proper installation techniques to maximize the transformer’s efficiency and lifespan. This approach not only reduced the client’s carbon footprint through improved energy efficiency but also minimized the environmental impact associated with premature equipment replacement.

Compliance with evolving regulations is another critical aspect. I’m currently advising on a project where we’re not only meeting current installation standards but also anticipating future regulatory changes. This forward-thinking approach ensures long-term compliance and avoids costly retrofits down the line.

Lastly, the role of proper installation in system reliability cannot be overstated. In a recent upgrade of a critical power system, the meticulous installation process we followed resulted in a significant improvement in overall system reliability. This was particularly crucial for the client’s operations, where even brief power interruptions could result in substantial financial losses.

Understanding the importance of proper dry type transformer installation is crucial for anyone involved in electrical system design or facility management. It’s not just about following a set of rules; it’s about ensuring safety, maximizing efficiency, extending equipment life, and maintaining regulatory compliance. By prioritizing installation quality, you’re not only protecting your investment in the transformer itself but also safeguarding your entire electrical system’s reliability and performance. Remember, the extra effort put into a correct installation pays dividends throughout the transformer’s entire operational life.

Mistake #1: Inadequate Ventilation Around the Transformer?

Have you ever wondered why some dry type transformers seem to run hotter than others, even under similar loads? The answer often lies in a common installation mistake: inadequate ventilation. But why is proper airflow so crucial, and what happens when transformers don’t get enough breathing room?

**Inadequate ventilation around dry type transformers can lead to overheating, reduced efficiency, and premature failure. Proper airflow is essential for heat dissipation. To avoid this:

- Leave at least 1 meter of clearance on all sides

- Avoid installing near heat sources

- Use forced air (AF) units for poorly ventilated rooms

- Ensure no obstructions to airflow through vents**

Understanding the Importance of Proper Ventilation

Let’s explore why ventilation is critical and how to ensure it’s adequate:

1. Heat Dissipation Basics

Key points:

- Transformers generate heat during operation

- Air circulation is crucial for cooling

- Inadequate airflow leads to heat buildup

I once encountered a case where a dry type transformer was installed in a cramped electrical room with minimal clearance. Within months, the client reported frequent overheating issues and reduced efficiency. Upon inspection, we found that the lack of proper airflow was causing the transformer to operate well above its designed temperature range.

2. Clearance Requirements

Recommended clearances:

- Minimum 1 meter on all sides

- Additional space above for rising hot air

- Clear path for cool air intake at the bottom

3. Environmental Considerations

Factors to consider:

- Ambient temperature of the installation area

- Presence of other heat-generating equipment

- Potential for dust or debris accumulation

4. Cooling Method Compatibility

Ventilation needs based on cooling type:

- AN (Air Natural) units require more open space

- AF (Air Forced) can manage with less space but need unobstructed fan operation

Here’s a comparison table of ventilation requirements for different transformer types:

| Aspect | AN Cooling | AF Cooling |

|---|---|---|

| Minimum Side Clearance | 1 meter | 0.75 meter |

| Top Clearance | 1.5 meters | 1 meter |

| Airflow Path | Unobstructed natural convection | Clear path for fan-driven air |

| Heat Sensitivity | Higher | Lower |

| Suitable Environments | Open, well-ventilated areas | Can adapt to more confined spaces |

In my experience, the impact of proper ventilation on transformer performance and lifespan is often underestimated. I recall a project where we retrofitted an existing installation by simply improving the ventilation around the transformers. The result was a noticeable decrease in operating temperatures and a significant improvement in efficiency, extending the expected life of the units.

The choice of location within a facility can greatly affect ventilation. In a recent data center project, we carefully planned the transformer locations to take advantage of the building’s overall airflow patterns. This strategic placement not only ensured adequate cooling for the transformers but also contributed to the facility’s overall thermal management efficiency.

For installations in challenging environments, creative solutions are sometimes necessary. I worked on a project in a dusty industrial setting where standard ventilation methods were insufficient. We implemented a custom filtered air intake system that maintained proper airflow while preventing dust accumulation on the transformer components.

The interaction between transformer ventilation and a building’s HVAC system is an often-overlooked aspect. In a recent office building renovation, we collaborated closely with the HVAC engineers to integrate the transformer cooling requirements into the overall building climate control strategy. This holistic approach resulted in improved energy efficiency for both the transformers and the building as a whole.

Monitoring and maintenance of ventilation systems are crucial for long-term performance. I’ve implemented remote monitoring solutions for transformer installations that continuously track temperature and airflow. This proactive approach allows for early detection of ventilation issues before they can impact transformer performance or lifespan.

Lastly, the trend towards more compact and efficient transformers is changing ventilation requirements. I’m currently working on a project utilizing the latest high-efficiency dry type transformers. While these units generate less heat, they still require careful attention to ventilation to ensure optimal performance, especially in high-density power applications.

Ensuring adequate ventilation for dry type transformers is not just about following a set of clearance guidelines; it’s about understanding the specific needs of your installation and environment. Proper ventilation is crucial for maintaining transformer efficiency, extending its lifespan, and ensuring safe operation. By carefully considering factors like clearance, environmental conditions, and cooling method compatibility, you can create an installation that allows your transformer to operate at peak performance for years to come. Remember, the small effort of planning proper ventilation during installation can prevent major headaches and costs down the line.

Mistake #2: Incorrect Mounting or Uneven Foundation?

Have you ever noticed excessive vibration or unusual noise coming from your dry type transformer? These symptoms often point to a common but serious installation mistake: incorrect mounting or an uneven foundation. But why is a stable base so crucial for transformer performance, and what risks do you face with improper mounting?

**Incorrect mounting or uneven foundation can lead to vibration, noise, and mechanical stress on transformer windings. This can result in reduced efficiency, premature wear, and even catastrophic failure. To avoid this:

- Install on a level concrete pad or vibration-damped base

- Use appropriate mounting hardware and torque settings

- Check alignment and flatness during commissioning**

The Importance of Proper Mounting and Foundation

Let’s explore why correct mounting is critical and how to ensure it:

1. Stability and Vibration Control

Key points:

- Transformers generate vibrations during operation

- Stable mounting minimizes vibration transfer

- Reduced vibration extends component lifespan

I once investigated a case where a client complained of excessive noise from their newly installed transformer. Upon inspection, we discovered that the transformer was mounted on an uneven surface, causing misalignment and amplifying operational vibrations. Correcting the foundation resolved the issue and significantly improved the transformer’s performance.

2. Alignment and Stress Distribution

Critical factors:

- Even weight distribution across the base

- Proper alignment of core and windings

- Prevention of mechanical stress on internal components

3. Foundation Requirements

Essential elements:

- Level concrete pad of sufficient thickness

- Vibration isolation pads or springs when needed

- Proper anchoring to prevent movement

4. Installation Process

Key steps:

- Accurate leveling before final placement

- Use of appropriate mounting hardware

- Torque application as per manufacturer specifications

Here’s a comparison table of mounting methods and their impacts:

| Aspect | Direct Floor Mounting | Raised Platform | Vibration-Isolated Base |

|---|---|---|---|

| Vibration Control | Limited | Moderate | Excellent |

| Cost | Low | Medium | High |

| Flexibility | Low | Moderate | High |

| Maintenance Access | Limited | Good | Excellent |

| Suitability | Stable environments | General use | Sensitive or high-vibration areas |

In my experience, the long-term benefits of proper mounting far outweigh the initial extra effort and cost. I recall a project where we insisted on a custom-designed vibration-isolated base for a transformer installed near sensitive laboratory equipment. The client initially questioned the additional expense, but the result was flawless operation with no interference to nearby instruments, ultimately saving costs on potential relocations or equipment damage.

The choice of mounting method can significantly impact maintenance accessibility. In a recent industrial installation, we opted for a slightly raised platform design. This not only provided better vibration control but also greatly improved access for maintenance and inspections, reducing downtime during routine checks and repairs.

For installations in seismic zones, mounting considerations become even more critical. I worked on a project in an earthquake-prone area where we implemented an advanced seismic mounting system for the transformers. This involved not just a reinforced foundation but also specially designed flexible connections to allow for movement during seismic events, ensuring continuity of power even under extreme conditions.

The interaction between transformer mounting and building structures is an often-overlooked aspect. In a multi-story building project, we collaborated closely with structural engineers to design mounting solutions that not only stabilized the transformers but also minimized vibration transfer to the building structure. This holistic approach improved overall building performance and occupant comfort.

Monitoring and periodic checks of mounting integrity are crucial for long-term performance. I’ve implemented maintenance programs that include regular inspections of mounting hardware, foundation integrity, and vibration levels. This proactive approach has helped catch and address potential issues before they could develop into serious problems.

Lastly, the trend towards more compact and efficient transformers is changing mounting requirements. I’m currently working on a project utilizing high-density power transformers that generate more heat and vibration in a smaller footprint. This has led us to develop innovative mounting solutions that combine advanced vibration isolation with enhanced cooling capabilities.

Ensuring correct mounting and a stable foundation for dry type transformers is crucial for their long-term performance and reliability. It’s not just about placing the transformer on a flat surface; it’s about creating a stable, well-designed base that can support the unit throughout its operational life. By carefully considering factors like vibration control, alignment, and environmental conditions, you can create an installation that maximizes transformer efficiency and lifespan while minimizing noise and potential damage. Remember, the extra attention paid to proper mounting during installation can prevent costly issues and ensure smooth operation for years to come.

Mistake #3: Choosing the Wrong IP Rating for the Environment?

Have you ever encountered a transformer that failed prematurely due to environmental factors? This common issue often stems from a critical installation mistake: selecting the wrong IP (Ingress Protection) rating for the transformer’s environment. But why is the right IP rating so important, and what happens when you get it wrong?

**Choosing the wrong IP rating for dry type transformers can lead to insulation failure, corrosion, and equipment breakdown. The IP rating must match the installation environment to ensure proper protection. To avoid this:

- Use IP23 or IP54 models for industrial, wet, or outdoor use

- Avoid exposed installations in basements or near water pipes

- Follow IEC/UL guidelines based on site environment**

Understanding IP Ratings and Their Importance

Let’s explore why the right IP rating is crucial and how to select it correctly:

1. IP Rating Basics

Key points:

- IP ratings define protection against solid objects and water

- First digit indicates solid particle protection (0-6)

- Second digit indicates liquid ingress protection (0-8)

I once investigated a transformer failure in a coastal industrial facility. The unit, rated only IP21, had been installed in an area exposed to salt spray. The resulting corrosion and insulation degradation led to a complete failure within two years, a situation that could have been avoided with a properly rated IP54 or higher unit.

2. Common IP Ratings for Transformers

Typical ratings and their applications:

- IP00: Open type, for use in controlled environments only

- IP21: Basic protection, suitable for clean, dry indoor locations

- IP23: Limited water protection, good for most indoor industrial use

- IP54: Dust and splash-proof, suitable for outdoor or wet environments

3. Environmental Considerations

Factors to consider:

- Presence of dust, dirt, or airborne particles

- Exposure to water (drips, splashes, or jets)

- Humidity levels and condensation risk

- Presence of corrosive atmospheres

4. Installation Location Impact

How location affects IP rating choice:

- Indoor vs. outdoor placement

- Proximity to water sources or high humidity areas

- Exposure to industrial processes or contaminants

Here’s a comparison table of IP ratings and their suitability:

| IP Rating | Solid Protection | Liquid Protection | Suitable Environments |

|---|---|---|---|

| IP21 | Protected against objects >12.5mm | Protected against vertically falling drops | Clean, dry indoor areas |

| IP23 | Protected against objects >12.5mm | Protected against spraying water | Most indoor industrial settings |

| IP54 | Dust protected | Protected against splashing water | Outdoor or wet industrial areas |

| IP65 | Dust tight | Protected against water jets | Harsh outdoor or washdown areas |

In my experience, the impact of choosing the correct IP rating extends far beyond just preventing immediate failures. I recall a project where we upgraded the transformers in a food processing plant from IP23 to IP54 units. This not only eliminated the frequent maintenance issues they were experiencing due to moisture ingress but also allowed for more thorough cleaning procedures, improving overall plant hygiene and regulatory compliance.

The choice of IP rating can significantly affect installation flexibility. In a recent project for a chemical manufacturing facility, we opted for IP65-rated transformers. This high level of protection allowed us to install the units closer to the production areas, reducing power distribution losses and improving overall plant efficiency. The initial higher cost of the IP65 units was quickly offset by the savings in installation and operational efficiency.

For installations in varying environments, creative solutions are sometimes necessary. I worked on a project for a large warehouse with both indoor and semi-outdoor areas. We implemented a hybrid approach, using IP23 units for the fully enclosed sections and IP54 units for the loading dock areas. This tailored solution provided appropriate protection while optimizing costs.

The interaction between IP rating and cooling efficiency is an often-overlooked aspect. In a recent data center project, we had to balance the need for high IP ratings to protect against dust with the requirement for efficient cooling. We ended up designing a custom enclosure that maintained an IP54 rating while incorporating filtered ventilation to ensure adequate cooling, demonstrating that with proper design, you don’t have to sacrifice cooling for protection.

Climate change considerations are increasingly influencing IP rating selections. I’m currently advising on a long-term infrastructure project where we’re factoring in projected increases in extreme weather events. This has led us to choose higher IP ratings than currently required, ensuring the transformers will be protected even as environmental conditions become more challenging over their operational lifespan.

Maintenance implications of different IP ratings should not be underestimated. I’ve seen cases where lower-rated transformers in borderline environments required frequent, costly maintenance interventions. In contrast, properly rated units often need only routine checks, significantly reducing lifetime operational costs.

Lastly, the trend towards smart grid technologies is influencing IP rating considerations. In a recent smart city project, we needed to ensure that the transformers’ IP ratings were sufficient not just for environmental protection but also for safeguarding the integrated monitoring and communication equipment. This dual requirement led to some innovative enclosure designs that protected both the transformer and its smart components.

Selecting the correct IP rating for dry type transformers is crucial for ensuring their longevity, reliability, and performance in various environments. It’s not just about meeting minimum standards; it’s about understanding the specific challenges of your installation site and choosing a rating that provides adequate protection against all potential threats. By carefully considering factors like dust, moisture, temperature fluctuations, and even future environmental changes, you can select an IP rating that will protect your transformer investment for years to come. Remember, while a higher IP rating might seem like an unnecessary expense initially, it often proves to be a wise investment in the long run, preventing costly failures and downtime.

Mistake #4: Poor Cable Terminations and Loose Connections?

Have you ever experienced unexplained power quality issues or intermittent faults in your electrical system? These problems often trace back to a common but critical installation error: poor cable terminations and loose connections in transformers. But why are proper connections so vital, and what risks do you face when they’re not done correctly?

**Poor cable terminations and loose connections in dry type transformers can lead to overheating, energy losses, and even electrical fires. These issues are a major cause of transformer damage and system unreliability. To avoid this:

- Use properly sized lugs and compression tools

- Follow torque specifications for all connections

- Inspect and tighten all terminals before energizing

- Avoid routing cables in tension or with sharp bends**

The Importance of Proper Cable Terminations and Connections

Let’s explore why correct cable terminations are crucial and how to ensure they’re done right:

1. Heat Generation and Energy Loss

Key points:

- Loose connections create resistance

- Increased resistance leads to localized heating

- Heat can damage insulation and surrounding components

I once investigated a case where a client reported frequent tripping of their main circuit breaker. Upon inspection, we found severely overheated terminals at the transformer connections. The root cause was improperly torqued bolts that had loosened over time, creating high-resistance points. Correcting these connections resolved the issue and prevented potential equipment damage.

2. Electrical Safety Risks

Critical safety concerns:

- Arcing potential at loose connections

- Fire hazard from overheating

- Risk of electric shock from exposed conductors

3. Power Quality Issues

Impact on system performance:

- Voltage fluctuations due to inconsistent connections

- Harmonic distortion from poor contact

- Potential for single-phasing in three-phase systems

4. Long-term Reliability

Factors affecting longevity:

- Gradual degradation of loose connections over time

- Accelerated aging of insulation due to heat stress

- Increased maintenance requirements and downtime

Here’s a comparison table of proper vs. improper termination practices:

| Aspect | Proper Termination | Improper Termination |

|---|---|---|

| Heat Generation | Minimal | Significant |

| Contact Resistance | Low and stable | High and variable |

| Insulation Stress | Normal aging | Accelerated degradation |

| Maintenance Needs | Routine checks | Frequent interventions |

| System Reliability | High | Compromised |

In my experience, the long-term benefits of proper cable terminations far outweigh the initial time investment. I recall a large industrial project where we implemented a rigorous termination protocol, including precise torque specifications and third-party inspections. Years later, during a routine maintenance check, we found that these connections were still in excellent condition, with no signs of overheating or loosening, demonstrating the lasting value of proper installation practices.

The choice of termination hardware can significantly impact long-term reliability. In a recent high-vibration environment installation, we opted for specialized vibration-resistant connectors. While more expensive initially, these connectors have maintained solid connections despite constant vibration, preventing the frequent maintenance issues the client had experienced with standard connectors in the past.

For installations in corrosive or high-humidity environments, additional considerations are necessary. I worked on a project in a coastal chemical plant where we implemented a comprehensive anti-corrosion strategy for all terminations. This included using corrosion-resistant materials, applying protective coatings, and implementing a regular inspection schedule. The result was a significant improvement in connection reliability and a reduction in corrosion-related failures.

The impact of proper cable routing on termination integrity is often underestimated. In a recent data center upgrade, we paid special attention to cable management, ensuring that cables were routed with proper support and without sharp bends or tension at the termination points. This approach not only improved the reliability of the connections but also facilitated easier maintenance and future modifications.

Thermal imaging has become an invaluable tool in assessing termination quality. I’ve implemented regular thermal scanning programs for critical transformer installations. This proactive approach has allowed us to identify and address potential connection issues before they develop into failures, significantly improving overall system reliability.

Lastly, the trend towards higher power densities in modern electrical systems is placing even greater importance on proper terminations. I’m currently working on a project involving high-capacity transformers where the termination points are handling unprecedented current levels. This has led us to develop new termination techniques and materials to ensure long-term reliability under these demanding conditions.

Ensuring proper cable terminations and connections in dry type transformers is crucial for system reliability, safety, and efficiency. It’s not just about tightening bolts; it’s about creating a stable, low-resistance electrical path that will maintain its integrity over the transformer’s entire operational life. By carefully considering factors like proper sizing, torque specifications, environmental conditions, and long-term stress factors, you can create terminations that will provide years of trouble-free operation. Remember, the extra time and attention paid to proper terminations during installation can prevent costly failures, improve system efficiency, and ensure the safety of your electrical infrastructure.

Mistake #5: Skipping Pre-Commissioning Tests?

Have you ever been tempted to rush a transformer installation, skipping some of the pre-commissioning tests to save time? This shortcut can lead to serious consequences down the line. But why are these tests so crucial, and what risks do you face by omitting them?

**Skipping pre-commissioning tests on dry type transformers can mask dangerous installation flaws, leading to early failures or safety hazards. These tests are crucial for verifying proper installation and transformer health. To avoid issues:

- Conduct insulation resistance testing (Megger)

- Check for short circuits or open phases

- Verify temperature sensor functionality

- Record results for documentation and warranty**

The Importance of Pre-Commissioning Tests

Let’s explore why these tests are vital and what they involve:

1. Insulation Resistance Testing

Key points:

- Verifies insulation integrity

- Detects moisture or contamination issues

- Establishes baseline for future comparisons

I once encountered a case where a client insisted on energizing a new transformer immediately after installation, without proper testing. Within weeks, they experienced a major failure due to insulation breakdown. Our subsequent investigation revealed moisture ingress during transport that could have been easily detected and addressed through proper pre-commissioning tests.

2. Winding Resistance Measurements

Critical checks:

- Ensures proper internal connections

- Detects any winding damage

- Verifies tap changer functionality

3. Turns Ratio Test

Important verifications:

- Confirms correct transformer ratio

- Checks for shorted turns or incorrect winding connections

- Essential for proper voltage transformation

4. Functional Checks of Accessories

Necessary verifications:

- Temperature monitoring systems

- Cooling fans (for AF units)

- Tap changer mechanisms (if applicable)

Here’s a comparison table of outcomes with and without pre-commissioning tests:

| Aspect | With Pre-Commissioning Tests | Without Pre-Commissioning Tests |

|---|---|---|

| Initial Issues Detection | High | Low |

| Operational Reliability | Verified | Uncertain |

| Warranty Validity | Ensured | Potentially Compromised |

| Baseline Data for Future | Available | Absent |

| Safety Assurance | Confirmed | Assumed |

In my experience, the value of thorough pre-commissioning tests becomes most apparent in the long run. I recall a large-scale industrial project where we insisted on comprehensive testing despite tight deadlines. This process uncovered a minor manufacturing defect in one unit that could have led to a major failure if left undetected. The slight delay in commissioning was insignificant compared to the potential downtime and replacement costs we avoided.

The data gathered during pre-commissioning tests is invaluable for future maintenance. In a recent power distribution upgrade project, we conducted extensive baseline tests on all new transformers. This data has since proven crucial in identifying subtle changes in transformer condition during routine maintenance, allowing for proactive interventions before issues become critical.

For installations in harsh environments, pre-commissioning tests can be particularly revealing. I worked on a project in a high-humidity coastal area where insulation resistance tests indicated potential moisture issues in several units. This led to additional drying procedures before installation, likely preventing premature insulation failures.

The integration of advanced diagnostic tools in pre-commissioning has revolutionized the process. In a recent smart grid project, we utilized online partial discharge testing as part of the commissioning process. This advanced technique allowed us to detect subtle insulation weaknesses that traditional tests might have missed, ensuring an even higher level of reliability for these critical components.

Pre-commissioning tests also play a crucial role in warranty validation. I’ve seen cases where transformer failures were initially disputed by manufacturers due to a lack of proper commissioning data. Now, I always advise clients to maintain detailed records of all pre-commissioning tests, as this documentation can be invaluable in the event of warranty claims.

Lastly, the trend towards more compact and efficient transformers is changing the landscape of pre-commissioning tests. I’m currently working on a project involving high-efficiency amorphous core transformers. These units require specialized testing procedures to verify their unique performance characteristics, highlighting the need for continual adaptation of testing protocols to keep pace with evolving technology.

Conducting thorough pre-commissioning tests on dry type transformers is not just a procedural formality; it’s a critical step in ensuring the safety, reliability, and longevity of your electrical system. These tests provide vital information about the condition of the transformer at installation, establish important baselines for future comparisons, and can uncover hidden issues before they become major problems. By investing time in proper testing, you’re not just verifying the current state of the transformer; you’re laying the groundwork for its entire operational life. Remember, the relatively small investment in time and resources for pre-commissioning tests can prevent major headaches, costly failures, and potential safety hazards down the line.

Mistake #6: Ignoring Load Profile and Cooling Method Match?

Have you ever encountered a transformer that consistently runs hot or trips unexpectedly under load? This common issue often stems from a critical mismatch between the transformer’s cooling method and its actual load profile. But why is this match so important, and what happens when you get it wrong?

**Ignoring the match between load profile and cooling method in dry type transformers can lead to overheating, reduced efficiency, and premature failure. The cooling system must be adequate for the actual load conditions. To avoid this:

- Match cooling type (AN or AF) to load conditions

- Use AF units for high ambient temperatures or cyclic loads

- Consider thermal sensors for continuous monitoring**

Understanding the Importance of Load Profile and Cooling Method Compatibility

Let’s explore why this match is crucial and how to ensure it’s correct:

1. Load Profile Basics

Key considerations:

- Steady-state vs. variable loads

- Peak load durations and frequencies

- Daily and seasonal load variations

I once investigated a case where a data center experienced frequent transformer overheating alarms. The root cause was an AN (Air Natural) cooled transformer being used in an environment with highly variable loads. Replacing it with an AF (Air Forced) unit resolved the issue, highlighting the importance of matching cooling method to actual load patterns.

2. Cooling Method Characteristics

Comparison of cooling types:

- AN: Suitable for steady, lower loads

- AF: Better for variable or higher loads

- Hybrid systems for flexible load handling

3. Environmental Factors

Impact on cooling efficiency:

- Ambient temperature fluctuations

- Installation location (indoor vs. outdoor)

- Air quality and potential for contamination

4. Energy Efficiency Considerations

Balancing cooling and efficiency:

- Over-cooling can lead to energy waste

- Under-cooling risks equipment damage

- Optimal matching improves overall system efficiency

Here’s a comparison table of cooling methods and their suitability for different load profiles:

| Load Profile | AN Cooling | AF Cooling | Hybrid System |

|---|---|---|---|

| Steady, Low Load | Excellent | Good (may be overkill) | Good |

| Variable Load | Poor | Excellent | Very Good |

| High Ambient Temp | Poor | Good | Very Good |

| Frequent Overloads | Poor | Good | Excellent |

| Energy Efficiency | High (for suitable loads) | Moderate | High (with smart control) |

In my experience, the long-term benefits of properly matching cooling methods to load profiles far outweigh the initial planning effort. I recall a project for a manufacturing plant where we implemented a hybrid cooling system – AN base with AF boost for peak loads. This approach not only handled the variable load profile effectively but also optimized energy consumption, leading to significant operational cost savings over time.

The impact of environmental conditions on cooling method selection is often underestimated. In a recent project in a hot, arid climate, we opted for AF cooling even for relatively steady loads. The high ambient temperatures made AN cooling insufficient, and the AF system ensured reliable operation even during the hottest parts of the day.

For installations with highly variable or unpredictable loads, advanced monitoring can be crucial. I worked on a renewable energy integration project where the transformer load varied significantly based on solar and wind generation. We implemented a smart cooling system with real-time load monitoring and adaptive fan control. This approach ensured optimal cooling under all conditions while minimizing energy consumption.

The trend towards more energy-efficient transformers is changing the landscape of cooling requirements. I’m currently involved in a project using high-efficiency amorphous core transformers. These units generate less heat overall, but still require careful cooling consideration, especially for peak load handling. We’re implementing a sophisticated thermal management system that balances the transformer’s improved efficiency with appropriate cooling for various load scenarios.

Retrofitting existing installations to better match cooling methods to actual load profiles can be challenging but rewarding. In a recent industrial upgrade project, we modified several AN-cooled transformers to AF systems based on years of load data. This retrofit not only improved reliability but also allowed for increased power throughput without replacing the entire transformer.

Lastly, the integration of transformers into smart grid systems is introducing new dynamics in load profile management. I’m currently advising on a smart grid project where transformer cooling systems are being integrated with grid-level load management. This allows for predictive cooling adjustments based on anticipated load changes, further optimizing the balance between cooling effectiveness and energy efficiency.

The importance of matching load profiles to cooling methods in dry type transformers cannot be overstated. It’s not just about preventing overheating; it’s about ensuring optimal performance, energy efficiency, and longevity of the transformer. By carefully analyzing load patterns, considering environmental factors, and selecting the appropriate cooling method, you can create a transformer installation that operates reliably and efficiently under all conditions. Remember, the extra effort spent on proper cooling method selection during the planning phase can prevent costly operational issues and extend the life of your transformer significantly.

Mistake #7: No Grounding or Improper Grounding?

Have you ever experienced unexplained electrical disturbances or safety concerns with your transformer installation? These issues often trace back to a critical but sometimes overlooked aspect: proper grounding. But why is grounding so crucial, and what risks do you face when it’s done incorrectly or neglected entirely?

**Lack of grounding or improper grounding in dry type transformers can lead to safety hazards, equipment damage, and power quality issues. Proper grounding is essential for personnel safety and equipment protection. To ensure correct grounding:

- Ensure both core and enclosure grounding

- Use conductors sized per NEC/IEC standards

- Verify continuity with multimeter during commissioning**

Understanding the Importance of Proper Grounding

Let’s explore why correct grounding is vital and how to implement it effectively:

1. Safety Considerations

Key safety aspects:

- Protection against electric shock

- Fault current diversion

- Mitigation of step and touch potentials

I once investigated a case where maintenance personnel reported receiving mild shocks when touching the transformer enclosure. Our inspection revealed that the equipment grounding conductor had been improperly terminated, creating a potentially dangerous situation. Correcting the grounding immediately resolved the safety issue.

2. Equipment Protection

Grounding benefits for equipment:

- Overvoltage protection

- Reduction of electromagnetic interference

- Stabilization of voltage levels

3. Power Quality Improvement

Impact on system performance:

- Reduction of common-mode noise

- Minimization of ground loops

- Enhanced overall system stability

4. Regulatory Compliance

Adherence to standards:

- National Electrical Code (NEC) requirements

- IEC standards for international installations

- Local electrical safety regulations

Here’s a comparison table of proper vs. improper grounding practices:

| Aspect | Proper Grounding | Improper or No Grounding |

|---|---|---|

| Personnel Safety | High | Compromised |

| Equipment Protection | Effective | Limited or None |

| Power Quality | Improved | Potentially Degraded |

| EMI/RFI Mitigation | Good | Poor |

| Regulatory Compliance | Assured | Non-Compliant |

In my experience, the importance of proper grounding often becomes most apparent in troubleshooting scenarios. I recall a project where a facility was experiencing persistent issues with sensitive electronic equipment. Our investigation revealed that improper transformer grounding was creating ground potential differences, leading to circulating currents and electromagnetic interference. Implementing a proper grounding system resolved these issues, highlighting the far-reaching impacts of correct grounding practices.

The choice of grounding method can significantly affect system performance. In a recent data center project, we implemented a carefully designed equipotential grounding system for all transformers and associated equipment. This approach not only enhanced safety but also dramatically reduced noise in the facility’s sensitive data processing equipment.

For installations in areas with poor soil conductivity, creative grounding solutions are sometimes necessary. I worked on a project in a rocky terrain where achieving low ground resistance was challenging. We implemented an extensive ground grid system combined with soil treatment to achieve the required grounding performance. This solution ensured both safety and proper equipment operation in a challenging environment.

The interaction between transformer grounding and lightning protection systems is an often-overlooked aspect. In a recent high-rise building project, we integrated the transformer grounding system with the building’s lightning protection. This comprehensive approach provided enhanced protection against both internal faults and external lightning strikes.

Monitoring and maintenance of grounding systems are crucial for long-term effectiveness. I’ve implemented programs for periodic testing of ground resistance and continuity in critical installations. This proactive approach has helped identify and address potential grounding issues before they could impact safety or equipment performance.

The trend towards more complex power systems with multiple sources, including renewable energy, is changing grounding requirements. I’m currently working on a microgrid project where the grounding system must accommodate bidirectional power flow and varying system configurations. This has led to the development of adaptive grounding strategies that can adjust to different operational modes.

Lastly, the increasing use of power electronics in and around transformers is placing new demands on grounding systems. In a recent industrial automation project, we had to design a grounding system that could effectively handle high-frequency noise from variable frequency drives while still providing traditional power frequency protection. This required a multi-layered approach combining traditional grounding techniques with high-frequency grounding strategies.

Proper grounding of dry type transformers is not just a regulatory requirement; it’s a fundamental aspect of safe and reliable electrical system operation. It protects personnel, safeguards equipment, improves power quality, and ensures regulatory compliance. By carefully considering factors like conductor sizing, connection methods, and system-wide grounding strategy, you can create a grounding system that provides comprehensive protection and optimal performance. Remember, while proper grounding might seem like a basic aspect of installation, its importance cannot be overstated – it’s often the difference between a safe, reliable system and one prone to hazards and operational issues.

Summary Checklist: Dry Type Transformer Installation Essentials?

Are you preparing for a dry type transformer installation and want to ensure you’ve covered all the critical bases? This comprehensive checklist will guide you through the essential steps to avoid common pitfalls and ensure a safe, efficient, and reliable installation. Let’s make sure you’ve got all your bases covered before powering up your transformer.

Essential checklist for dry type transformer installation:

✅ Allow proper ventilation (≥1m clearance)

✅ Use vibration-damped, level foundations

✅ Select correct IP rating based on environment

✅ Tighten and inspect all cable connections

✅ Perform insulation and functional tests

✅ Match cooling method to load profile

✅ Ground transformer body and core securely

Comprehensive Dry Type Transformer Installation Checklist

Let’s break down each point in detail:

1. Ventilation and Clearance

Key requirements:

- Minimum 1 meter clearance on all sides

- Unobstructed airflow path

- No heat sources near the transformer

I once consulted on a project where inadequate clearance led to chronic overheating issues. Redesigning the installation layout to provide proper ventilation resolved the problem and significantly improved the transformer’s performance and lifespan.

2. Foundation and Mounting

Critical aspects:

- Level, reinforced concrete pad

- Vibration isolation if needed

- Proper anchoring and alignment

3. Environmental Protection (IP Rating)

Considerations:

- Indoor vs. outdoor installation

- Presence of dust, moisture, or corrosive elements

- Future environmental changes

4. Cable Connections

Important steps:

- Use properly sized and rated cables

- Apply correct torque to all connections

- Implement proper cable management

5. Pre-Commissioning Tests

Essential tests:

- Insulation resistance (Megger test)

- Winding resistance measurement

- Turns ratio test

- Functional checks of all accessories

6. Cooling System Verification

Key points:

- Match cooling type (AN/AF) to load profile

- Verify fan operation for AF units

- Ensure proper thermostat settings

7. Grounding

Critical elements: